Modified Starch-Based Materials for Sustainable Food Packaging

DOI:

https://doi.org/10.12928/biste.v8i1.15092Keywords:

Bioactive Compound, Bio-Packaging, Biopolymer, Modified Starch, Sustainable MaterialAbstract

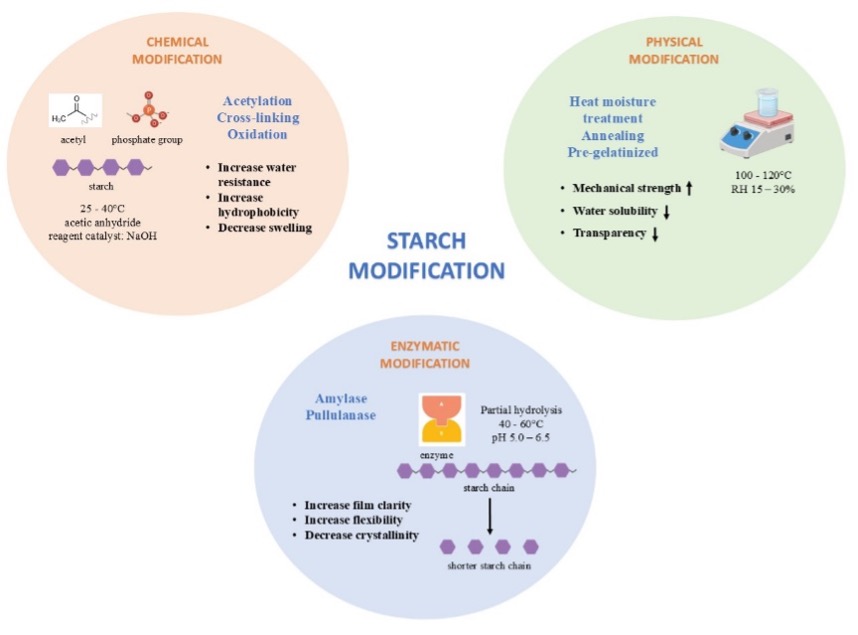

Food packaging is a significant contributor to plastic waste, prompting a search for sustainable alternatives. Among these alternatives, modified starch-based materials have emerged as promising solutions due to their biodegradability, renewability, and abundance. However, the hydrophilic nature, poor mechanical properties, and limited thermal stability of native starch pose challenges for its use in food packaging. This review explores various modification techniques—chemical, physical, and enzymatic—that enhance the performance of starch-based materials for food packaging. The methods discussed include acetylation, crosslinking, heat-moisture treatments, and enzymatic hydrolysis, each improving the material's strength, flexibility, and barrier properties. Results demonstrate that starch modifications significantly improve the mechanical, thermal, and water vapor barrier properties of packaging films. Notably, the combination of modified starch with other biopolymers such as chitosan or gelatin further enhances these properties, making them suitable for active packaging applications. The incorporation of antimicrobial agents and nanofillers into starch-based films has expanded their functionality, enabling food shelf-life extension and quality monitoring. Despite these advancements, challenges remain in balancing the biodegradability and durability of starch-based films. Future research should focus on optimizing modification processes, enhancing scalability, and addressing regulatory concerns to ensure the commercial viability of modified starch as an eco-friendly packaging material.

References

S. A. Attaran, A. Hassan, and M. U. Wahit, “Materials for food packaging applications based on bio-based polymer nanocomposites,” J. Thermoplast. Compos. Mater., vol. 30, no. 2, pp. 143–173, 2017, https://doi.org/10.1177/0892705715588801.

G. A. M. Guerrero and M. S. Guerrero, “Biodegradation of Single Use Plastic Waste by Insect Larvae: A Comparative Study of Yellow Mealworms and Superworms,” J. Sci. Agrotechnology, vol. 2, no. 1, pp. 61–75, 2023, https://doi.org/https://doi.org/10.21107/jsa.v1i2.14.

L. K. Ncube, A. U. Ude, E. N. Ogunmuyiwa, R. Zulkifli, and I. N. Beas, “Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials,” Materials (Basel)., vol. 13, no. 21, p. 4994, 2020, https://doi.org/10.3390/ma13214994.

J. Li, Y. Hou, S. Song, and H. Chen, “Casein-caffeic acid-cellulose nanocrystals composite edible films for microwave food packaging application,” Int. J. Biol. Macromol., p. 149320, 2025, https://doi.org/10.1016/j.ijbiomac.2025.149320.

R. Thakur, P. Pristijono, C. J. Scarlett, M. Bowyer, S. P. Singh, and Q. V. Vuong, “Starch-based films: Major factors affecting their properties,” Int. J. Biol. Macromol., vol. 132, pp. 1079–1089, 2019, https://doi.org/10.1016/j.ijbiomac.2019.03.190.

R. A. Sari, R. P. Utami, and U. R. G. Natalie, “Exploration of Instant Functional Drinks Based on Angkak and Kidney Bean Flour: Implications on Bioactive Compound and Antioxidant Activity,” J. Agri-Food Sci. Technol., vol. 6, no. 3, pp. 161–167, 2025, https://doi.org/https://doi.org/10.12928/jafost.v6i3.12856.

M. W. Ahmed, M. A. Haque, M. Mohibbullah, M. S. I. Khan, M. A. Islam, M. H. T. Mondal, and R. Ahmmed, “A review on active packaging for quality and safety of foods: Current trends, applications, prospects and challenges,” Food Packag. Shelf Life, vol. 33, p. 100913, 2022, https://doi.org/10.1016/j.fpsl.2022.100913.

W. Gunawan, R. E. Putra, P. Pujo, F. I. W. Rohmat, D. S. Hanifah, F. Awaliyah, R. D. Anggraeni, and N. Nuradzkia, “Determination of Potential in Pratama Taro (Colocasia esculenta (L). Schott var. Pratama) in Sumedang District, Bandung Regency, Indonesia,” J. Agri-Food Sci. Technol., vol. 6, no. 1, pp. 11–21, 2025, https://doi.org/10.12928/jafost.v6i1.12592.

A. K. Kimu, “A Comprehensive Review of Harnessing Bioinformatics in Biochemistry: A New Era of Data-Driven Discoveries and Applications,” Control Syst. Optim. Lett., vol. 3, no. 1, pp. 117–123, 2025, https://doi.org/https://doi.org/10.59247/csol.v3i1.168.

E. Ojogbo, E. O. Ogunsona, and T. H. Mekonnen, “Chemical and physical modifications of starch for renewable polymeric materials,” Mater. Today Sustain., vol. 7–8, p. 100028, 2020, https://doi.org/10.1016/j.mtsust.2019.100028.

M. N. Azkia and S. B. Wahjuningsih, “Sensory Characteristics of Mocaf-Substituted Noodles Enriched with Latoh (Caulerpa lentillifera),” J. Agri-food Sci. Technol., vol. 6, no. 3, pp. 141–151, 2025, https://doi.org/https://doi.org/10.12928/jafost.v6i3.14145.

A. Surendren, A. K. Mohanty, Q. Liu, and M. Misra, “A review of biodegradable thermoplastic starches, their blends and composites: recent developments and opportunities for single-use plastic packaging alternatives,” Green Chem., vol. 24, no. 22, pp. 8606–8636, 2022, https://doi.org/10.1039/D2GC02169B.

B. Khan, M. Bilal Khan Niazi, G. Samin, and Z. Jahan, “Thermoplastic Starch: A Possible Biodegradable Food Packaging Material—A Review,” J. Food Process Eng., vol. 40, no. 3, 2017, https://doi.org/10.1111/jfpe.12447.

R. F. Santana, I. de C. B. Muniz, C. M. G. Lima, C. M. Veloso, F. G. Santos, and R. C. F. Bonomo, “Starch-based bioplastics and natural antimicrobials: a sustainable alternative for active packaging,” Food Biosci., vol. 74, p. 107786, 2025, https://doi.org/10.1016/j.fbio.2025.107786.

T. Jiang, Q. Duan, J. Zhu, H. Liu, and L. Yu, “Starch-based biodegradable materials: Challenges and opportunities,” Adv. Ind. Eng. Polym. Res., vol. 3, no. 1, pp. 8–18, 2020, https://doi.org/10.1016/j.aiepr.2019.11.003.

L. M. Mena-Chacon et al., “Lemon verbena (Aloysia citriodora) essential oil: Physicochemical characterization, microencapsulation, and application in starch-based bioplastics,” Appl. Food Res., vol. 5, no. 2, p. 101530, 2025, https://doi.org/10.1016/j.afres.2025.101530.

A. O. Ashogbon and E. T. Akintayo, “Recent trend in the physical and chemical modification of starches from different botanical sources: A review,” Starch - Stärke, vol. 66, no. 1–2, pp. 41–57, 2014, https://doi.org/10.1002/star.201300106.

D. Xie, J. Li, C. Zhang, S. Yang, A. Yang, S. Song, and Y. Song, “Design of heat-sealing starch-based bioplastics reinforced with different modified starches and TEMPO-CNF,” Ind. Crops Prod., vol. 232, p. 121303, 2025, https://doi.org/10.1016/j.indcrop.2025.121303.

S. M. Amaraweera et al., “Development of Starch-Based Materials Using Current Modification Techniques and Their Applications: A Review,” Molecules, vol. 26, no. 22, p. 6880, 2021, https://doi.org/10.3390/molecules26226880.

E. B. M. Viana, N. L. Oliveira, J. S. Ribeiro, M. F. Almeida, C. C. E. Souza, J. V. Resende, L. S. Santos, and C. M. Veloso, “Development of starch-based bioplastics of green plantain banana (Musa paradisiaca L.) modified with heat-moisture treatment (HMT),” Food Packag. Shelf Life, vol. 31, p. 100776, 2022, https://doi.org/10.1016/j.fpsl.2021.100776.

A. Dodero, A. Escher, S. Bertucci, M. Castellano, and P. Lova, “Intelligent Packaging for Real-Time Monitoring of Food-Quality: Current and Future Developments,” Appl. Sci., vol. 11, no. 8, p. 3532, 2021, https://doi.org/10.3390/app11083532.

M. S. Khatun, “Antioxidant Peptides from Proteins: Separation, Identification, Mechanisms, and Applications in Food Systems,” Control Syst. Optim. Lett., vol. 3, no. 2, pp. 221–227, 2025, https://doi.org/https://doi.org/10.59247/csol.v3i2.192.

S. Punia, “Barley starch modifications: Physical, chemical and enzymatic - A review,” Int. J. Biol. Macromol., vol. 144, pp. 578–585, 2020, https://doi.org/10.1016/j.ijbiomac.2019.12.088.

H. Nawaz, R. Waheed, M. Nawaz, and D. Shahwar, “Physical and Chemical Modifications in Starch Structure and Reactivity,” in Chemical Properties of Starch, IntechOpen, 2020. https://doi.org/10.5772/intechopen.88870.

E. S. da Cruz, E. da C. Nunes, M. J. U. Toro, and R. da S. Pena, “The isolation method and oxidation modify the physicochemical and technological properties of non-conventional Calathea allouia starch,” LWT, vol. 223, p. 117813, 2025, https://doi.org/10.1016/j.lwt.2025.117813.

S. Srinivasan, C. Ge, C. L. Lewis, S. S. Begum, A. B. Samui, and H. F. Noyes, “Effect of chemical modification of corn starch for the development of films for packaging applications: Impact of glutaraldehyde and organically modified montmorillonite incorporation,” Carbohydr. Polym., vol. 367, p. 124019, 2025, https://doi.org/10.1016/j.carbpol.2025.124019.

L. A. Bello‐Perez, P. C. Flores‐Silva, E. Agama‐Acevedo, and J. Tovar, “Starch digestibility: past, present, and future,” J. Sci. Food Agric., vol. 100, no. 14, pp. 5009–5016, 2020, https://doi.org/10.1002/jsfa.8955.

S. U. Kadam, B. K. Tiwari, and C. P. O’Donnell, “Improved thermal processing for food texture modification,” in Modifying Food Texture, Elsevier, 2015, pp. 115–131. https://doi.org/10.1016/B978-1-78242-333-1.00006-1.

B. Olawoye, O. S. Jolayemi, T. Y. Akinyemi, M. Nwaogu, T. D. Oluwajuyitan, O. O. Popoola-Akinola, O. F. Fagbohun, and C. T. Akanbi, “Modification of Starch,” in Starch: Advances in Modifications, Technologies and Applications, pp. 11–54, 2023, https://doi.org/10.1007/978-3-031-35843-2_2.

C. Sudheesh, L. Varsha, K. V. Sunooj, and S. Pillai, “Influence of crystalline properties on starch functionalization from the perspective of various physical modifications: A review,” Int. J. Biol. Macromol., vol. 280, p. 136059, 2024, https://doi.org/10.1016/j.ijbiomac.2024.136059.

Z. Ma, X. Hu, and J. I. Boye, “Research advances on the formation mechanism of resistant starch type III: A review,” Crit. Rev. Food Sci. Nutr., vol. 60, no. 2, pp. 276–297, 2020, https://doi.org/10.1080/10408398.2018.1523785.

N. Bhati et al., “Eco‐Friendly Enzymatic Starch Modification: Precision Strategies for Tailored Industrial and Biomedical Functionalities,” Starch - Stärke, vol. 77, no. 9, 2025, https://doi.org/10.1002/star.70087.

M. A. Zailani, H. Kamilah, A. Husaini, A. Z. R. Awang Seruji, and S. R. Sarbini, “Starch Modifications via Physical Treatments and the Potential in Improving Resistant Starch Content,” Starch - Stärke, vol. 75, no. 1–2, 2023, https://doi.org/10.1002/star.202200146.

P. Ge, Y. Tian, H. Yan, Q. Li, T. Yao, J. Yao, L. Xiao, M. Zhu, and Y. Han, “Functional Modification and Applications of Rice Starch Emulsion Systems Based on Interfacial Engineering,” Foods, vol. 14, no. 13, p. 2228, 2025, https://doi.org/10.3390/foods14132228.

E. M. Gonçalves, M. Silva, L. Andrade, and J. Pinheiro, “From Fields to Films: Exploring Starch from Agriculture Raw Materials for Biopolymers in Sustainable Food Packaging,” Agriculture, vol. 14, no. 3, p. 453, 2024, https://doi.org/10.3390/agriculture14030453.

I. Kusuma, S. N. Rahmadhia, and A. Ma’arif, “Exploring the Role of Biotechnology and Biodiversity in Achieving Sustainable and Nutritional Food Systems,” J. Sci. Agrotechnology, vol. 2, no. 1, pp. 21–29, 2024, https://doi.org/https://doi.org/10.21107/jsa.v2i1.20.

M. Haroon et al., “Chemical modification of starch and its application as an adsorbent material,” RSC Adv., vol. 6, no. 82, pp. 78264–78285, 2016, https://doi.org/10.1039/C6RA16795K.

E. Subroto, Y. Cahyana, R. Indiarto, and T. A. Rahmah, “Modification of Starches and Flours by Acetylation and Its Dual Modifications: A Review of Impact on Physicochemical Properties and Their Applications,” Polymers (Basel)., vol. 15, no. 14, p. 2990, 2023, https://doi.org/10.3390/polym15142990.

I. Choi, W. Hong, J.-S. Lee, and J. Han, “Influence of acetylation and chemical interaction on edible film properties and different processing methods for food application,” Food Chem., vol. 426, p. 136555, 2023, https://doi.org/10.1016/j.foodchem.2023.136555.

S. Dimri, Aditi, Y. Bist, and S. Singh, “Oxidation of Starch,” in Starch: Advances in Modifications, Technologies and Applications, pp. 55–82, 2023, https://doi.org/10.1007/978-3-031-35843-2_3.

C. Beveridge and A. Sabiston, “Methods and benefits of crosslinking polyolefins for industrial applications,” Mater. Des., vol. 8, no. 5, pp. 263–268, 1987, https://doi.org/10.1016/0261-3069(87)90003-3.

R. . Tharanathan, “Biodegradable films and composite coatings: past, present and future,” Trends Food Sci. Technol., vol. 14, no. 3, pp. 71–78, 2003, https://doi.org/10.1016/S0924-2244(02)00280-7.

J. Meimoun, V. Wiatz, R. Saint‐Loup, J. Parcq, A. Favrelle, F. Bonnet, and P. Zinck, “Modification of starch by graft copolymerization,” Starch - Stärke, vol. 70, no. 1–2, 2018, https://doi.org/10.1002/star.201600351.

M. Gosecka and T. Basinska, “Hydrophilic polymers grafted surfaces: preparation, characterization, and biomedical applications. Achievements and challenges,” Polym. Adv. Technol., vol. 26, no. 7, pp. 696–706, 2015, https://doi.org/10.1002/pat.3554.

L. M. Fonseca, S. L. M. El Halal, A. R. G. Dias, and E. da R. Zavareze, “Physical modification of starch by heat-moisture treatment and annealing and their applications: A review,” Carbohydr. Polym., vol. 274, p. 118665, 2021, https://doi.org/10.1016/j.carbpol.2021.118665.

Y. Cahyana et al., “Properties Comparison of Oxidized and Heat Moisture Treated (HMT) Starch-Based Biodegradable Films,” Polymers (Basel)., vol. 15, no. 9, p. 2046, 2023, https://doi.org/10.3390/polym15092046.

E. da R. Zavareze and A. R. G. Dias, “Impact of heat-moisture treatment and annealing in starches: A review,” Carbohydr. Polym., vol. 83, no. 2, pp. 317–328, 2011, https://doi.org/10.1016/j.carbpol.2010.08.064.

T. Yao, Z. Sui, and S. Janaswamy, “Annealing,” in Physical Modifications of Starch, pp. 73–89, 2023, https://doi.org/10.1007/978-981-99-5390-5_5.

S. Biswas and T. U. Rashid, “Effect of ultrasound on the physical properties and processing of major biopolymers—a review,” Soft Matter, vol. 18, no. 44, pp. 8367–8383, 2022, https://doi.org/10.1039/D2SM01339H.

A. J. Vela, M. Villanueva, and F. Ronda, “Ultrasonication: An Efficient Alternative for the Physical Modification of Starches, Flours and Grains,” Foods, vol. 13, no. 15, p. 2325, 2024, https://doi.org/10.3390/foods13152325.

M. J. E. . van der Maarel, B. van der Veen, J. C. Uitdehaag, H. Leemhuis, and L. Dijkhuizen, “Properties and applications of starch-converting enzymes of the α-amylase family,” J. Biotechnol., vol. 94, no. 2, pp. 137–155, 2002, https://doi.org/10.1016/S0168-1656(01)00407-2.

S. O. Hashim, “Starch-Modifying Enzymes,” pp. 221–244, 2019, https://doi.org/10.1007/10_2019_91.

P. Zhang, F. Sun, X. Cheng, X. Li, H. Mu, S. Wang, H. Geng, and J. Duan, “Preparation and biological activities of an extracellular polysaccharide from Rhodopseudomonas palustris,” Int. J. Biol. Macromol., vol. 131, pp. 933–940, 2019, https://doi.org/10.1016/j.ijbiomac.2019.03.139.

E. M. Milczek, “Commercial Applications for Enzyme-Mediated Protein Conjugation: New Developments in Enzymatic Processes to Deliver Functionalized Proteins on the Commercial Scale,” Chem. Rev., vol. 118, no. 1, pp. 119–141, 2018, https://doi.org/10.1021/acs.chemrev.6b00832.

M. C. Operti, A. Bernhardt, V. Sincari, E. Jager, S. Grimm, A. Engel, M. Hruby, C. G. Figdor, and O. Tagit, “Industrial Scale Manufacturing and Downstream Processing of PLGA-Based Nanomedicines Suitable for Fully Continuous Operation,” Pharmaceutics, vol. 14, no. 2, p. 276, 2022, https://doi.org/10.3390/pharmaceutics14020276.

E. Basiak, A. Lenart, and F. Debeaufort, “Effect of starch type on the physico-chemical properties of edible films,” Int. J. Biol. Macromol., vol. 98, pp. 348–356, 2017, https://doi.org/10.1016/j.ijbiomac.2017.01.122.

P. Song and H. Wang, “High‐Performance Polymeric Materials through Hydrogen‐Bond Cross‐Linking,” Adv. Mater., vol. 32, no. 18, 2020, https://doi.org/10.1002/adma.201901244.

S. N. Rahmadhia, A. A. Sidqi, and Y. A. Saputra, “Physical Properties of Tapioca Starch-based Film Indicators with Anthocyanin Extract from Purple Sweet Potato (Ipomea batatas L.) and Response to pH Changes,” Sains Malaysiana, vol. 52, no. 6, pp. 1685–1697, 2023, https://doi.org/10.17576/jsm-2023-5206-06.

Z. Eslami, S. Elkoun, M. Robert, and K. Adjallé, “A Review of the Effect of Plasticizers on the Physical and Mechanical Properties of Alginate-Based Films,” Molecules, vol. 28, no. 18, p. 6637, 2023, https://doi.org/10.3390/molecules28186637.

J. Li, Z. Li, Y. Yan, D. Shao, Y. Guo, and R. Lin, “Study on the structure–property relationship of starch/PLA composite films modified by the synergistic effect of aromatic rings and aliphatic chains,” Polym. Degrad. Stab., vol. 241, p. 111567, 2025, https://doi.org/10.1016/j.polymdegradstab.2025.111567.

A. A. Al-Hassan and M. H. Norziah, “Starch–gelatin edible films: Water vapor permeability and mechanical properties as affected by plasticizers,” Food Hydrocoll., vol. 26, no. 1, pp. 108–117, 2012, https://doi.org/10.1016/j.foodhyd.2011.04.015.

K. Czerwiński, T. Rydzkowski, J. Wróblewska-Krepsztul, and V. K. Thakur, “Towards Impact of Modified Atmosphere Packaging (MAP) on Shelf-Life of Polymer-Film-Packed Food Products: Challenges and Sustainable Developments,” Coatings, vol. 11, no. 12, p. 1504, 2021, https://doi.org/10.3390/coatings11121504.

H. Onyeaka, K. Obileke, G. Makaka, and N. Nwokolo, “Current Research and Applications of Starch-Based Biodegradable Films for Food Packaging,” Polymers (Basel)., vol. 14, no. 6, p. 1126, 2022, https://doi.org/10.3390/polym14061126.

M. Zabihzadeh Khajavi, A. Ebrahimi, M. Yousefi, S. Ahmadi, M. Farhoodi, A. Mirza Alizadeh, and M. Taslikh, “Strategies for Producing Improved Oxygen Barrier Materials Appropriate for the Food Packaging Sector,” Food Eng. Rev., vol. 12, no. 3, pp. 346–363, 2020, https://doi.org/10.1007/s12393-020-09235-y.

F. Versino, O. V. Lopez, M. A. Garcia, and N. E. Zaritzky, “Starch‐based films and food coatings: An overview,” Starch - Stärke, vol. 68, no. 11–12, pp. 1026–1037, 2016, https://doi.org/10.1002/star.201600095.

S. Singha and M. S. Hedenqvist, “A Review on Barrier Properties of Poly(Lactic Acid)/Clay Nanocomposites,” Polymers (Basel)., vol. 12, no. 5, p. 1095, 2020, https://doi.org/10.3390/polym12051095.

M. L. Sanyang, S. M. Sapuan, M. Jawaid, M. R. Ishak, and J. Sahari, “Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (arenga pinnata) starch for food packaging,” J. Food Sci. Technol., vol. 53, no. 1, pp. 326–336, 2016, https://doi.org/10.1007/s13197-015-2009-7.

T. R. Arruda et al., “An Overview of Starch-Based Materials for Sustainable Food Packaging: Recent Advances, Limitations, and Perspectives,” Macromol, vol. 5, no. 2, p. 19, 2025, https://doi.org/10.3390/macromol5020019.

Y. Liu, L. Yang, C. Ma, and Y. Zhang, “Thermal Behavior of Sweet Potato Starch by Non-Isothermal Thermogravimetric Analysis,” Materials (Basel)., vol. 12, no. 5, p. 699, 2019, https://doi.org/10.3390/ma12050699.

X. Liu, Y. Wang, L. Yu, Z. Tong, L. Chen, H. Liu, and X. Li, “Thermal degradation and stability of starch under different processing conditions,” Starch - Stärke, vol. 65, no. 1–2, pp. 48–60, 2013, https://doi.org/10.1002/star.201200198.

M. O. Tuhin, N. Rahman, M. E. Haque, R. A. Khan, N. C. Dafader, R. Islam, M. Nurnabi, and W. Tonny, “Modification of mechanical and thermal property of chitosan–starch blend films,” Radiat. Phys. Chem., vol. 81, no. 10, pp. 1659–1668, 2012, https://doi.org/10.1016/j.radphyschem.2012.04.015.

Y. Garavand, A. Taheri-Garavand, F. Garavand, F. Shahbazi, D. Khodaei, and I. Cacciotti, “Starch-Polyvinyl Alcohol-Based Films Reinforced with Chitosan Nanoparticles: Physical, Mechanical, Structural, Thermal and Antimicrobial Properties,” Appl. Sci., vol. 12, no. 3, p. 1111, 2022, https://doi.org/10.3390/app12031111.

D. Phothisarattana and N. Harnkarnsujarit, “Migration, aggregations and thermal degradation behaviors of TiO2 and ZnO incorporated PBAT/TPS nanocomposite blown films,” Food Packag. Shelf Life, vol. 33, p. 100901, 2022, https://doi.org/10.1016/j.fpsl.2022.100901.

J. M. Fernández, C. Plaza, A. Polo, and A. F. Plante, “Use of thermal analysis techniques (TG–DSC) for the characterization of diverse organic municipal waste streams to predict biological stability prior to land application,” Waste Manag., vol. 32, no. 1, pp. 158–164, 2012, https://doi.org/10.1016/j.wasman.2011.08.011.

A. Jiménez, M. J. Fabra, P. Talens, and A. Chiralt, “Edible and biodegradable starch films: A review,” Food Bioprocess Technol., vol. 5, no. 6, pp. 2058–2076, 2012, https://doi.org/10.1007/s11947-012-0835-4.

S. Mehboob, T. M. Ali, M. Sheikh, and A. Hasnain, “Effects of cross linking and/or acetylation on sorghum starch and film characteristics,” Int. J. Biol. Macromol., vol. 155, pp. 786–794, 2020, https://doi.org/10.1016/j.ijbiomac.2020.03.144.

M. Shahbazi, G. Rajabzadeh, A. Rafe, R. Ettelaie, and S. J. Ahmadi, “Physico-mechanical and structural characteristics of blend film of poly (vinyl alcohol) with biodegradable polymers as affected by disorder-to-order conformational transition,” Food Hydrocoll., vol. 71, pp. 259–269, 2017, https://doi.org/10.1016/j.foodhyd.2017.04.017.

K. Vaezi, G. Asadpour, and H. Sharifi, “Effect of ZnO nanoparticles on the mechanical, barrier and optical properties of thermoplastic cationic starch/montmorillonite biodegradable films,” Int. J. Biol. Macromol., vol. 124, pp. 519–529, 2019, https://doi.org/10.1016/j.ijbiomac.2018.11.142.

A. F. Routh, “Drying of thin colloidal films,” Reports Prog. Phys., vol. 76, no. 4, p. 046603, 2013, https://doi.org/10.1088/0034-4885/76/4/046603.

C. I. La Fuente Arias, M. T. K. Kubo, C. C. Tadini, and P. E. D. Augusto, “Bio-based multilayer films: A review of the principal methods of production and challenges,” Crit. Rev. Food Sci. Nutr., vol. 63, no. 14, pp. 2260–2276, 2023, https://doi.org/10.1080/10408398.2021.1973955.

L. de S. Falcão, D. B. Coelho, P. C. Veggi, P. H. Campelo, P. M. Albuquerque, and M. A. de Moraes, “Starch as a Matrix for Incorporation and Release of Bioactive Compounds: Fundamentals and Applications,” Polymers (Basel)., vol. 14, no. 12, p. 2361, 2022, https://doi.org/10.3390/polym14122361.

F. A. Triana, M. Devi, and S. Soekopitojo, “The Effect of Breadfruit Leaves (Artocarpus altilis) Addition to Antioxidant Content and Organoleptic Properties of Ginger Wedang,” J. Agri-Food Sci. Technol., vol. 2, no. 1, pp. 81–87, 2022, https://doi.org/10.12928/jafost.v2i1.4314.

M. Hadi, A. Permadi, T. E. Suharto, M. W. Putri, H. A. P. Gulo, N. O. Maema, H. Halimathusyakhdyah, and A. Lupi, “Phytochemical Test of Sacha Inchi Oil from Central Java,” J. Agri-Food Sci. Technol., vol. 6, no. 3, pp. 168–177, 2025, https://doi.org/https://doi.org/10.12928/jafost.v6i3.12885.

R. Syafiq, S. M. Sapuan, M. Y. M. Zuhri, R. A. Ilyas, A. Nazrin, S. F. K. Sherwani, and A. Khalina, “Antimicrobial Activities of Starch-Based Biopolymers and Biocomposites Incorporated with Plant Essential Oils: A Review,” Polymers (Basel)., vol. 12, no. 10, p. 2403, 2020, https://doi.org/10.3390/polym12102403.

M. S. Khatun, “Challenges and Prospects of Bioactive Peptides Produced from Plants as Sustainable Source - A Case Study,” J. Sci. Agrotechnology, vol. 3, no. 1, pp. 1–9, 2025, https://doi.org/https://doi.org/10.21107/jsa.v3i1.23.

S. O. Olunusi, N. H. Ramli, F. Adam, and S. N. Rahmadhia, “Stability, antioxidant and antimicrobial activities of ginger essential oil nanoemulsion: Impact of droplet size and concentration with molecular dynamics insights into zingiberene bioactivity,” Food Biosci., vol. 71, p. 107174, 2025, https://doi.org/10.1016/j.fbio.2025.107174.

L. Diniz do Nascimento et al., “Bioactive Natural Compounds and Antioxidant Activity of Essential Oils from Spice Plants: New Findings and Potential Applications,” Biomolecules, vol. 10, no. 7, p. 988, 2020, https://doi.org/10.3390/biom10070988.

M. S. Khatun and A. Jahan, “Bioinformatics Analysis of Toxicity and Functional Properties of Plant-Derived Bioactive Proteins,” Control Syst. Optim. Lett., vol. 2, no. 2, pp. 241–247, 2024, https://doi.org/10.59247/csol.v2i2.112.

F. C. Agustia, R. Salma, S. A. Hamidah, K. R. Dewi, and S. Sanayei, “Total Phenolic Content and Hedonic Quality of Germinated Jack Bean Tempeh at Different Fermentation Times and Packaging Types,” J. Agri-Food Sci. Technol., vol. 6, no. 2, pp. 73–86, 2025, https://doi.org/10.12928/jafost.v6i2.12698.

S. N. Rahmadhia and T. Juwitaningtyas, “Physicochemical Properties of Klutuk banana Leaves (Musa balbisiana Colla) Susu and Wulung Cultivars with its Potential as Antioxidant,” J. Agri-Food Sci. Technol., vol. 1, no. 1, p. 18, 2020, https://doi.org/10.12928/jafost.v1i1.1942.

J. R. Rendón-Villalobos, J. Solorza-Feria, F. Rodríguez-González, and E. Flores-Huicochea, “Barrier properties improvement using additives,” in Food Packaging, Elsevier, 2017, pp. 465–495. https://doi.org/10.1016/B978-0-12-804302-8.00014-5.

W. Weisany, S. Yousefi, N. A. Tahir, N. Golestanehzadeh, D. J. McClements, B. Adhikari, and M. Ghasemlou, “Targeted delivery and controlled released of essential oils using nanoencapsulation: A review,” Adv. Colloid Interface Sci., vol. 303, p. 102655, 2022, https://doi.org/10.1016/j.cis.2022.102655.

N. P. Mbonambi, J. O. Adeyemi, F. Seke, and O. A. Fawole, “Fabrication and Application of Bio-Based Natural Polymer Coating/Film for Food Preservation: A Review,” Processes, vol. 13, no. 8, p. 2436, 2025, https://doi.org/10.3390/pr13082436.

A. Belasli, L. Aguerri, L. Ait Ouahioune, R. Becerril, M. Quintero, E. Canellas, A. Ariño, D. Djenane, C. Nerín, and F. Silva, “Microbial safety improvement of date fruits using a Thymus numidicus essential oil-based active packaging,” Food Packag. Shelf Life, vol. 52, p. 101673, 2025, https://doi.org/10.1016/j.fpsl.2025.101673.

A. L. G. Rosas, N. R. Kleinübing, C. K. Bierhals, B. da Fonseca Antunes, A. F. Carloto, D. R. Silveira, W. P. da Silva, E. da Rosa Zavareze, G. V. Lopes, and A. D. Meinhart, “Cryogels based on Brazilian purple yam (Dioscorea trifida L.f.) starch: An antimicrobial active packaging approach for microbial and moisture control in fresh cheese,” Int. J. Biol. Macromol., p. 149281, 2025, https://doi.org/10.1016/j.ijbiomac.2025.149281.

P. Koirala, A. Thuanthong, S. S. Sablani, and N. Nirmal, “Formulation and characterization of green tea spent extract incorporated crude tangerine pectin /gelatin active packaging film,” Ind. Crops Prod., vol. 238, p. 122347, 2025, https://doi.org/10.1016/j.indcrop.2025.122347.

S. Castellanos-González, T. Jiménez-Ariza, and D. A. Castellanos, “Development and evaluation of starch-based composite active sheets for the preservation and packaging of blueberry (Vaccinium corymbosum) fresh fruits,” Food Packag. Shelf Life, vol. 52, p. 101645, 2025, https://doi.org/10.1016/j.fpsl.2025.101645.

X. Liu, Y. Liu, M. Fan, K. Qian, W. Ma, D. Li, and L. Li, “Development of antibacterial starch-based PLA/PBAT active packaging films for enhanced beef preservation,” Food Chem., vol. 493, p. 145804, 2025, https://doi.org/10.1016/j.foodchem.2025.145804.

D. Kossyvaki, M. Contardi, A. Athanassiou, and D. Fragouli, “Colorimetric Indicators Based on Anthocyanin Polymer Composites: A Review,” Polymers (Basel)., vol. 14, no. 19, p. 4129, 2022, https://doi.org/10.3390/polym14194129.

E. de M. Teixeira et al., “Assessment of the properties of ginger starch-based films and their potential application as intelligent packaging,” Int. J. Biol. Macromol., vol. 330, p. 148120, 2025, https://doi.org/10.1016/j.ijbiomac.2025.148120.

H. Lv et al., “Starch-based biodegradable active intelligent packaging with color superimposition via emulsion electrospinning nanofiber for meat freshness monitoring and shelf-life extension,” Carbohydr. Polym., vol. 367, p. 123940, 2025, https://doi.org/10.1016/j.carbpol.2025.123940.

W. Song, N. Wu, Y. He, H. Zhao, J. Xu, and L. Ren, “Intelligent color changing packaging film based on esterified starch and black rice anthocyanins,” Food Chem. X, vol. 24, p. 101930, 2024, https://doi.org/10.1016/j.fochx.2024.101930.

C. Jiang, G. Liu, Q. Zhang, S. Wang, and Y. Zou, “Preparation and characterization of intelligent packaging labels based on pea starch, κ-carrageenan and black raspberry extract for monitoring freshness of pork,” Food Chem. X, vol. 24, p. 101850, 2024, https://doi.org/10.1016/j.fochx.2024.101850.

N. Li, H. Qin, Q. Tang, D. Peng, X. Luo, H. Li, and Z. Zou, “Development and application of intelligent packaging films based on carboxymethyl starch/PVA with Cu-LTE nanocrystal as functional compatibilizer,” Food Packag. Shelf Life, vol. 43, p. 101306, 2024, https://doi.org/10.1016/j.fpsl.2024.101306.

D. Liu, C. Zhang, Y. Pu, S. Chen, L. Liu, Z. Cui, and Y. Zhong, “Recent Advances in pH-Responsive Freshness Indicators Using Natural Food Colorants to Monitor Food Freshness,” Foods, vol. 11, no. 13, p. 1884, 2022, https://doi.org/10.3390/foods11131884.

A. Aberoumand and F. Fardaei, “Difference in Biochemical Composition and Nutritional Trait in Different Areas of Fillets of Dorsal, Venter-cha, and Ventral of Carangoides fulvoguttatus,” J. Agri-Food Sci. Technol., vol. 6, no. 1, pp. 22–31, 2025, https://doi.org/10.12928/jafost.v6i1.11459.

N. Hidayah, M. S. Hawa, B. Purwono, and S. N. Rahmadhia, “Development of Packaging Film from Purple Heart (Tradescantia pallida) Anthocyanin for Fish Freshness Indicator,” Trends Sci., vol. 22, no. 7, p. 10077, 2025, https://doi.org/10.48048/tis.2025.10077.

I. Kusuma and A. N. Khairi, “Physicochemical and Microbiological Contaminants in Pasteurized Canned Crab Meat at PT Pan Putra Samudra, Cirebon,” J. Sci. Agrotechnology, vol. 2, no. 2, pp. 1–7, 2024, https://doi.org/https://doi.org/10.21107/jsa.v2i2.31.

M. P. Bimantio, A. Wulandari, and I. B. B. Partha, “The Application of Potato Starch-Based (Amylum solani) Edible Coating on Tomatoes (Solanum lycopersicum L.),” J. Agri-Food Sci. Technol., vol. 6, no. 2, pp. 87–97, 2025, https://doi.org/10.12928/jafost.v6i2.12123.

L. Chen, W. Wang, W. Wang, and J. Zhang, “Effect of Anthocyanins on Colorimetric Indicator Film Properties,” Coatings, vol. 13, no. 10, p. 1682, 2023, https://doi.org/10.3390/coatings13101682.

F. Bagri, G. Pircheraghi, Z. Riahi, M. Imani, and J.-W. Rhim, “Multifunctional carrageenan/gelatin nanocomposite film incorporating carbon dot-silica nanohybrid and anthocyanins from red cabbage for intelligent shrimp packaging,” Int. J. Biol. Macromol., vol. 321, p. 146311, 2025, https://doi.org/10.1016/j.ijbiomac.2025.146311.

F. Xu, X. Liu, C. Tang, H. Yong, J. Kan, and J. Liu, “Fabrication of chitosan/black rice anthocyanin composite films cross-linked with dialdehyde pullulan for shrimp freshness indicating,” Food Chem., vol. 493, p. 145716, 2025, https://doi.org/10.1016/j.foodchem.2025.145716.

S. B. H. Hashim et al., “Intelligent colorimetric pH sensoring packaging films based on sugarcane wax/agar integrated with butterfly pea flower extract for optical tracking of shrimp freshness,” Food Chem., vol. 373, p. 131514, 2022, https://doi.org/10.1016/j.foodchem.2021.131514.

B. Enaru, G. Drețcanu, T. D. Pop, A. Stǎnilǎ, and Z. Diaconeasa, “Anthocyanins: Factors affecting their stability and degradation,” Antioxidants, vol. 10, no. 12, p. 1967, 2021, https://doi.org/10.3390/antiox10121967.

H. Xue, J. Zhao, Y. Wang, Z. Shi, K. Xie, X. Liao, and J. Tan, “Factors affecting the stability of anthocyanins and strategies for improving their stability: A review,” Food Chem. X, vol. 24, p. 101883, 2024, https://doi.org/10.1016/j.fochx.2024.101883.

X. Huang et al., “Exploring the Integration of Anthocyanins with Functional Materials in Smart Food Packaging: From Stabilization to Application,” Foods, vol. 14, no. 16, p. 2896, 2025, https://doi.org/10.3390/foods14162896.

Q. Su, W. Su, S. Xing, and M. Tan, “Enhanced stability of anthocyanins by cyclodextrin–metal organic frameworks: Encapsulation mechanism and application as protecting agent for grape preservation,” Carbohydr. Polym., vol. 326, p. 121645, 2024, https://doi.org/10.1016/j.carbpol.2023.121645.

A. Duan, J. Yang, L. Wu, T. Wang, Q. Liu, and Y. Liu, “Preparation, physicochemical and application evaluation of raspberry anthocyanin and curcumin based on chitosan/starch/gelatin film,” Int. J. Biol. Macromol., vol. 220, pp. 147–158, 2022, https://doi.org/10.1016/j.ijbiomac.2022.08.053.

A. Karnwal, A. Rauf, A. Y. Jassim, M. Selvaraj, A. R. M. S. Al-Tawaha, P. Kashyap, D. Kumar, and T. Malik, “Advanced starch-based films for food packaging: Innovations in sustainability and functional properties,” Food Chem. X, vol. 29, p. 102662, 2025, https://doi.org/10.1016/j.fochx.2025.102662.

P. A. Pawase, A. M. Pathare, O. Bashir, F. Saleem, E. Shrama, S. Mudgal, and M. Ahmad, “Physical, chemical, and nano-enabled modifications of starch for sustainable food packaging films: recent trends, challenges, and prospects,” Carbohydr. Polym. Technol. Appl., vol. 11, p. 100986, 2025, https://doi.org/10.1016/j.carpta.2025.100986.

P. F. Muñoz-Gimena, V. Oliver-Cuenca, L. Peponi, and D. López, “A Review on Reinforcements and Additives in Starch-Based Composites for Food Packaging,” Polymers (Basel)., vol. 15, no. 13, p. 2972, 2023, https://doi.org/10.3390/polym15132972.

C. Cazan, A. Enesca, and L. Andronic, “Synergic Effect of TiO2 Filler on the Mechanical Properties of Polymer Nanocomposites,” Polymers (Basel)., vol. 13, no. 12, p. 2017, 2021, https://doi.org/10.3390/polym13122017.

R. A. Shapi’i, S. H. Othman, R. K. Basha, and M. N. Naim, “Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles,” Nanotechnol. Rev., vol. 11, no. 1, pp. 1464–1477, 2022, https://doi.org/10.1515/ntrev-2022-0094.

J. Nandhini, M. Bellarmin, S. Siva Prakash, D. Sowmya Sri, and E. Karthikeyan, “Advancements in metal oxide bio‐nanocomposites for sustainable food packaging: Fabrication, applications, and future prospectives,” Food Bioeng., vol. 3, no. 4, pp. 438–463, 2024, https://doi.org/10.1002/fbe2.12106.

J. George, B. Aaliya, K. V. Sunooj, and R. Kumar, “An Overview of Higher Barrier Packaging Using Nanoadditives,” in Nanotechnology‐Enhanced Food Packaging, Wiley, 2022, pp. 235–264. https://doi.org/10.1002/9783527827718.ch10.

M. G. A. Vieira, M. A. da Silva, L. O. dos Santos, and M. M. Beppu, “Natural-based plasticizers and biopolymer films: A review,” Eur. Polym. J., vol. 47, no. 3, pp. 254–263, 2011, https://doi.org/10.1016/j.eurpolymj.2010.12.011.

V. Jamwal and A. Mittal, “Recent Progresses in Nanocomposite Films for Food-Packaging Applications: Synthesis Strategies, Technological Advancements, Potential Risks and Challenges,” Food Rev. Int., vol. 40, no. 10, pp. 3634–3665, 2024, https://doi.org/10.1080/87559129.2024.2368065.

M. A. Bastomy and S. N. Rahmadhia, “The Effect of Chitosan-Based Edible Coating on The Moisture Content, Texture, and Microbial Count of Chicken Sausages,” J. Ilmu-Ilmu Peternak., vol. 35, no. 1, pp. 67–79, 2025, https://doi.org/10.21776/ub.jiip.2025.035.01.7.

I. F. Islami and S. N. Rahmadhia, “The effect of sago starch (Metroxylon sp.) and chitosan as edible coating on physical and chemical characteristics of red chili (Capsicum annuum L.),” Adv. Food Sci. Sustain. Agric. Agroindustrial Eng., vol. 7, no. 3, pp. 265–273, 2024, https://doi.org/10.21776/ub.afssaae.2024.007.03.7.

A. Yarahmadi, B. Dousti, M. Karami-Khorramabadi, and H. Afkhami, “Materials based on biodegradable polymers chitosan/gelatin: a review of potential applications,” Front. Bioeng. Biotechnol., vol. 12, 2024, https://doi.org/10.3389/fbioe.2024.1397668.

H. Rostamabadi, I. Demirkesen, R. Colussi, S. Roy, N. Tabassum, J. G. de Oliveira Filho, Y. Bist, Y. Kumar, M. Nowacka, S. Galus, and S. R. Falsafi, “Recent trends in the application of films and coatings based on starch, cellulose, chitin, chitosan, xanthan, gellan, pullulan, Arabic gum, alginate, pectin, and carrageenan in food packaging,” Food Front., vol. 5, no. 2, pp. 350–391, 2024, https://doi.org/10.1002/fft2.342.

O. L. Orhotohwo, P. Lucci, A. K. Jaiswal, S. Jaiswal, and D. Pacetti, “Enhancing the functional properties of chitosan-alginate edible films using spent coffee ground extract for fresh-cut fruit preservation,” Curr. Res. Food Sci., vol. 11, p. 101124, 2025, https://doi.org/10.1016/j.crfs.2025.101124.

C. A. Díaz-Cruz, C. Caicedo, E. J. Jiménez-Regalado, R. Díaz de León, R. López-González, and R. Y. Aguirre-Loredo, “Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals,” Polymers (Basel)., vol. 14, no. 11, p. 2166, 2022, https://doi.org/10.3390/polym14112166.

J. Chen, J. Zhang, D. Liu, C. Zhang, H. Yi, and D. Liu, “Preparation, characterization, and application of edible antibacterial three-layer films based on gelatin–chitosan–corn starch–incorporated nisin,” Food Packag. Shelf Life, vol. 34, p. 100980, 2022, https://doi.org/10.1016/j.fpsl.2022.100980.

B. E. Ștefănescu, C. Socaciu, and D. C. Vodnar, “Recent Progress in Functional Edible Food Packaging Based on Gelatin and Chitosan,” Coatings, vol. 12, no. 12, p. 1815, 2022, https://doi.org/10.3390/coatings12121815.

Y. Li, C. Yuan, B. Cui, P. Liu, Y. Fang, Z. Wu, H. Zhao, and J. Liu, “Chitosan/pre-gelatinized waxy corn starch composite edible orally disintegrating film for taurine delivery,” Food Hydrocoll., vol. 159, p. 110710, 2025, https://doi.org/10.1016/j.foodhyd.2024.110710.

J. D. N. Ogbonna, F. C. Kenechukwu, S. A. Chime, and A. A. Attama, “Cellulose-Based Biopolymers: Formulation and Delivery Applications,” in Encyclopedia of Biomedical Polymers and Polymeric Biomaterials, Taylor & Francis, pp. 1378–1408, 2016, https://doi.org/10.1081/E-EBPP-120050066.

M. Younis, R. M. Kamel, A. Alhamdan, E. El. Fadly, A. I. Zein El-Abedein, and M. N. Saleh, “Improving Barhi date shelf life with cellulose nanocrystals/cinnamon oil Pickering emulsion incorporated into sodium alginate-based films,” Int. J. Biol. Macromol., vol. 309, p. 143058, 2025, https://doi.org/10.1016/j.ijbiomac.2025.143058.

Y. A. Shah, S. Bhatia, A. Al-Harrasi, F. Oz, M. H. Khan, S. Roy, T. Esatbeyoglu, and A. Pratap-Singh, “Thermal Properties of Biopolymer Films: Insights for Sustainable Food Packaging Applications,” Food Eng. Rev., vol. 16, no. 4, pp. 497–512, 2024, https://doi.org/10.1007/s12393-024-09380-8.

M. Miao, B. Jiang, Z. Jin, and J. N. BeMiller, “Microbial Starch‐Converting Enzymes: Recent Insights and Perspectives,” Compr. Rev. Food Sci. Food Saf., vol. 17, no. 5, pp. 1238–1260, 2018, https://doi.org/10.1111/1541-4337.12381.

E. M. N. Polman, G.-J. M. Gruter, J. R. Parsons, and A. Tietema, “Comparison of the aerobic biodegradation of biopolymers and the corresponding bioplastics: A review,” Sci. Total Environ., vol. 753, p. 141953, 2021, https://doi.org/10.1016/j.scitotenv.2020.141953.

X. Yao, X. Yang, Y. Lu, Y. Qiu, and Q. Zeng, “Review of the Synthesis and Degradation Mechanisms of Some Biodegradable Polymers in Natural Environments,” Polymers (Basel)., vol. 17, no. 1, p. 66, 2024, https://doi.org/10.3390/polym17010066.

N. A. Rosli, M. Karamanlioglu, H. Kargarzadeh, and I. Ahmad, “Comprehensive exploration of natural degradation of poly(lactic acid) blends in various degradation media: A review,” Int. J. Biol. Macromol., vol. 187, pp. 732–741, 2021, https://doi.org/10.1016/j.ijbiomac.2021.07.196.

A. Wojtowicz, “Biodegradability and Compostability of Biopolymers,” in Thermoplastic Starch, Wiley, pp. 55–76, 2009, https://doi.org/10.1002/9783527628216.ch3.

P. G. Ponnusamy and S. Mani, “Life cycle assessment of manufacturing cellulose nanofibril-reinforced chitosan composite films for packaging applications,” Int. J. Life Cycle Assess., vol. 27, no. 3, pp. 380–394, 2022, https://doi.org/10.1007/s11367-022-02035-y.

M. Mannan, T. Al-Ansari, H. R. Mackey, and S. G. Al-Ghamdi, “Quantifying the energy, water and food nexus: A review of the latest developments based on life-cycle assessment,” J. Clean. Prod., vol. 193, pp. 300–314, 2018, https://doi.org/10.1016/j.jclepro.2018.05.050.

M. A. V. T. Garcia, C. F. Garcia, and A. A. G. Faraco, “Pharmaceutical and Biomedical Applications of Native and Modified Starch: A Review,” Starch - Stärke, vol. 72, no. 7–8, 2020, https://doi.org/10.1002/star.201900270.

K. Mohammed, D. Yu, A. A. Mahdi, L. Zhang, M. Obadi, W. Al-Ansi, and W. Xia, “Influence of cellulose viscosity on the physical, mechanical, and barrier properties of the chitosan-based films,” Int. J. Biol. Macromol., vol. 259, p. 129383, 2024, https://doi.org/10.1016/j.ijbiomac.2024.129383.

F. Versino, F. Ortega, Y. Monroy, S. Rivero, O. V. López, and M. A. García, “Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations,” Foods, vol. 12, no. 5, p. 1057, 2023, https://doi.org/10.3390/foods12051057.

C. Vasile and M. Baican, “Lignins as Promising Renewable Biopolymers and Bioactive Compounds for High-Performance Materials,” Polymers (Basel)., vol. 15, no. 15, p. 3177, 2023, https://doi.org/10.3390/polym15153177.

K. Srirangan, L. Akawi, M. Moo-Young, and C. P. Chou, “Towards sustainable production of clean energy carriers from biomass resources,” Appl. Energy, vol. 100, pp. 172–186, 2012, https://doi.org/10.1016/j.apenergy.2012.05.012.

V. Sharma, M.-L. Tsai, P. Nargotra, C.-W. Chen, C.-H. Kuo, P.-P. Sun, and C.-D. Dong, “Agro-Industrial Food Waste as a Low-Cost Substrate for Sustainable Production of Industrial Enzymes: A Critical Review,” Catalysts, vol. 12, no. 11, p. 1373, 2022, https://doi.org/10.3390/catal12111373.

A. L. Allison, F. Lorencatto, S. Michie, and M. Miodownik, “Barriers and Enablers to Buying Biodegradable and Compostable Plastic Packaging,” Sustainability, vol. 13, no. 3, p. 1463, 2021, https://doi.org/10.3390/su13031463.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Isnainul Kusuma, Safinta Nurindra Rahmadhia, Alfian Ma'arif, Agus Aktawan, Titisari Juwitaningtyas, Noor Hanuni, Samuel Olugbenga Olunusi

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.