Design of a Liquid Tank Filling Control System Using PID

DOI:

https://doi.org/10.12928/biste.v5i3.8915Keywords:

Liquid Filling, PID Control, Ultrasonic, ArduinoAbstract

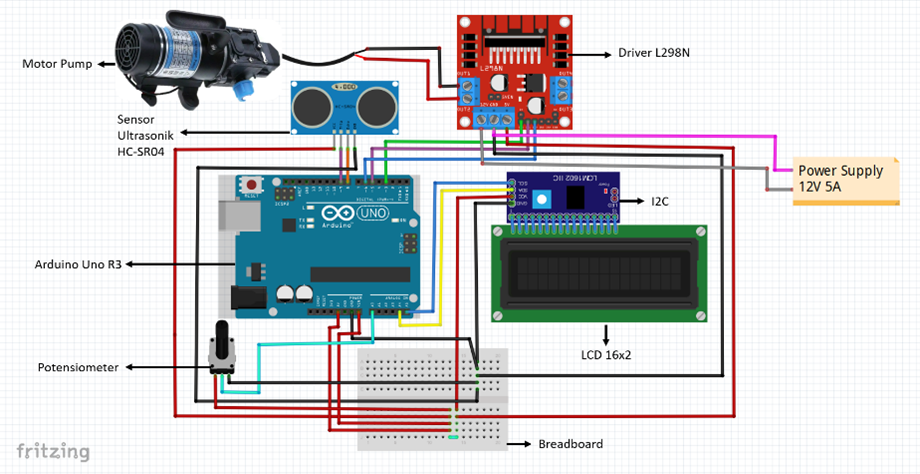

This research investigates the precise regulation of liquid filling in tanks, specifically focusing on water storage systems. It employs the Proportional-Integral-Derivative (PID) control method in conjunction with an HC-SR04 ultrasonic sensor and an Arduino Uno microcontroller. Given the paramount importance of water as a resource, accurate management of its storage is of utmost significance. The PID control method, known for its rapid responsiveness, minimal overshoot, and robust stability, effectively facilitates this task. Integrating the ultrasonic sensor and microcontroller further augments the precision of water level regulation. The article expounds upon the foundational principles of the PID control method and elucidates its application in the context of liquid tank filling. It offers a comprehensive insight into the hardware configuration, encompassing pivotal components such as the Arduino Uno microcontroller, HC-SR04 ultrasonic sensor, and the L298 driver responsible for water pump control. The experimental approach is meticulous, presenting results from tests involving the Proportional Controller, Proportional Integral (PI) Controller, and Proportional Integral Derivative (PID) Controller. These tests rigorously analyze the impact of varying Proportional Gain (Kp), Integral Gain (Ki), and Derivative Gain (Kd) parameters on crucial performance metrics such as response time, overshoot, and steady-state error. The findings underscore the critical importance of an optimal parameter configuration, emphasizing the delicate equilibrium between response speed, precision, and error minimization. This research significantly advances PID control implementation in liquid tank filling, offering insights that pave the way for developing more efficient liquid management systems across various sectors. The identified optimal parameter configuration is Kp = 5.0, Ki = 0.3, and Kd = 0.2.

References

S. Shankar and M. Dakshayini, “IoT-Mobile Enabled Smart Water Level Controlling System to Regulate Water Wastage,” in International Conference on Advances in Computing, Communications and Informatics (ICACCI), pp. 2045–2048, 2018, https://doi.org/10.1109/ICACCI.2018.8554373.

W. A. Jabbar et al., "Design and Fabrication of Smart Home With Internet of Things Enabled Automation System," in IEEE Access, vol. 7, pp. 144059-144074, 2019, https://doi.org/10.1109/ACCESS.2019.2942846.

M. Singh and S. Ahmed, “IoT based smart water management systems: A systematic review,” in Materials Today: Proceedings, vol. 46, pp. 5211-5218, 2021, https://doi.org/10.1016/j.matpr.2020.08.588.

S. A. H. Almetwally, M. K. Hassan, and M. H. Mourad, “Real Time Internet of Things (IoT) Based Water Quality Management System,” in Procedia CIRP, vol. 91, pp. 478–485, 2020, https://doi.org/10.1016/j.procir.2020.03.107.

H. M. Yasin, S. R. , M. Zeebaree, and I. M. , I. Zebari, “Arduino Based Automatic Irrigation System: Monitoring and SMS Controlling,” in 4th Scientific International Conference Najaf (SICN), pp. 109–114, 2019, https://doi.org/10.1109/SICN47020.2019.9019370.

H. N. Saha et al., “Smart Irrigation System Using Arduino and GSM Module,” in 9th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), pp. 532–538, 2018 https://doi.org/10.1109/IEMCON.2018.8614839.

Y. Pachipala, C. Nagaraju, R. Anitha, A. Yeswanth, K. Karthik, and P. Surendra, “IoT Based Water Level Meter,” in International Conference on Smart Systems and Inventive Technology (ICSSIT), pp. 448–456, 2018, https://doi.org/10.1109/ICSSIT.2018.8748838.

S. A. Kulkarni, V. D. Raikar, B. K. Rahul, L. V. Rakshitha, K. Sharanya and V. Jha, "Intelligent Water Level Monitoring System Using IoT," 2020 IEEE International Symposium on Sustainable Energy, Signal Processing and Cyber Security (iSSSC), pp. 1-5, 2020, https://doi.org/10.1109/iSSSC50941.2020.9358827.

P. Mohindru, “Development of liquid level measurement technology: A review,” Flow Measurement and Instrumentation, vol. 89, 2023, https://doi.org/10.1016/j.flowmeasinst.2022.102295.

A. Ahfas, D. Hadidjaja, S. Syahrorini, and J. Jamaaluddin, “Implementation of ultrasonic sensor as a chemical percol fluid level control based on Atmega 16,” IOP Conf Ser Mater Sci Eng, vol. 1098, no. 4, p. 042046, 2021, https://doi.org/10.1088/1757-899X/1098/4/042046.

T. S. R. Pereira, T. P. de Carvalho, T. A. Mendes, and K. T. M. Formiga, “Evaluation of Water Level in Flowing Channels Using Ultrasonic Sensors,” Sustainability (Switzerland), vol. 14, no. 9, 2022, https://doi.org/10.3390/su14095512.

Y. Guo and M. E. A. Mohamed, “Speed Control of Direct Current Motor Using ANFIS Based Hybrid P-I-D Configuration Controller,” IEEE Access, vol. 8, pp. 125638–125647, 2020, https://doi.org/10.1109/ACCESS.2020.3007615.

S. Kadry and V. Rajinikanth, “Design of PID Controller for Magnetic Levitation System using Harris Hawks Optimization,” Jurnal Ilmiah Teknik Elektro Komputer dan Informatika, vol. 6, no. 2, p. 70, 2021, https://doi.org/10.26555/jiteki.v6i2.19167.

E. W. Suseno and A. Ma’Arif, “Tuning of PID Controller Parameters with Genetic Algorithm Method on DC Motor,” International Journal of Robotics and Control Systems, vol. 1, no. 1, pp. 41–53, 2021, https://doi.org/10.31763/ijrcs.v1i1.249.

P. Du, Y. Liu, W. Chen, S. Zhang, and J. Deng, “Fast and Precise Control for the Vibration Amplitude of an Ultrasonic Transducer Based on Fuzzy PID Control,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 68, no. 8, pp. 2766–2774, 2021, https://doi.org/10.1109/TUFFC.2021.3078663.

B. Verma and P. K. Padhy, “Robust Fine Tuning of Optimal PID Controller with Guaranteed Robustness,” IEEE Transactions on Industrial Electronics, vol. 67, no. 6, pp. 4911–4920, 2020, https://doi.org/10.1109/TIE.2019.2924603.

A. Sayyed and M. W. Aziz, “Towards an Autonomous and Smart Water Tank System,” International Journal of Emerging Trends in Engineering Research, vol. 9, no. 3, pp. 240–244, 2021, https://doi.org/10.30534/ijeter/2021/15932021.

Y. Saragih, J. H. Prima Silaban, H. Aliya Roostiani and S. A. Elisabet, "Design of Automatic Water Flood Control and Monitoring Systems in Reservoirs Based on Internet of Things (IoT)," 2020 3rd International Conference on Mechanical, Electronics, Computer, and Industrial Technology (MECnIT), pp. 30-35, 2020, https://doi.org/10.1109/MECnIT48290.2020.9166593.

M. R. Hidayat, A. Charisma, and S. Sambasri, “Soft Water Tank Level Monitoring System Using Ultrasonic HC-SR04 Sensor Based On ATMega 328 Microcontroller,” in 5th International Conference on Wireless and Telematics (ICWT), 2019, pp. 1–4, https://doi.org/10.1109/ICWT47785.2019.8978229.

A. Ma’arif, Iswanto, N. M. Raharja, P. Aditya Rosyady, A. R. Cahya Baswara and A. Anggari Nuryono, "Control of DC Motor Using Proportional Integral Derivative (PID): Arduino Hardware Implementation," 2020 2nd International Conference on Industrial Electrical and Electronics (ICIEE), pp. 74-78, 2020, https://doi.org/10.1109/ICIEE49813.2020.9277258.

A. A. Cahya and R. D. Puriyanto, “The Design of Rice Milling and Screening Systems Uses the DC Motor PID Method,” Control Systems and Optimization Letters, vol. 1, no. 1, pp. 1–6, 2023, https://doi.org/10.59247/csol.v1i1.2.

O. Arrieta, D. Castillo, R. Vilanova, and J. D. Rojas, “Model Reference based tuning for fractional-order 2DoF PI controllers with a robustness consideration,” IFAC-PapersOnLine, vol. 52, no. 1, pp. 207-212, 2019, https://doi.org/10.1016/j.ifacol.2019.06.063.

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Bagas Putra Anggara, Alfian Ma'arif

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

This journal is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.