Design of Measurement of Coffee Seed Water Content Using Load Cell Sensor On Coffee Dryer

DOI:

https://doi.org/10.12928/biste.v2i3.2707Keywords:

Load Cell, Kadar Air, Mesin Pengering Kopi, Hybrid Collektor, Gas LPGAbstract

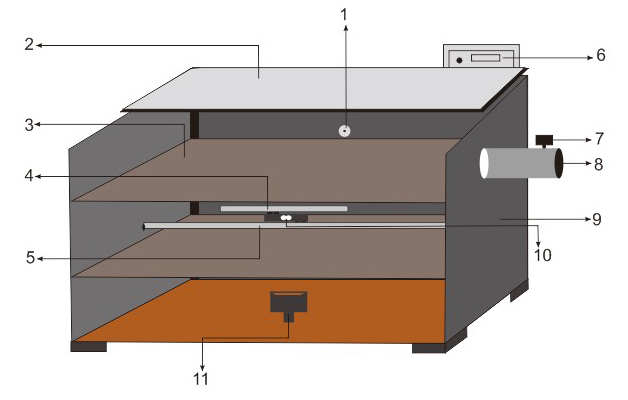

The conventional method of drying coffee beans that depend on sunlight (drying) has a number of drawbacks, one of which is that the drying productivity takes a long time. In general, coffee drying is carried out until it reaches a moisture content of 12.5% to achieve a quality bean standard. Mathematically, the moisture content can be assessed by paying attention to the initial weight of the coffee beans and the final weight of the coffee beans. So that the use of the Load Cell sensor to read the depreciation value of the coffee bean weight on a coffee dryer powered by Hybrid Collector and LPG coffee beans. Research that has been carried out during 200 minutes of drying in a coffee dryer, the Load Cell sensor is able to read the depreciation value of the coffee bean weight by 114 grams from the initial weight of 978 grams. Therefore, it can be concluded that the final moisture content of coffee beans has reached 12.01% and the final weight of coffee beans is 864 grams.

References

H. Syah, R. Agustina and R Moulana, “Rancang Bangun Pengering Surya Tipe Bak untuk Biji Kopi,” Jurnal Rona Teknik Pertanian, vol. 9, no.1, pp, 25-38, 2016. DOI: 10.17969/rtp.v9i1.4382

S. D. Masiyati, T. Prihandono, and S. H. B. Prastowo, “Pengukuran Kadar Air Biji Kopi dengan Rancangan Alat Kapasitor Sebagai Kajian Bahan Ajar Fisika di SMA,” FKIP e-PROCEEDING, vol. 3, no. 2, pp, 134-144, 2018. Online

A. A. Dwirossi, “Rancang Bangun Sistem Monitoring Kadar Air Biji Kopi pada Mesin Pengering Biji Kopi Berbasis Penjejak Matahari Aktif dengan Mikrokontroler Atmega16”, Diploma Thesis, 2017. Online

H. A. Setiawan, T. Rijanto, “Rancang Bangun Sistem Kontrol Pengisian Air Minum dalam Kemasan Menggunakan Arduino Uno dengan Sensor Load Cell,” Jurnal Teknik Elektro Unesa, vol. 8, no. 3, pp. 579–585, 2019. Online

Wahyudi, A. Rahman, M. Nawawi, “Perbandingan Nilai Ukur Sensor Load Cell pada Alat Penyortir Buah Otomatis terhadap Timbangan Manual”, Jurnal Elkomika, vol. 5, no. 2, pp. 207 – 220, Juli - Desember 2017. DOI: 10.26760/elkomika.v5i2.207

D. Suryono, “Instrumentasi Pengering Daun Sirsak Untuk Obat Herbal Menggunakan Sensor Load Cell dan Kontrol PID pada Suhu Ruangan,” Skripsi Universitas Jember, 2019. Online

U. Arifin, “Rancang Bangun Prototype Alat Pengukur Kadar Air Dan Berat Pada Biji Kopi Berbasis Adruino”, Skripsi Universitas Jember, 2018. Online

Ishaq, Azhar, Muhaimin, “Rancang Bangun Neraca Elektronik Menggunakan Sensor Load Cell Pada Mesin Penggiling Kunyit Kering,” Jurnal Tektro, vol.3, no.1, pp, 14-19, Maret 2019. Online

D. S. Sihotang, “Perancang Alat Ukur Kadar Air pada Biji Kopi Dengan Menggunakan Sensor YL-69 Berbasis Arduino”, Skripsi Universitas Sumatera Utara, 2019. Online

M. Azizah, RTM Sutamihardja and N. Wijaya, “Karakteristik Kopi Bubuk Arabika (Coffea Arabica L) Terfermentasi Saccharomyces Cerevisiae”, Jurnal Sains Natural, Vol. 9, No.1, Januari 2019, pp. 37 – 46, 2019. DOI: 10.31938/jsn.v9i1.173

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 muhammad mistu ad

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.