The Effect of Drying Methods on the Physicochemical Characteristics of Curly Red Chili (Capsicum annuum L.)

DOI:

https://doi.org/10.12928/jafost.v6i4.12906Keywords:

Capsaicin, Curly red chili, Drying, Freeze-drying, Vitamin CAbstract

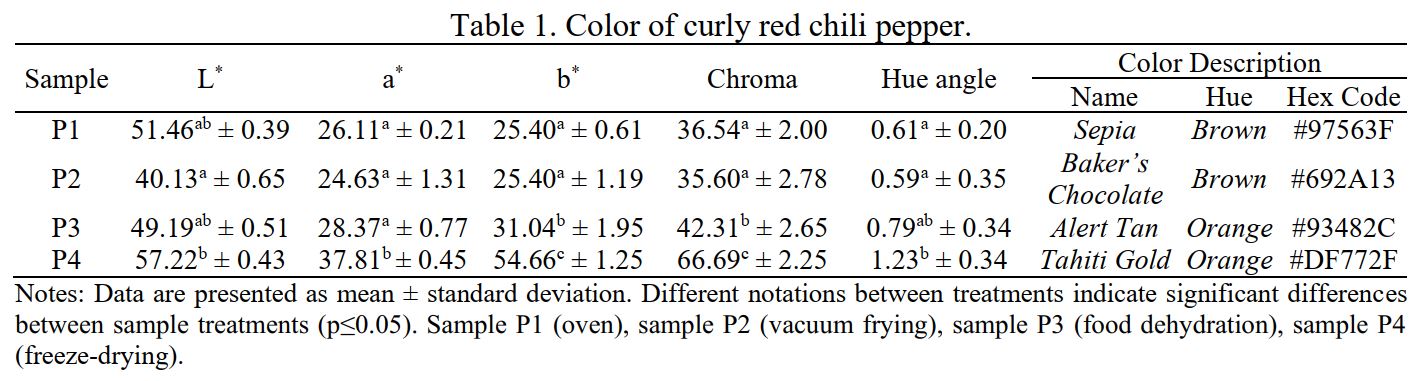

Curly red chili has high nutritional content, which includes capsaicinoids, vitamin C, carotenoids, and antioxidant compounds. However, their high moisture content renders them perishable. During peak harvest seasons, prices for chili significantly decrease, while they tend to rise in colder months. Inefficient postharvest technologies contribute to substantial waste due to damage. Effective postharvest processing, such as drying, mitigates these challenges by reducing moisture content and extending shelf life. Various drying methods, including food dehydration, oven, vacuum frying, and freeze drying, have distinct advantages and disadvantages. Comparative studies have been conducted on these methods specifically for curly red chili. This study contributes to evaluating the effects of different drying methods on the color, moisture content, vitamin C content, and capsaicin concentration of curly red chili (Capsicum annuum L.) in order to determine the most effective method for preserving its nutritional and physicochemical qualities. The results indicate that the drying method significantly influences the physicochemical properties of curly red chili. Among the methods tested, freeze-drying emerged as the most effective, based on the color of 66.69 ± 2.25, moisture content of 3.81%, and vitamin C of 94.34 mg/100g. The optimal treatment yielded a spiciness level of 16504.71 SHU with a capsaicinoid content of 1100.32 mcg/g. Further research is needed to explore how moisture content affects capsaicin levels in curly red chili.

References

A. Lukas, A. N. Kairupan, A. Hendriadi, A. Arianto, L. Parulian Manalu, L. Sumarno, J. Munarso, M. Hadipernata, H. M. Elmatsani, B. O. Benyamin, A. Junaidi, M. Jusuf Djafar, R. Elizabeth, Sahlan, Nasruddin, et al., “Fresh chili agribusiness: Opportunities and problems in Indonesia,” in Agricultural Economics and Agri-Food Business, O. Özçatalbaş and U. Iyer-Raniga, Eds., United Nations Sustainable Development Goals, 2024, https://doi.org/10.5772/intechopen.112786.

M. Rachmaniah, A. I. Suroso, M. Syukur, and I. Hermadi, “Supply and demand model for a chili enterprise system using a simultaneous equations system,” Economies, vol. 10, no. 12, p. 312, 2022, https://doi.org/10.3390/economies10120312.

I. G. B. T. Ananta and D. G. A. Anjasmara, “Antioxidant and antibacterial potency of red chillies extract (Capsicum annum var. Longum),” J. Ilm. Medicam., vol. 8, no. 1, pp. 48–55, 2022, https://doi.org/10.36733/medicamento.v8i1.3170.

M. Palumbo, G. Attolico, V. Capozzi, R. Cozzolino, A. Corvino, M. L. V. de Chiara, B. Pace, S. Pelosi, I. Ricci, R. Romaniello, and M. Cefola, “Emerging postharvest technologies to enhance the shelf-life of fruit and vegetables: An overview,” Foods, vol. 11, no. 23, p. 3925, 2022, https://doi.org/10.3390/foods11233925.

I. F. Islami and S. N. Rahmadhia, “The effect of sago starch (Metroxylon sp.) and chitosan as edible coating on physical and chemical characteristics of red chili (Capsicum annuum L.),” Adv. Food Sci. Sustain. Agric. Agroindustrial Eng., vol. 7, no. 3, pp. 265–273, 2024, https://doi.org/10.21776/ub.afssaae.2024.007.03.7.

N. W. Ranawati, U. Ahmad, and D. Wulandani, “Shelf-life estimation of dried chili in vacuum packaging,” J. Tek. Pertan. Lampung., vol. 13, no. 1, p. 60, 2024, https://doi.org/10.23960/jtep-l.v13i1.60-70.

R. Rana, A. Islam, A. A. Sabuz, M. Hasan, and R. Ara, “Effect of blanching pretreatments on the physicochemical and drying characteristics of chui jhal (Piper chaba H.) stem,” Int. J. Food Sci. Agric., vol. 4, no. 4, pp. 482–491, 2020, https://doi.org/10.26855/ijfsa.2020.12.017.

E. Elamin, “Horticultural insights into the effect of blanching and drying on the shelf life of green peas,” Int. J. Hortic. Food Sci., vol. 6, no. 1, pp. 153–156, 2024, https://doi.org/10.33545/26631067.2024.v6.i1b.231.

S. Mandliya, J. Majumdar, S. Misra, M. Pattnaik, and H. N. Mishra, “Evaluation of dry microwave and hot water blanching on physicochemical, textural, functional and organoleptic properties of Indian gooseberry (Phyllanthus emblica),” J. Food Meas. Charact., vol. 17, no. 3, pp. 2881–2891, 2023, https://doi.org/10.1007/s11694-023-01833-8.

R. Pande, S. Tyagi, S. Vishwakarma, and S. Mandliya, “Dry microwave and hot water blanching of underutilized star fruit (Averrhoa carambola): A comparative assessment of quality attributes and sensory evaluation using chemometric approach,” Food Phys., vol. 2, p. 100056, 2025, https://doi.org/10.1016/j.foodp.2025.100056.

N. Thi Thanh Huong, P. Thinh, D. Vinh Long, H. Bao Long, U. Thanh Dat, D. Tan Phat, P. Tri Nhut, T. Bui Phuc, and T. Thi Yen Nhi, “Effects of microwave and ultrasound treatment on vitamin C, polyphenols and antioxidant activity of mango (Mangifera indica) during low temperature drying,” Mater. Today Proc., vol. 59, pp. 781–786, 2022, https://doi.org/10.1016/j.matpr.2021.12.581.

A. Arslan and İ. Alibaş, “Assessing the effects of different drying methods and minimal processing on the sustainability of the organic food quality,” Innov. Food Sci. Emerg. Technol., vol. 94, p. 103681, 2024, https://doi.org/10.1016/j.ifset.2024.103681.

A. M. Fallah, R. M. Putri, W. Yuliani, W. Wagiman, and M. A. F. Falah, “Characterization of freeze-dried strawberries (Fragaria x ananassa var. Mencir): quality on physical information,” J. Agri-Food Sci. Technol., vol. 5, no. 2, pp. 85–93, 2024, https://doi.org/10.12928/jafost.v5i2.9468.

H. W. Woldemariam, S. Admassu Emire, P. Getachew Teshome, S. Toepfl, and K. Aganovic, “Physicochemical, functional, oxidative stability and rheological properties of red pepper (Capsicum annuum L.) powder and paste,” Int. J. Food Prop., vol. 24, no. 1, pp. 1416–1437, 2021, https://doi.org/10.1080/10942912.2021.1969945.

AOAC, Official Methode of Analysis Association of Official Analytical Chemists. 2005.

N. Kalathil, N. Thirunavookarasu, K. Lakshmipathy, D. V. Chidanand, M. Radhakrishnan, and N. Baskaran, “Application of light based, non-thermal techniques to determine physico-chemical characteristics, pungency and aflatoxin levels of dried red chilli pods (Capsicum annuum),” J. Agric. Food Res., vol. 13, p. 100648, 2023, https://doi.org/10.1016/j.jafr.2023.100648.

F. Wang, L. Bian, Z. Zhan, Y. Chen, C. Ling, H. Guo, Y. Gai, G. Liu, T. Xu, Y. Wang, Y. Xu, and Y. Huo, “Determination of optimal sampling time of grape embryo rescue based on near infrared spectroscopy combined with machine learning,” Plant Phenomics, vol. 7, no. 2, p. 100044, 2025, https://doi.org/10.1016/j.plaphe.2025.100044.

C. Chen, M. Espinal‐Ruiz, A. Francavilla, I. J. Joye, and M. G. Corradini, “Morphological changes and color development during cookie baking—Kinetic, heat, and mass transfer considerations,” J. Food Sci., vol. 89, no. 7, pp. 4331–4344, 2024, https://doi.org/10.1111/1750-3841.17117.

J. Shen, M. Zhang, A. S. Mujumdar, Y. Wang, K. Chen, and J. Chen, “Investigation on the discoloration of freeze-dried carrots and the color protection by microwave combined with coating pretreatment,” Dry. Technol., vol. 40, no. 16, pp. 3568–3579, 2022, https://doi.org/10.1080/07373937.2022.2067865.

K. R. Ward and P. Matejtschuk, “The principles of freeze-drying and application of analytical technologies,” in Cryopreservation and Freeze-Drying Protocols, W. F. Wolkers and H. Oldenhof, Eds., New York: Springer, 2021, pp. 99–127, https://doi.org/10.1007/978-1-0716-0783-1_3.

N. Mohd Zain, M. Abd. Ghani, Z. Mohd Kasim, and H. Hashim, “Effects of different drying methods on the functional properties and physicochemical characteristics of chia mucilage powder (Salvia hispanica L.),” Sains Malaysiana, vol. 50, no. 12, pp. 3603–3615, 2021, https://doi.org/10.17576/jsm-2021-5012-12.

A. K. Pandey, N. Ravi, and O. P. Chauhan, “Quality attributes of vacuum fried fruits and vegetables: A review,” J. Food Meas. Charact., vol. 14, no. 3, pp. 1543–1556, 2020, https://doi.org/10.1007/s11694-020-00403-6.

H. Sun, Y. Wu, B. Lin, M. Duan, Z. Yang, H. Zhao, Z. Wei, S. Yu, S. Li, and J. Song, “Indoor thermal environment improvement based on switchable radiation/convection-combined intermittent heating: Comparison between conventional terminals and an integrated novel terminal,” Engineering, vol. 53, pp. 58–75, 2025, https://doi.org/10.1016/j.eng.2024.08.020.

J. Dehghannya and M. Ngadi, “Recent advances in microstructure characterization of fried foods: Different frying techniques and process modeling,” Trends Food Sci. Technol., vol. 116, pp. 786–801, 2021, https://doi.org/10.1016/j.tifs.2021.03.033.

S. Mandliya, S. Vishwakarma, and H. N. Mishra, “Modeling of vacuum drying of pressed mycelium (Pleurotus eryngii) and its microstructure and physicochemical properties,” J. Food Process Eng., vol. 45, no. 10, 2022, https://doi.org/10.1111/jfpe.14124.

M. E. Sosa‐Morales, A. P. Solares‐Alvarado, S. P. Aguilera‐Bocanegra, J. F. Muñoz‐Roa, and G. A. Cardoso‐Ugarte, “Reviewing the effects of vacuum frying on frying medium and fried foods properties,” Int. J. Food Sci. Technol., vol. 57, no. 6, pp. 3278–3291, 2022, https://doi.org/10.1111/ijfs.15572.

Y.-X. Bi, S. Zielinska, J.-B. Ni, X.-X. Li, X.-F. Xue, W.-L. Tian, W.-J. Peng, and X.-M. Fang, “Effects of hot-air drying temperature on drying characteristics and color deterioration of rape bee pollen,” Food Chem. X, vol. 16, p. 100464, 2022, https://doi.org/10.1016/j.fochx.2022.100464.

L. Rani, M. Kumar, D. Kaushik, J. Kaur, A. Kumar, F. Oz, C. Proestos, and E. Oz, “A review on the frying process: Methods, models and their mechanism and application in the food industry,” Food Res. Int., vol. 172, p. 113176, 2023, https://doi.org/10.1016/j.foodres.2023.113176.

C. Pacco and Honorato, “Temperature simulation and control for lab-scale convection dehydrators,” Procedia Comput. Sci., vol. 180, pp. 922–934, 2021, https://doi.org/10.1016/j.procs.2021.01.343.

M. Mieszczakowska-Frąc, K. Celejewska, and W. Płocharski, “Impact of innovative technologies on the content of vitamin C and its bioavailability from processed fruit and vegetable products,” Antioxidants, vol. 10, no. 1, p. 54, 2021, https://doi.org/10.3390/antiox10010054.

F. Susa and R. Pisano, “Advances in ascorbic acid (vitamin C) manufacturing: Green extraction techniques from natural sources,” Processes, vol. 11, no. 11, p. 3167, 2023, https://doi.org/10.3390/pr11113167.

H.-W. Xiao, Z. Pan, L.-Z. Deng, H. M. El-Mashad, X.-H. Yang, A. S. Mujumdar, Z.-J. Gao, and Q. Zhang, “Recent developments and trends in thermal blanching – A comprehensive review,” Inf. Process. Agric., vol. 4, no. 2, pp. 101–127, 2017, https://doi.org/10.1016/j.inpa.2017.02.001.

A. Krzykowski, S. Rudy, R. Polak, B. Biernacka, A. Krajewska, E. Janiszewska-Turak, I. Kowalska, J. Żuchowski, B. Skalski, and D. Dziki, “Drying of red chili pepper (Capsicum annuum L.): Process kinetics, color changes, carotenoid content and phenolic profile,” Molecules, vol. 29, no. 21, p. 5164, 2024, https://doi.org/10.3390/molecules29215164.

S. Nazeer, T. T. R. Afzal, Sana, M. Saeed, S. Sharif, and M. Zia-Ul-Haq, “Chili pepper,” in Essentials of Medicinal and Aromatic Crops, Cham: Springer International Publishing, 2023, pp. 855–885. https://doi.org/10.1007/978-3-031-35403-8_33.

P. Popelka, P. Jevinová, K. Šmejkal, and P. Roba, “Determination of capsaicin content and pungency level of different fresh and dried chilli peppers,” Folia Vet., vol. 61, no. 2, pp. 11–16, 2017, https://doi.org/10.1515/fv-2017-0012.

W. Zhang, S. Li, H. Tang, Q. Huang, P. Meng, H. Deng, Z. He, C. Liu, P. Liu, T. Li, and Y. Yuan, “Investigation of the flavor profiles on chili rapeseed oil: A study on flavor generation by chili addition and frying oil temperature,” LWT, vol. 228, p. 118064, 2025, https://doi.org/10.1016/j.lwt.2025.118064.

J. P. L. Aguiar, E. P. da Silva, A. P. G. da Silva, W. G. Sganzerla, J. Xiao, and F. das C. do A. Souza, “Influence of freeze-drying treatment on the chemical composition of peppers (Capsicum L.) from the Brazilian Amazonia region,” Biocatal. Agric. Biotechnol., vol. 38, p. 102220, 2021, https://doi.org/10.1016/j.bcab.2021.102220.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Birgitta Allison Kesuma, Ika Yohanna Pratiwi, Yohannes Somawiharja

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with the Journal of Agri-food Science and Technology (JAFOST) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.