Corn Flour Quality Identification System Based on Angle Image

DOI:

https://doi.org/10.12928/biste.v3i2.1490Abstract

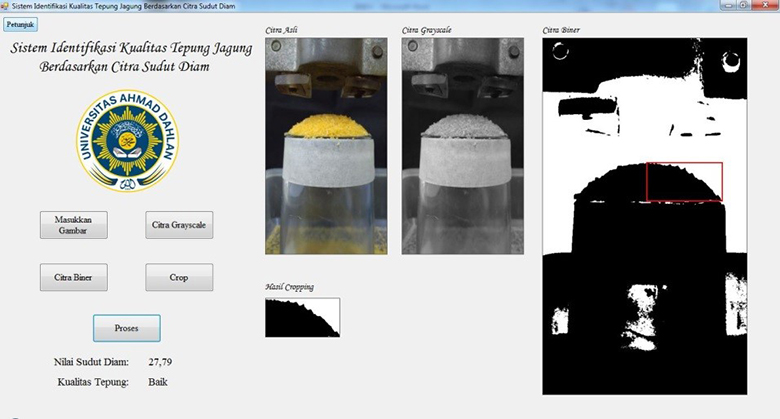

Corn can be processed into corn flour, this can make it easier for consumers to consume and process it into other food ingredients. Therefore we need a system that is able to identify the quality of corn flour automatically. Data retrieval is done by inserting corn flour into a container to calculate the angle of repose. The valve of the container is opened and the cornstarch flows into a mound above the cross-sectional base. The image of the corn flour mound was taken using a cellphone camera and stored in a laptop as a database. The sample of this research is corn flour with three types of particle sizes, namely 20 mesh, 10 mesh and 8 mesh. In the identification process, the corn flour image is converted into a grayscale and binary image and cropping is done, then identified based on the calculation of the angle of repose. The results of this study obtained that the average value of 20 mesh, 10 mesh and 8 mesh corn flour was 30.91 degrees; 33.96 degrees and 36.80 degrees. After testing and comparison, it can be concluded that corn flour with good quality is corn flour with an angle of less than 32 degrees.

Jagung dapat diolah menjadi tepung jagung, hal ini dapat memudahkan konsumen dalam mengonsumsi dan mengolahnya menjadi bahan pangan lain. Oleh karena itu dibutuhkan sistem yang mampu mengidentifikasi kualitas tepung jagung secara otomatis. Pengambilan data dilakukan dengan memasukkan tepung jagung ke dalam wadah hitung sudut diam. Katup wadah dibuka dan tepung jagung mengalir membentuk gundukan di atas alas penampang. Citra dari gundukan tepung jagung diambil menggunakan kamera handphone dan disimpan ke dalam laptop sebagai database. Sampel penelitian ini tepung jagung dengan tiga jenis ukuran partikel, yaitu 20 mesh, 10 mesh dan 8 mesh. Dalam proses identifikasi citra terpung jagung dikonversikan menjadi citra greyscale dan biner serta dilakukan cropping, lalu diidentifikasi berdasarkan perhitungan sudut diam. Hasil penelitian yang dilakukan mendapatkan nilai rata-rata tepung jagung 20 mesh, 10 mesh dan 8 mesh berturut-turut adalah 30,91 derajat; 33,96 derajat dan 36,80derajat. Setelah dilakukan pengujian dan perbandingan, dapat disimpulkan bahwa tepung jagung dengan kualitas baik yaitu tepung jagung dengan sudut kurang dari sama dengan 32derajat.References

S. Suarni and M. Yasin, “Jagung sebagai Sumber Pangan Fungsional,” IPTEK Tanam. Pangan, vol. 6, no. 1, pp. 41–56 2011. http://ejurnal.litbang.pertanian.go.id/index.php/ippan/article/view/2595

Suarni and H. Subagio, “Potensi Pengembangan Jagung Dan Sorgum Sebagai Sumber Pangan Fungsional,” Balai Penelit. Tanam. Serealia, vol. 32, no. 2, pp. 47–55, 2013. http://ejurnal.litbang.pertanian.go.id/index.php/jppp/article/view/1236

R. W. Arief, A. Yani, Asropi, and F. Dewi, “Kajian Pembuatan Tepung Jagung Dengan Proses Pengolahan Yang Berbeda,” Pros. Semin. Nas. “Inovasi Teknol. Pertan. Spesifik Lokasi, 2014. http://kalsel.litbang.pertanian.go.id/ind/images/pdf/semnas2014/69_ratna.pdf

A. D. Candra and A. Fadlil, “Sistem Penentuan Sudut Diam Granul Menggunakan Metode Pengolahan Citra Berbasis Android,” J. Ilm. Tek. Elektro Komput. dan Inform., vol. 3, no. 2, p. 118, 2018. https://doi.org/10.26555/jiteki.v3i2.7419

C. N. Prabiantissa, A. R. T. H. Ririd, and R. A. Asmara, “Sistem Identifikasi Batik Alami Dan Batik Sintetis Berdasarkan Karakteristik Warna Citra Dengan Metode K-Means Clustering,” J. Inform. Polinema, vol. 3, no. 2, pp. 26–31, 2017. https://doi.org/10.33795/jip.v3i2.10

H. Musa, I. Emenike, O. Elija, S. Timothy, and M. Gwarzo, “Extraction and Characterization of White Guinea Corn (Sorghum arundinaceum) Starch : A Potential Source of Pharmaceutical Raw Excipient Material,” Int. J. Pharm. Pharm. Res., vol. 6, no. 3, pp. 434–441, 2016.

D. A. Darmajana, R. Ekafitri, R. Kumalasari, and N. Indrianti, “Pengaruh Variasi Ukuran Partikel Tepung Jagung terhadap Karakteristik Fisikokimia Mi Jagung Instan,” PANGAN, vol. 25, no. 1, pp. 1–11, 2016. http://www.jurnalpangan.com/index.php/pangan/article/view/301

M. A. Pagani, “Wheat Milling and Flour Quality Evaluation,” Bak. Prod. Sci. Technol., pp. 17-53, 2014. https://doi.org/10.1002/9781118792001.ch2

F. Setiyaningrum and K. Firdausy, “Metode Thresholding Untuk Segmentasi Citra Telur Berbasis Android,” Simp. Nas. Teknol. Terap. 4, 2016, pp. 105-111. https://www.researchgate.net/publication/345151001

I. Kanedi, Jauhari, and A. Wulandari, “Tata Kelola Perpustakaan Menggunakan Bahasa Pemrograman Visual Basic 6.0,” J. Media Infotama, vol. 9, no. 1, pp. 46–66, 2013. https://jurnal.unived.ac.id/index.php/jmi/article/view/26

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Dimas Murtia Atmojo, Abdul Fadlil

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.