Modeling and simulation of friction stir welding process: A neural approach

DOI:

https://doi.org/10.12928/ijio.v5i1.9010Keywords:

Vertical axis Friction Stir, Safe bending strength, Bending toughness, Flexible neural network model, OptimizationAbstract

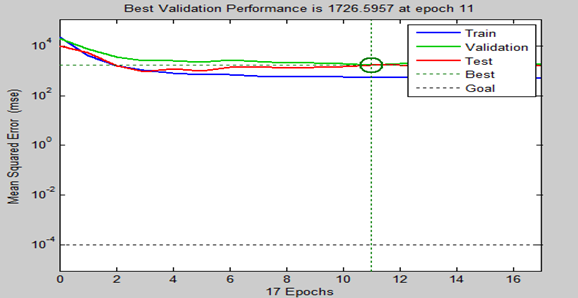

Friction Stir Welding (FSW) stands out as a groundbreaking method in solid-state joining for aluminum alloys, presenting an innovative way to achieve joints of exceptional quality. This research delves into the application of FSW for bonding, focusing on plates that are 6mm thick and made from aluminum alloys Al6063, Al5083, and AL6061, aiming to produce a variety of FSW joints. To evaluate the quality of these joints, the study compares mechanical properties such as tensile strength, safe bending strength, and bending toughness necessary for achieving a 90° bend. The investigation leverages welding data to formulate a neural model, starting with using a conventional feedforward neural model (CFNM). It tackles the limitations of CFNM, including its intensive training requirements and the challenge of dealing with unknown configurations, by proposing a new, more adaptable neural network model known as FNNM. When comparing the two models, it becomes evident that CFNM is constrained by a root mean square error (RMSE) of 7-15%, whereas FNNM marks a significant improvement with a minimal RMSE of 1-3%. This indicates that FNNM improves accuracy and effectively navigates the complexities of modeling with unknown parameters. Through this study, insightful contributions are made to understanding FSW in joining aluminum alloys and developing an advanced neural model capable of predicting the outcomes of welding with greater precision.

References

M. Sindhuja, S. Neelakrishnan, and B. S. Davidson, "Effect of Welding Parameters on Mechanical Properties of Friction Stir Welding of Dissimilar Metals - A Review," In IOP conference series: materials science and engineering, vol. 1185, no. 1, 2021, doi: 10.1088/1757-899X/1185/1/012019

H.K. Sharma, K. Bhatt, K. Shah, U. Joshi, "Experimental Analysis of Friction Stir Welding of Dissimilar Alloys AA6061 and Mg AZ31 Using Circular Butt Joint Geometry," Procedia Technology, vol. 23, pp. 566–572, 2016, doi: 10.1016/j.protcy.2016.03.064

N. R. J. Hyness, M. V. Prabhu, P. S. Velu, R. Kumar, R. Tharmaraj, M. U. Farooq, C. I. Pruncu, "An experimental insight of friction stir welding of dissimilar AA 6061/Mg AZ 31 B joints," Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, vol. 236, no. 6–7, pp. 787–797, 2022, doi 10.1177/09544054211043474

B. Meyghani and C. Wu, "Progress in Thermomechanical Analysis of Friction Stir Welding," Chinese Journal of Mechanical Engineering, Springer, vol. 33, 2020, doi: 10.1186/s10033-020-0434-7

M. Garware, G.T. Kridli, and P.K. Mallick, "Tensile and Fatigue Behavior of Friction-Stir Welded Tailor-Welded Blank of Aluminum Alloy 5754," Journal of Materials Engineering and Performance, vol. 19, no. 8, pp. 1161-1171, 2010, doi: 10.1007/s11665-009-9589-1

M. Sahin, "Joining of Aluminium and Copper materials with Friction," The International Journal of Advanced Manufacturing Technology, vol. 49, pp. 527-534, 2010, doi: 10.1007/s00170-009-2443-7

J. Adamowski and M. Szkodo, "Friction Stir Welds (FSW) of aluminium alloy AW6082-T6," Journal of Achievements in Materials and Manufacturing Engineering, vol. 20, pp. 403-406, 2007, Available: www.infona.pl/

F. Ji, S. Xue, J. Lou, Y. Lou, S. Wang, "Microstructure and Properties of cu/Al Joints Brazed with Zn–Al Filler Metals," Transactions of Nonferrous Metals Society of China, vol. 22, no. 2, pp. 281–287, 2012, doi: 10.1016/S1003-6326(11)61172-2

M. Weigl, F. Albert, and M. Schmidt, "Enhancing the Ductility of Laser-Welded Copper-Aluminum Connections by Using Adapted Filler Mater," Physics Procedia, vol. 12, pp. 332–338, 2011, doi: 10.1016/j.phpro.2011.03.141

G. Joseph and K. I. C. Kundig, "Copper: Its Trade, Manufacture, Use, and Environmental Status," ASM Int., 1998.

W. Miller, L. Zhuang, J. Bottema, A. Wittebrood, P. De Smet, A. Haszler, A. J. M. S. Vieregge, "Recent Development in Aluminium Alloys for the Automotive Industry," Materials Science and Engineering: A, vol. 280, no. 1, pp. 37–49, 2000, doi: 10.1016/S0921-5093(99)00653-X

G. Joseph and K. I. C. Kundig, "Copper: Its Trade, Manufacture, Use, and Environmental Status," ASM International, 1998, Available: https://www.osti.gov/

S. T. Amancio-Filho, S. Sheikhi, J. F. dos Santos, C. Bolfarini, "Preliminary Study on the Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Aircraft Aluminium Alloys 2024-t351 and 6056-t4," Journal of Materials Processing Technology, vol. 206, no. 1, pp. 132–142, 2008, doi: 10.1016/j.jmatprotec.2007.12.008

R. Nandan, T. DebRoy, and H. Bhadeshia, "Recent Advances in Friction-Stir Welding – Process, Weldment Structure and Properties," Prog. Mater. Sci., vol. 53, no. 6, pp. 980–1023, 2008, doi: 10.1016/j.pmatsci.2008.05.001

M. Ghosh, K. Kumar, S. V. Kailas, and A. K. Ray, "Optimization of Friction Stir Welding Parameters for Dissimilar Aluminum Alloys," Materials & Design, vol. 31, no. 6, pp. 3033–3037, 2010, doi: 10.1016/j.matdes.2010.01.028

J. Ouyang and R. Kovacevic, "Material Flow and Microstructure in the Friction Stir Butt Welds of the Same and Dissimilar Aluminum Alloys," Journal of Materials Engineering and Performance, vol. 11, no. 1, pp. 51–63, 2002, doi: 10.1007/s11665-002-0008-0

L. E. Murr, R. D. Flores, J. C. McClure, G. Liu, and D. Brown, "Friction-Stir Welding: Microstructural Characterization," Material Research Innovations, vol. 1, no. 4, pp. 211–223, 1998, doi: 10.1007/s100190050043

J. H. Cho, D. E. Boyce, and P. R. Dawson, "Modeling Strain Hardening and Texture Evolution in Friction Stir Welding of Stainless Steel," Materials Science and Engineering: A, vol. 398, no. 1, pp. 146–163, 2005, doi: 10.1016/j.msea.2005.03.002

K. P. Mehta and V. J. Badheka, "Effects of Tilt Angle on the Properties of Dissimilar Friction Stir Welding Copper to Aluminum," Materials and Manufacturing Processes, vol. 31, no. 3, pp. 255–263, 2016, doi: 10.1080/10426914.2014.994754

Y. Zhao, S. Lin, and F. Qu, "The Influence of Pin Geometry on Bonding and Mechanical Properties in Friction Stir Weld 2014 Al Alloy," Materials Letters, vol. 23, pp. 2948–2952, 2005, doi: 10.1016/j.matlet.2005.04.048

A. Kumar and L. S. Raju, "Influence of Tool Pin Profiles on Friction Stir Welding of Copper," Materials and Manufacturing Processes, vol. 27, no. 12, pp. 1414–1418, 2012, doi: 10.1080/10426914.2012.689455

A.P. Reynolds and W. Tang, "Alloy, tool geometry, and process parameter effects on friction stir weld energies and resultant FSW joint properties," in Friction Stir Welding and Processing, pp. 15-23, 2001.

S. Ahmed, R. A. ur Rahman, A. Awan, S. Ahmad, W. Akram, M. Amjad, M. Aamir, and I. Khan, "Optimization of process parameters in friction stir welding of AA5451," 2022, doi: 10.21203/rs.3.rs-1606359/v1

M. Aissani, S. Gachi, F. Boubenider, and Y. Benkedda, "Design and Optimization of Friction Stir Welding Tool," Materials and Manufacturing Processes, vol. 25, pp. 1199–1205, 2010, doi: 10.1080/10426910903536733

H. Eftekharinia, A. A. Amadeh, A. Khodabandeh, M. Paidar, "Microstructure and wear behavior of AA6061/SiC surface composite fabricated via friction stir processing with different pins and passes," Rare Metals, 2016, doi: 10.1007/s12598-016-0691-x

V. Haribalaji, S. Boopathi, M. Asif, "Optimization of friction stir welding process to join dissimilar AA2014 and AA7075 aluminum alloys," Materials Today: Proceedings, 2021, doi: 10.1016/j.matpr.2021.09.499

D. Vijayan and S. V. Rao, "Parametric optimization of friction stir welding process of age hardenable aluminum alloys − ANFIS modeling," Journal of Central South University, vol. 23, pp. 1847−1857, 2016, doi: 10.1007/s11771-016-3239-1

D.K. Chaturvedi, "Modelling and Simulation of Systems using Matlab/Simulink," CRC Press, New York, 2010.

D.K. Chaturvedi, "Soft Computing Techniques and its Applications in Electrical Engineering," Springer, Berlin, 2008.

Kasman, "Multi-response optimization using the Taguchi-base d grey relational analysis: a case study for dissimilar friction stir butt welding of AA6082-T6/AA5754-H111," Springer Verlag London, 2013, pp.795–804., doi: 10.1007/s00170-012-4720-0

M. S. Hasan, M. Akbari, P. Asadi, "Multi-Objective Optimization of Friction Stir Welding Parameters Using FEM and Neural Network," International Journal of Precision Engineering and Manufacturing, vol. 15, no. 11, pp. 2351-2356, 2014, doi: 10.1007/s12541-014-0600-x

F. Badour, N. Merah, A. Shuaib, and A. Bazoune, "Thermo-mechanical finite element model of friction stir welding of dissimilar alloys," Springer-Verlag London, 2014, pp. 607–617, doi: 10.1007/s00170-014-5680-3

H.D. Naghibi, M. Shakeri, M. Hosseinzadeh, "Neural Network and Genetic Algorithm Based Modeling and Optimization of Tensile Properties in FSW of AA 5052 to AISI 304 Dissimilar Joints," The Indian Institute of Metals - IIM, 2015, pp. 891–900, doi: 10.1007/s12666-015-0572-2

S. K. Gupta, K. N. Pandey, R. Kumar, "Artificial intelligence-based modelling and multi-objective optimization of friction stir welding of dissimilar AA5083-O and AA6063-T6 aluminium alloys," In Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2016, pp.1–10, doi: 10.1177/1464420715627293

D. Vijayan and S. V. Rao, "Parametric optimization of friction stir welding process of age hardenable aluminum alloys − ANFIS modeling," Journal of Central South University, vol. 23, pp. 1847−1857, 2016, doi: https://doi.org/10.1007/s11771-016-3239-1

M.V.R. Durga Prasad and K.K. Namala, "Process Parameters Optimization in Friction Stir Welding by ANOVA," Materials Today: Proceedings, vol. 5, pp. 4824–4831, 2018, doi: 10.1016/j.matpr.2017.12.057

K. N. Wakchaure, A. G. Thakurb, V. Gadakh, and A. Kumar, "Multi-Objective Optimization of Friction Stir Welding of Aluminium Alloy 6082-T6 Using hybrid Taguchi-Grey Relation Analysis- ANN Method," Materials Today: Proceedings, vol. 5, pp. 7150–7159, 2018, doi: 10.1016/j.matpr.2017.11.380

T. Srichok, R. Pitakaso, K. Sethanan, W. Sirirak, and P. Kwangmuang, "Combined Response Surface Method and Modified Differential Evolution for Parameter Optimization of Friction Stir Welding," Processes, vol. 8, 1080, 2020, doi: 10.3390/pr8091080

A. Kubit, T. Trzepieciński, R. Kluz, K. Ochałek, and J. Slota, "Multi-Criteria Optimisation of Friction Stir Welding Parameters for EN AW-2024-T3 Aluminium Alloy Joints," Materials, vol. 15, 5428, 2022, doi: 10.3390/ma15155428

K. Suganeswaran, P. Muthukumar, R. Sathiskumar, R. Parameshwaran, and N. Nithyavathy "Evaluation of microstructural, tribological and tensile characteristics of AA7075 surface composites fabricated through friction stir process," In Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2023, doi: 10.1177/09544089231170987

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Devendra Kumar Chaturvedi, Atul Suri

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)