Analysis of the effect of temperature and raw material mixes on the pyrolysis process with single retort-rocket stove technology on the characteristics of sawdust charcoal briquettes

DOI:

https://doi.org/10.12928/ijio.v4i1.6688Keywords:

Charcoal Briquette, Pyrolysis, Sawdust, Single retort rocket stoveAbstract

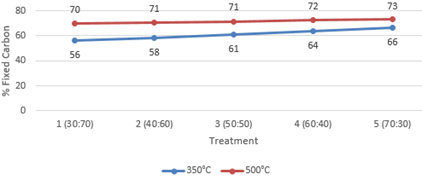

Government-subsidized LPG gas as household fuel for the poor is increasingly scarce. The discourse to return to using traditional fuels emerged because one of the biomass wastes, namely wood processing in the form of sawdust produced by small and medium industries, can be used to replace LPG gas. This study aims to determine the effect of peak temperature and sawdust mixture on making charcoal briquettes with Single Retort-Rocket Stove Pyrolysis Technology. This technology is one of the alternative pyrolysis technology used for self-heating. This technology is cleaner because the smoke can help speed up combustion to be more energy-efficient. The Rocket Stove system allows spreading of heat from the bottom to the top of the reactor. The raw material for use from Mahogany and Sonokeling Sawdust. Both types of sawdust combine with different ratios. Completely Randomized Design (CRD) non-factorial methods showed that all treatments, namely the ratio of sawdust mixtures and the temperature settings used, greatly influenced the proximate value obtained, where all experiments were very significantly different because Fcalculate > Ftable (0.05). The best briquette proximate results were found in an optimum mixture of rosewood and mahogany with a ratio of 70:30 at 350°C with a setting time of 1 hour, which is close to the SNI 01-6235 standard, with respective characteristic values, namely: 5.5% moisture content; ash content 5.3%; bonded carbon 66.2%; volatile matter content of 22.8% and a caloric value of 6470 cal/gr.

References

H. Gil, A. Ortega, and J. Pérez, “Mechanical behavior of mortar reinforced with sawdust waste,” Procedia Eng., vol. 200, pp. 325–332, 2017, doi: https://doi.org/10.1016/j.proeng.2017.07.046.

M. M. Manyuchi, C. Mbohwa, and E. Muzenda, “Value addition of coal fines and sawdust to briquettes using molasses as a binder,” South African J. Chem. Eng., vol. 26, pp. 70–73, 2018, doi: https://doi.org/10.1016/j.sajce.2018.09.004.

Z. Liu et al., “Effects of temperature and low-concentration oxygen on pine wood sawdust briquettes pyrolysis: Gas yields and biochar briquettes physical properties,” Fuel Process. Technol., vol. 177, pp. 228–236, 2018, doi: https://doi.org/10.1016/j.fuproc.2018.05.001.

B. Lela, M. Barišić, and S. Nižetić, “Cardboard/sawdust briquettes as biomass fuel: Physical–mechanical and thermal characteristics,” Waste Manag., vol. 47, pp. 236–245, 2016, doi: https://doi.org/10.1016/j.wasman.2015.10.035.

M. Thabuot, T. Pagketanang, K. Panyacharoen, P. Mongkut, and P. Wongwicha, “Effect of Applied Pressure and Binder Proportion on the Fuel Properties of Holey Bio-Briquettes,” Energy Procedia, vol. 79, pp. 890–895, 2015, doi: https://doi.org/10.1016/j.egypro.2015.11.583.

C. Antwi-Boasiako and B. B. Acheampong, “Strength properties and calorific values of sawdust-briquettes as wood-residue energy generation source from tropical hardwoods of different densities,” Biomass and Bioenergy, vol. 85, pp. 144–152, 2016, doi: https://doi.org/10.1016/j.biombioe.2015.12.006.

N. Kongprasert, P. Wangphanich, and A. Jutilarptavorn, “Charcoal Briquettes from Madan Wood Waste as an Alternative Energy in Thailand,” Procedia Manuf., vol. 30, pp. 128–135, 2019, doi: https://doi.org/10.1016/j.promfg.2019.02.019.

S. Wu, S. Zhang, C. Wang, C. Mu, and X. Huang, “High-strength charcoal briquette preparation from hydrothermal pretreated biomass wastes,” Fuel Process. Technol., vol. 171, pp. 293–300, 2018, doi: https://doi.org/10.1016/j.fuproc.2017.11.025.

S. Steve, “Multiple Household Fuel Use: a Balanced Choice Between Firewood, Charcoal and LPG, Berlin Germany,” no. February 2014, 2014.

D. K. Okot, P. E. Bilsborrow, and A. N. Phan, “Briquetting characteristics of bean straw-maize cob blend,” Biomass and Bioenergy, vol. 126, pp. 150–158, 2019, doi: https://doi.org/10.1016/j.biombioe.2019.05.009.

T. Rajaseenivasan, V. Srinivasan, G. Syed Mohamed Qadir, and K. Srithar, “An investigation on the performance of sawdust briquette blending with neem powder,” Alexandria Eng. J., vol. 55, no. 3, pp. 2833–2838, 2016, doi: https://doi.org/10.1016/j.aej.2016.07.009.

Z. Liu, F. Zhang, H. Liu, F. Ba, S. Yan, and J. Hu, “Pyrolysis/gasification of pine sawdust biomass briquettes under carbon dioxide atmosphere: Study on carbon dioxide reduction (utilization) and biochar briquettes physicochemical properties,” Bioresour. Technol., vol. 249, pp. 983–991, 2018, doi: https://doi.org/10.1016/j.biortech.2017.11.012.

R. J. Sari et al., “Pemanfaatan Limbah Serbuk Kayu dalam Peningkatan Ekonomi Masyarakat Dusun Wonosari Desa Sambireme Kecamatan Kalijambe,” pp. 281–295, 2022.

T. Tantiwatthanaphanich and X. Zou, “Empowering The Local Community Via Biomass Utilization: A Case Study In Thailand,” Int. Rev. Spat. Plan. Sustain. Dev., vol. 4, no. 2, pp. 30–45, 2016, doi: 10.14246/irspsd.4.2_30.

D. Marsetiya Utama, “An Effective Hybrid Sine Cosine Algorithm to Minimize Carbon Emission on Flow-shop Scheduling Sequence Dependent Setup,” J. Tek. Ind., vol. 20, no. 1, pp. 62–72, 2019, doi: 10.22219/jtiumm.vol20.no1.62-72.

S. Mansyur, “Multiple Regression Analysis on Influence Factors of Household Cooking Fuels in Indonesia,” Conserv. J. Energy Environ. Stud., vol. 1, no. 1, pp. 9–19, 2017, doi: 10.30588/cjees.v1i1.249.

S. Mansyur, Black Gold : Bisnis dan Teknologi Pembuatan Produk Briket Arang dan Turunannya, 2nd ed. Yogyakarta: Graha Ilmu, 2019.

H. Cai et al., “Thermal degradations and processes of waste tea and tea leaves via TG-FTIR: Combustion performances, kinetics, thermodynamics, products and optimization,” Bioresour. Technol., vol. 268, pp. 715–725, 2018, doi: https://doi.org/10.1016/j.biortech.2018.08.068.

D. Czajczyńska et al., “Potential of pyrolysis processes in the waste management sector,” Therm. Sci. Eng. Prog., vol. 3, pp. 171–197, 2017, doi: https://doi.org/10.1016/j.tsep.2017.06.003.

R. Soysa, Y. S. Choi, S. J. Kim, and S. K. Choi, “Fast pyrolysis characteristics and kinetic study of Ceylon tea waste,” Int. J. Hydrogen Energy, vol. 41, no. 37, pp. 16436–16443, 2016, doi: https://doi.org/10.1016/j.ijhydene.2016.04.066.

U. B. Deshannavar, P. G. Hegde, Z. Dhalayat, V. Patil, and S. Gavas, “Production and characterization of agro-based briquettes and estimation of calorific value by regression analysis: An energy application,” Mater. Sci. Energy Technol., vol. 1, no. 2, pp. 175–181, 2018, doi: https://doi.org/10.1016/j.mset.2018.07.003.

S. Utomo, “Komposisi Optimal Serbuk Kayu Gergaji dan Oli Bekas pada Pembuatan Briket Kayu,” J. Konversi, vol. 2, no. 2, pp. 31–44, 2013, doi: https://doi.org/10.24853/konversi.2.2.%25p.

U. Malik, “Penelitian Berbagai Jenis Kayu Limbah Pengolahan Untuk Pemilihan Bahan Baku Briket Arang,” J. Ilm. Edu Res., vol. I, no. 2, pp. 21–26, 2012.

K. Nabawiyah, “Kontrol tuning ketergantungan transmitansi bangunan glazur pada panjang gelombang radiasi matahari untuk mengoptimalkan penerangan alami dan efisiensi energi bangunan. Energi dan Bangunan,” J. Neutrino, vol. 3, no. 1, pp. 108–118., 2010.

E. Yulianti, R. Jannah, L. M. Khoiroh, and V. N. Istighfarini, “Briket Arang Tempurung Kawista (Limonia acidissima) Teraktivasi NaOH dengan Perekat Alami,” al-Kimiya, vol. 6, no. 1, pp. 1–8, 2019, doi: 10.15575/ak.v6i1.4798.

H. dos Santos Viana, A. Martins Rodrigues, R. Godina, J. de Oliveira Matias, and L. Jorge Ribeiro Nunes, “Evaluation of the Physical, Chemical and Thermal Properties of Portuguese Maritime Pine Biomass,” Sustainability, vol. 10, no. 8, 2018, doi: 10.3390/su10082877.

I. Isa, “Briket Arang Dan Arang Aktif Dari Limbah Tongkol Jagung,” Univ. Negeri Gorontalo, pp. 1–50, 2012, doi : http://repository.ung.ac.id/get/simlit/1/168/2/ Briket-Arang-Dan-Arang-Aktif-Dari-Limbah-Tongkol-Jagung.pdf

J. Hyt, “Heating Value And Ash Content Of Intensively Managed Stands,” vol. 60, no. January, pp. 71–82, 2015.

A. F. D. Júnior, L. P. Pirola, S. Takeshita, A. Q. Lana, J. O. Brito, and A. M. de Andrade, “Higroscopicidade do carvão vegetal produzido em diferentes temperaturas,” Cerne, vol. 22, no. 4, pp. 423–430, 2016, doi: 10.1590/01047760201622032175.

H. A. Ajimotokan, A. O. Ehindero, K. S. Ajao, A. A. Adeleke, P. P. Ikubanni, and Y. L. Shuaib-Babata, “Combustion characteristics of fuel briquettes made from charcoal particles and sawdust agglomerates,” Sci. African, vol. 6, p. e00202, 2019, doi: https://doi.org/10.1016/j.sciaf.2019.e00202.

D. Purwanto & Sofyan, 2014. “The Effect of Carbonization Temperature and

Carbonization Time on The Quality of Charcoal Briquette from Oil Palm Shell Waste”. Jurnal Litbang Industri, Vol. 4 No. 1, Juni 2014: 29-38.

D. R. Nhuchhen and M. T. Afzal, “HHV Predicting Correlations for Torrefied Biomass Using Proximate and Ultimate Analyses,” Bioengineering, vol. 4, no. 1, 2017, doi: 10.3390/bioengineering4010007.

K. C. Briseño-Uribe, A. Carrillo-Parra, V. Bustamante-García, H. González-Rodríguez, and R. Foroughbachk, “Firewood Production, Yield and Quality of Charcoal From Eucalyptus camaldulensis and E. microtheca Planted in the Semiarid Land of Northeast Mexico,” Int. J. Green Energy, vol. 12, no. 9, pp. 961–969, 2015, doi: 10.1080/15435075.2014.891121.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Syaiful Mansyur, Enda Apriani

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)