Optimization of Temperature and Time for High-Quality Roasted Barley (Kolo)

DOI:

https://doi.org/10.12928/jafost.v6i1.12666Keywords:

Acrylamide, Barley, Kolo, Physico-chemical composition, RoastingAbstract

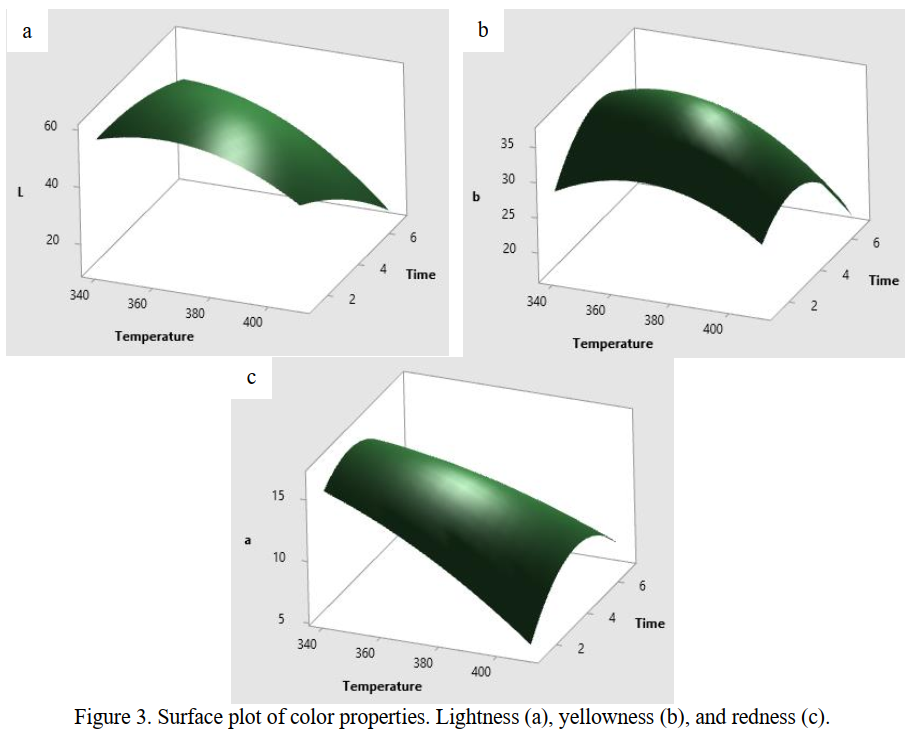

The consumption of roasted barley (kolo) is prevalent in all regions of Ethiopia. However, high-temperature heat treatment can result in the formation of acrylamide in roasted starchy foods. Acrylamide can be a health hazard if continuously consumed at high levels. This research contributes to optimize temperature and duration of roasting barley and investigate their impact on acrylamide formation, sensory profile, and nutritional profile of kolo sourced from both street vendors and industrial processors in Addis Ababa, Ethiopia. Locally produced kolo samples exhibited higher acrylamide contents ranging from 216.60 to 334.80μg/kg, while industrially processed kolo had lower values ranging from 200.28 to 308.95μg/kg. Results indicate that roasting temperature and duration significantly (p<0.05) affected acrylamide levels of kolo. The optimal roasting conditions of 352 ℃ for duration of 2 minutes gave desirability of 0.71. The optimum roasting conditions resulted in kolo with acrylamide of 148.64μg/kg, protein of 11.88%, ash of 3.28%, fat of 2.80%, crude fiber of 14.72%, carbohydrates of 67.35%, lightness (L*) of 57.50%, yellowness (b*) of 33.89%, redness (a*) of 15.52%, taste of 8.35, texture of 8.92, odor of 8.10 and overall sensory acceptability score of 8.18. Roasting barley grains transform them into value-added products and/ or nutritional food ingredients.

References

J. Lukinac and M. Jukić, “Barley in the production of cereal-based products,” Plants, vol. 11, no. 24, p. 3519, 2022, https://doi.org/10.3390/plants11243519.

A. Assamere, A. Mamuye, K. Amare, and M. Fiseha, “Diversity, distribution, agronomic and post-harvest management of local barley (Hordeum vulgare L.) variety in South Wollo, Ethiopia,” PLoS One, vol. 16, no. 5, p. e0250899, 2021, https://doi.org/10.1371/journal.pone.0250899.

E. Wada, A. Abdulahi, T. F. Tehelku, M. Ergando, and H. D. Degu, “Farmers’ knowledge on cultivation, utilization and conservation practices of barley (Hordeum vulgare L.) in three selected districts in Ethiopia,” J. Ethnobiol. Ethnomed., vol. 18, no. 1, p. 58, 2022, https://doi.org/10.1186/s13002-022-00556-2.

J. Mohammed, S. Seleshi, F. Nega, and M. Lee, “Revisit to Ethiopian traditional barley-based food,” J. Ethn. Foods, vol. 3, no. 2, pp. 135–141, 2016, https://doi.org/10.1016/j.jef.2016.06.001.

Z. Li, C. Zhao, and C. Cao, “Production and inhibition of acrylamide during coffee processing: A literature review,” Molecules, vol. 28, no. 8, p. 3476, 2023, https://doi.org/10.3390/molecules28083476.

V. Gökmen, “Acrylamide in thermally processed potato products,” Potato Res., vol. 66, no. 4, pp. 1315–1329, 2023, https://doi.org/10.1007/s11540-023-09634-8.

M. G. Lee, H. Han, S. H. Ham, S. Lee, Y. J. Choi, and J. Hahn, “Reducing the production of acrylamide during the roasting of balloon flower roots in consumer appliances and industrial equipment,” Food Sci. Biotechnol., vol. 32, no. 8, pp. 1029–1037, 2023, https://doi.org/10.1007/s10068-023-01242-z.

L. Acquaticci, S. Angeloni, N. Cela, F. Galgano, S. Vittori, G. Caprioli, and N. Condelli, “Impact of coffee species, post-harvesting treatments and roasting conditions on coffee quality and safety related compounds,” Food Control, vol. 149, p. 109714, 2023, https://doi.org/10.1016/j.foodcont.2023.109714.

F. Esposito, E. Fasano, A. De Vivo, S. Velotto, F. Sarghini, and T. Cirillo, “Processing effects on acrylamide content in roasted coffee production,” Food Chem., vol. 319, p. 126550, 2020, https://doi.org/10.1016/j.foodchem.2020.126550.

M. Kamankesh, A. Nematollahi, A. Mohammadi, and R. Ferdowsi, “Investigation of composition, temperature, and heating time in the formation of acrylamide in snack: Central composite design optimization and microextraction coupled with gas chromatography-mass spectrometry,” Food Anal. Methods, vol. 14, no. 1, pp. 44–53, 2021, https://doi.org/10.1007/s12161-020-01849-6.

T. Bertuzzi, S. Rastelli, A. Mulazzi, and A. Pietri, “Survey on acrylamide in roasted coffee and barley and in potato crisps sold in Italy by a LC–MS/MS method,” Food Addit. Contam. Part B, vol. 10, no. 4, pp. 1–8, 2017, https://doi.org/10.1080/19393210.2017.1351498.

M. Mencin, H. Abramovič, R. Vidrih, and M. Schreiner, “Acrylamide levels in food products on the Slovenian market,” Food Control, vol. 114, p. 107267, 2020, https://doi.org/10.1016/j.foodcont.2020.107267.

H. Endeshaw and A. Belay, “Optimization of the roasting conditions to lower acrylamide content and improve the nutrient composition and antioxidant properties of Coffea arabica,” PLoS One, vol. 15, no. 8, p. 0237265, 2020, https://doi.org/10.1371/journal.pone.0237265.

N. Ashenafi, A. G. Mezgebe, and E. Leka, “Optimization of amount of spices, roasting temperature and time for field pea (Pisum sativum) shiro flour using response surface methodology,” Appl. Food Res., vol. 3, no. 1, p. 100257, 2023, https://doi.org/10.1016/j.afres.2022.100257.

AOAC, “Official Methode of Analysis Association of Official Analytical Chemists,” 2016.

A. J. Meléndez-Martínez, I. M. Vicario, and F. J. Heredia, “Application of tristimulus colorimetry to estimate the carotenoids content in ultrafrozen orange juices,” J. Agric. Food Chem., vol. 51, no. 25, pp. 7266–7270, 2003, https://doi.org/10.1021/jf034873z.

W. Schlörmann, S. Zetzmann, B. Wiege, N. U. Haase, A. Greiling, S. Lorkowski, C. Dawczynski, and M. Glei, “Impact of different roasting conditions on chemical composition, sensory quality and physicochemical properties of waxy-barley products,” Food Funct., vol. 10, no. 9, pp. 5436–5445, 2019, https://doi.org/10.1039/C9FO01429B.

C. P. Boyaci Gunduz, “Formulation and processing strategies to reduce acrylamide in thermally processed cereal-based foods,” Int. J. Environ. Res. Public Health, vol. 20, no. 13, p. 6272, 2023, https://doi.org/10.3390/ijerph20136272.

EFSA CONTAM Panel (EFSA Panel on Contaminants in the Food Chain), “Scientific opinion on acrylamide in food,” EFSA J., vol. 13, no. 6, 2015, https://doi.org/10.2903/j.efsa.2015.4104.

R. Akinoso, A. R. Tanimola, and A. E. Abereola, “Effects of roasting conditions on the properties of Amaranth (Amaranthus cruentus L.) grain using response surface methodology,” Food Humanit., vol. 2, p. 100298, 2024, https://doi.org/10.1016/j.foohum.2024.100298.

T. C. Polachini, J. A. Cárcel, E.-A. Norwood, S. S. Chevallier, P. Le-Bail, and A. Le-Bail, “Hot-air ultrasound-assisted drying of green wheat and barley malts to enhance process kinetics, amylase activity and their application in bread formulation,” Food Bioprod. Process., vol. 142, pp. 17–28, 2023, https://doi.org/10.1016/j.fbp.2023.08.009.

F. M. Allai, P. M. Junaid, Z. R. A. A. Azad, K. Gul, B. N. Dar, S. A. Siddiqui, and J. Manuel Loenzo, “Impact of moisture content on microstructural, thermal, and techno-functional characteristics of extruded whole-grain-based breakfast cereal enriched with Indian horse chestnut flour,” Food Chem. X, vol. 20, p. 100959, 2023, https://doi.org/10.1016/j.fochx.2023.100959.

M. Martínez-Subirà, B. Meints, E. Tomasino, and P. Hayes, “Effects of roasting and steeping on nutrients and physiochemical compounds in organically grown naked barley teas,” Food Chem. X, vol. 22, p. 101385, 2024, https://doi.org/10.1016/j.fochx.2024.101385.

M. Alefe, B. D. Abera, and M. A. Delele, “The Ethiopian snack food (‘Kolo’): Existing knowledge and research directions on processing practices, quality and consumption,” Heliyon, vol. 10, no. 7, p. 29067, 2024, https://doi.org/10.1016/j.heliyon.2024.e29067.

C. G. Kuyu, Y. B. Tola, A. Mohammed, T. Yazew, and S. N. Negeyie, “Optimization of pretreatment and convective drying temperature for better nutritional and bioactive contents of orange fleshed sweet potatoes flour,” LWT, vol. 217, p. 117414, 2025, https://doi.org/10.1016/j.lwt.2025.117414.

V. Kohli and S. Singha, “Protein digestibility of soybean: how processing affects seed structure, protein and non-protein components,” Discov. Food, vol. 4, no. 1, p. 7, 2024, https://doi.org/10.1007/s44187-024-00076-w.

Y. Abeshu and E. Abrha, “Evaluation of proximate and mineral composition profile for different food barley varieties grown in central highlands of Ethiopia,” World J. Food Sci. Technol., vol. 1, no. 3, pp. 97–100, 2017, https://doi.org/10.11648/j.wjfst.20170103.12.

S. Li, Z. Wang, D. Feng, Y. Pan, E. Li, J. Wang, and C. Li, “The important role of starch fine molecular structures in starch gelatinization property with addition of sugars/sugar alcohols,” Carbohydr. Polym., vol. 330, p. 121785, 2024, https://doi.org/10.1016/j.carbpol.2024.121785.

S. Coghe, B. Gheeraert, A. Michiels, and F. R. Delvaux, “Development of maillard reaction related characteristics during malt roasting,” J. Inst. Brew., vol. 112, no. 2, pp. 148–156, 2006, https://doi.org/10.1002/j.2050-0416.2006.tb00244.x.

S. He, S. He, L. Niu, C. Sun, Z. Zeng, and J. Xiao, “Effects of different roasting conditions on sugars profile, volatile compounds, carotenoids and antioxidant activities of orange-fleshed sweet potato,” Food Chem. X, vol. 25, p. 102201, 2025, https://doi.org/10.1016/j.fochx.2025.102201.

V. V. Freitas, L. L. Rodrigues Borges, G. A. Dias Castro, M. Henrique dos Santos, M. C. Teixeira Ribeiro Vidigal, S. A. Fernandes, and P. C. Stringheta, “Impact of different roasting conditions on the chemical composition, antioxidant activities, and color of Coffea canephora and Coffea arabica L. samples,” Heliyon, vol. 9, no. 9, p. 19580, 2023, https://doi.org/10.1016/j.heliyon.2023.e19580.

P. Sharma, H. S. Gujral, and C. M. Rosell, “Effects of roasting on barley β-glucan, thermal, textural and pasting properties,” J. Cereal Sci., vol. 53, no. 1, pp. 25–30, 2011, https://doi.org/10.1016/j.jcs.2010.08.005.

H. Cui, J. Yu, Y. Zhai, L. Feng, P. Chen, K. Hayat, Y. Xu, X. Zhang, and C.-T. Ho, “Formation and fate of amadori rearrangement products in maillard reaction,” Trends Food Sci. Technol., vol. 115, pp. 391–408, 2021, https://doi.org/10.1016/j.tifs.2021.06.055.

I. Qureshi, K. Bashir, S. Jan, A. Tarafdar, M. Habib, and K. Jan, “Effect of sand roasting on physicochemical, thermal, functional, antinutritional, and sensory properties of sattu, a nourishing form of chickpea,” J. Food Qual., vol. 2023, pp. 1–12, 2023, https://doi.org/10.1155/2023/5564365.

I. Boublenza, H. A. Lazouni, L. Ghaffari, K. Ruiz, A.-S. Fabiano-Tixier, and F. Chemat, “Influence of roasting on sensory, antioxidant, aromas, and physicochemical properties of carob pod powder (Ceratonia siliqua L.),” J. Food Qual., vol. 2017, pp. 1–10, 2017, https://doi.org/10.1155/2017/4193672.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Tewodros Mebratie Bimrew, Surafel Yihune, Isabella Nyambayo

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with the Journal of Agri-food Science and Technology (JAFOST) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.