Joint production and human replacement optimization policy for a deteriorating manufacturing system

DOI:

https://doi.org/10.12928/ijio.v6i2.11284Keywords:

Production Planning, Human factor, Optimal control, Stochastic process, Preventive replacementAbstract

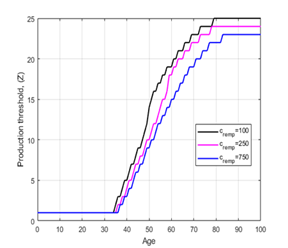

This article examines the integration of production and human resource and human resource management, considering the operator as a production unit whose efficiency decreases over time, in an unreliable production system marked by significant deterioration. This deterioration impacts the reliability and continuity of the production unit in two main ways. To mitigate the impact of this deterioration, a replacement action can be implemented based on the system's current state. The objective of this study is to establish an effective production policy and replacement strategy to meet customer demand. We employ a combination of stochastic dynamic programming and numerical methods to solve this optimal control problem. Additionally, a numerical example is presented to demonstrate the applicability of the proposed approach and to explore the interaction between a specific production strategy and human resource management. The main contribution of this research lies in the development of innovative methods and solutions aimed at optimizing the performance of a complex system through stochastic optimal control. The impact of the new approach, based on a logical implementation, is discussed following a sensitivity analysis of the numerical example. The results include a comparative study between recent research and the proposed policy. Lastly, an implementation chart is created to assist decision-makers in determining production rates and managing human resources effectively to meet customer demand.

References

N. Günther and Reiff-Stephan Jörg, “Prescriptive Education im Zuge der Industrie 5.0,” in AALE 2020 - 17. Fachkonferenz, Automatisierung und Mensch-Technik-Interaktion, 2020, pp. 315–320. [Online]. Available at: https://www.vde-verlag.de/proceedings-en/565180036.html.

B. Emami-Mehrgani, W. P. Neumann, S. Nadeau, and M. Bazrafshan, “Considering human error in optimizing production and corrective and preventive maintenance policies for manufacturing systems,” Appl. Math. Model., vol. 40, no. 3, pp. 2056–2074, Feb. 2016, doi: 10.1016/j.apm.2015.08.013.

S. Bragança, E. Costa, I. Castellucci, and P. M. Arezes, “A Brief Overview of the Use of Collaborative Robots in Industry 4.0: Human Role and Safety,” in Studies in Systems, Decision and Control, vol. 202, Springer, Cham, 2019, pp. 641–650, doi: 10.1007/978-3-030-14730-3_68.

B. Strauch, Investigating Human Error: Incidents, Accidents, and Complex Systems. Routledge, 2017, doi: 10.4324/9781315251851.

M. Green and J. W. Senders, “Human Error In Road Accidents,” p. 10, 1999. [Online]. Available at: https://trid.trb.org/View/643706.

J. R. Treat et al., “Tri-level study of the causes of traffic accidents: Final report. Volume I: Casual factor tabulations and assessments,” United States. National Highway Traffic Safety Administration, Mar. 1979, p. 82, doi: 10.1037/e488172008-001.

C. P. Nemeth, Human Factors Methods for Design. CRC Press, pp. 1-392 , 2004, doi: 10.1201/9780203643662.

T. S. Baines and J. M. Kay, “Human performance modelling as an aid in the process of manufacturing system design: A pilot study,” Int. J. Prod. Res., vol. 40, no. 10, pp. 2321–2334, Jan. 2002, doi: 10.1080/00207540210128198.

T. S. Baines, R. Asch, L. Hadfield, J. P. Mason, S. Fletcher, and J. M. Kay, “Towards a theoretical framework for human performance modelling within manufacturing systems design,” Simul. Model. Pract. Theory, vol. 13, no. 6, pp. 486–504, Sep. 2005, doi: 10.1016/j.simpat.2005.01.003.

M. Peruzzini and M. Pellicciari, “A framework to design a human-centred adaptive manufacturing system for aging workers,” Adv. Eng. Informatics, vol. 33, pp. 330–349, Aug. 2017, doi: 10.1016/j.aei.2017.02.003.

G. G. Udo and A. A. Ebiefung, “Human factors affecting the success of advanced manufacturing systems,” Comput. Ind. Eng., vol. 37, no. 1–2, pp. 297–300, Oct. 1999, doi: 10.1016/S0360-8352(99)00078-9.

J.-M. Hoc, N. Mebarki, and J. Cegarra, “L’assistance à l’opérateur humain pour l’ordonnancement dans les ateliers manufacturiers,” Trav. Hum., vol. 67, no. 2, p. 181, 2004, doi: 10.3917/th.672.0181.

A. CHARBA and A. LAHRECH, “L’implication du facteur humain et son importance dans la réussite des démarches qualités,” Rev. Econ. Gest. Société, no. 3, 2015. [Online]. Available at: https://revues.imist.ma/index.php/REGS/article/view/4170.

H. Rivera-Gómez, A. Gharbi, J.-P. Kenné, O. Montaño-Arango, and J. R. Corona-Armenta, “Joint optimization of production and maintenance strategies considering a dynamic sampling strategy for a deteriorating system,” Comput. Ind. Eng., vol. 140, p. 106273, Feb. 2020, doi: 10.1016/j.cie.2020.106273.

H. Rivera-Gómez, A. Gharbi, J.-P. Kenné, R. Ortiz-Zarco, and J. R. Corona-Armenta, “Joint production, inspection and maintenance control policies for deteriorating system under quality constraint,” J. Manuf. Syst., vol. 60, pp. 585–607, Jul. 2021, doi: 10.1016/j.jmsy.2021.07.018.

S. Panda and S. Saha, “Optimal production rate and production stopping time for perishable seasonal products with ramp-type time-dependent demand,” Int. J. Math. Oper. Res., vol. 2, no. 6, p. 657, 2010, doi: 10.1504/IJMOR.2010.035493.

V. Polotski, A. Gharbi, and J.-P. Kenne, “Production control of unreliable manufacturing systems with perishable inventory,” Int. J. Adv. Manuf. Technol., vol. 116, no. 7–8, pp. 2473–2496, Oct. 2021, doi: 10.1007/s00170-021-07503-7.

V. Polotski, J.-P. Kenné, and A. Gharbi, “Production control of hybrid manufacturing–remanufacturing systems under demand and return variations,” Int. J. Prod. Res., vol. 57, no. 1, pp. 100–123, Jan. 2019, doi: 10.1080/00207543.2018.1461272.

A. Gharbi, J.-P. Kenné, and R. Kaddachi, “Dynamic optimal control and simulation for unreliable manufacturing systems under perishable product and shelf life variability,” Int. J. Prod. Econ., vol. 247, p. 108417, May 2022, doi: 10.1016/j.ijpe.2022.108417.

F. I. Dehayem Nodem, J.-P. Kenne, and A. Gharbi, “Production planning and repair/replacement switching policy for deteriorating manufacturing systems,” Int. J. Adv. Manuf. Technol., vol. 57, no. 5–8, pp. 827–840, Nov. 2011, doi: 10.1007/s00170-011-3327-1.

N.-H. Shih and C.-H. Wang, “Determining an optimal production run length with an extended quality control policy for an imperfect process,” Appl. Math. Model., vol. 40, no. 4, pp. 2827–2836, Feb. 2016, doi: 10.1016/j.apm.2015.09.045.

S. Ouaret, J.-P. Kenné, and A. Gharbi, “Production and replacement policies for a deteriorating manufacturing system under random demand and quality,” Eur. J. Oper. Res., vol. 264, no. 2, pp. 623–636, Jan. 2018, doi: 10.1016/j.ejor.2017.06.062.

S. Ouaret, J.-P. Kenné, and A. Gharbi, “Production and replacement planning of a deteriorating remanufacturing system in a closed-loop configuration,” J. Manuf. Syst., vol. 53, pp. 234–248, Oct. 2019, doi: 10.1016/j.jmsy.2019.09.006.

G.-R. Kibouka, D. Nganga-Kouya, J.-P. Kenne, V. Songmene, and V. Polotski, “Production Planning of a Failure-Prone Manufacturing System under Different Setup Scenarios,” J. Appl. Math., vol. 2016, no. 1, pp. 1–15, Jan. 2016, doi: 10.1155/2016/4930817.

A. Gharbi and J. P. Kenne, “Optimal production control problem in stochastic multiple-product multiple-machine manufacturing systems,” IIE Trans., vol. 35, no. 10, pp. 941–952, Oct. 2003, doi: 10.1080/07408170309342346.

J. Wakiru, L. Pintelon, P. N. Muchiri, and P. Chemweno, “Maintenance Optimization: Application of Remanufacturing and Repair Strategies,” Procedia CIRP, vol. 69, pp. 899–904, Jan. 2018, doi: 10.1016/j.procir.2017.11.008.

F. I. Dehayem Nodem, J. P. Kenné, and A. Gharbi, “Simultaneous control of production, repair/replacement and preventive maintenance of deteriorating manufacturing systems,” Int. J. Prod. Econ., vol. 134, no. 1, pp. 271–282, Nov. 2011, doi: 10.1016/j.ijpe.2011.07.011.

R. Zheng and Y. Zhou, “A dynamic inspection and replacement policy for a two-unit production system subject to interdependence,” Appl. Math. Model., vol. 103, pp. 221–237, Mar. 2022, doi: 10.1016/j.apm.2021.10.028.

S. Ouaret, J.-P. Kenné, and A. Gharbi, “Joint Production and Replacement Planning for an Unreliable Manufacturing System Subject to Random Demand and Quality,” IFAC-PapersOnLine, vol. 51, no. 11, pp. 951–956, Jan. 2018, doi: 10.1016/j.ifacol.2018.08.485.

S. Ouaret, J.-P. Kenné, A. Gharbi, and V. Polotski, “Age-dependent production and replacement strategies in failure-prone manufacturing systems,” Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., vol. 231, no. 3, pp. 540–554, Feb. 2017, doi: 10.1177/0954405415616060.

M.-T. Lai and Y.-C. Chen, “Optimal periodic replacement policy for a two-unit system with failure rate interaction,” Int. J. Adv. Manuf. Technol., vol. 29, no. 3–4, pp. 367–371, Jun. 2006, doi: 10.1007/s00170-004-2486-8.

J. P. Kenne and L. J. Nkeungoue, “Simultaneous control of production, preventive and corrective maintenance rates of a failure-prone manufacturing system,” Appl. Numer. Math., vol. 58, no. 2, pp. 180–194, Feb. 2008, doi: 10.1016/j.apnum.2006.11.010.

H. J. Kushner, “Numerical Methods for Stochastic Control Problems in Continuous Time,” SIAM J. Control Optim., vol. 28, no. 5, pp. 999–1048, Sep. 1990, doi: 10.1137/0328056.

J. P. Kenne, E. K. Boukas, and A. Gharbi, “Control of production and corrective maintenance rates in a multiple-machine, multiple-product manufacturing system,” Math. Comput. Model., vol. 38, no. 3–4, pp. 351–365, Aug. 2003, doi: 10.1016/S0895-7177(03)90093-8.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Hanan Majria, Honorine Angue Mintsa, Guy-Richard Kibouka , Jean-Pierre Kenne

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

License and Copyright Agreement

In submitting the manuscript to the journal, the authors certify that:

- They are authorized by their co-authors to enter into these arrangements.

- The work described has not been formally published before, except in the form of an abstract or as part of a published lecture, review, thesis, or overlay journal. Please also carefully read the International Journal of Industrial Optimization (IJIO) Author Guidelines at http://journal2.uad.ac.id/index.php/ijio/about/submissions#onlineSubmissions

- That it is not under consideration for publication elsewhere,

- That its publication has been approved by all the author(s) and by the responsible authorities tacitly or explicitly of the institutes where the work has been carried out.

- They secure the right to reproduce any material that has already been published or copyrighted elsewhere.

- They agree to the following license and copyright agreement.

Copyright

Authors who publish with the International Journal of Industrial Optimization (IJIO) agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.

1.png)