Research on bearing fault diagnosis technology based on machine learning

DOI:

https://doi.org/10.12928/ijio.v5i1.8106Keywords:

Machine learning, Pattern recognition, Clustering algorithm, Python, Bearing failure parametersAbstract

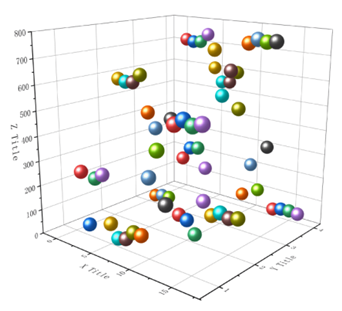

As industrial equipment complexity continues to rise, the importance of bearings within these systems has become more critical, given their pivotal role in equipment functionality. Bearing faults can result in severe production accidents and safety issues. Hence, there is an urgent need for advanced bearing fault diagnosis technology. This study concentrates on rolling bearings, analyzing their structural characteristics and key parameters to classify fault types—inner race faults, rolling element faults, and outer race faults. Utilizing a dataset of 80 sets of bearing factory data, time and frequency domain analyses are conducted, establishing seven feature parameters (five in the time domain and two in the frequency domain). This data is organized into a 7-dimensional matrix for subsequent analysis and model development. The K-Means algorithm is chosen for its effectiveness in automatically recognizing fault patterns in rolling bearings. Training on the 7-dimensional matrix identifies four clustering centers corresponding to normal conditions, inner race faults, rolling element faults, and outer race faults. The fault diagnosis system is implemented using Python, and algorithm optimization improves efficiency. The study concludes with insights drawn from the analysis and proposes optimization methods, which contributing to advancing bearing fault diagnosis technology, particularly addressing industrial equipment reliability and safety concerns.

References

P. Li, F. Kong, Q. He, and Y. Liu, “Multiscale slope feature extraction for rotating machinery fault diagnosis using wavelet analysis,” Measurement, 46(1), 497-505, 2013, doi: 10.1016/j.measurement.2012.08.007

H. Lin, Z. Xinyue, and L. Handong, “Bearing fault diagnosis based on BP neural network. In IOP Conference Series: Earth and Environmental Science, IOP Publishing, 208(1), p. 012092, 2018, doi: 10.1088/1755-1315/208/1/012092

Z. Chen, S. Deng, X. Chen, C. Li, R. V. Sanchez, and H. Qin, “Deep neural networks-based rolling bearing fault diagnosis,” Microelectronics Reliability, 75, 327-333, 2017, doi: 10.1016/j.microrel.2017.03.006

R. A. Makowski, and R. Zimroz, "Adaptive bearings vibration modelling for diagnosis." International Conference on Adaptive and Intelligent Systems. Berlin, Heidelberg: Springer Berlin Heidelberg, 2011, doi: 10.1007/978-3-642-23857-4_26

P. Borghesani, R. Ricci, S. Chatterton, and P. Pennacchi, "A new procedure for using envelope analysis for rolling element bearing diagnostics in variable operating conditions." Mechanical systems and signal processing 38.1, 2013: 23-35, doi: 10.1016/j.ymssp.2012.09.014

R. Jiao, S. Li, Z. Ding, L. Yang, and G. Wang, "Fault diagnosis of rolling bearing based on BP neural network with fractional order gradient descent." Journal of Vibration and Control,2023: 10775463231175267.doi: 10.1177/10775463231175267

S. Snehsheel, and S. K. Tiwari, "A novel feature extraction method based on weighted multi-scale fluctuation based dispersion entropy and its application to the condition monitoring of rotary machines." Mechanical Systems and Signal Processing 171, 2022: 108909. doi: 10.1016/j.ymssp.2022.108909

O. Janssens, V. Slavkovikj, B. Vervisch, K. Stockman, M. Loccufier, S. Verstockt, ... and S. V. Hoecke, "Convolutional neural network based fault detection for rotating machinery." Journal of Sound and Vibration 377, 2016: 331-345. doi: 10.1016/j.jsv.2016.05.027

R. Wang, Z. Feng, S. Huang, X. Fang, and J. Wang, "Research on voltage waveform fault detection of miniature vibration motor based on improved WP-LSTM." Micromachines 11.8, 2020: 753. doi: 10.3390/mi11080753

J. Hu, "Research on Rolling Bearing Defect Diagnosis Based on BP Neural Network."Huazhong University of Science and Technology,2006.

A. Karami, M. Guerrero-Zapata, "A fuzzy anomaly detection system based on hybrid PSO-Kmeans algorithm in content-centric networks." Neurocomputing 149, 2015: 1253-1269.doi: 10.1016/j.neucom.2014.08.070

H. Liu, X. Wang, and C. Lu, "Rolling bearing fault diagnosis under variable conditions using Hilbert-Huang transform and singular value decomposition." Mathematical Problems in Engineering 2014. doi: 10.1155/2014/765621

J. Wu, and G. R. Feng, "Intrusion detection based on simulated annealing and fuzzy c-means clustering." In 2009 International Conference on Multimedia Information Networking and Security. Vol. 2. IEEE, 2009. doi: 10.1109/MINES.2009.46

D. T. Hoang, and H. J. Kang, "A survey on deep learning based bearing fault diagnosis." Neurocomputing 335, 2019: 327-335. doi: 10.1016/j.neucom.2018.06.078

S. Zhang, S. Zhang, B. Wang, and T. G. Habetler, "Deep learning algorithms for bearing fault diagnostics—A comprehensive review." IEEE Access 8, 2020: 29857-29881. doi: 10.1109/ACCESS.2020.2972859

J. Zhang, S. Yi, L. Guo, H. l. Gao, X. Hong, and H. l. Song, "A new bearing fault diagnosis method based on modified convolutional neural networks." Chinese Journal of Aeronautics 33.2, 2020: 439-447. doi: 10.1016/j.cja.2019.07.011

H. Li, T. Liu, X. Wu, and Q. Chen, "An optimized VMD method and its applications in bearing fault diagnosis." Measurement 166, 2020: 108185. doi: 10.1016/j.measurement.2020.108185

X. Song, Y. Cong, Y. Song, Y. Chen, and P. Liang, "A bearing fault diagnosis model based on CNN with wide convolution kernels." Journal of Ambient Intelligence and HumanizedComputing 13.8, 2022: 4041-4056. doi: 10.1007/s12652-021-03177-x

X. Zhang, B. Zhao, and Y. Lin, "Machine learning based bearing fault diagnosis using thecase western reserve university data: a review." IEEE Access 9, 2021: 155598-155608. doi: 10.1109/ACCESS.2021.3128669

J. Wang, Z. Mo, H. Zhang, and Q. Miao, "A deep learning method for bearing fault diagnosis based on time-frequency image." IEEE Access 7, 2019: 42373-42383. doi: 10.1109/ACCESS.2019.2907131

H. Zhu, Z. He, J. Wei, J. Wang, and H. Zhou, "Bearing fault feature extraction and fault diagnosis method based on feature fusion." Sensors 21.7, 2021: 2524. doi: 10.3390/s21072524

Y. Xu, K. Zhang, C. Ma, L. Cui, and W. Tian, "Adaptive Kurtogram and its applications in rolling bearing fault diagnosis." Mechanical Systems and Signal Processing 130 (2019): 87-107. doi: 10.1016/j.ymssp.2019.05.003

J. Zhao, S. Yang, Q. Li, Y. Liu, X. Gu, and W. Liu, "A new bearing fault diagnosis method based on signal-to-image mapping and convolutional neural network." Measurement 176, 2021: 109088. doi: 10.1016/j.measurement.2021.109088

X. Li, W. Zhang, Q. Ding, and J. Q. Sun, "Multi-layer domain adaptation method for rolling bearing fault diagnosis." Signal processing 157, 2019: 180-197. doi: 10.1016/j.sigpro.2018.12.005

X. Chen, B. Zhang, and D. Gao, "Bearing fault diagnosis base on multi-scale CNN and LSTM model." Journal of Intelligent Manufacturing 32, 2021: 971-987. doi: 10.1007/s10845-020-01600-2

Z. Zhu, G. Peng, Y. Chen, and H. Gao, "A convolutional neural network based on a capsule network with strong generalization for bearing fault diagnosis." Neurocomputing 323, 2019: 62-75. doi: 10.1016/j.neucom.2018.09.050

Z. Wu, H. Jiang, K. Zhao, and X. Li, "An adaptive deep transfer learning method for bearing fault diagnosis." Measurement 151, 2020: 107227. doi: 10.1016/j.measurement.2019.107227

J. Zhu, N. Chen, and C. Shen, "A new deep transfer learning method for bearing fault diagnosis under different working conditions." IEEE Sensors Journal 20.15, 2019: 8394-8402. doi: 10.1109/JSEN.2019.2936932

X. Li, W. Zhang, and Q. Ding, "Understanding and improving deep learning-based rolling bearing fault diagnosis with attention mechanism." Signal processing 161, 2019: 136-154. doi: 10.1016/j.sigpro.2019.03.019

H. Wang, J. Xu, R. Yan, and R. X. Gao, "A new intelligent bearing fault diagnosis method using SDP representation and SE-CNN." IEEE Transactions on Instrumentation and Measurement 69.5, 2019: 2377-2389. doi: 10.1109/TIM.2019.2956332

K. Zhang, Y. Xu, Z. Liao, L. Song, and P. Chen, "A novel Fast Entrogram and its applications in rolling bearing fault diagnosis." Mechanical Systems and Signal Processing 154, 2021: 107582. doi: 10.1016/j.ymssp.2020.107582

D. T. Hoang, and H. J. Kang, "Rolling element bearing fault diagnosis using convolutional neural network and vibration image." Cognitive Systems Research 53, 2019: 42-50. doi: 10.1016/j.cogsys.2018.03.002

B. Muruganatham, M. A. Sanjith, B. Krishnakumar, and S. S. Murty, "Roller element bearing fault diagnosis using singular spectrum analysis." Mechanical systems and signal processing 35.1-2 ,2013: 150-166. doi: 10.1016/j.ymssp.2012.08.019

Y. Chen, G. Peng, C. Xie, W. Zhang, C. Li, and S. Liu, "ACDIN: Bridging the gap between artificial and real bearing damages for bearing fault diagnosis." Neurocomputing 294, 2018: 61-71. doi: 10.1016/j.neucom.2018.03.014

A. Zhang, S. Li, Y. Cui, W. Yang, R. Dong, and J. Hu, "Limited data rolling bearing fault diagnosis with few-shot learning." IEEE Access 7, 2019: 110895-110904. doi: 10.1109/ACCESS.2019.2934233

W. Zhang, C. Li, G. Peng, Y. Chen, and Z. Zhang, "A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load." Mechanical systems and signal processing 100, 2018: 439-453. doi: 10.1016/j.ymssp.2017.06.022

Y. Zhang, K. Xing, R. Bai, D. Sun, and Z. Meng, "An enhanced convolutional neural network for bearing fault diagnosis based on time–frequency image." Measurement 157, 2020: 107667. doi: 10.1016/j.measurement.2020.107667

L. Eren, T. Ince, and S. Kiranyaz, "A generic intelligent bearing fault diagnosis system using compact adaptive 1D CNN classifier." Journal of Signal Processing Systems 91, 2019: 179-189. doi: 10.1007/s11265-018-1378-3

Y. Sun, and S. Li, "Bearing fault diagnosis based on optimal convolution neural network." Measurement 190, 2022: 110702. doi: 10.1016/j.measurement.2022.110702

W. Huang, J. Cheng, Y. Yang, and G. Guo, "An improved deep convolutional neural network with multi-scale information for bearing fault diagnosis." Neurocomputing 359, 2019: 77-92. doi: 10.1016/j.neucom.2019.05.052

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Yu Xia, XiaoJun Guo, ErChuan Su, LingPei Kong

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)