Optimizing welding parameters for high deposition efficiency in waam by using the taguchi method

DOI:

https://doi.org/10.12928/ijio.v5i2.9046Keywords:

Wire arc additive manufacturing, Deposition efficiency, Taguchi methodAbstract

Wire arc additive manufacturing (WAAM) is a type of additive manufacturing technology that offers high flexibility in shaping products and is cost-effective due to its low material consumption and rapid time to market. Material consumption can be evaluated by assessing deposition efficiency during welding. The efficiency of a deposited metal depends on various processes and welding parameters, including travel speed, wire feed rate, voltage, distance of the torch from the base, and many others. Therefore, process capability can be efficiently achieved by crucially determining the key parameters that have the most significant effect. In this study, the main objective is to determine the most significant parameters to obtain the optimum deposition efficiency of a gas metal arc welding-based 3D welding machine. The Taguchi experimental design method is used to determine the optimal welding parameters. Results showed that the distance of the torch from the base is the most significant parameter, followed by welding speed and wire feed rate. The observation is validated via a confirmation test.

References

D. Jafari, T.H.J. Vaneker, and I. Gibson, “Wire and arc additive manufacturing: Opportunities and challenges to contr ol the quality and accuracy of manufactured parts”, Materials & Design, vol. 202, pp. 109471, 2021, doi: 10.1016/j.matdes.2021.109471.

C. Xia, Z. Pan, J. Polden, H. Li, Y. Xu, S. Chen, and Y. Zhang, “A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system”, Journal of Manufacturing Systems, vol. 57, pp. 31-45, 2020, doi: 10.1016/j.jmsy.2020.08.008.

L. Zidong, S. Kaijie, and Y. Xinghua, “A review on wire and arc additive manufacturing of titanium alloy”, Journal of Manufacturing Processes, vol. 70, pp. 24-45, 2021, doi: 10.1016/j.jmapro.2021.08.018

T. A. Rodrigues, V. Duarte, R. M. Miranda, T. G. Santos, and J. Oliveira, “Current status and perspectives on wire and arc additive manufacturing (WAAM),” Materials, vol. 12, no. 7, p. 1121, 2019, doi: 10.3390/ma12071121.

A. Suárez, P. Ramiro, F. Veiga, T. Ballesteros, and P. Villanueva, “Benefits of Aeronautical Preform Manufacturing through Arc-Directed Energy Deposition Manufacturing”, Materials (Basel), vol. 16, no. 22, pp. 7177, 2023, doi: 10.3390/ma16227177

A. Josten, and M. Höfemann, “Arc-welding, based additive manufacturing for body reinforcement in automotive engineering”, Weld World, vol. 64, pp. 1449–1458, 2020. doi: 10.1007/s40194-020-00959-3

B. O. Omiyale, T. O. Olugbade, T. E. Abioye, and P. K. Farayibi, “Wire arc additive manufacturing of aluminium alloys for aerospace and automotive applications: a review”, Materials Science and Technology, vol. 38, no. 7, pp. 391-408, 2022. doi: 10.1080/02670836.2022.2045549

A. Taşdemir, and S. Nohut, “An overview of wire arc additive manufacturing (WAAM) in shipbuilding industry”, Ships and Offshore Structures, vol. 16, no. 7, pp. 797-814, 2021, doi: 10.1080/17445302.2020.1786232

M. Ziółkowski, and T. Dyl, “Possible Applications of Additive Manufacturing Technologies in Shipbuilding: A Review”, Machines, vol. 8, no. 4, pp. 84, 2020, doi: 10.3390/machines8040084

Y. Li, C. Su, and J. Zhu, “Comprehensive review of wire arc additive manufacturing: Hardware system, physical process, monitoring, property characterization, application and future prospects”, Results in Engineering, vol. 13, 2022, doi: 10.1016/j.rineng.2021.100330

K. Treutler and V. Wesling, “The Current State of Research of Wire Arc Additive Manufacturing (WAAM): A Review”, Applied Sciences, vol. 11, no. 18, pp. 8619, 2021, doi: 10.3390/app11188619

C. Wang, W. Suder, J. Ding, and S. Williams, “The effect of wire size on high deposition rate wire and plasma arc additive manufacture of Ti-6Al-4V”, Journal of Materials Processing Technology, vol. 288, pp. 116842, 2021, doi: 10.1016/j.jmatprotec.2020.116842

L. Vazquez, A. Iturrioz, P. Lopez de Uralde, and P. Alvarez, “Maximising the Deposition Rate of 5356 Aluminium Alloy by CMT-Twin-Based WAAM While Reducing Segregation-Related Problems by Local IR Thermography”, Metals, vol. 12, no. 11, pp. 1890, 2023, doi: 10.3390/met13111890

X. Wang, C. Zhou, M. Luo, L. Liu, and F. Liu, “Fused plus wire arc additive manufacturing materials and energy saving in variable-width thin-walled”, Journal of Cleaner Production, vol. 373, pp. 133765, 2022, doi: 10.1016/j.jclepro.2022.133765

U. Reisgen, R. Sharma, and S. Mann, “Increasing the manufacturing efficiency of WAAM by advanced cooling strategies”, Weld World, vol. 64, pp. 1409–1416, 2020, doi: 10.1007/s40194-020-00930-2

B. Wu, Z. Pan, D. Ding, D. Cuiuri, H. Li, J. Xu, and J. Norrish, “A review of the wire arc additive manufcaturing of metals: properties, defects and quality improvement”, Journal of Manufacturing Processes, vol. 35, pp. 127–139, 2018, doi: 10.1016/j.jmapro.2018.08.001

M. Dias, J. P. M. Pragana, B. Ferreira, I. Ribeiro, and C. M. A. Silva, “Economic and Environmental Potential of Wire-Arc Additive Manufacturing”, Sustainability, vol. 14, no. 9, pp. 5197, 2022, doi: 10.3390/su14095197

C. M. A. Silva, I. M. F. Bragança, A. Cabrita, L. Quintino, and P. A. F. Martins, “Formability of a wire arc deposited aluminium alloy”, J. Braz. Soc. Mech. Sci. Eng, vol. 39, pp. 4059–4068, 2017, doi: 10.1007/s40430-017-0864-z

N. A. Rosli, M. R. Alkahari, M. F. Abdollah, S. Maidin, F. R. Ramli, and S. G. Herawan, “Review on effect of heat input for wire arc additive manufacturing process”, Journal of Materials Research and Technology, vol. 11, pp. 2127-2145, 2021, doi: 10.1016/j.jmrt.2021.02.002

A. Feier, I. Buta, C. Florica, and L. Blaga, “Optimization of Wire Arc Additive Manufacturing (WAAM) Process for the Production of Mechanical Components Using a CNC Machine”, Materials, vol. 16, pp. 17, 2023. doi: 10.3390/ ma16010017

M. Chaturvedi, E. Scutelnicu, C.C. Rusu, L. R. Mistodie, D. Mihailescu, and A. V. Subbiah, “Wire arc additive manufacturing: review on recent findings and challenges in industrial applications and materials characterization”, Metals, vol. 11, pp. 939, 2021. doi: 10.3390/met11060939

J. Shi, F. Li, and S. Chen, “Effect of in-process active cooling on forming quality and efficiency of tandem GMAW–based additive manufacturing”, International Journal of Advanced Manufacturing Technology, vol. 101, pp. 1349–1356, 2019. doi: 10.1007/s00170-018-2927-4

D. Ding, Z. Pan, D. Cuiuri, and H. Li, “A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures”, Robotics and Computer Integrated Manufacturing, vol. 34, pp. 8-19, 2015, doi: 10.1016/j.rcim.2015.01.003

M. Gierth, P. Henckell, Y. Ali, J. Scholl, and J. P. Bergmann, “Wire Arc Additive Manufacturing (WAAM) of Aluminum Alloy AlMg5Mn with Energy-Reduced Gas Metal Arc Welding (GMAW)”, Materials, vol. 13, no. 12, pp. 2671, 2020. doi: 10.3390/ma13122671

C. Gianni, M. Filippo, V. Giuseppe, I. Giuseppe, and P. Paolo C, “Integrated WAAM-Subtractive Versus Pure Subtractive Manufacturing Approaches: An Energy Efficiency Comparison”, International Journal of Precision Engineering and Manufacturing Green Technology, vol. 7, no. 1, pp. 1-11, 2020, doi: 10.1007/s40684-019-00071-y

M. Kumar, S. S. Kumar, and A. Sharma, “Bi-polynomial Fourth-Order Weld Bead Model for Improved Material Utilization and Accuracy in Wire-arc Additive Manufacturing: A Case of Transverse Twin-Wire Welding”, Advances in Industrial and Manufacturing Engineering, vol. 2, pp. 100049, 2021. doi: 10.1016/j.aime.2021.100049

A. Kumar and K. Maji, “Selection of process parameters for near-net shape deposition in wire arc additive manufacturing by genetic logarithm”, Journal of Materials Engineering and Performance, vol. 29, no. 5, pp. 3334-3352, 2020, doi: 10.1007/s11665-020-04847-1

O. Panchenko, D. Kurushkin, I. Mushnikov, A. Khismatullin, and A. Popovich, “A high-performance WAAM process for Al–Mg–Mn using controlled short-circuiting metal transfer at increased wire feed rate and increased travel speed”, Materials & Design, vol. 195, pp. 109040, 2020. doi: 10.1016/j.matdes.2020.109040

C. Xiaoxuan, S. Xin, Z. Zirong, and C. Sheng-Gui, “A Review of the Development Status of Wire Arc Additive Manufacturing Technology”, Advances in Materials Science & Engineering, pp. 5757484, 2022. doi: 10.1155/2022/5757484s

K. Wandtke, D. Schroepfer, and R. Scharf-Wildenhain, “Influence of the WAAM process and design aspects on residual stresses in high-strength structural steels”, Weld World, vol. 67, pp. 987–996, 2023. doi: 10.1007/s40194-023-01503-9

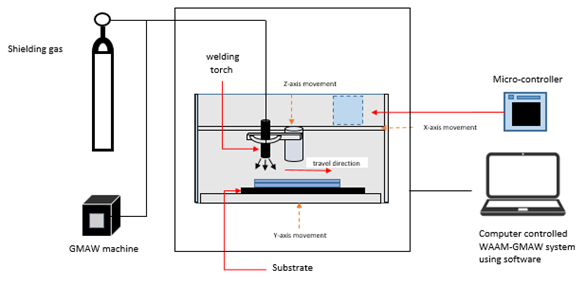

Z. K. Wani, A. B. Abdullah, and A. F. Pauzi, “Semi-automatic 3D Metal Deposition Machine Based on Wire Arc Additive Manufacturing (WAAM)” In Proceedings of the 11th International Conference on Robotics, Vision, Signal Processing and Power Applications. Lecture Notes in Electrical Engineering, vol. 829, pp. 119-124, 2022. Springer, Singapore. doi: 10.1007/978-981-16-8129-5_19

https://www.materialwelding.com/er70s-6-welding-wire-mtc-specification-chemical-mechanical-properties/. Access date: 17 January 2024

Z. K. Wani and A. B. Abdullah, “Bead Geometry Control in Wire Arc Additive Manufactured Profile - A Review”, Pertanika Journal of Science and Technology, vol. 32, no. 2, 2023, doi: 10.47836/pjst.32.2.23

A. A. Lordejani, L. Vitali, M. Guagliano, and S. Bagherifard, “Estimating deposition efficiency and chemical composition variation along thickness for cold spraying of composite feedstocks”, Surface and Coatings Technology, vol. 436, pp. 128239, 2022. doi: 10.1016/j.surfcoat.2022.128239

T. H. Lee, M. Kang, J. H. Oh, and D. Kam, “Deposition quality and efficiency improvement method for additive manufacturing of Ti–6Al–4V using gas metal arc with CMT”, Journal of Materials Processing Technology, vol. 308, pp. 117720, 2022. doi: 10.1016/j.jmatprotec.2022.117720

https://www.thefabricator.com/thewelder/article/consumables/understanding-the-relationship-between-deposition-rate-deposition-efficiency-and-production-output. Access date: 17/1/2024.

https://weldingtech.net/arc-weld-deposition-efficiency/. Access date: 17/1/2024

X. Wang, C. Zhou, M. Luo, L. Liu and F. Liu, “Fused plus wire arc additive manufacturing materials and energy saving in variable-width thin-walled”, Journal of Cleaner Production, vol. 373, pp. 133765, 2022. doi: 10.1016/j.jclepro.2022.133765

A. Shah, A. Rezo, Z. Henning and K. Stefan, "A Review of the Recent Developments and Challenges in Wire Arc Additive Manufacturing (WAAM) Process" Journal of Manufacturing and Materials Processing, vol. 7, no. 3, pp. 97, 2023, doi: 10.3390/jmmp7030097

M. Srivastava, S. Rathee, A. Tiwari and M. Dongre, “Wire arc additive manufacturing of metals: A review on processes, materials and their behaviour”, Materials Chemistry and Physics, vol. 294, 126988, 2023, doi: 10.1016/j.matchemphys.2022.126988

A. Hamrani, F. Z. Bouarab, A. Agarwal, K. Ju and H. Akbarzadeh, “Advancements and applications of multiple wire processes in additive manufacturing: a comprehensive systematic review”. Virtual and Physical Prototyping, vol. 18, no. 1, e2210541. 2023, doi: 10.1080/17452759.2023.2210541

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ahmad Baharuddin Abdullah, Zarirah Karrim Wani, Noor Azam Jaafar

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)