Implementation of Metabolomic Approaches on Fermented Cereals

DOI:

https://doi.org/10.12928/jafost.v6i1.12610Keywords:

Cereal, Fermentation, Food processing, MetabolomicAbstract

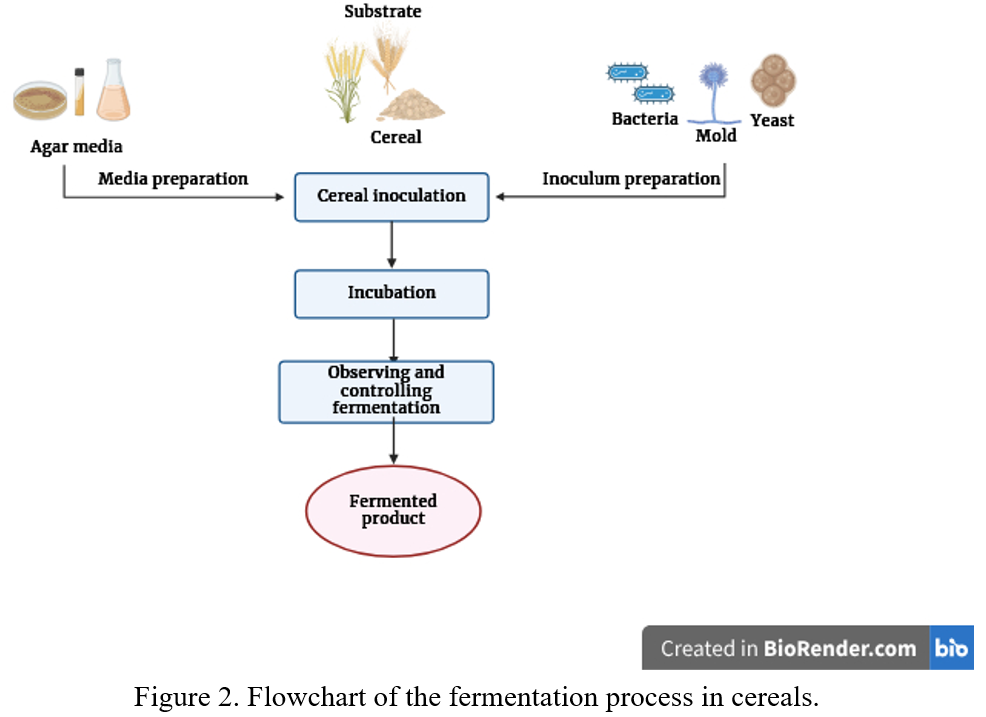

Fermentation is a widely utilized food processing technique that enhances sensory characteristics, extends shelf life, and increases product diversity, particularly in cereals. Furthermore, fermentation processes can generate bioactive metabolites that confer various health benefits. Metabolomics is employed to assess changes in the nutritional composition and metabolite profile of fermented cereal products. This research contributes to identify and synthesize findings from various studies that evaluate the effects of fermentation on the quality of the final product using a metabolomics approach, with particular emphasis on metabolic pathways and the metabolites formed. The research highlights that metabolomics, through sophisticated analytical techniques, has successfully identified metabolites produced during fermentation, which are categorized into volatile compounds (such as organic acids, alcohols, and aldehydes) and non-volatile compounds (including polyphenols, amino acids, fatty acids, free sugars, esters, and amides). These compounds play a pivotal role in enhancing the sensory properties of the product and exhibit bioactive potential that can help prevent the development of metabolic diseases, including diabetes, obesity, digestive disorders, and liver cancer. Despite its potential, the metabolomic approach faces challenges due to the large and intricate datasets it produces. Recent technological advancements have led several studies to incorporate Artificial Intelligence (AI) to enhance the accuracy of data derived from metabolite databases. Moreover, integrating other omics disciplines, such as foodomics, is crucial for achieving more detailed research results, encompassing metabolite composition, sensory attributes, and their effects on health. Such integration would contribute to a more holistic understanding and help bridge the gaps in contemporary metabolomic research.

References

M. Verni, C. G. Rizzello, and R. and Coda, “Fermentation biotechnology applied to cereal industry by-products: nutritional and functional insight,” Front. Nutr., vol. 6, 42, 2019, https://doi.org/10.3389/fnut.2019.00042.

H. Widiastuti, Pengolahan hasil nabati komoditas serealia dan kacang-kacangan. Penerbit Mitra Cendekia Media, 2021.

P. Tsafrakidou, A.-M. Michaelidou, and C. and Biliaderis, “Fermented cereal-based products: nutritional aspects, possible impact on gut microbiota and health implications,” Foods, vol. 9, 734, 2019, https://doi.org/10.3390/foods9060734.

P. Petrova and K. Petrov, “Lactic acid fermentation cereals and pseudocereals: ancient nutritional biotechnologies with modern applications,” Nutrients, vol. 12, 1118, 2020, https://doi.org/10.3390/nu12041118.

G. Yaxin, H. Lizhen, G. Jie, L. Danfeng, T. Zhiliang, F. Bei, W. Fengzhong and L. Shuying, “Metabolomics approaches for the comprehensive evaluation of fermented foods: a review,” Foods, vol. 10, p. 2294, 2021, https://doi.org/10.3390/foods10102294.

M. Utpott, E. Rodrigues, A. Oliveira Rios, G. M. Mercalli, and S. H. Flores, “Metabolomics: an analytical technique for food processing evaluation,” Food Chem., vol. 366. 13068, 2022, https://doi.org/10.1016/j.foodchem.2021.130685.

R. Gupta and S. Gaur, “LC-MS investigated as a tool to study the metabolomic characteristics of cereal fermentation,” Appl. Food Res., vol. 4. 100365, 2021, https://doi.org/10.1016/j.afres.2023.100365.

O. A. Adebo, S. A. Oyeyinka, J. A. Adebiyi, X. Feng, J. D. Wilkin, Y. O. Kewuyemi, A. M. Abrahams and F. Tugizimana, “Application of gas chromatography mass spectrometry (GC-MS)-based metabolomics for the study of fermented cereal and legume foods: a review,” Int. J. Food Sci. Technol., vol. 56, no. ue 4, pp. 1514–1534, 2021, https://doi.org/10.1111/ijfs.14794.

E. Koberg and A. Longoni, “A systematic review of sustainable supply chain management in global supply chains,” J. Clean. Prod, vol. 207, pp. 1084–1098, 2019, https://doi.org/10.1016/j.jclepro.2018.10.033.

I. C. Maia, T. D’Almeida, D. Freire, E. Calvancanti, L. Cameron, J. Dias, and M. Ferreira, “Effect of solid-state fermentation over the release of phenolic compounds from brewer’s spent grain revealed by UPLC-MS,” LWT-Food Sci. Technol., vol. 133 . 1101, 2020, https://doi.org/10.1016/j.lwt.2020.110136.

K. Li, Z. Duan, J. Zhang, and H. Cui, “Growth kinetics, metabolomic changes, antioxidant activity of probiotics in fermented highland barley-based yogurt,” LWT-Food Sci. Technol., vol. 173, p. 114239, 2023, https://doi.org/10.1016/j.lwt.2022.114239.

X. Fan, X. Li, T. Zhang, Y. Guo, Z. Shi, Z.Wu, X. Zheng, and D. Pan, “Novel millet-based flavored yogurt enriched with superoxide dismutase,” Front. Nutr., vol. 8, Article, 2022, https://doi.org/10.3389/fnut.2021.791886.

Y. Pan Y. Wang, W. Hao, S. Zhou, C. Duan, Q. Li, J. Wei, and G. Liu, “Exploring the role of active functional microbiota in flavor generation by integrated metatranscriptomics and metabolomics during niulanshan bijiu fermentation,” Foods, vol. 12, p. 4140, 2022, https://doi.org/10.3390/foods12224140.

S. Majumder, S. Chakraborty, A. Ghosh, and M. Bhattacharya, “The himalayan ethnic beverage tongba with therapeutic properties in high-altitude illnesses and metabolomics similarities to japanese sake,” Acta Univ. Sapientiae, Aliment., vol. 15, pp. 67–83, 2021, https://doi.org/10.2478/ausal-2022-0006.

S. Majumder, A. Ghosh, S. Chakraborty, S. Saha, and M. Battacharya, “Metabolomics affirms traditional alcoholic beverage raksi as a remedy for high-altitude sickness,” J. Ethn. Foods, vol. 8, no. 17, 2021, https://doi.org/10.1186/s42779-021-00094-4.

F. R. Pinu, S. A. Goldansaz, and J. Jaine, “Translational metabolomics: current challenges and future opportunities,” Metabolites, vol. 9, no. 6, 2019, https://doi.org/10.3390/metabo9060108

X. Zhang, C. Zhang, L. Xiao, X. Wang, K. Ma, and F. Ji., “Gas chromatography-mass spectrometry and non-targeted metabolomics analysis reveals the flavor and nutritional metabolic differences of cow’s milk fermented by Lactiplantibacillus plantarum with different phenotypic,” Food Biosci., vol. 60. Articl, 2024, https://doi.org/10.1016/j.fbio.2024.104433.

J. Wang D. Wang, M. Huang, B. Sun, F. Ren, J. Wu, and J. Zhang, “Identification of nonvolatile chemical constituents in Chinese Huangjiu using widely targeted metabolomics,” Food Res. Int., vol. 172, Artic, 2023, https://doi.org/10.1016/j.foodres.2023.113226.

N. Reyes-Garces and E. Gionfriddo, “Recent developments and applications of solid phase microextraction as a sample preparation approach for mass-spectrometry-based metabolomics and lipidomics,” TrAC Tends Anal. Chem., vol. 113, pp. 172–81, 2019, https://doi.org/10.1016/j.trac.2019.01.009.

A. Khakpour, N. A. Shadmehri, H. Amrulloh, and H. Kioumarsi, “Antibacterial effect of Juglans regia, Citrus sinensis, Vicia faba ̧ and Urtica urens extracts under in vitro conditions,” Bioactives, vol. 1, no. 2, pp. 74–80, 2023, https://doi.org/10.47352/bioactivities.2963-654X.195.

L. Kalavari, N. Nasiri, F. Ahmadian, and H. Kioumarsi, “Enrichment of doogh with olive leaf extract and investigation of its physiochemical, microbial and sensory properties during storage,” J. Multidiscip. Appl. Nat. Sci., vol. 3, no. 1, pp. 34–42, 2023, https://doi.org/10.47352/jmans.2774-3047.143.

A. A. K. Harmita, Y. Harahap, and Supandi, Liquid chromatography-tandem mass spectrometry (LC-MS/MS), ISBN-978-602-17850-7-2, 2019, Jakarta: Penerbit PT. ISFI Penerbitan.

W. Mancino, P. Carnevali, V. Terzi, P. G. Perez, L. Zhang, G. Giuberti, L. Morelli, V. Patrone, and L. Lucini, “Hierarchical effects of lactic fermentation and grain germination on the microbial and metabolomic profile of rye doughs,” Foods, vol. 12, p. 998, 2023, https://doi.org/10.3390/foods12050998.

S. Bocchi, G. Rocchetti, M. Elli, L. Lucini, C.-Y. Lim, and L. Morelli, “The Combined effect of fermentation of lactic acid bacteria and in vitro digestion on metabolomic and oligosaccharide profile of oat beverage,” Food Res. Int., vol. 142, p. 110216, 2021, https://doi.org/10.1016/j.foodres.2021.110216.

D. Magro, M. Venezia, and C. R. Balistreri, “The omics technologies and liquid biopsies: Advantages, limitations, applications,” Med. Omi., vol. 11, 100039, 2024, https://doi.org/10.1016/j.meomic.2024.100039.

N. Ghafari and L. Sleno, “Challenges and recent advances in quantitative mass spectrometry-based metabolomics,” Anal Sci Adv, vol. 5:e2400007, 2024, https://doi.org/10.1002/ansa.202400007.

O. Lopez-Fernandez, R. Dominguez, M. Pateiro, P. E. S. Munekata, G. Rocchetti, and J. M. Lorenzo, “Determination of polyphenols using liquid chromatography-tandem mass spectrometry technique (LC-MS/MS): a review,” Antioxidants, vol. 9, p. 479, 2020, https://doi.org/10.3390/antiox9060479.

S. J. Heo, A. H. Kim, M.-J. Park, K. Kang, and D. Y. Soung, “Nutritional and functional properties of fermented mixed grains by solid-state fermentation with Bacillus amyloliquefaciens 245,” Foods, vol. 9, p. 1693, 2020, https://doi.org/10.3390/foods9111693.

J. O. Odukoya S. Saeger, M. Boevre, G. OAdegoke, F. Devlieghere, S. Croubels, G. Antonissen, O. A. Adebo, S. Gbashi, and P. B Njobeh “Mycotoxin reduction and metabolite profiles of ogi produced using traditional fermentation methods,” Food Hydrocoll. Heal., vol. 4, 100160, 2023, https://doi.org/10.1016/j.fhfh.2023.100160.

Y. Zhao, C. Wu, Y. Zhu, C. Zhou, Z. Xiong, A. S. Eweys, H. Zhou, Y. Dong, and X. Xiao, “Metabolomics strategy for revealing the components in fermented barley extracts with Lactobacillus plantarum dy-1,” Food Res. Int., 2020, https://doi.org/10.1016/j.foodres.2020.109808.

B. Mao, W. Guo, M. Chen, X. Tang, Q. Zhang, J. Zhao, H. Zhang, and S. Cui, “Effects of Streptococcus thermiphilus fermentation on the flavors and antioxidant properties of barley juice,” Fermentation, vol. 9, p. 263, 2023, https://doi.org/10.3390/fermentation9070623.

H. B. Jiang, P. Nie, Z. H. Lin, C. Zhu, L. Y. Zhong, F. F. Wei, Y. Wu, and L. H. Song, “The polyphenols profile of co-fermented quinoa and black barley with Lactobacillus kisonensis and its in vitro bioactivities,” Food Biosci., vol. 58, 103712, 2024, https://doi.org/10.1016/j.fbio.2024.103712.

A. Tyagi, S.-J. Yeon, E. B.-M. Daliri, X. Chen, R. Chelliah, and D.-H. Oh, “Untargeted metabolomics of korean fermented brown rice using UHPLC-Q-TOF-MS/MS reveal an abundance of potential dietary antioxidative and stress-reducing compounds,” Antioxidants, vol. 10, p. 626, 2021, https://doi.org/10.3390/antiox10040626.

O. A. Adebo, E. Kayitesi, F. Tugizimana, and P. B. Njobeh, “Differential metabolic signatures in naturally and lactic acid bacteria (LAB) fermented ting (a southern african food) with different tannin content, as revealed by gas chromatography mass spectrometry (GC-MS)-based metabolomics,” Food Res. Int., vol. 121, pp. 326–335, 2019, https://doi.org/10.1016/j.foodres.2019.03.050.

M. Ghamry, L. Li, and W. Zhao, “A metabolomics comparison of Lactobacillus communities isolated from breast milk and camel milk and Lactobacillus apis isolated from bee gut during cereals-based fermentation vs. Lactobacillus plantarum as a reference,” LWT-Food Sci. Technol., vol. 146, p. 111400, 2021, https://doi.org/10.1016/j.lwt.2021.111400.

M. L. Kutt, K. Orgusaar, I. Stulova, R. Priidik, D. Pismennoi, H. Vaikma, A. Kallastu, A. Zhogoleva, I. Morell, and T. Krisciunaite, “Starter culture growth dynamics and densory properties of fermented oat drink,” Heliyon, vol. 9, e15627, 2023, https://doi.org/10.1016/j.heliyon.

M. K. Park, H. S. Choi, Y. S. Kim, and I. H. Cho, “Comparison of volatile profiles in Fagopyrum esculentum (buckwheat) soksungjang prepared with different starter cultures during fermentation,” Food Sci Biotechnol, 2019, https://doi.org/10.1007/s10068-018-00549-6.

C. Wang, S. Wei, M. Jin, B. Liu, M. Yue, and Y. Wang, “Integrated microbiomic and metabolomic dynamics of fermented corn and soybean by-product mixed substrate,” Front. Nutr., vol. 9, Article, 2022, https://doi.org/10.3389/fnut.2022.831243.

V. I. Nakhod, T. V. Butkova, K. A. Malsagova, D. V. Petrovskiy, A. A. Izotov, K. S. Nikolsky, and A. L. Kaysheva, “Sample preparation for metabolomic analysis in exercise physiology,” Biomolecules, vol. 14, p. 1561, 2024, https://doi.org/10.3390/biom14121561.

C. Diez-Simon, R. Mumm, and R. D. Hall, “Mass spectrometry-based metabolomics of volatiles as a new tool for understanding aroma and flavour chemistry in processed food products,” Metabolomics, vol. 15, no. 41, 2019, https://doi.org/10.1007/s11306-019-1493-6.

J. Sun and Y. Xia, “Pretreating and normalizing metabolomics data for statistical analysis,” Genes Dis., vol. 2532–3042, 2023, https://doi.org/10.1016/j.gendis.2023.04.018.

C. R. Balcazar-Zumaeta, E. M. Castro-Alayo, I. S. Cayo-Colca, G. Idrogo-Vasquez, and L. D. Munoz-Astecker, “Metabolomics during the spontaneous fermentation in cocoa (Theobroma cacao L.): an exploraty review,” Food Res. Int., vol. 163, p. 112190, 2023, https://doi.org/10.1016/j.foodres.2022.112190.

J. Chi, J. Shu, M. Li, R. Mudappathi, Y. Jin, F. Lewis, A. Boon, X. Qin, L. Liu, and H. Gu, “Artificial intelligence in metabolomics: a current review,” Trends Anal. Chem., vol. 178, p. 117852, 2024, https://doi.org/10.1016/j.trac.2024.117852.

X. Cai, T. Wijesekara, and B. Xu, “New insights into recent development, health benefits, emerging technologies, and future trends of cereal-based fermented products,” in Process Biochemistry, Elsevier BV, 2024, https://doi.org/10.1016/j.procbio.2024.10.010.

B. W. Lemi, “Microbiology of Ethiopian traditionally fermented beverages and condiments [review of microbiology of Ethiopian rraditionally fermented beverages and condiments,” Int. J. Microbiol., vol. 1, 2020, https://doi.org/10.1155/2020/1478536.

R. H. Mallappa, C. Balasubramaniam, B. H. Nataraj, C. Ramesh, S. Kadyan, D. Pradhan, S. K. Muniyappa, and S. Grover, “Microbial diversity and functionality of traditional fermented milk products of India: Current scenario and future perspectives,” Int. Dairy J., vol. 114, p. 104941, 2020, https://doi.org/10.1016/j.idairyj.2020.104941.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Yani Magfiroh, Laksmi Hartajanie, Lindayani Lindayani, Dyah Wulandari

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with the Journal of Agri-food Science and Technology (JAFOST) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.