Programmable Logic Controller (PLC) Based Paint Viscosity Control System

DOI:

https://doi.org/10.12928/biste.v3i1.1109Keywords:

PLC, Viskositas, Kendali Suhu, LM35DZ, CX-ProgrammerAbstract

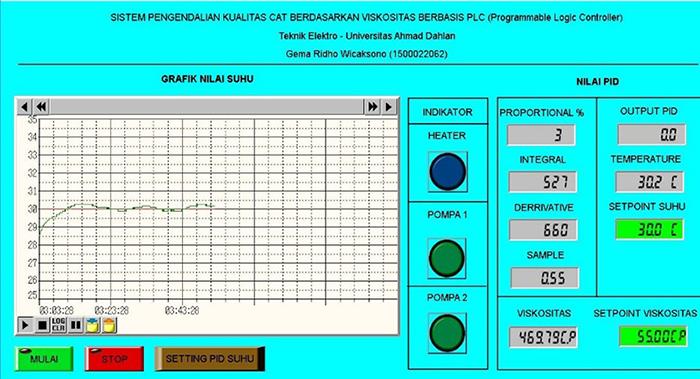

Automatic control has been developed in various fields, one of which is paint quality control. Paint quality can be controlled from various categories, including paint quality based on its viscosity. Therefore, we need a system that can control the viscosity of the paint. The paint viscosity control system uses the PLC OMRON CP1E-NA20DRA with a heater as a heat source, and the LM35DZ sensor as a temperature reading sensor, and the RPM reading is used to calculate the viscosity value. The programming language used is the ladder diagram on the CX-Programmer. This system uses the PID (Proportional, Integral, and Derivative) Algorithm so that temperature control can be set at 30ºC so as not to affect the viscosity of the paint. In addition, this prototype provides two PID tuning options, namely manual and auto-tuning. Researchers get the results that a good temperature control system response has a PB value = 0.2%; Ti = 452.5s and TD = 66.6s. and control the accuracy level of paint viscosity control of 67.82%.References

N. J. Habibie and S. Anwar, “Pengaruh Perbandingan Campuran Cat dengan Thinner Terhadap Kualitas Hasil Pengecatan,” JTM, vol. 2, no. 3, pp. 97–104, 2014. Online

F. I. Permana and S. Anwar, “Pengaruh kualitas Thinner pada Campuran Cat Terhadap Hasil Pengecatan,” JTM, vol. 3, no. 2, pp. 53–61, 2014. Online

P. M. Khadafi, “Alat Ukur Viskositas Cairan Menggunakan Metode Silinder Konsentris Berputar,” F. MIPA UI, 2013.

A. Suwandi, “Peningkatan Kualitas untuk Meminimasi Cacat Produk Cat Polyurethane dengan Metode Taguchi,” Jurnal Inovisi, vol. 12, no. 02, pp. 55-71, 2016. Online

OMRON, “Instructions Reference Manual PLC Omron,” 2014. Online

R. D. Puriyanto, S. A. Akbar, and A. Aktawan, “Desain Sistem Biodiesel Berbasis PLC Berdasarkan Diagram Keadaan,” J. Ilm. Tek. Elektro Komput. dan Inform., vol. 4, no. 2, p. 1, 2019. DOI: https://doi.org/10.26555/jiteki.v4i2.12051

OMRON, “CP1E CPU Unit Hardware User Manual,” 2016. Online

M. F. Al Andzar and R. D. Puriyanto, “PID Control for Temperature and Motor Speed Based on PLC”, Sig.Img.Proc.Lett, vol. 1, no. 1, pp. 7-13, Mar. 2019. DOI: https://doi.org/10.31763/simple.v1i1.150

A. Junaidi and W. S. Aji, “Sistem Pengontrol Suhu Ruangan dengan Algoritma PID Menggunakan PLC Omron CP1e-NA20DR-A,” J. Ilm. Tek. Elektro Komput. dan Inform., vol. 3, no. 2, p. 47, 2017. DOI: https://doi.org/10.26555/jiteki.v3i2.7069

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Gema Ridho Wicaksono, Riky Dwi Puriyanto

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.