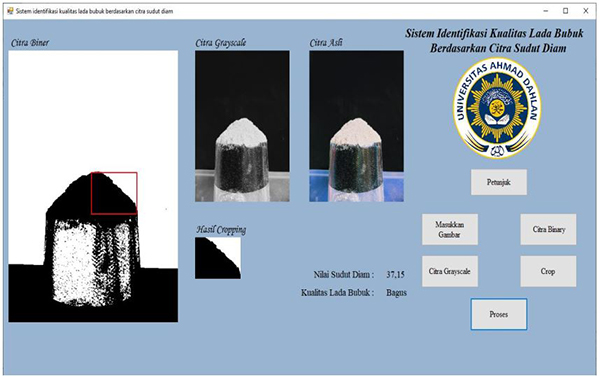

Pepper Powder Quality Identification System Based on Silent Angle Imagery

DOI:

https://doi.org/10.12928/biste.v2i1.1491Keywords:

Lada Bubuk, Visual Studio 2010 ultimate, Sudut Diam citra, Grayscale, Biner, CroppingAbstract

This research identifies the quality of pepper powder using a computer automatically. The research method uses the stationary angle method. The design of this system is done by image processing techniques. The image of ground pepper that has been taken is then cropped to remove the unused portion of the image. The next step is to convert the original image into grayscale and then convert it to binary. The parameter of the stationary angle is when it has an angle of less than or equal to 38 °, the ground pepper includes fine ground pepper. If the angle ranges from 38o to 40o, including medium powdered pepper, and if the angle is greater than 41o, including the texture of coarse pepper powder. Testing 3 different types of samples obtained 40 mesh is 35.18 o; for 20 mesh is 40.46o and 10 mesh is 41.66o. Therefore, it can be seen that the smaller the texture of the size of ground pepper, the finer the quality.

Penelitian ini mengidentifikasi kualitas lada bubuk menggunakan komputer secara otomatis. Metode penelitian menggunakan metode sudut diam. Perancangan sistem ini dilakukan dengan teknik pengolahan citra. Citra lada bubuk yang telah diambil selanjutnya di-cropping untuk menghilangkan bagian citra yang tidak terpakai. Langkah selanjutnya adalah citra hasil asli tersebut dikonversi dalam bentuk grayscale dan selanjutnya dikonversi dalam bentuk biner. Parameter sudut diam adalah ketika memiliki sudut kurang dari atau sama dengan 38o, lada bubuk tersebut termasuk lada bubuk yang halus. Jika sudutnya berkisar antara 38o sampai 40o maka termasuk lada bubuk sedang, dan jika sudutnya lebih besar dari 41o maka termasuk tekstur lada bubuk kasar. Pengujian 3 jenis sampel yang berbeda didapatkan 40 mesh adalah 35,18o; untuk 20 mesh adalah 40,46o dan 10 mesh adalah 41,66o. Oleh karena itu dapat diketahui bahwa semakin kecil tekstur ukuran lada bubuk, semakin halus kualitasnya.

References

S. Usmiati, ri, and N. Nurdjannah, “Pengaruh lama perendaman dan cara pengeringan terhadap mutu lada putih.,” J. Tek. Ind. Pert., vol. 16, no. 3, pp. 91–98, 2007.

T. Hidayat, N. Nurdjannah, S. Usmiati, B. Besar, and P. Pascapanen, “ANALISIS TEKNIS DAN FINANSIAL PAKET TEKNOLOGI PENGOLAHAN LADA PUTIH ( White Pepper ) SEMI MEKANIS Technical and Financial Analysis of Technology Package for Semi- Mechanic White Pepper Processing FDA (Food and Drug Administration) Eropa terhadap produk ,” vol. 20, no. 1, pp. 77–91, 2009.

D. Produk, L. Piper, and N. Untuk, “Diversivikasi Produk Lada(Piper Nigrum) Untuk Peningkatan Nilai Tambah,” Bul. Teknol. Pasca Panen, vol. 8, no. 1, pp. 15–26, 2016.

F. Arief, A. P. Munir, and A. Rindang, “Test of Flat Burr Mill Type Pepper Grinding,” J. Rekayasa Pangan dan Pertan., vol. 3, no. 1, pp. 105–108, 2015.

M. Syakir, T. Hidayat, Msi, and R. Maya, “Karakteristik Mutu Lada Putih Butiran Dan Bubuk Yang Dihasilkan Melalui Pengolahan Semi Mekanis Di Tingkat Petani,” J. Penelit. Pascapanen Pertan., vol. 14, no. 3, p. 134, 2018, doi: 10.21082/jpasca.v14n3.2017.134-143.

A. D. Candra and A. Fadlil, “Sistem Penentuan Sudut Diam Granul Menggunakan Metode Pengolahan Citra Berbasis Android,” J. Ilm. Tek. Elektro Komput. dan Inform., vol. 3, no. 2, p. 118, 2018, doi: 10.26555/jiteki.v3i2.7419.

R. D. Kusumanto, A. N. Tompunu, and S. Pambudi, “Klasifikasi Warna Menggunakan Pengolahan Model Warna HSV Abstrak,” J. Ilm. Tek. Elektro, vol. 2, no. 2, pp. 83–87, 2011.

H. Al Fatta, “Konversi Format Citra Rgb Ke Format Grayscale Menggunakan Visual Basic,” Semin. Nas. Teknol., vol. 2007, no. November, pp. 1–6, 2007.

Y. Yuhandri, “Perbandingan Metode Cropping Pada Sebuah Citra Untuk Pengambilan Motif Tertentu Pada Kain Songket Sumatera Barat,” Komtekinfo, vol. 6, no. 1, pp. 95–105, 2019, doi: 10.35134/komtekinfo.v6i1.273.

N. E. Putri and S. Azpar, “Jurnal Edik Informatika Sistem Informasi Pengolahan Data Pendidikan Anak Usia Dini ( PAUD ) Terpadu Amalia Syukra Padang Jurnal Edik Informatika,” Sist. Inf. Pengolah. Data Pendidik. Anak Usia Dini Terpadu Amalia Syukra Padang, pp. 203–212, 2016.

F. Syafii, C. H. Wijaya, and B. Nurtama, “OPTIMASI PROSES PEMBUATAN BUBUK OLEORESIN LADA (Piper nigrum) MELALUI PROSES EMULSIFIKASI DAN MIKROENKAPSULASI,” Agritech, vol. 36, no. 2, pp. 128–136, 2016.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Muhaimin Gusrin, Abdul Fadlil

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.