Experiment Evaluation on the Porosity of Plasma Coating from Ceramic Al2O3 – TiO2 Using the Metallography

DOI:

https://doi.org/10.12928/spekta.v5i1.9133Keywords:

Plasma spray, ceramic material, Al2O3 – TiO2, design experiment, metallographic porosityAbstract

Background: The objective of this paper is an experimental investigation of the metallographic porosity of plasma coating using standard materials from the ceramic system Al2O3-TiO2 on the substrate of steel SS400 at laboratory scale Lab at the Research Institute of Mechanical Engineering.

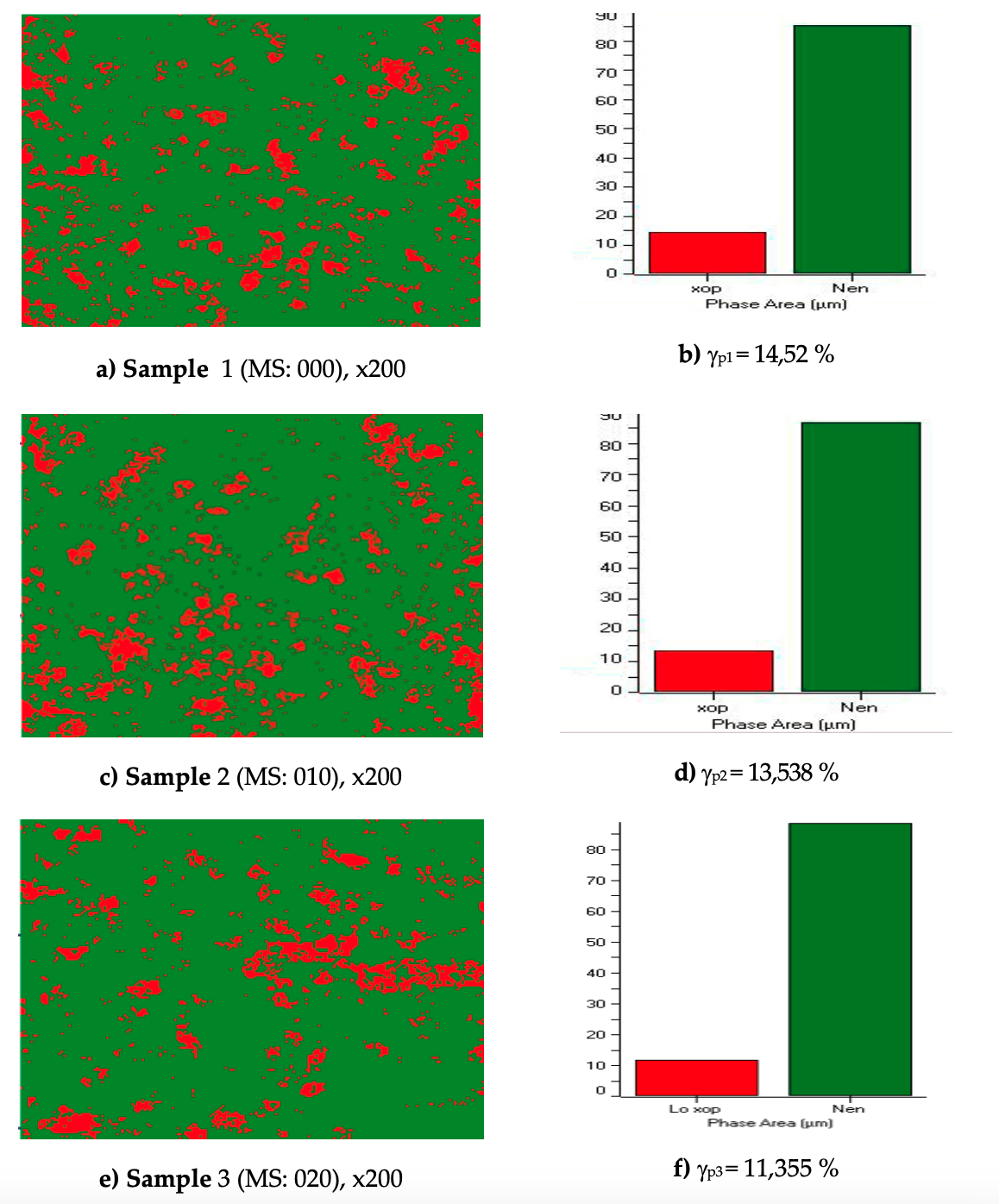

Contribution: The main contribution of the research is the evaluation of the porosity of the coating under the influence of the main technological parameters since the porosity plays a significant role in the performance of the working surface using the built-in Image Pro-Analyzer software in the Axiovert 25 MAT microscope.

Method: The spraying material is Al2O3-TiO2 powder. The input parameters are: spraying distance (Lp; current of plasma stream (Ip); powder feed flow (Gp and spraying rate (Vp).

Results: The findings show that the average porosity of the Al2O3-TiO2 plasma coating is inversely decreasing in the increasing direction of the distance: spray in the range Lp = 100–200 mm, increase proportional to the increase of the current plasma flow rate in the range Ip = 400–600 A, provided that the powder feed flow Gp = 1.7 kg/h and the spraying rate Vp = 50 mm/min.

Conclusion: The degree of influence of the three main technological parameters (Lp, Ip, and Gp) in the survey limit domain may be due to the selected Lp spray distance within the relatively wide recommended range of the plasma spraying equipment supplier. It is recommended to conduct the experimental planning of the L27 type to localize the optimum area.

References

J. Pan, Y. Zheng, Y. Zheng, W. Ye, W. Yu, “Solidification mechanismand microstructure evolution of Al2O3-ZrO2 ceramic coating prepared by combustion synthesis and thermal explosion spraying”, Ceramic International,43(5),4034-4041,2017, doi: 10.1016/j.ceramint.2016.11.153

I. V. Blinkov, D. S. Belov, A I Laptev, A. S. Anikeev and V. V. Ivanov, “Flame sprayed and plasma sprayed Al2O3-TiO2 coatings”, J. Phys.: Conf. Ser. 1954 012003, 15th International Conference on Films and Coatings (ICFC 2021), doi:10.1088/1742-6596/1954/1/012003

K. Yang, J. Li, Q. Wang, Z. Li, Y. Jiang, Y. Bao,” Effect of laser remelting on microstructure and wear resistance of plasma sprayed Al2O3- 40%TiO2 coating”, Wear, vol 426-427, Part A,314-318, doi: 10.1016/j.wear.2019.01.100

Y. Lu, Y. Peng, Z. Shi,” Plasma sprayed Al2O3–40%TiO2 coating by laser remelting: Structural evolution, tribological properties and DFT calculation”, Tribology International, vol 189,109009,2023, doi: 10.1016/j.triboint.2023.109009

G. M. T. Basha, A. Srikanth, B. Venkateshwarlu,” A Critical Review on Nano structured Coatings for Alumina-Titania (Al2O3-TiO2) Deposited by Air Plasma Spraying Process (APS)”, Materialstoday: Proceedings,22(4), 1554-1562,2020, doi: 10.1016/j.matpr.2020.02.117

W. T. Urmi, M.M. Rahman, W.A.W. Hamzah,” An experimental investigation on the thermophysical properties of 40% ethylene glycol based TiO2-Al2O3 hybrid nanofluids”, International Communication in Heat and Mass Transfer,116,104663,2020, doi: 10.1016/j.icheatmasstransfer.2020.104663

A. Richter, L. M. Berger, Y. J. Sohn, S. Conze, K. Sempf, R. Vaßen, “Impact of Al2O3-40 wt.% TiO2 feedstock powder characteristics on the sprayability, microstructure and mechanical properties of plasma sprayed coatings”, Journal of European Ceramic Society,39(16),5391-5402,2019, doi: 10.1016/j.jeurceramsoc.2019.08.026

M. Michalak, L. Latka, P. Sokolowski, Rolando T. Candidato & Andrzej Ambroziak, “Effect of TiO2 on the microstructure and phase composition of Al2O3 – TiO2 APS sprayed coatings”, Bulletine of the Polish Academy of Sciences, Technical Sciences, 69(2), 2021, doi:10.24425/bpasts.2021.136735

Material Product Data Sheet Aluminum Oxide 40% Titanium Dioxide Powders, Oerlikon Metco, 2022.

Material Product Data Sheet Aluminum Oxide 13 % Titanium Dioxide Powders, Oerlikon Metco, 2020.

TS1380 Aluminum Oxide and 3 % Titanium Dioxide Powders.Standford Advance Material. https://www.sputtertargets.net/aluminum-oxide-and-3-titanium-oxide-powder

J. J. Zhang, Z. H. Wang, P. H. Lin, L. Q. Si, G. J. Shen, Z. H. Zhou, S. Q. Jiang and W. H. Lu “Corrosion of plasma sprayed NiCrAl / Al2O3 – 13% TiO2 coatings with and without sealing”, Surface Engineering,2012, Vol. 28, No 5, doi :10.1179/1743294412Y.0000000004

M. Michalak, L. Łatka, P. Sokołowski, A. Niemiec and A. Ambroziak,” The Microstructure and Selected Mechanical Properties of Al2O3 + 13 wt % TiO2 Plasma Sprayed Coatings”, Coatings,10(2),173,2020, doi: 10.3390/coatings10020173

J. Antoš, K. Lencová and A. Keslová, “ Influence of processing parameters and heat input level on the functional properties of atmospheric plasma sprayed Al2O3-3TiO2 commercial coating”, IOP Conference Series Materials Science and Engineering 1178(1):012003, doi:10.1088/1757-899X/1178/1/012003

A. R. M. Sahaba, N. H. Saadb, S. Kasolangb, and J. Saedonb,” Impact of Plasma Spray Variables Parameters on Mechanical and Wear Behaviour of Plasma Sprayed Al2O3 3%wt TiO2 Coating in Abrasion and Erosion Application”, International Symposium on Robotics and Intelligent Sensors 2012 (IRIS 2012), Procedia Engineering, 41(2012),1689-1695, doi: 10.1016/j.proeng.2012.07.369

T. D. Duy, V. Duong,” A New Solusion to Save Production Cost in the Deposition of the Wear-Resistant Coating”, Chapter in eBook “Coating for High-Temperature Environment “, Editors: A. Pakseresh &K. K Amirtharaj Mosas, Springer Nature, pp.126-160, 2024, doi: 10.1007/978-3-031-45534-6_6

R. Yılmaz, A. O. Kurt, A. Demir, and Z. Tatlı, “Effects of TiO2 on the mechanical properties of the Al2O3–TiO2 plasma sprayed coating,” Journal of the European Ceramic Society, vol. 27, no. 2–3, pp. 1319–1323, 2007, doi: 10.1016/j.jeurceramsoc.2006.04.099

T. S. Rajesh and R. V. Rao, “Experimental Investigation and Parameter Optimization of Al2O3-40% TiO2 Atmospheric Plasma Spray Coating on SS316 Steel Substrate,” Materials Today: Proceedings, vol. 5, no. 2, pp. 5012–5020, Jan. 2018, doi: 10.1016/j.matpr.2017.12.079

P. Kazimierczak and A. Przekora, “Osteoconductive and Osteoinductive Surface Modifications of Biomaterials for Bone Regeneration: A Concise Review,” Coatings, vol. 10, no. 10, p. 971, 2020, doi: 10.3390/coatings10100971

R. J. K. Wood and P. Lu, “Coatings and Surface Modification of Alloys for Tribo-Corrosion Applications,” Coatings, vol. 14, no. 1, p. 99, 2024, doi: 10.3390/coatings14010099

A. Thakur, A. Kumar, S. Kaya, R. Marzouki, F. Zhang, and L. Guo, “Recent Advancements in Surface Modification, Characterization and Functionalization for Enhancing the Biocompatibility and Corrosion Resistance of Biomedical Implants,” Coatings, vol. 12, no. 10, p. 1459, 2022, doi: 10.3390/coatings12101459

Q. Zheng, Y. Li, C. Ma, J. Sun, Y. Gao, and L. Feng, “Investigation on Al-Al2O3 refractories with Al2O3-Ti2O3 raw material at evaluate temperatures,” Journal of the European Ceramic Society, vol. 44, no. 2, pp. 1289–1295, Feb. 2024, doi: 10.1016/j.jeurceramsoc.2023.10.006

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 duong vu

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with SPEKTA (Jurnal Pengabdian Kepada Masyarakat: Teknologi dan Aplikasi) agree to the following terms:

- Authors retain copyright and grant the journal the right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.