Experimental Design in Plasma Welding of SUS 304 Stainless Steel Thin Plates

DOI:

https://doi.org/10.12928/spekta.v4i1.7864Keywords:

Plasma welding of stainless steel, Experiment design, Tensile strength, Mathematical mode, Butt weldAbstract

Background: This research focuses on the evaluation of the independent influence and the bidirectional interaction of some welding parameters in butt welding for the SUS 304 stainless steel thin plates using the automatic plasma welding system (450 +/- Plasma, SP7Turmatic from Lincoln).

Contribution: The findings will serve as a reliable background to design the mathematical model for the prediction of the tensile strength for the plasma welding of steel SUS 304 thin plates in terms of the nomination of the optimal process for adopting the requirement in industry.

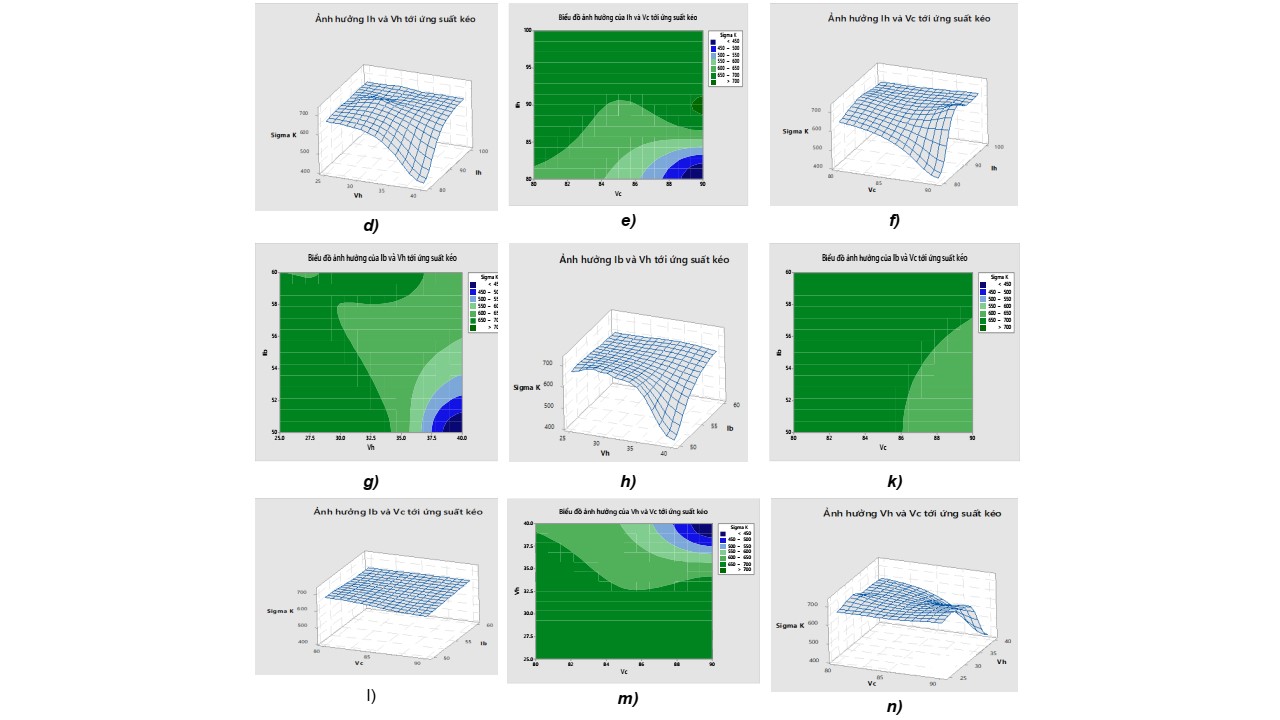

Method: The welding setting is nominated for 04 main changing parameters, such as the peak current of welding (Ih, A); the background current of welding (Ib, A); the welding speed (vh, cm/min); the feeding rate of the welding wire (vc.d, cm/min); the diameter of the wire (d = 1.0 mm); and the flow rate of the shielding gas (Gk.p, 2.0 l/min). Mathematical statistics software ANOVA using to analyze the influence of the parameters on the tensile strength of the weld as the target function.

Results: The tensile strength of the plasma welding samples is about 650 MPa at the equivalent level of the other publications. This proved the reasonable welding setting for the preliminary investigation.

Conclusion: Authors proved the nomination of the main plasma welding technological parameters, such as the peak current, the background current, the welding speed, and the feeding rate of the wire, is reasonable towards the maximum tensile strength, one of the important criteria in the weld performance

References

Đỗ Hải Tĩnh, Hà Minh Hùng, Đào Duy Trung,” Experimental Researching to plasma butt weld of SUS 304 Stainless Steel thin plates”, T Vietnam Mechanical Engineering Journal, ISSN 2615-9910,No.291,pp 5-13,2022.

Đỗ Hải Tĩnh, Hà Minh Hùng, Đào Duy Trung, “Mechanical strenght charcteristic of the plasma butt welded material of SUS 304 stainless steel thin plates”, Vietnam Mechanical Engineering Journal, ISSN 2615-9910, ISSN 2815 - 5505 (on line), No.293, pp 85-92;2022.

Đỗ Hải Tĩnh, Hà Minh Hùng, Đào Duy Trung (2022),” Study on the characteristics and microstructure of plasma welding metall thin plates stainless steel SUS304”, Vietnam Mechanical Engineering Journal, ISSN 2615-9910, ISSN 2815 - 5505 (on line), No.293, pp 85-92;2022.

Piotr Noga., Marek Weglowski.,Patrycja Zemierska-Nowak.,Maria Richert.,Jerzy Dworak., JanuszRykala, “ influence of welding techniques on microstructure and hardness of steel joints used in automotive air conditioners “, Metallurgy and Foundry Engineering,43(4),281-290,2017. http://dx.doi.org/10.7494/mafe.2017.43.4.281

Kondapalli Siva Prasad., Chalamasetti Srinivasa Rao., Damera Nageswara Rao, “ An investigation on weld quality characteristics of pulse current micro plasma arc welded austenitic stainless steel “, International Journal of Engineering, Science and Technology,4(2),159-168,2012. DOI: http/dx.doi.org/10.4314/ijest. v4i2.12.

R.Selva Bharathi., N.Siva Shanmugam., R.Murali Kannan & S.Arungalai Vendan,” Study on the Parametric Effects of Plasma Arc Welding of 2205 Duplex Steinless Steel”, High Temp.Mater.Proc, 37(3),219-232,2019.DOI: 10.1515/htmp-2016-0087.

A. Balaram Naik., Dr.A. Chennakesava Reddy & Dr.B.Balakrishna,” Characteristics Optimization of Different Welding on Duplex Stainless Steel Using Statistical Approach and Taguchi Tecnique – A Review Guide”, International Journal of Engineering Inventions,2(3),26-34,2013. www.ijeijournal.com. e-ISSN:2278-7461.

Kondapalli Siva Prasad.,Chalamalasetti Srinivasa Rao & Damera Nageswara Rao,” A Review on Welding of AISI 304L Austenite Stainless Steel”, J.Manuf.Sci.Prod.,14(1),1-11,2014. DOI:10.1515/jmsp-2012-0007.

Jigar Chaudhary.,Neelesh Kummar Jain., Sunil Pathak & S.C Koria,” Investigations on thin SS sheet joining by pulsed micro-plasma transferred arc process”, Jounal of micromanufacturing, 2(1),15-24,2019. DOI:10.1177/2516598418820470.

Harshal M.Pargaonkar & S.R.Kulkarni,” Process Parameter Optimization for Tensile Strength for Plasma Arc Welding of SS304”, Journal of Engineering Research and Application,8(6),part1,16-19,2018. DOI:10.9790/9622-0806011619.

Anthony Ozimu Adekola.,Sunday Ayoola Oke & Ogochukwu Sixtus Nwantiki,” Optimization of Process Parameter of Tungsten Inert Gas Welding for Austenitic Stainless Steel Using Grey Wolf Optimization”. International Journal of Industrial Engineering and Engineering Management,4(2),93-106,2022. http://ojs.uajy.ac.id/index.php/IJIEEM.

Harshal M.Pargaonkar & S.R.Kulkarni,” Process Parameter Optimization for Tensile Strength for Plasma Arc Welding of SS304”, International Journal of Engineering Research & Technology,7(3),23-26,2018.ISSN: 2378-0181. http://www.ijert.org . IJERTV7IS030038.

Kondapalli Siva Prasad., Chalamalasetti Srinavasa Rao & Damera Nageswara Rao,” Application of Hook and Jeeves Algorithm in Optimizing Fusion Zone Grain Size and Hardness of Pulse Current Micro Plasma Arc Welded AISI 304L Sheet”, Journal of Minerals and Material Characterization and Engineering,11(9),869-875,2012. DOI: 10.4236/jmmce.2012.119081.

Minh Hung Ha, Hai Tinh Do, Duong Vu, Duy Trung Dao, Thu Quy Le, “The Experimental Research on Plasma Welding of SUS 304 Stainless Steel Plates “, 5th International Conference on Engineering and Research Application 22 (ICERA 2022), December, 1-2, 2022, Code IP: 0767 (Q4);

Kha Мyn Khung ,” Rarabotka y vniedrienyie promusliennoy tiekhnologyy polutrienyia vdruvom Antiphrictsyonnukh kompoditxionnuk materialov dlia podsipnikov xkolgieniia “,Moskovski ordena octiabrxhoi revoliutxia y ordena trudovogo kraxnogo dnameny Inxtitut Xtali y xplavov , (МYXiX), dixx. Kandidata teckh. Nauk, Matxcova, 269 xtr,1991. (Dissertation Original in russian language).

M .Gnanasekaran., A.Kumaravel.,S.Jerome,” Effect of oxide layer and activating flux on corrosion behavior of TIG welding of 304 austenite stainless steel weldments”, International journal of Chem Tech Research, 9(4),360-356, ISSN :0974-4290.

Haikal, Moch Kamim., Deni Andriyansyah, Emanuel Budi Raharjo, Ario Sunnar Baskoro & Isnarno, “Effect of Magnetic Field Induce Arc in Autogenous TIG Welding of 304 Stainless Steel Butt Joint”, Automotive Experience,4(1),27-35, 2021. https://doi.org/10.31603/ae.4199.

Benjamin Durakovic,” Design of Experiments Application, Concepts, Examples: State of the Art”,Periodicals of Engineering and Natural Science, 5(3),421-439,2017. DOI :10.21533/pen. v5i3.145.

Condapalli Siva Presad., Chalamalasetti Srinivasa Rao & Damera Nageswara Rao,”Study on Weld Quality Characteristics of Micro Plasma Arc Welded Austenistic Stainless Steel”,Procedia Engineering, 97, 752-757,2014.Elsevier.

Condapalli Siva Presad., Chalamalasetti Srinivasa Rao & Damera Nageswara Rao,” Study of Pulse Micro Plasma Arc welding parameters on Weld Bead Geometry of AISI 304L Sheet using Factorial Method”,Thamasat International Journal of Science and Technology,17(1),31-41,2012.

V.A Setyowati, Suheni, F Abdul & S Ariyadi,” Effect of welding methods for different carbon content of SS304 and SS304L materials on the mechanical properties and microstructure”,ICATECH 2020, IOP Conf .Series: Materials Science and Engineering 1010 (2021) 012018. Doi : 10.1088/1757-899X/1010/1/012018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Minh Hung Ha , Duong Vu , Hai Tinh Do

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with SPEKTA (Jurnal Pengabdian Kepada Masyarakat: Teknologi dan Aplikasi) agree to the following terms:

- Authors retain copyright and grant the journal the right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.