Dynamic small-series fashion order allocation and supplier selection: a ga-topsis-based model

DOI:

https://doi.org/10.12928/ijio.v4i2.7640Keywords:

Multi criteria decision making, Genetic Algorithm, TOPSIS, Supplier Selection, pareto frontAbstract

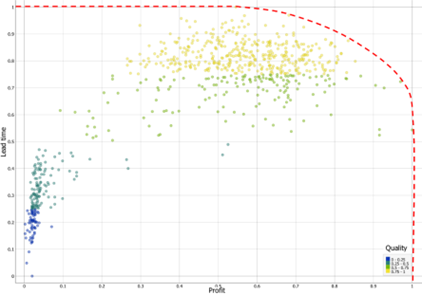

The fashion industry is currently confronted with significant economic and environmental challenges, necessitating the exploration of novel business models. Among the promising approaches is small series production on demand, though this poses considerable complexities in the highly competitive sector. Traditional supplier selection and production planning processes, known for their lengthy and intricate nature, must be replaced with more dynamic and effective decision-making procedures. To tackle this problem, GA-TOPSIS hybrid model is proposed as the methodology. The model integrates Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) evaluation into the fitness function of Genetic Algorithm (GA) to comprehensively consider both qualitative and quantitative criteria for supplier selection. Simultaneously, GA efficiently optimizes the order sequence for production planning. The model's efficacy is demonstrated through implementation on real orders, showcasing its ability to handle diverse evaluation criteria and support supplier selection in different scenarios. Moreover, the proposed model is employed to compute the Pareto front, which provides optimal sets of solutions for the given objective criteria. This allows for an effective demand-driven strategy, particularly relevant for fashion retailers to select supplier and order planning optimization decisions in dynamic and multi-criteria context. Overall, GA-TOPSIS hybrid model offers an innovative and efficient decision support system for fashion retailers to adapt to changing demands and achieve effective supplier selection and production planning optimization. The model's incorporation of both qualitative and quantitative criteria in a dynamic environment contributes to its originality and potential for addressing the complexities of the fashion industry's supply chain challenges

References

D. A. Serel, “Intelligent procurement systems to support fast fashion supply chains in the apparel industry,” in Information Systems for the Fashion and Apparel Industry, Elsevier, 2016, pp. 121–144, doi : https://doi.org/10.1016/B978-0-08-100571-2.00007-5.

Y. Liang, S.-H. Lee, and J. E. Workman, “Implementation of Artificial Intelligence in Fashion: Are Consumers Ready?,” Cloth. Tex. Res. J., vol. 38 no. 1, pp. 3-18, 2020, doi : https://doi.org/10.1177/0887302X19873437.

A. Ait-Alla, M. Teucke, M. Lütjen, S. Beheshti-Kashi, and H. R. Karimi, “Robust Production Planning in Fashion Apparel Industry under Demand Uncertainty via Conditional Value at Risk,” Math. Probl. Eng., vol. 2014, pp. 1–10, Apr. 2014, doi : https://doi.org/10.1155/2014/901861.

J. W. M. Betrand and H. P. G. van Ooijen, “Optimal work order release for make-to-order job shops with customer order lead-time costs, tardiness costs and work-in-process costs,” Int. J. Prod. Econ., vol. 116, no. 2, pp. 233–241, Dec. 2008, doi : https://doi.org/10.1016/j.ijpe.2008.08.055.

W. K. Wong, S. Y. S. Leung, Z. X. Guo, Z. H. Zeng, and P. Y. Mok, “Intelligent apparel product cross-selling using radio frequency identification (RFID) technology for fashion retailing,” in Fashion Supply Chain Management Using Radio Frequency Identification (RFID) Technologies, Elsevier, 2014, pp. 159–186. doi : https://doi.org/10.1533/9780857098115.159.

T. Wu, L. Shi, J. Geunes, and K. Akartunalı, “An optimization framework for solving capacitated multi-level lot-sizing problems with backlogging,” Eur. J. Oper. Res., vol. 214, no. 2, pp. 428–441, Oct. 2011, doi : https://doi.org/10.1016/j.ejor.2011.04.029.

C. Bai, Q. Zhu and J. Sarkis, “Supplier portfolio selection and order allocation under carbon neutrality: Introducing a “Cool”ing model”, Comput. Ind. Eng., vol. 170, 2022, doi : https://doi.org/10.1016/j.cie.2022.108335

Z.S. Hosseini, S. Douwe Flapper and M. Pirayesh, “Sustainable supplier selection and order allocation under demand, supplier availability and supplier grading uncertainties”, Comput. Ind. Eng., vol. 165, 2022, https://doi.org/10.1016/j.cie.2021.107811

J. Feng and Z. Gong, “Integrated linguistic entropy weight method and multi-objective programming model for supplier selection and order allocation in a circular economy: A case study”, J. Clean. Prod., vol. 277, 2020, doi: https://doi.org/10.1016/j.jclepro.2020.122597

Z. X. Guo, E. W. T. Ngai, C. Yang, and X. Liang, “An RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment”, Int. J. Prod. Econ., vol. 159, pp. 16–28, Jan 2015, doi : https://doi.org/10.1016/j.ijpe.2014.09.004.

S. Islam, S.H. Amin and L.J. Wardley, “Supplier selection and order allocation planning using predictive analytics and multi-objective programming”, Comput. Ind. Eng., vol. 174, 2022, doi: https://doi.org/10.1016/j.cie.2022.108825

S.Islam, S.H. Amin, L.J. Wardley, “Machine learning and optimization models for supplier selection and order allocation planning”, Int. J. Prod. Eco., vol. 242, 2021, doi : https://doi.org/10.1016/j.ijpe.2021.108315

C. A. Coello Coello, “Evolutionary multi-objective optimization: A historical view of the field,” IEEE Comput. Intell. Mag., vol. 1, no. 1, pp. 28–36, Feb. 2006. doi: https://doi.org/10.1109/MCI.2006.1597059.

C. H. Lin and C. C. Chuang, “A rough set penalty function for marriage selection in multiple-evaluation genetic algorithms,” in Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics), vol. 4481 LNAI, pp. 500–507,2007. https://doi.org/10.1007/978-3-540-72458-2_62.

F. Rosso, V. Ciancio, J. Dell’Olmo, and F. Salata, “Multi-objective optimization of building retrofit in the Mediterranean climate by means of genetic algorithm application”, Energ. Buildings, vol. 216, 2020, doi : https://doi.org/10.1016/j.enbuild.2020.109945.

B. Ombuki, B. Ross, F. H.-A. Intelligence, and undefined 2006, “Multi-objectives genetic algorithms for vehicle routing problem with time windows,” Appl. Intell., vol. 24, pp.17–30, 2006, doi : https://doi.org/10.1007/s10489-006-6926-z.

H. S. Kilic, “An integrated approach for supplier selection in multi-item/multi-supplier environment,” Appl. Math. Model., vol. 37, no. 14–15, pp. 7752–7763, Aug. 2013, doi : https://doi.org/10.1016/j.apm.2013.03.010.

P. Ávila, A. Mota, A. Pires, J. Bastos, G. Putnik, and J. Teixeira, “Supplier’s Selection Model based on an Empirical Study,” Procedia Technol., vol. 5, pp. 625–634, Jan. 2012, doi : https://doi.org/10.1016/j.protcy.2012.09.069.

G. W. Dickson, “An Analysis Of Vendor Selection Systems And Decisions,” J. Purch., vol. 2, no. 1, pp. 5–17, Feb. 1966, doi : https://doi.org/10.1111/j.1745-493X.1966.tb00818.x.

E. E. Karsak and M. Dursun, “An integrated fuzzy MCDM approach for supplier evaluation and selection,” Comput. Ind. Eng., vol. 82, pp. 82–93, 2015, doi : https://doi.org/10.1016/j.cie.2015.01.019.

S. Hamdan and A. Cheaitou, “Supplier selection and order allocation with green criteria: An MCDM and multi-objective optimization approach,” Comput. Oper. Res., vol. 81, pp. 282–304, May 2017, doi : https://doi.org/10.1016/j.cor.2016.11.005.

S. Y. Chou and Y. H. Chang, “A decision support system for supplier selection based on a strategy-aligned fuzzy SMART approach,” Expert Syst. Appl., vol. 34, no. 4, pp. 2241–2253, May 2008, doi : https://doi.org/10.1016/j.eswa.2007.03.001.

C. Bai, S. Kusi-Sarpong, H. Badri Ahmadi, and J. Sarkis, “Social sustainable supplier evaluation and selection: a group decision-support approach,” Int. J. Prod. Res., vol. 57, no. 22, pp. 7046–7067, Nov. 2019, doi : https://doi.org/10.1080/00207543.2019.1574042.

N. Harale, S. Thomassey, and X. Zeng, “Small Series Fashion Supplier Selection Using MCDM Methods,” Contrib. to Manag. Sci., pp. 203–224, Jun. 2019. https://doi.org/10.1016/j.ijpe.2018.11.018

A. Y. Adhami, S. M. Muneeb, and M. A. Nomani, “A multi-level decision making model for the supplier selection problem in a fuzzy situation,” Oper. Res. Decis., vol. 27, no. 4, pp. 5–26, 2017, doi : https://doi.org/10.5277/ord170401.

C. K. Kwong, W. H. Ip, and J. W. K. Chan, “Combining scoring method and fuzzy expert systems approach to supplier assessment: A case study,” Integr. Manuf. Syst., vol. 13, no. 7, pp. 512–519, 2002, doi : https://doi.org/10.1108/09576060210442671.

A. Shemshadi, H. Shirazi, M. Toreihi, and M. J. Tarokh, “A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting,” Expert Syst. Appl., vol. 38, no. 10, pp. 12160–12167, Sep. 2011 doi : https://doi.org/10.1016/j.eswa.2011.03.027.

M. S. Memon, Y. H. Lee, and S. I. Mari, “Group multi-criteria supplier selection using combined grey systems theory and uncertainty theory,” Expert Syst. Appl., vol. 42, no. 21, pp. 7951–7959, Nov. 2015, doi : https://doi.org/10.1016/j.eswa.2015.06.018.

G. Bruno, E. Esposito, A. Genovese, and M. Simpson, “Applying supplier selection methodologies in a multi-stakeholder environment: A case study and a critical assessment,” Expert Syst. Appl., vol. 43, pp. 271–285, Jan. 2016, doi : https://doi.org/10.1016/j.eswa.2015.07.016.

D. Kannan, A. B. L. De Sousa Jabbour, and C. J. C. Jabbour, “Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company,” Eur. J. Oper. Res., vol. 233, no. 2, pp. 432–447, Mar. 2014, doi : https://doi.org/10.1016/j.ejor.2013.07.023.

M. Tavana, A. Fallahpour, D. Di Caprio, and F. J. Santos-Arteaga, “A hybrid intelligent fuzzy predictive model with simulation for supplier evaluation and selection,” Expert Syst. Appl., vol. 61, pp. 129-144, 2016, doi : https://doi.org/10.1016/j.eswa.2016.05.027.

G. Büyüközkan and G. Ifi, “A novel hybrid MCDM approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy TOPSIS to evaluate green suppliers,” Expert Syst. Appl., vol. 39, no. 3, pp. 3000–3011, Feb. 2012, doi : https://doi.org/10.1016/j.eswa.2011.08.162.

M.R. Galankashi, A. Chegeni, A. Soleimanynanadegany, A. Memari, A. Anjomshoae, S.A. Helmi, and A. Dargi, “Prioritizing Green Supplier Selection Criteria Using Fuzzy Analytical Network Process,” Procedia CIRP, vol. 26, pp. 689–694, Jan. 2015, doi : https://doi.org/10.1016/j.procir.2014.07.044.

A. Amindoust, S. Ahmed, A. Saghafinia, and A. Bahreininejad, “Sustainable supplier selection: A ranking model based on fuzzy inference system,” Appl. Soft Comput., vol. 12, no. 6, pp. 1668–1677, Jun. 2012, doi : https://doi.org/10.1016/j.asoc.2012.01.023.

D. Kannan, K. Govindan, and S. Rajendran, “Fuzzy Axiomatic Design approach based green supplier selection: a case study from Singapore,” J. Clean. Prod., vol. 96, pp. 194–208, Jun. 2015, doi : https://doi.org/10.1016/j.jclepro.2013.12.076.

B. M. dos Santos, L. P. Godoy, and L. M. S. Campos, “Performance evaluation of green suppliers using entropy-TOPSIS-F,” J. Clean. Prod., vol. 207, pp. 498–509, Jan. 2019, doi : https://doi.org/10.1016/j.jclepro.2018.09.235.

I. Dobos and G. Vörösmarty, “Green supplier selection and evaluation using DEA-type composite indicators,” Int. J. Prod. Econ., vol. 157, no. 1, pp. 273–278, Nov. 2014, doi : https://doi.org/10.1016/j.ijpe.2014.09.026.

M. Keshavarz Ghorabaee, M. Amiri, J. Salehi Sadaghiani, and G. Hassani Goodarzi, “Multiple criteria group decision-making for supplier selection based on COPRAS method with interval type-2 fuzzy sets,” Int. J. Adv. Manuf. Technol., vol. 75, no. 5–8, pp. 1115–1130, Oct. 2014, doi : https://doi.org/10.1007/s00170-014-6142-7.

Z. H. Che, “A multi-objective optimization algorithm for solving the supplier selection problem with assembly sequence planning and assembly line balancing,” Comput. Ind. Eng., vol. 105, pp. 247–259, Mar. 2017, doi : https://doi.org/10.1016/j.cie.2016.12.036.

N. Hashmi, S. A. Jalil, and S. Javaid, “Carbon footprint based multi-objective supplier selection problem with uncertain parameters and fuzzy linguistic preferences,” Sustain. Oper. Comput., vol. 2, pp. 20–29, Jan. 2021, doi : https://doi.org/10.1016/j.susoc.2021.03.001.

F. Faez, S. H. Ghodsypour, and C. O’Brien, “Vendor selection and order allocation using an integrated fuzzy case-based reasoning and mathematical programming model,” Int. J. Prod. Econ., vol. 121, no. 2, pp. 395–408, Oct. 2009, doi : https://doi.org/10.1016/j.ijpe.2006.11.022.

A. Fallahpour, E. U. Olugu, S. N. Musa, D. Khezrimotlagh, and K. Y. Wong, “An integrated model for green supplier selection under fuzzy environment: application of data envelopment analysis and genetic programming approach,” Neural Comput. Appl., vol. 27, no. 3, pp. 707–725, Apr. 2016, doi : https://doi.org/10.1007/s00521-015-1890-3.

F. Faez, S. H. Ghodsypour, and C. O’Brien, “Vendor selection and order allocation using an integrated fuzzy case-based reasoning and mathematical programming model,” Int. J. Prod. Econ., vol. 121, no. 2, pp. 395–408, Oct. 2009, doi : https://doi.org/10.1016/j.ijpe.2006.11.022.

W. Xia and Z. Wu, “Supplier selection with multiple criteria in volume discount environments,” Omega, vol. 35, no. 5, pp. 494–504, Oct. 2007, doi : https://doi.org/10.1016/j.omega.2005.09.002.

E. A. Demirtas and Ö. Üstün, “An integrated multiobjective decision making process for supplier selection and order allocation,” Omega, vol. 36, no. 1, pp. 76–90, Feb. 2008, doi : https://doi.org/10.1016/j.omega.2005.11.003.

S. A. S. Haeri and J. Rezaei, “A grey-based green supplier selection model for uncertain environments,” J. Clean. Prod., vol. 221, pp. 768–784, Jun. 2019, doi : https://doi.org/10.1016/j.jclepro.2019.02.193.

M. Ghorbani, S.M. Arabzad and M. Bahrami, “Implementing Shannon entropy, SWOT and mathematical programming for supplier selection and order allocation”, Int. J. Sup. Chain. Mgt, vol. 1, no. 1, June 2012, doi: https://doi.org/10.1504/IJSCM.2012.046224.

A. H. I. Lee, H. Y. Kang, and C. Ter Chang, “Fuzzy multiple goal programming applied to TFT-LCD supplier selection by downstream manufacturers,” Expert Syst. Appl., vol. 36, no. 3, pp. 6318–6325, Apr. 2009, doi : https://doi.org/10.1016/j.eswa.2008.08.044.

S. Perçin, “An application of the integrated AHP-PGP model in supplier selection,” Meas. Bus. Excell., vol. 10, no. 4, pp. 34–49, 2006, doi : https://doi.org/10.1108/13683040610719263.

B. D. Rouyendegh (Babek Erdebilli) and T. E. Saputro, “Supplier Selection Using Integrated Fuzzy TOPSIS and MCGP: A Case Study,” Procedia - Soc. Behav. Sci., vol. 116, pp. 3957–3970, Feb. 2014, doi : https://doi.org/10.1016/j.sbspro.2014.01.874.

M. A. Sodenkamp, M. Tavana, and D. Di Caprio, “Modeling synergies in multi-criteria supplier selection and order allocation: An application to commodity trading,” Eur. J. Oper. Res., vol. 254, no. 3, pp. 859–874, Nov. 2016, doi : https://doi.org/10.1016/j.ejor.2016.04.015.

W. Y. Wu, B. M. Sukoco, C. Y. Li, and S. H. Chen, “An integrated multi-objective decision-making process for supplier selection with bundling problem,” Expert Syst. Appl., vol. 36, no. 2, pp. 2327–2337, 2009, doi : https://doi.org/10.1016/j.eswa.2007.12.022.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nitin Harale, Sébastien Thomassey, Xianyi Zeng

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)