Supplier's selection of plate material using analytical hierarchy process and additive ratio assessment methods

DOI:

https://doi.org/10.12928/ijio.v4i2.8127Keywords:

AHP, ARAS, Dickson's Criteria, Supplier SelectionAbstract

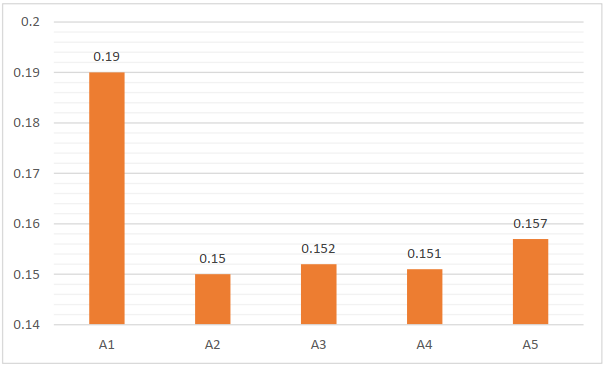

PT PAL Indonesia (PERSERO) is among the prominent shipyard companies in Indonesia that currently employs a simplistic supplier selection weighting system, prioritizing low prices and material specification conformity. This approach often leads to subjective assessments, making it challenging for the company to identify suitable suppliers from a large pool. Therefore, this study proposed a methodology to enhance supplier selection by incorporating additional criteria based on Dickson's criteria and company policies. The Analytical Hierarchy Process (AHP) and Additive Ratio Assessment (ARAS) methods were utilized for this purpose. The findings indicate that PT Krakatau Steel (A1) emerges as the top-ranked supplier with a Ki value of 0.19, followed by PT Diansakti Sejahtera (A5) in second place with a Ki value of 0.157, and PT Gunawan Dianjaya Steel (A3) in third place with a Ki value of 0.152. PT Jastindo Raya (A4) secures the fourth position with a Ki value of 0.151, while PT Gunung Raja Paksi (A2) takes the fifth and final spot with a Ki value of 0.15. This research helps the company effectively select the best suppliers, particularly in the procurement sector, by employing the AHP-ARAS method and considering Dickson's criteria, thereby addressing existing gaps the company encounters.

References

M. Rahman, A. B. M. M. Bari, S. Mithun, and A. Taghipour, “Resources , Conservation & Recycling Advances Sustainable supplier selection in the textile dyeing industry : An integrated multi-criteria decision analytics approach,” Resour. Conserv. Recycl. Adv., vol. 15, no. September, p. 200117, 2022, doi: https://doi.org/10.1016/j.rcradv.2022.200117

F. P. Mulya and R. Rusindiyanto, “Pemilihan Supplier Bahan Baku Rajungan Menggunakan Metode Ahp (Analytical Hierarchy Process) Dan Aras (Additive Ratio Assessment) Di Pt. Xyz,” Juminten, vol. 2, no. 3, pp. 119–130, 2021, Available online at: https://garuda.kemdikbud.go.id/documents/detail/2231536

L. M. Ellram and M. L. Ueltschy, "Supply chain management in industrial marketing – Relationships matter," Ind. Mark. Manag., vol. 79, pp. 36–45, Mar. 2019. doi: https://doi.org/10.1016/j.indmarman.2019.03.007

N. Jahani, A. Sepehri, H. R. Vandchali, and E. B. Tirkolaee, “Application of industry 4.0 in the procurement processes of supply chains: A systematic literature review,” Sustain., vol. 13, no. 14, pp. 1–25, 2021, doi: https://doi.org/10.3390/su13147520.

R. Ali, S. Ashiquzzaman, and S. Ahmed, “A decision support system for classifying supplier selection criteria using machine learning and random forest approach,” Decis. Anal. J., vol. 7, pp. 100238, 2023, doi: https://doi.org/10.1016/j.dajour.2023.100238.

F. X. Libianto, “Pemilihan alternatif pemasok bahan baku menggunakan pendekatan multi kriteria dengan metode PROMETHEE (PT. XYZ),” Jurnal Terapan Teknik Industri, vol. 04 , no. 2, pp. 227-236, Nov. 2023, doi : https://doi.org/10.37373/jenius.v4i2.556.

H. T. Adikoro and F. Wurjaningrum, “Analisis Pemilihan Supplier Kain Byemi Official Store Dengan Metode Fuzzy AHP dan Fuzzy Topsis,” J. Manaj. dan Perbank., vol. 9, no. 2, pp. 38–53, 2022, doi : https://doi.org/10.55963/jumpa.v9i2.458.

P. Samaranayake, S. Nagalingam, and T. Laosirihongthong, “Supplier Selection and Ranking Towards Sustainable Procurement with Multiple Decision Makers,” IEEE Int. Conf. Ind. Eng. Eng. Manag., vol. 2, pp. 906–910, 2019, doi: https://doi.org/10.1109/IEEM44572.2019.8978888.

W. D. Pratama, Y. R. Sianturi, A. P. Silaen, I. H. Sitorus, and B. A. H. Siboro, “Pemilihan Supplier Lampu Uv Dalam Pembuatan Box Sterilization Menggunakan Metode Analytical Hierarchy Process,” J. Ilm. Tek. Ind., vol. 9, no. 2, pp. 158, 2021, doi: https://doi.org/10.24912/jitiuntar.v9i2.10542.

M. Rani, R. Ardiansyah, and D. Christina, “Sistem pendukung keputusan pemilihan supplier cosmetic dengan metode weighted product,” JRTI (Jurnal Ris. Tindakan Indones., vol. 6, no. 1, pp. 77, 2021, doi: https://doi.org/10.29210/3003848000.

J. Gidiagba, L. Tartibu, and M. Okwu, “ScienceDirect ScienceDirect Sustainable supplier selection in the oil and gas industry : An integrated multi-criteria decision making approach,” Procedia Comput. Sci., vol. 217, no. 2022, pp. 1243–1255, 2023, doi: https://doi.org/10.1016/j.procs.2022.12.323.

A. Rasmussen, H. Sabic, S. Saha, and I. E. Nielsen, “Supplier selection for aerospace & defense industry through MCDM methods,” Clean. Eng. Technol., vol. 12, no. June 2022, pp. 100590, 2023, doi: https://doi.org/10.1016/j.clet.2022.100590.

C. Bhowmik, S. Gangwar, and S. Bhowmik, "Optimum Selection of Energy-Efficient Material : A MCDM-Based Distance Approach Evaluation of Mixed Data," in Springer Singapore, 2018. doi: https://doi.org/10.1007/978-981-10-8049-4_3

S. B. Bhosale, S. Bhowmik, and A. Ray, “Multi Criteria Decision Making for Selection of Material Composition for Powder Metallurgy Process,” Mater. Today Proc., vol. 5, no. 2, pp. 4615–4620, 2018, doi: https://doi.org/ 10.1016/j.matpr.2017.12.032.

S. S. Goswami and D. K. Behera, “Implementation of ENTROPY-ARAS decision making methodology in the selection of best engineering materials,” Mater. Today Proc., vol. 38, pp. 2256–2262, 2020, doi: https://doi.org/ 10.1016/j.matpr.2020.06.320.

M. Marzouk and E. M. Abdelakder, “On the use of multi-criteria decision making methods for minimizing environmental emissions in construction projects,” Decis. Sci. Lett., vol. 8, no. 4, pp. 373–392, 2019, doi: https://doi.org/ 10.5267/j.dsl.2019.6.002.

V. K. Koganti, N. Menikonda, S. P. Anbuudayasankar, T. Krishnaraj, R. K. Athhukuri, and M. S. Vastav, “GRAHP TOP model for supplier selection in Supply Chain: A hybrid MCDM approach,” Decis. Sci. Lett., vol. 8, no. 1, pp. 65–80, 2019, doi:https://doi.org/ 10.5267/j.dsl.2018.5.002.

B. Masoomi, I. G. Sahebi, M. Fathi, F. Yıldırım, and S. Ghorbani, “Strategic supplier selection for renewable energy supply chain under green capabilities (fuzzy BWM-WASPAS-COPRAS approach),” Energy Strateg. Rev., vol. 40, no. January, p. 100815, 2022, doi: https://doi.org/ 10.1016/j.esr.2022.100815.

J. Li, H. Fang, and W. Song, “Sustainable supplier selection based on SSCM practices: A rough cloud TOPSIS approach,” J. Clean. Prod., vol. 222, pp. 606–621, 2019, doi: https://doi.org/ 10.1016/j.jclepro.2019.03.070.

J. E. Leal, “AHP-express: A simplified version of the analytical hierarchy process method,” MethodsX, vol. 7, 2020, doi: https://doi.org/10.1016/j.mex.2019.11.021.

F. Ecer, “A consolidated MCDM framework for performance assessment of battery electric vehicles based on ranking strategies,” Renew. Sustain. Energy Rev., vol. 143, pp. 110916, 2021, doi: https://doi.org/10.1016/j.rser.2021.110916.

H. Hamria and A. Azwar, “Sistem Pendukung Keputusan Penilaian Kinerja Aparatur Desa Menggunakan Metode Additive Ratio Assessment (Aras) Pada Kantor Desa Kotaraja,” Simtek J. Sist. Inf. dan Tek. Komput., vol. 6, no. 1, pp. 61–69, 2021, doi: https://doi.org/10.51876/simtek.v6i1.96.

K. Yilmaz, E. Yüce, and A. Özdağoğlu, “An Integration of HF-AHP and ARAS Techniques in Supplier Selection: A Case Study in Waste Water Treatment Facility,” Dokuz Eylul Univ. Iktis. ve Idari Bilim. Derg., vol. 33, no. 2, pp. 477–497, 2019, doi: https://doi.org/10.24988/deuiibf.2018332744.

Y. K. Fu, “An integrated approach to catering supplier selection using AHP-ARAS-MCGP methodology,” J. Air Transp. Manag., vol. 75, no. November 2018, pp. 164–169, 2019, doi: https://doi.org/10.1016/j.jairtraman.2019.01.011.

A. A. Suryani and D. Ernawati, “Pemilihan Mitra Kerja Pemanfaatan Limbah Jonjot Menggunakan Metode Aras (Additive Ratio Assessment) Di Perum Xyz,” Juminten, vol. 1, no. 4, pp. 37–48, 2020, doi: https://doi.org/10.33005/juminten.v1i4.104.

S. S. Goswami and D. K. Behera, “Solving Material Handling Equipment Selection Problems in an Industry with the Help of Entropy Integrated COPRAS and ARAS MCDM techniques,” In Process Integr. Optim. Sustain., vol. 5, no. 4, pp. 947–973, 2021, doi: https://doi.org/10.1007/s41660-021-00192-5.

F. Abastante, S. Corrente, S. Greco, A. Ishizaka, and I. M. Lami, “A new parsimonious AHP methodology: Assigning priorities to many objects by comparing pairwise few reference objects,” Expert Syst. Appl., vol. 127, pp. 109–120, 2019, doi: https://doi.org/10.1016/j.eswa.2019.02.036.

T. Baroto and D. M. Utama, “Integrasi ahp dan saw untuk penyelesaian green supplier selection,” SENTRA Semin. Nas. Teknol. dan Rekayasa, pp. 38–44, 2020, doi : https://doi.org/10.22219/sentra.v0i6.3895.

B. Güneri and M. Deveci, “Evaluation of supplier selection in the defense industry using q-rung orthopair fuzzy set based EDAS approach,” Expert Syst. Appl., vol. 222, no. March, p. 119846, 2023, doi: https://doi.org/10.1016/j.eswa.2023.119846.

L. Coffey and D. Claudio, “In defense of group fuzzy AHP : A comparison of group fuzzy AHP and group AHP with confidence intervals,” Expert Syst. Appl., vol. 178, no. April, p. 114970, 2021, doi: https://doi.org/10.1016/j.eswa.2021.114970.

S. B. Tv, P. Iman, S. Putra, I. Husni, and A. Amin, “Implementasi Metode AHP Untuk Menentukan Pilihan,” vol. 16, no. 2, pp. 15–28, 2022, doi : https://doi.org/10.33365/jtk.v16i2.1564.

J. Simon, A. Adamu, A. Abdulkadir, and A. S. Henry, “Analytical Hierarchy Process (AHP) Model for Prioritizing Alternative Strategies for Malaria Control Analytical Hierarchy Process ( AHP ) Model for Prioritizing Alternative Strategies for Malaria Control,” 2019, doi: https://doi.org/10.9734/ajpas/2019/v5i130124.

K. Kraugusteeliana, A. Subagiyo, and F. Setyawan, “Pemilihan Jenis Obat Terbaik Untuk Gejala Batuk Remaja dengan Menggunakan Metode AHP dan ARAS,” JURIKOM (Jurnal Ris. Komputer), vol. 9, no. 6, pp. 2172, 2022, doi: https://doi.org/10.30865/jurikom.v9i6.5235.

E. Purba and H. T. Sihotang, “Decision Support System For Prospective Recipients Of The Healthy Indonesia Card (Kis) In The Village Of Bah Sidua Dua With The Analytical Hierarchy Process (AHP) Method,” J. Mantik, vol. 3, no. 3, pp. 82–90, 2019. Available at: http://iocscience.org/ejournal/index.php/mantik/article/view/320.

K. Xu and J. Xu, “A direct consistency test and improvement method for the analytic hierarchy process,” Fuzzy Optim. Decis. Mak., vol. 19, no. 3, pp. 359–388, 2020, doi: https://doi.org/10.1007/s10700-020-09323-y.

Y. Liu, C. M. Eckert, and C. Earl, “Expert Systems with Applications A review of fuzzy AHP methods for decision-making with subjective judgements,” Expert Syst. Appl., vol. 161, pp. 113738, 2020, doi: https://doi.org/ 10.1016/j.eswa.2020.113738.

B. Andika and R. Kustini, “Pemilihan Anggota Tim Sub Bagian Administrasi Ketarunaan Dan Alumni Menggunakan Metode ARAS,” vol. 2, pp. 209–218, 2023, doi : https://doi.org/10.53513/jursi.v2i2.5348.

H. Karimi and Z. Nikkhah-Farkhani, “Performance Appraisal of Knowledge Workers Using Augmented Additive Ratio Assessment (A-ARAS) Method: A Case Study,” IEEE Trans. Eng. Manag., vol. 69, no. 5, pp. 2285–2295, 2022, doi: https://doi.org/10.1109/TEM.2020.3009134.

J. Hutagalung, D. Nofriansyah, and M. A. Syahdian, “Penerimaan Bantuan Pangan Non Tunai (BPNT) Menggunakan Metode ARAS,” J. Media Inform. Budidarma, vol. 6, no. 1, p. 198, 2022, doi: https://doi.org/10.30865/mib.v6i1.3478.

M. Ghram and H. Frikha, “Multiple criteria hierarchy process within ARAS method,” 2019 6th Int. Conf. Control. Decis. Inf. Technol. CoDIT 2019, pp. 995–1000, 2019, doi: https://doi.org/10.1109/CoDIT.2019.8820401.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ja'iza Salsabila, Dira Ernawati

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)