Encapsulation of Dadih with Maltodextrin and Gum Arabic: Effect on Nutritional and Sensory Properties of Probiotic Instant Milk

DOI:

https://doi.org/10.12928/jafost.v6i3.12910Keywords:

Dadih, Encapsulation, Instant milk, Maltodextrin, ProbioticAbstract

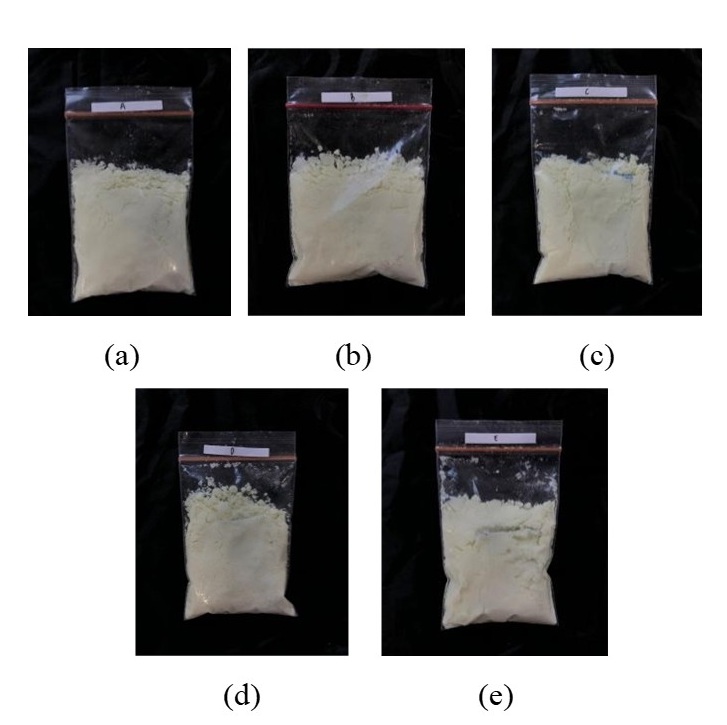

The conversion of dadih, a traditional Indonesian fermented buffalo milk, into a probiotic instant milk powder can enhance its shelf life and commercial potential. This study aimed to evaluate the impact of encapsulating dadih using maltodextrin (MD) and gum Arabic (GA) on the physicochemical properties and sensory characteristics of the resulting probiotic instant milk. The dadih was encapsulated with varying MD and GA ratios (100%:0%, 80%:20%, 70%:30%, 60%:40%, 50%:50%) and processed using freeze drying. Moisture, ash, protein, fat content, and lactic acid bacteria (LAB) viability were analyzed. The results showed that higher gum Arabic content increased moisture and ash, while maltodextrin contributed to higher protein and fat retention. The highest LAB count was observed in the 100% MD formulation, indicating that maltodextrin was more effective in preserving probiotics. Sensory evaluation indicated that the 70% MD and 30% GA formulations provided the best texture and flavor making them the most preferred among consumers. This study concludes that the encapsulation ratio of MD and GA plays a crucial role in optimizing the physicochemical properties, probiotic survival, and sensory quality of the probiotic instant milk, offering valuable insights for improving product stability and consumer acceptance.

References

M. E. Baldassarre, V. Palladino, A. Amoruso, S. Pindinelli, P. Mastromarino, M. Fanelli, A. Di Mauro, and N. Laforgia, “Rationale of probiotic supplementation during pregnancy and neonatal period,” Nutrients, vol. 10, no. 11, pp. 1–22, 2018, https://doi.org/10.3390/nu10111693.

E. Navarro‐tapia, G. Sebastiani, S. Sailer, L. A. Toledano, M. Serra‐delgado, Ó. García-Algar, and V. Andreu‐fernández, “Probiotic supplementation during the perinatal and infant period: Effects on gut dysbiosis and disease,” Nutrients, vol. 12, no. 8, pp. 1–42, 2020, https://doi.org/10.3390/nu12082243.

E. Roza, S. N. Aritonang, Y. Yellita, H. Susanty, Rizqan, and Y. E. Pratama, “Potential of dadiah kapau from Agam District, West Sumatra, Indonesia as a source of probiotics for health,” Biodiversitas, vol. 23, no. 1, pp. 564–571, 2022, https://doi.org/10.13057/biodiv/d230161.

R. Amelia, K. Philip, Y. E. Pratama, and E. Purwati, “Characterization and probiotic potential of lactic acid bacteria isolated from dadiah sampled in West Sumatra,” Food Sci. Technol., vol. 41, pp. 746–752, 2021, https://doi.org/10.1590/fst.30020.

E. Valero-Cases, D. Cerdá-Bernad, J.-J. Pastor, and M.-J. Frutos, “Non-dairy fermented beverages as potential carriers to ensure probiotics, prebiotics, and bioactive,” Nutrients, vol. 12, pp. 1–18, 2020, https://doi.org/10.3390/nu12061666.

C. M. Muntu, C. Avanti, H. Hayun, and S. Surini, “Stability study of spray freeze-dried insulin dry powder formulations used for nose-to-brain delivery,” J. Appl. Pharm. Sci., vol. 13, no. 10, pp. 225–237, 2023, https://doi.org/10.7324/JAPS.2023.148983.

B. Sunitha, J. Naga Bhavya, G. Arvind, and Sk. Farzana, K. Anusha, “Production of powdered yoghurt by spray drying,” Int. J. Eng. Res., vol. 5, no. 05, pp. 668–678, 2016, https://doi.org/10.17577/ijertv5is050791.

E. L. Fatchiyah, S. Arumingtyas, S. Widyarti., and R. S., Biologi molekuler prinsip dasar analisis. Jakarta: Erlangga, 2011.

G. N. Divya, and P. S. Babu, “Production of dahi powder using vacuum tray drier,” Indian Journal of Applied Research, vol 5, no. 11, pp. 33–34, 2015, https://shorturl.at/vX4Ss.

A. Putra, Y. Marlida, S. Y. D. Khasrad, Azhike, and R. Wulandari, “Perkembangan dan usaha pengembangan dadih: sebuah review tentang susu fermentasi tradisional Minangkabau,” Jurnal Peternakan Indonesia, vol. 13, no. 3, pp. 1–23, 2016, https://doi.org/10.25077/jpi.13.3.159-170.2011.

M. S. Abbas, M. Afzaal, F. Saeed, A. Asghar, L. Jianfeng, A. Ahmad, Q. Ullah, S. Elahi, H. Ateeq, Y. A. Shah, M. Nouman, and M. A. Shah, “Probiotic viability as affected by encapsulation materials: recent updates and perspectives,” Int. J. Food Prop., vol. 26, no. 1, pp. 1324–1350, 2023, https://doi.org/10.1080/10942912.2023.2213408.

P. Choudhary, H. B. Kraatz, C. M. Lévesque, and S. G. Gong, “Microencapsulation of probiotic Streptococcus salivarius LAB813,” ACS Omega, vol. 8, no. 13, pp. 12011–12018, 2023, https://doi.org/10.1021/acsomega.2c07721.

M. Azeem, F. Saeed, M. Afzaal, H. Ateeq, A. Ahmad, A. Liaqat, R. Busquets, J. M. Lorenzo, and M. Asif Shah, “Encapsulation of probiotics in solid lipid micro particle for improved viability and stability under stressed conditions,” Int. J. Food Prop., vol. 26, no. 1, pp. 1612–1623, 2023, https://doi.org/10.1080/10942912.2023.2223776.

A. Letona, S. Ahn, S. An, D. Yun, Y. R. Kim, M. Muralles, and D. Chung, “High-shear granulation of hygroscopic probiotic-encapsulated skim milk powder: Effects of moisture-activation and resistant maltodextrin,” Pharmaceuticals, vol. 16, no. 2, 2023, https://doi.org/10.3390/ph16020217.

G. Gullifa, R. Risoluti, C. Mazzoni, L. Barone, E. Papa, A. Battistini, R. Martin Fraguas, and S. Materazzi, “Microencapsulation by a spray drying approach to produce innovative probiotics-based products extending the shelf-life in non-refrigerated conditions,” Molecules, vol. 28, no. 2, 2023, https://doi.org/10.3390/molecules28020860.

AOAC, Official Methods of Analysis of the Association of Analytical Chemist, vol. 1, no. 1, 2005, https://doi.org/10.1201/9781003354116-6.

Fardiaz, Analisis Mikrobiologi Pangan. Jakarta: PT Raja Grafindo Persada, 1999.

D. Setyaningsih, A. Ariyantono, and M. P. Sari, Analisis Sensori. Bogor: IPB Press, 2010.

A. P. Cahya, M. Syaflan, and N. Ngatirah, “Probiotic (Lactobacillus casei) encapsulation using the method of spray drying with combined prebiotic from iles-iles (Amorphopallus oncophyllus) and protectant agent (skim milk, gum arabic, maltodextrin),” Indones. Food Nutr. Prog., vol. 15, no. 2, p. 61, 2018, https://doi.org/10.22146/ifnp.33423.

C. R. de Menezes, J. S. Barin, A. J. Chicoski, L. Q. Zepka, E. Jacob-Lopes, L. L. M. Fries, N. N. Terra, “Microencapsulation of probiotics: progress and prospects,” Cienc. Rural, vol. 43, no. 7, pp. 1309–1316, 2013, https://doi.org/10.1590/S0103-84782013005000084.

J. Jin, C. Liu, H. Tong, Y. Sun, M. Huang, G. Ren, and H. Xie, “Encapsulation of EGCG by Zein-gum arabic complex nanoparticles and in vitro simulated digestion of complex nanoparticles,” Foods, vol. 11, no. 14, 2022, https://doi.org/10.3390/foods11142131.

C. Zhang, S. L. A. Khoo, P. Swedlund, Y. Ogawa, Y. Shan, and S. Y. Quek, “Fabrication of spray-dried microcapsules containing noni juice using blends of maltodextrin and gum acacia: physicochemical properties of powders and bioaccessibility of bioactives during in vitro digestion,” Foods, vol. 9, no. 9, pp. 1–17, 2020, https://doi.org/10.3390/foods9091316.

D. Chaabane, I. Mirmazloum, A. Yakdhane, E. Ayari, K. Albert, G. Vatai, M. Ladányi, A. Koris, and A. Nath, “Microencapsulation of olive oil by dehydration of emulsion: Effects of the Emulsion formulation and dehydration process,” Bioengineering, vol. 10, no. 6, pp. 1–18, 2023, https://doi.org/10.3390/bioengineering10060657.

S. Tatasciore, V. Santarelli, L. Neri, R. González Ortega, M. Faieta, C. D. Di Mattia, A. Di Michele, and P. Pittia, “Freeze-drying microencapsulation of hop extract: Effect of carrier composition on physical, techno-functional, and stability properties,” Antioxidants, vol. 12, no. 2, 2023, https://doi.org/10.3390/antiox12020442.

L. Pudziuvelyte, M. Marksa, K. Sosnowska, K. Winnicka, R. Morkuniene, and J. Bernatoniene, “Freeze-drying technique for microencapsulation of Elsholtzia ciliata ethanolic extract using different coating materials,” Molecules, vol. 25, no. 9, pp. 1–16, 2020, https://doi.org/10.3390/molecules25092237.

S. M. San, M. Jaturanpinyo, and W. Limwikrant, “Effects of wall material on medium-chain triglyceride (mct) oil microcapsules prepared by spray drying,” Pharmaceutics, vol. 14, no. 6, 2022, https://doi.org/10.3390/pharmaceutics14061281.

N. A. Chasquibol, G. Gallardo, R. B. Gómez-Coca, D. Trujillo, W. Moreda, and M. C. Pérez-Camino, “Glyceridic and unsaponifiable components of microencapsulated sacha inchi (Plukenetia huayllabambana L. and Plukenetia volubilis L.) edible oils,” Foods, vol. 8, no. 12, pp. 1–18, 2019, https://doi.org/10.3390/foods8120671.

D. Ogrodowska, M. Tańska, W. Brandt, and S. Czaplicki, “The influence of emulsion drying on the fatty acid composition, bioactive compounds content and oxidative stability of encapsulated bio-oils,” CYTA - J. Food, vol. 17, no. 1, pp. 949–959, 2019, https://doi.org/10.1080/19476337.2019.1676316.

T. R. Lia Umi Khasanah, Baskara Katri Anandhito, “Pengaruh rasio bahan penyalut maltodekstrin, gum arab dan susu skim terhadap karakteristik fisik dan kimia makrokapsul oleoresin daun kayu manis (Cinnamomum burmannii),” AGRITECH, vol. 35, no. 4, 2015, https://doi.org/10.22146/agritech.9325.

G. Broeckx, D. Vandenheuvel, I. J. J. Claes, S. Lebeer, and F. Kiekens, “Drying techniques of probiotic bacteria as an important step towards the development of novel pharmabiotics,” Int. J. Pharm., vol. 505, no. 1–2, pp. 303–318, 2016, https://doi.org/10.1016/j.ijpharm.2016.04.002.

R. V. Tonon, C. Brabet, and M. D. Hubinger, “Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying,” J. Food Eng., vol. 88, no. 3, pp. 411–418, 2008, https://doi.org/10.1016/j.jfoodeng.2008.02.029.

T. Dan, W. Ren, Y. Liu, J. Tian, H. Chen, T. Li, and W. Liu, “Volatile flavor compounds profile and fermentation characteristics of milk fermented by Lactobacillus delbrueckii subsp. bulgaricus,” Front. Microbiol., vol. 10, pp. 1–12, 2019, https://doi.org/10.3389/fmicb.2019.02183.

A. Gharsallaoui, G. Roudaut, O. Chambin, A. Voilley, and R. Saurel, “Applications of spray-drying in microencapsulation of food ingredients: An overview,” Food Res. Int., vol. 40, no. 9, pp. 1107–1121, 2007, https://doi.org/10.1016/j.foodres.2007.07.004.

M. English, O. D. Okagu, K. Stephens, A. Goertzen, and C. C. Udenigwe, “Flavour encapsulation : A comparative analysis of relevant techniques, physiochemical characterisation, stability, and food applications,” Front. Nutr., vol. 10, pp. 1–15, 2023, https://doi.org/10.3389/fnut.2023.1019211.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Novelina, Daimon Syukri, Mahfuzatul Khairani

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with the Journal of Agri-food Science and Technology (JAFOST) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.