Experimental design of steel bearings and ceramic bearings to find efficient energy consumption

DOI:

https://doi.org/10.12928/ijio.v4i2.7137Keywords:

bearing, ceramic, steel, electric motor, energy consumptionAbstract

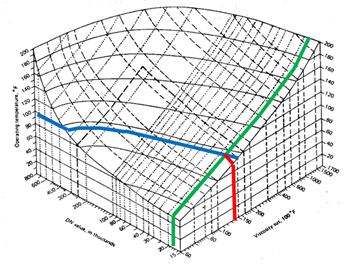

A bearing is a vital machine component that supports shafts, enabling smooth rotation and minimizing friction. The level of friction is determined by the coefficient of friction, which varies based on the bearing material. In this study, we evaluated two types of bearings: steel and ceramic, with the aim of identifying the one with the lowest frictional force and, consequently, the least input power required. To conduct a comprehensive comparison, we performed comparative tests on the Nogogeni Evo V vehicle, analyzing the energy consumption impact of both steel and ceramic bearings. The tests involved measuring the input power of each bearing type at various throttle openings, ranging from 10% to 100%. The results revealed that ceramic bearings exhibited superior energy efficiency compared to their steel counterparts. At all throttle openings, the ceramic bearings consistently demanded lower input power, indicating their higher efficiency. For instance, at 100% throttle opening, the input power for steel bearings was 17,939 watts, while ceramic bearings required only 17,290 watts, representing a 3.6% reduction. Moreover, ceramic bearings achieved higher rotation speeds, with the ceramic bearing rotating at 598 rpm, a 3.5% increase compared to the steel bearing's 577 rpm. Based on these findings, it can be concluded that the implementation of ceramic bearings would significantly enhance the energy efficiency of the Mobil Nogogeni Evo V electric motor. Therefore, for improved performance and reduced energy consumption, we recommend the incorporation of ceramic bearings in the vehicle's design.

References

S. Pan, D. Wang, and W. Huang, “A novel small motor measurement system based on ultrasonic bearings,” Meas., vol. 168, Aug 2020, doi: https://doi.org/10.1016/j.measurement.2020.108307.

B. K. Ginty, “Bearing materials for small electric motors,” Tribol. Int., vol. 15, no. 2, pp. 85–88, 1982, doi: https://doi.org/10.1016/0301-679X(82)90057-3.

W. Liu, “The prevalent motor bearing premature failures due to the high frequency electric current passage,” Eng. Fail. Anal., vol. 45, pp. 118–127, 2014, doi: https://doi.org/10.1016/j.engfailanal.2014.06.021.

M. Herrmann, Ceramic Bearings and Seals, Second Edi. Elsevier Inc., 2013, doi: https://doi.org/10.1016/B978-0-12-385469-8.00017-4.

J. Oliver, G. Guerrero, and J. Goldman, “Ceramic bearings for electric motors,” in IEEE Cement Industry Technical Conference (Paper), pp. 1–11, 2015, doi: 10.1109/CITCON.2015.7122604.

A. Gabelli and G. E. Morales-Espejel, “A model for hybrid bearing life with surface and subsurface survival,” Wear., vol. 422–423, pp. 223–234, 2019, doi: https://doi.org/10.1016/j.wear.2019.01.050.

M. N. A. Rahman, N. S. M. Zubir, R. A. C. Leuveano, J. A. Ghani, and W. M. F. Wan Mahmood, “Reliability study of solder paste alloy for the improvement of solder joint at surface mount fine-pitch components,” Materials, vol. 7, no. 12, pp. 7706–7721, 2014, doi: https://doi.org/10.3390/ma7127706

M. A. Hannan, M. M. Hoque, A. Mohamed, and A. Ayob, “Review of energy storage systems for electric vehicle applications: Issues and challenges,” Renew. Sustain. Energy Rev., vol. 69, pp. 771–789, 2017, doi: https://doi.org/10.1016/j.rser.2016.11.171.

H. K. D. H. Bhadeshia, “Steels for bearings,” Prog. Mater. Sci., vol. 57, no. 2, pp. 268–435, 2012, doi: https://doi.org/10.1016/j.pmatsci.2011.06.002.

A. Hermawan, I. B. Rahardja, M. Y. Syam, H. Sukismo, and N. Patah, “Analysis of Viscosity of Lubricating Oil on Generator Machine Working Hours at KP. Macan Tutul 4203,” J. Appl. Sci. Adv. Technol., vol. 1, no. 3, pp. 69–74, 2019, [Online]. Available: https://jurnal.umj.ac.id/index.php/JASAT/article/view/4312/3086

A. Xu, P. Tian, H. Li, S. Wen, and Y. Tian, “Extreme pressure lubrication between ceramic and bearing steel with liquid metal,” Tribol. Int., vol. 174, no. July, p. 107797, 2022, doi: https://doi.org/10.1016/j.triboint.2022.107797.

H. K. Danielsen et al., “Accelerated White Etch Cracking (WEC) FE8 type tests of different bearing steels using ceramic rollers,” Wear, vol. 494–495, 2022, doi: https://doi.org/10.1016/j.wear.2021.204230.

M. V. Khaire, “Electrical vehicles’ bearings: technological impact, applications and requirements,” Int. J. Elect. and Hybrid Veh., vol. 10, no. 4, 2018, doi: https://doi.org/10.1504/IJEHV.2018.098093.

S. Rachev, D. Stefanov, L. Dimitrov, and D. Koeva, “Evaluation of Electric Power Losses of an Induction Motor Driving a Compact Electric Vehicle at Change of Parameters and Loads,” Electric Vehicles International Conference & Show, 2019, doi: 10.1109/EVICS.2019.8784156.

V. Migal, A. Lebedev, M. Shuliak, E. Kalinin, S. Arhun, and V. Korohodskyi, “Reducing the vibration of bearing units of electric vehicle asynchronous traction motors,” J. of Vib. and Control, Vol 1-9, 2020 doi: https://doi.org/10.1177/1077546320937634

F. D. Pero, M. Delogu, and M. Pierini, “Life cycle assessment in the automotive sector: a comparative case study of internal combustion engine and electric car”, in AIAS 2018 International Conference on Stress Analysis, Procedia Struct. Integr., vol. 12, pp. 521-537, 2018, doi: https://doi.org/10.1016/j.prostr.2018.11.073.

N. O. Kapustin and D. A. Grushevenko, “Long-term electrical vehicles outlook and their potential impact on electric grid, Energy policy, vol. 137, 2020, doi: https://doi.org/10.1016/j.enpol.2019.111103

K. Holmberg and A. Erdemir, “The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars,” Tribol. Int., vol. 135, pp. 389-396, 2019, doi: https://doi.org/10.1016/j.triboint.2019.02.039.

A. Pandey, S. Manocha, and P. Saini, "A study on an automobile revolution and future of electric cars in India," Int. J. Manage., vol. 11, no. 3, pp. 107–113, 2020, doi: 10.34218/IJM.11.3.2020.013.

L. I. Farfan-Cabrera, “Tribology of electric vehicles: A review of critical components, current state and future improvement trends,” Tribol. Int., vol. 138, pp. 473–486, 2019, doi: https://doi.org/10.1016/j.triboint.2019.06.029.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Suhariyanto Suhariyanto, Heru Mirmanto, Azlan Arifin Khan , Rohmadoni Rohmadoni

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)