Development of an energy management system for palm oil refinery facilities: implementing a systems approach

Keywords:

Energy management system, Energy performance indicators, Specific energy consumption, Palm oil refineryAbstract

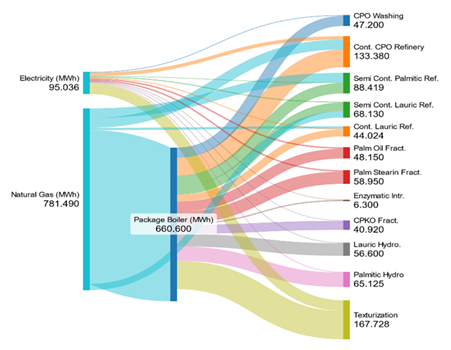

This study aims to develop a proactive Energy Management System (EnMS) for a palm oil refinery using a comprehensive systems-based approach implemented carefully during the plant design phase. Unlike conventional methods that rely mainly on historical operational data, this research deliberately utilizes engineering design specifications together with simulation modeling to estimate accurate energy consumption baselines and formulate an ISO 50001-compliant EnMS. A regression-based analysis is systematically applied to define reliable Energy Performance Indicators (EnPIs), using production volume and running hours as key variables influencing overall energy utilization. The resulting analytical model estimates a Specific Energy Consumption (SEC) of 2.168 MWh/MT—significantly higher than the 0.45 MWh/MT BAT benchmark—primarily due to assumptions of full-capacity, simultaneous operation under conservative conditions. To support continuous energy performance improvement, the system incorporates PDCA-based review mechanisms and establishes progressive energy-saving targets: an initial 10% reduction, followed by 1–2% annual incremental improvements. Validation through structured feedback sessions from plant management confirmed the system's strong alignment with operational needs, feasibility within industrial contexts, and readiness for phased implementation. Ultimately, this study contributes a novel, simulation-based framework for integrating EnMS during the design stage, offering a scalable and adaptable model for energy-intensive industries that aim to enhance efficiency and achieve long-term sustainability from the outset.

References

International Energy Agency, 2021, World Energy Outlook 2021.

S. R. W. Alwi, M. A. T. Jaya, Z. A. Manan, “Cost effective retrofit of a palm oil refinery using pinch analysis”, Jurnal Teknologi, vol. 51, 2009, doi: 10.11113/jt.v51.144.

Mapping the palm oil value chain – Opportunities for sustainable palm oil in Indonesia and China, UNDP China, 2020.

M. A. Sulaiman, A. O. Oni, D. A. Fadare,”Energy and exergy analysis of a vegetable oil refinery”, Energy and power engineering, vol. 4, no. 1, pp. 358-364, 2012, doi: 10.4236/epe.2012.45047.

N. W. Qammar, Z. U. R. Afridi, S. W. Qammar, F. Muhammad, F. Ali, N. Ullah,”What factors cause weak industrial energy management practices?”, Strategic planning for energy and the environment, vol. 39, no. 1-4, pp. 93-116, 2021, doi: 10.13052/spee1048-4236.39145.

A. A. A. Gassar, C. Koo, T. W. Kim, S. H. Cha, “Performance optimization studies on heating, cooling and lighting energy systems of buildings during the design stage: a review”, Sustainability, vol. 13, 2021, doi: 10.3390/su13179815.

B. Dusi and R. Schultz, "Energy management and efficiency — A systems approach," 2012 IEEE-IAS/PCA 54th Cement Industry Technical Conference, San Antonio, TX, USA, pp. 1-8, 2012, doi: 10.1109/CITCON.2012.6215689.

A. McKane, D. Desai, M. Matteini, W. Meffert, R. Williams, R. Risser, “Thinking globally: How ISO 50001 – energy management can make industrial energy efficiency standard practice”, Lawrence Berkeley National Laboratory, 2009, doi: 10.2172/983191.

M. S. Genç, S. T. Azgin, Z. İpekli, “Assessing waste-to-energy potential and landfill site suitability via a holistic approach”, Process Safety and Environmental Protection, vol. 189, pp. 343–355, 2024, doi: 10.1016/j.psep.2024.06.064.

International Organization for Standardization, ISO 50001:2018 Energy Management Systems — Requirements with guidance for use, 2018.

F. Mohamad, N. H. Abdullah, N. K. Kamarudding, M. Mohammad, “Implementation of ISO50001 energy management system – a case study of a Malaysian copper manufacturer”, Research acculturation grant scheme, 2014, doi: 10.1109/ISTMET.2014.6936518.

E. Andersson, P. Thollander, “Key performance indicators for energy management in the Swedish pulp and paper industry”, Energy strategy reviews, vol. 24, pp. 229-235, 2019, doi: 10.1016/j.esr.2019.03.004.

D. Apriyanti, B. Warsito and T. Prasetyo, "Creating Green Industry through the Implementation of an Energy Management System : Case Study at PT. X," 2018 Conference on Power Engineering and Renewable Energy (ICPERE), Solo, Indonesia, pp. 1-5, 2018, doi: 10.1109/ICPERE.2018.8739493.

M. B. Custodio, W. M. Rodriguez, D. A. Giron, A. N. Ayala, J. A. Sanchez, A. M. Vilela, S. R. Yovera, A. C. Diaz, E. D. Ronceroz, “Energy efficiency management according to ISO 50001: A case study in the brick industry”, EAI Endorsed Trans Energy Web, vol. 10, 2023, doi: 10.4108/ew.3560.

B. L. Capehart, W. C. Turner, and W. J. Kennedy, “Guide To Energy Management,” 7th ed., Lilburn, GA: The Fairmont Press, 2012.

P. Thollander, J. Palm, “Improving energy efficiency in industrial energy systems”, Springer, 2013, doi: 10.1007/978-1-4471-4162-4.

P. Karcher, “Success factors and organizational approaches for the implementation of energy management systems according to ISO 50001”, The TQM journal, vol. 27, no. 4, pp. 361-381, 2015, doi: 10.1108/TQM-01-2015-0016.

International Organization for Standardization, ISO 50006:2023 Energy Management Systems-Evaluating Energy Performance Using Energy Performance Indicators and Energy Baselines, 2023.

G. May, M. Taisch, D. Kelly, “Enhanced energy management in manufacturing through system integration”, Researchgate conference paper, 2013, doi: 10.1109/IECON.2013.6700386.

Y. Yang, M. Wei, Z. Liu, Y. Wang, C. Cai, M. Zhou, F. Song, “Integrated energy system multi-level planning model based on scenario reasoning, equipment selection, and capacity optimization”, International Journal of Green Energy, vol. 19, no. 14, pp. 1512–1530, 2021, doi: 10.1080/15435075.2021.2008397.

E. Elbeltagi, H. Wefki, R. Khallaf, “Sustainable Building Optimization Model for Early-Stage Design”, Buildings, vol. 13, no. 74, 2023, doi: 10.3390/buildings13010074.

R. Williams, A. McKane, “Global overview – the systems approach to energy efficiency in industry”, WIREs Energy Environ, vol. 2, pp. 363-373, 2013, doi: 10.1002/wene.72.

L. Miserocchi, A. Franco, D. Testi, “An integrated framework for energy performance improvement in manufacturing: from mapping to optimization”, Journal of cleaner production, vol. 411, 2023, doi: 10.1016/j.jclepro.2023.137387.

F. M. Kanchiralla, N. Jalo, S. Johnsson, P. Thollander, M. Andersson, “Energy end-use categorization and performance indicators for energy management in the engineering industry”, Energies, vol. 13, no. 369, 2020, doi: 10.3390/en13020369.

Y. S. Tan, T. B. Tjandra, B. Song, “Energy efficiency benchmarking methodology for mass and high-mix low-volume productions”, Procedia CIRP, vol. 29, pp. 120-125, 2015, doi: 10.1016/j.procir.2015.02.200.

P. Hehenberger, D. Leherbauer, O. Penas, R. Delabeye, S. Patalano, F. Vitolo, A. Rega, P. Alefragis, M. Birbas, A. Birbas, P. Katrakazas, “Holistic System Modelling and Analysis for Energy-Aware Production: An Integrated Framework”, Systems, vol. 11, no. 100, 2023, doi: 10.3390/systems11020100.

E. Andersson, H. Dernegard, M. Wallen, P. Thollander, “Decarbonization of industry: Implementation of energy performance indicators for successful energy management practices in kraft pulp mills”, Energy reports, vol. 7, pp. 1808-1817, 2021, doi: 10.1016/j.egyr.2021.03.009.

K. Tanaka, “Assessment of energy efficiency performance measures in industry and their application for policy”, Energy policy, vol. 36, no. 8, pp. 2887-2902, 2008, doi: 10.1016/j.enpol.2008.03.032.

E. Andersson, O. Arfwidsson, P. Thollander, “Benchmarking energy performance of industrial small and medium-sized enterprises using an energy efficiency index: Results based on an energy audit policy program”, Journal of cleaner production, 2018, doi: 10.1016/j.jclepro.2018.02.027.

K. Sommart, S. Pipatmanomai, “Assessment and improvement of energy utilization in crude palm oil mill”, International conference on chemistry and chemical process, vol. 10, 2011.

Z. Noranai, N. F. M. Joharudin, M. A. A. Redzwan, N. A. Latif, N. Z. Hassan, “Improving energy efficiency at palm oil mill industries”, Journal of physics: conference series, 2021, doi: 10.1088/1742-6596/1874/1/012013.

S. Lakshmanan, Y. L. Yung, B. S. Chan, Z. H. Chong, ”Sustainable practices of an edible oils refining complex”, Journal of oil palm, environment & health, vol. 11, no. 1, pp. 42-56, 2020, doi: 10.5366/jope.2020.05.

C. H. Eccleston, F. March, and T. Cohen, “Inside energy – developing and managing an ISO 50001 energy management system”, 1st ed., Boca Raton: CRC Press, 2012, pp. 29-35. ISBN 13: 978-1-4398-7671-8.

R. D. Pereira, A. C. Badino, A. J. G. Cruz, “Framework based on artificial intelligence to increase industrial bioethanol production”, energy & fuels, vol. 34, no. 4, doi: 10.1021/acs.energyfuels.0c00033.

J. Husar, A. Iakovets, “Plant Simulation as a Tool for Simulations Energy Drawings of Machines”, Advances in Thermal Processes and Energy Transformation, vol. 1, no. 4, pp. 83-86, 2018, ISSN 2585-9102, doi: 10.54570/atpet2018/01/04/0083.

A. P. Rossiter, & B. P. Jones, ”Energy Management and Efficiency for the Process Industries”, 1st ed., New Jersey: John Wiley & Sons, Inc, pp. 5, 2015, ISBN: 978-1-118-83825-9.

G. G. Santonja, P. Karlis, K. R. Stubdrup, T. Brinkmann, S. Roudier, “Best Available Techniques (BAT) Reference Document for the Food, Drink and Milk Industries”, European Commission, Luxembourg, Joint Research Centre for Policy Report, Industrial Emissions Directive 2010/75/EU, 2019, doi: 10.2760/243911.

S. R. Lidu, N. Mohamed, J. J. Klemeš, P. S. Varbanov, S. Yusup, “Evaluation of the energy saving opportunities for palm oil refining process: Sahabat Oil Products (SOP) in Lahad Datu, Malaysia”, Clean Techn Environ Policy, vol. 18, pp. 2453–2465, 2016, doi: 10.1007/s10098-016-1252-6.

H. Jouhara, N. Khordehgah, S. Almahmoud, B. Delpech, A. Chauhan, S. A. Tassou, “Waste heat recovery technologies and applications”, Thermal science and engineering progress, vol. 6, pp. 268-289, 2018, doi: 10.1016/j.tsep.2018.04.017.

W. Eichhammer, T. Fleiter, “Energy efficiency in electric motor systems: Technology, saving potentials and policy options for developing countries”, United Nations Industrial Development Organization: Vienna, Austria, 2012.

T. N. Nhat, “Improving energy efficiency”, World journal of advanced research and reviews, vol. 24, no. 3, pp. 2254-2257, 2024, doi: 10.30574/wjarr.2024.24.3.3899.

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Febrian Febrian, Adjar Pratoto

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)