Online synchronous inspection and system optimization of flexible food packaging bags by using machine vision and sensing technique

DOI:

https://doi.org/10.12928/ijio.v4i1.6619Keywords:

Machine vision, Flexible packaging bags for food, Online synchronous detection, System optimization design, Double arc locationAbstract

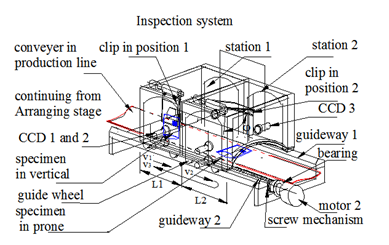

Flexible food packaging in the market is increasingly favored, and its quality is essential and indispensable for safety and convenience. However, quality inspection still stays in the manual stage, or partially manual inspection remains, in production, leading low efficiency, lack and even false inspection, hardly meeting the requirements of the modern output. This paper proposes and optimizes the design of an automatic detection system with intelligence for flexible food packaging bag, which can effectively be adopted to check the quality of packaging trademark patterns, fillers, and sealing quality. The inspection system runs with two-stage structure, machine vision, pressure sensing and synchronization to improve efficiency and ensure the normal production beat. Simplex Method is adopted to determine the best synchronous speeds online to achieve the best expectation. Comparison has been made between the manual inspection and our automatic operation, the sample of 10000 was statistically analyzed and results have shown that two workers were saved and the correctness rate of inspection raised up to 999.8‰.

References

Koo, Young Mo and Lee, Kyu Ho. A study on the performance improvement of 3D inspection equipment. Proceedings of 6th International Conference on Soft Computing and Intelligent Systems, and 13th International Symposium on Advanced Intelligence Systems, SCIS/ISIS November 20, 2012 - November 24, 2012: p 1867-1870

Wang, Zhi Long ; He, Bang Gui ; Tian, Qian Ru. The study of production process system of new multi-feature continuous reel soft pack trademarks. 3rd International Conference on Advanced Design and Manufacturing Engineering, ADME 2013, July 13, 2013 - July 14, 2013, Anshan, China. Applied Mechanics and Materials, Volume: 397-400, Advanced Design and Manufacturing Technology III. 2013: p 29-33.

Jie-Fang, Xing ;Yuan, Chen ; Lu-Jun, He. Double-position positioning test and analysis on holographic /protruding lettering of cigarette packet based on machine vision. Applied Mechanics and Materials. Volume 312, Applied Research and Engineering Solutions in Industry. 2013:p 597-602. International Conference on Electrical Information and Mechatronics, ICEIM 2012, December 23-25, 2012, Jiaozuo, China.

Schneider, M. and Franke, J. Resonant method for the measurement of quality of laminated cores. Proceedings of 5th International Conference on Electric Drives Production, EDPC 2015. September 15, 2015 - September 16, 2015, Nuremberg, Germany.

Liu, Jie ; Xu, Jianguo ; Gao, Chunli ; Liu, Qiuhang. Machine Vision-based Research on the Inspection of Dropper Defects of Overhead Contact Line. Journal of Railway Engineering Society. Volume: 39, Issue 5, 2022: 91-97.

Cantor, Stephen E. UV curable conformal coatings and peelable masks which display enhanced fluorescent response.Circuit World. Volume: 24 Issue (1), 1997:p 30-33

Liu,Wuneng ; Liu, Lilong; He, Gengli; Li, Peng .Visualization of Power Corridor Based on UAV Lin Inspection Data. International Journal of Wireless Information Networks. Volume: 28, Issue: 3, 2021:p 308-318

Megalingam, Rajesh Kannan ; Kota, Avinash Hegde ; Vijaya Krishna Tejaswi., P. ; Mohandas, Sreekanth Makkal. ROS Based Simulation Environment for Testing Power Line Inspection Robots. Proceedings of 2021 5th International Conference on Electrical, Electronics, Communication, Computer Technologies and Optimization Techniques, ICEECCOT 2021, December 10, 2021 - December 11, 2021, Mysuru, India. 2021: p 518-522.

Bedaka, Amit Kumar ; Lee, Shao-Chun ; Mahmoud, Alaa M. ; Cheng, Yong-Sheng; Lin, Chyi-Yeu . A camera-based position correction system for autonomous production line inspection. Sensors. Volume: 21, Issue: 12, 2021

Bellizzi, G. ; Crocco, L. ; Cavagnaro, M. ; Ricci, M. . A Simple Imaging Strategy for In-Line food Inspection via Microwave Imaging. Proceedings of 16th European Conference on Antennas and Propagation, EuCAP 2022. March 27, 2022 - April 1, 2022, Madrid, Spain.

Sumanth ; Srivastav, Akash ; Sagar, R ; Malik, Mohammed Anu ; Vishwanath, M.N . Mechanism, design and kinematics for a ransmission line inspection robot. Proceedings of 2021 2nd International Conference for Emerging Technology, INCET 2021, May 21, 2021 - May 23, 2021. Belgaum, India. Article number: 9456243

Mazzetto, Muriel ; Teixeira, Marcelo ; Rodrigues, Érick Oliveira ; Casanova, Dalcimar. Deep Learning Models for Visual Inspection on Automotive Assembling Line. arXiv. 2020

Sumagayan, Moheddin U. ; Premachandra, Chinthaka ; Mangorsi, Rohanni B. ; Salaan, Carl John ; Premachandra, H. Waruna H. ; Kawanaka, Hiroharu. Detecting Power Lines Using Point Instance Network for Distribution Line Inspection. IEEE Access, Volume: 9, Issue date: 2021:p107998-108008.

Liu, Shucong ; Zheng, Dezhi ; Li, Rui . Compensation method for pipeline centerline measurement of in-line inspection during odometer slips based on multi-sensor fusion and LSTM network. Sensors (Switzerland). Volume: 19, Issue: 17, 2019: Article number: 3740

Schneider, M. and Franke, J. Resonant method for the measurement of quality of laminated cores. Proceedings of 2015 5th International Conference on Electric Drives Production, EDPC 2015 , September 15, 2015 - September 16, 2015, Nuremberg, Germany. Article number: 7323195.

Chen, Binghuang; Miao, Xiren. Distribution Line Pole Detection and Counting Based on YOLO Using UAV Inspection Line Video. Journal of Electrical Engineering & Technology. Journal of Electrical Engineering and Technology. Volume 15, Issue 1,2020: p 441-448.

Zengin, Aydin Tarik ; Erdemir, Gokhan ;Akinci, Tahir Cetin ; Seker, Serhat. Measurement of Power Line Sagging Using Sensor Data of a Power Line Inspection Robot. IEEE Access. Volume 8, Issue date: 2020:p 99198-99204

Li, Jianxiong ; Zhou, Qian ; Li, Xinghui ; Chen, Ruiming ; Ni, Kai . An improved low-noise processing methodology combined with PCL for industry inspection based on laser line scanner. Sensors (Switzerland) Volume: 19, Issue: 15 ,2019: Article number: 3398

Liu, Xinyu ; Jin, Zhiheng ; Jiang, Hao ; Miao, Xiren ; Chen, Jing ; Lin, Zhicheng. Quality assessment for inspection images of power lines based on spatial and sharpness evaluation. IET Image Processing,Volume: 16, Issue: 2,2022:p356-364

Wang, Yishuang ; Yuan, Chao ; Zhai, Yongjie. Mechanism Design and Analysis of a New Overhead Transmission Line Inspection Robot . Xibei Gongye Daxue Xuebao. Volume: 38,Issue: 5,2020: 1105-1111

Nekovar, Frantisek ; Faigl, Jan ; Saska, Martin . Multi-Tour Set Traveling Salesman Problem in Planning Power Transmission Line Inspection. IEEE Robotics and Automation Letters. Volume: 6, Issue: 4, 2021:p 6196-6203.

Hou, Xingwei; Sivashanmugan, Kundan; Zhao, Yong; Zhang, Boxin; Wang, Alan X. ] Multiplex sensing of complex mixtures by machine vision analysis of TLC-SERS images. Sensors and Actuators B: Chemical, Volume 357, April 15, 2022.

Lyu, Ke ; Yan, Haizhang. Identification Method of Dress Pattern Drawing based on Machine Vision Algorithm. Proceedings of 3rd International Conference on Computer Vision, Image and Deep Learning and International Conference on Computer Engineering and Applications, CVIDL and ICCEA 2022, 2022: p 76-79

Dudkin, A.A. ; Voronov, A.A.; Awakaw, S.M. Algorithms and Systems of Machine Vision in Integrated Circuit Manufacturing Technology. Pattern Recognition and Image Analysis, Volume 32, Number 2, 2022:p 266-276

Rapolti, Laszlo ; Holonec, Rodica; Grindei, Laura; Viman, Oana. Automated Sorting of Pharmaceutical Waste Using Machine Vision Technology. IFMBE Proceedings of 7th International Conference on Advancements of Medicine and Health Care through Technology. Volume 88, 2022:p 409-416

Roshchin, D.A. Loading of Tracked Vehicles under their Own Power on a Trailer under the Control of a Machine Vision System. Measurement Techniques, Volume 65, Number 1,2022: p 24-32

Xu, Pengfei; Zhou, Zhiqing; Geng, Zexun. Technical Research on Moving Target Monitoring and Intelligent Tracking Algorithm Based on Machine Vision. Wireless Communications and Mobile Computing, Volume 2022, 2022

Peng, Xing ; Kong, Lingbao; Sun, Xiang. Design of a composite lighting system based on a freeform and a rod lens for machine vision. Applied Optics, Volume 61, Number 8,2022: p 2108-2117

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Lizhi Gu, Qiong Li, Ehui Huang, Mingrui Li, Shanping Gao, Kin Sam Yen, Shuting Li, Junqin Zhou, Zhenjie Chen

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)