Temperature-Controlled Process for Recycled Waste Tire Polymer-Polymer Composites: An Innovative and Sustainable Solution for Marine Fender Applications

DOI:

https://doi.org/10.12928/biste.v7i3.13813Keywords:

Fenders, Recycling, Sustainability, HDPE, RTV, Waste Tire, PID ControlAbstract

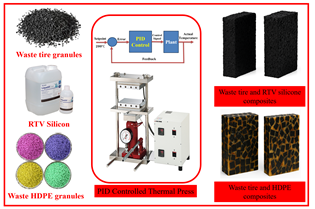

Marine fender prototypes play a critical role in protecting the ship and the berthing infrastructure from damage during docking. Recycling waste polymers, such as waste tires, into composite materials for marine fenders, can contribute to environmental sustainability and resource conservation. In marine Fender applications, compression testing often plays a crucial role; we should also test factors such as elasticity, stiffness, and hardness. In this study, pressure and hardness were selected, and Young's modulus was calculated for two types of composite materials: one manufactured from waste tires and high-density polyethylene (HDPE) and the other from waste tires and room-temperature vulcanized (RTV) silicone both in varying proportions. These types of materials were produced using a press machine equipped with a PID controller, which enables the adjustment of the temperature to a desired value, thereby achieving the best results. Prototypes containing 85% waste tire with 15% HDPE and 50% waste tire with 50% RTV silicone showed superior energy absorption and durability for marine fender applications. Despite achieving satisfactory hardness and hardness values, the waste tire and RTV silicone composite did not exceed those of the waste tire and HDPE composites, which had Young's modulus and Shore hardness values of 1.74 MPa and 56.6, respectively. The compression test showed that the waste tire and RTV silicone composites achieved higher values, surpassing 1990 kN. The findings provide a crucial foundation for utilizing waste composite materials in marine fender production.

References

S. Shiraishi, K. Nagai, and H. Akiyama, “Durability test and statistical evaluation of rubber fenders for vessel berthing,” Journal of Japan Society of Civil Engineers, vol. 9, no. 1, pp. 71–85, 2021, https://doi.org/10.2208/journalofjsce.9.1_71.

W. Galor, “The Analysis Of Effective Energy Of Ship’s Berthing To The Quay,” Journal of KONES. Powertrain and Transport, vol. 19, no. 4, 2015, https://doi.org/10.5604/12314005.1138340.

C. A. Thoresen, Port Designer’s Handbook. 2018. https://doi.org/10.1680/pdhbfe.63075.

G. Wang et al., “Condition Assessment of Aging Ships and Offshore Structures,” 17th International Ship and Offshore Structures Congress (ISSC2009), pp. 309-366, 2009, https://www.croris.hr/crosbi/publikacija/prilog-knjiga/41459.

S. Mita, K. Yamashita, and C. Nonomura, “Influence of the bow collision condition on the characteristic of the new material fender with bridge piers,” Nippon Kikai Gakkai Ronbunshu, A Hen/Transactions of the Japan Society of Mechanical Engineers, Part A, vol. 70, no. 1, 2004, https://doi.org/10.1299/kikaia.70.120.

R. Al-Sabur, Y. M. Ameen, H. I. Khalaf, A. Mishra, and A.-N. Sharkawy, “Modeling the Structural Dynamics of Carbon Fiber Composites for Robotic Systems Under Sinusoidal Load,” International Journal of Robotics and Control Systems, vol. 5, no. 1, pp. 570–584, 2025, https://doi.org/10.31763/ijrcs.v5i1.1693.

M. Bhong et al., “Review of composite materials and applications,” Mater Today Proc, 2023, https://doi.org/10.1016/j.matpr.2023.10.026.

G. Marsh, “Composites fight for share of military applications,” Reinforced Plastics, vol. 49, no. 5, 2005, https://doi.org/10.1016/S0034-3617(05)70641-X.

R. A. Shenoi, J. M. Dulieu-Barton, S. Quinn, J. I. R. Blake, and S. W. Boyd, “Composite Materials for Marine Applications: Key Challenges for the Future,” in Composite Materials, pp. 69-89, 2011, https://doi.org/10.1007/978-0-85729-166-0_3.

M. S. Atiq, A. K. J. Shajib, and K. N. Hoque, “Analysis of Marine Fender Systems Minimizing the Impact of Collision Damage,” SSRN Electronic Journal, 2023, https://doi.org/10.2139/ssrn.4445128.

D. C. Ali, A. K. Jassim, and R. Al-Sabur, “Recycling of Polyethylene and Polypropylene Waste to Produce Plastic Bricks,” Journal of Sustainable Development of Energy, Water and Environment Systems, vol. 11, no. 4, 2023, https://doi.org/10.13044/j.sdewes.d11.0462.

S. A. S. Almtori, R. J. Jassim, D. C. Ali, E. H. Kadhim, and R. Al-Sabur, “Sustainable Manufacturing Process Applied to Produce Waste Polymer-Polymer Matrix Composites,” Environmental Research, Engineering and Management, vol. 79, no. 1, pp. 122–132, 2023, https://doi.org/10.5755/j01.erem.79.1.32907.

A. S. Safaa, N. H. J. Al Hassan, D. C. Ali, M. A. Mohammed, and R. Al-Sabur, “Assessing the compressive performance of PVC coating on steel wire mesh reinforced concrete,” Cogent Eng, vol. 10, no. 1, 2023, https://doi.org/10.1080/23311916.2023.2231700.

L. Valentini and M. A. L. Manchado, “Classification of rubbers and components for harsh environmental systems,” in High-Performance Elastomeric Materials Reinforced by Nano-Carbons: Multifunctional Properties and Industrial Applications, pp. 1-14, 2019, https://doi.org/10.1016/B978-0-12-816198-2.00001-3.

C. Sathiskumar and S. Karthikeyan, “Recycling of waste tires and its energy storage application of by-products –a review,” Sustainable Materials and Technologies, vol. 22, p. e00125, 2019, https://doi.org/10.1016/j.susmat.2019.e00125.

Z. Čepić, V. Mihajlović, S. Đurić, M. Milotić, M. Stošić, B. Stepanov, and M. Ilić Mićunović, “Experimental analysis of temperature influence on waste tire pyrolysis,” Energies, vol. 14, no. 17, p. 5403, 2021, https://doi.org/10.3390/en14175403.

A. Alsaleh and M. L. Sattler, “Waste Tire Pyrolysis: Influential Parameters and Product Properties,” Current Sustainable/Renewable Energy Reports, vol. 1, no. 4, pp. 129-135, 2014, https://doi.org/10.1007/s40518-014-0019-0.

N. Oikonomou and S. Mavridou, “The use of waste tyre rubber in civil engineering works,” in Sustainability of Construction Materials, pp. 213-238 ,2009, https://doi.org/10.1533/9781845695842.213.

J. Nikiema and Z. Asiedu, “A review of the cost and effectiveness of solutions to address plastic pollution,” Environmental Science and Pollution Research, vol. 29, no. 17, pp. 24547-24573, 2022, https://doi.org/10.1007/s11356-021-18038-5.

J. J. Wang, L. J. Feng, A. L. Lei, A. J. Yan, and X. J. Wang, “Thermal stability and mechanical properties of room temperature vulcanized silicone rubbers,” J Appl Polym Sci, vol. 125, no. 1, 2012, https://doi.org/10.1002/app.35669.

H. N. Dhakal and S. O. Ismail, “Introduction to composite materials,” Sustainable Composites for Lightweight Applications, pp. 1–16, 2021, https://doi.org/10.1016/B978-0-12-818316-8.00001-3.

T. T. Lee, “Design criteria recommended for marine fender systems,” In Coastal Engineering 1968, pp. 1159-1184, 1968, https://doi.org/10.9753/icce.v11.73.

H. Agerschou et al., Planning and design of ports and marine terminals. Chichester: Wiley. 1983. https://doi.org/10.1016/0191-2607(84)90023-2.

J. Gaythwaite, Design of Marine Facilities for the Berthing, Mooring, and Repair of Vessels. 2004. https://doi.org/10.1061/9780784407264.

R. Iversen, M. L. Argo, S. C. Cortes, and J. J. Pyun, “Analysis of Measured Marine Oil Terminal Berthing Velocities,” in Ports 2019: Port Planning and Development - Papers from Sessions of the 15th Triennial International Conference, pp. 162-172, 2019, https://doi.org/10.1061/9780784482629.016.

F. Rubino, A. Nisticò, F. Tucci, and P. Carlone, “Marine application of fiber reinforced composites: A review,” Journal of Marine Science and Engineering, vol. 8, no. 1, p. 26, 2020, https://doi.org/10.3390/jmse8010026.

K. Zyka and A. Mohajerani, “Composite piles: A review,” Construction and building materials, vol. 107, pp. 394-410 2016, https://doi.org/10.1016/j.conbuildmat.2016.01.013.

M. Haward, “Ocean plastics charter,” In Essential Concepts of Global Environmental Governance, pp. 171-172, 2020, https://doi.org/10.4324/9780367816681-70.

J. Qian, L. Sun, and L. Song, “Material selection for hawsers for a side-by-side offloading system,” Journal of Marine Science and Application, vol. 13, no. 4, 2014, https://doi.org/10.1007/s11804-014-1272-8.

“AIMPLAS focuses on more efficient composites recycling,” Reinforced Plastics, vol. 65, no. 1, 2021, https://doi.org/10.1016/j.repl.2020.12.041.

H. Liang, Z. K. Sang, Y. Z. Wu, Y. H. Zhang, and R. Zhao, “High precision temperature control performance of a PID neural network-controlled heater under complex outdoor conditions,” Appl Therm Eng, vol. 195, 2021, https://doi.org/10.1016/j.applthermaleng.2021.117234.

M. Fiducioso, S. Curi, B. Schumacher, M. Gwerder, and A. Krause, “Safe contextual Bayesian optimization for sustainable room temperature PID control tuning,” arXiv preprint arXiv:1906.12086, 2019, https://doi.org/10.24963/ijcai.2019/811.

M. B. N. Shah et al., “PID-based temperature control device for electric kettle,” International Journal of Electrical and Computer Engineering, vol. 9, no. 3, 2019, https://doi.org/10.11591/ijece.v9i3.pp1683-1693.

A. H. Akbar, A. Ma’arif, C. Rekik, A. J. Abougarair, and A. M. Mekonnen, “Implementing PID Control on Arduino Uno for Air Temperature Optimization,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 6, no. 1, pp. 1–13, 2024, https://doi.org/10.12928/biste.v6i1.9725.

S. B. Joseph, E. G. Dada, A. Abidemi, D. O. Oyewola, and B. M. Khammas, “Metaheuristic algorithms for PID controller parameters tuning: Review, approaches and open problems,” Heliyon, vol. 8, no. 5, 2022, https://doi.org/10.1016/j.heliyon.2022.e09399.

S. Zeng, W. Li, Y. Peng, Y. Zhang, and G. Zhang, “Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling,” Polymers (Basel), vol. 15, no. 15, 2023, https://doi.org/10.3390/polym15153210.

A. A. Cuadri and J. E. Martín-Alfonso, “The effect of thermal and thermo-oxidative degradation conditions on rheological, chemical and thermal properties of HDPE,” Polym Degrad Stab, vol. 141, 2017, https://doi.org/10.1016/j.polymdegradstab.2017.05.005.

T. Mengistu and R. J. Pazur, “The thermal oxidation of hydrogenated acrylonitrile-co-butadiene rubber from ambient to 150 °C,” Polym Degrad Stab, vol. 188, 2021, https://doi.org/10.1016/j.polymdegradstab.2021.109574.

D. Obradovic and L. N. Mishra, “Mechanical Properties Of Recycled Paper And Cardboard,” The Journal of Engineering and Exact Sciences, vol. 6, no. 3, pp. 0429–0434, 2020, https://doi.org/10.18540/jcecvl6iss3pp0429-0434.

H. Zhao, D. Allanson, and X. J. Ren, “Use of Shore Hardness Tests for In-Process Properties Estimation/Monitoring of Silicone Rubbers,” Journal of Materials Science and Chemical Engineering, vol. 03, no. 07, 2015, https://doi.org/10.4236/msce.2015.37019.

R. Mohan, B. N. Das, and R. Sundaresan, “Effect of hardness and surface roughness on slip resistance of rubber,” J Test Eval, vol. 43, no. 6, 2015, https://doi.org/10.1520/JTE20140249.

A. N. Gent, “On the Relation between Indentation Hardness and Young’s Modulus,” Rubber Chemistry and Technology, vol. 31, no. 4, 1958, https://doi.org/10.5254/1.3542351.

D. Bakošová and A. Bakošová, “Testing of Rubber Composites Reinforced with Carbon Nanotubes,” Polymers (Basel), vol. 14, no. 15, p. 3039, 2022, https://doi.org/10.3390/polym14153039.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ali Habel Zaibel, Safaa A. S. Almtori, Raheem Al-Sabur, Abdel-Nasser Sharkawy

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.