Home Made Four-Point Probe: Case Studies of the Wobbly A and B Probes

DOI:

https://doi.org/10.12928/irip.v6i1.8362Keywords:

Home made four-point probe, Sheet resistivity, Wobbly probe, Relative errorAbstract

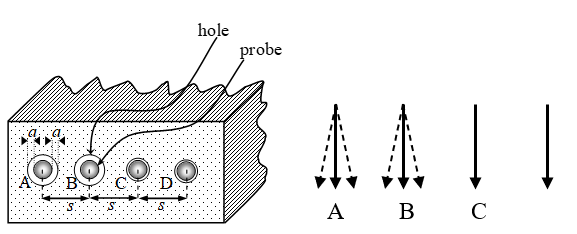

A simulation on the effect of probe deviation on sheet resistivity value (Rs) of Cu/Ni thin film was carried out in a home-made four-point probe (HM-FPP) type. This began by solving the Rs formula for normal probes, and then for wobbly probe when it was either A, or both A and B. The formula was implemented on a thin layer of Cu/Ni, which was a low temperature sensor material obtained from electrodeposition for 60s assisted by a 200G magnetic field at a current density of 0.07A/mm2. An electric current of 0.20118A was flown from probe A to D in order to produce a potential difference between probe C and D of 0.0005 volts. Furthermore, the distance between the probes was 5 mm and the deviation of each probe A and B were simulated from -0.5 mm to 0.5 mm. The maximum allowable limit for the relative error of Rs or SRs is 5%. The results showed that the ideal Rs value was 0.113 ohm/sq. Furthermore, for HM-FPP in which the wobbly probe only A, there is no problem encountered with the variation of the deviation because all SRs are less than 5%. For wobbly probes A and B, if they are on the same side of the center point of each probe, the maximum allowable deviation is 0.3 mm. The SRs for this case were 4.6%. However, if they are on different sides of the center point of each probe, the maximum allowable deviation is 0.1 mm with SRs of 2.9%. With these results, HM-FPP craftsmen must be more careful in making the size of the probe hole.

References

H. Chandra, S. Allen, S. Oberloier, N. Bihari, J. Gwamuri, and J. Pearce, “Open-Source Automated Mapping Four-Point Probe,” Materials (Basel)., vol. 10, no. 2, p. 110, Jan. 2017, https://doi.org/10.3390/ma10020110.

Y. Singh, “Electrical Resistivity Measurements: A Review,” Int. J. Mod. Phys. Conf. Ser., vol. 22, pp. 745–756, Jan. 2013, https://doi.org/10.1142/S2010194513010970.

Jandel, “Jandel Multiheight Four Point Probe Stand,” Jandel Engineering Limited, 2019. https://www.jandel.co.uk/site/wp-content/uploads/2019/06/Jandel_four_point_probe_General_Purpose.pdf (accessed Jul. 13, 2021).

Everbeing, “Four Point Probe,” Everbeing Int’l Corp., 2020. https://everbeingprober.com/products/four-point-probe/ (accessed Jul. 13, 2021).

Polytec, “Four-Point Probes,” Polytec GmbH., 2021. https://www.polytec.com/eu/optical-systems/products/semiconductor-measurement-technology/four-point-probes (accessed Jul. 13, 2021).

Semilab, “Four Point Probe Sheet Resistance,” Semilab Inc., 2021. https://semilab.com/category/products/four-point-probe-sheet-resistance-0 (accessed Jul. 13, 2021).

M. Toifur and D. Asmiarto, “Perbaikan Kinerja Probe 4 Titik Melalui Pelapisan Perak dengan Metode Electroplating pada Variasi Waktu Deposisi,” in The 5th Urecol Proceeding, 2017, pp. 1280–1286.

S. Seng, T. Shinpei, I. Yoshihiko, and K. Masakazu, “Development of a Handmade Conductivity Measurement Device for a Thin-Film Semiconductor and Its Application to Polypyrrole,” J. Chem. Educ., vol. 91, no. 11, pp. 1971–1975, Nov. 2014, https://doi.org/10.1021/ed500287q.

J. O. Agumba, P. M. Karimi, J. Okumu, and W. K. Njoroge, “Design and Fabrication of a Simple Four Point Probe System for Electrical Characterization of Thin Films,” Int. J. Curr. Res., vol. 3, no. 7, pp. 135–139, 2011, [Online]. Available: https://www.journalcra.com/article/design-and-fabrication-simple-four-point-probe-system-electrical-characterization-thin-films.

Y. Lu, L. M. Santino, S. Acharya, H. Anandarajah, and J. M. D’Arcy, “Studying Electrical Conductivity Using a 3D Printed Four-Point Probe Station,” J. Chem. Educ., vol. 94, no. 7, pp. 950–955, 2017, https://doi.org/10.1021/acs.jchemed.7b00119.

H. Nishikawa, S. Mikami, K. Miyake, A. Aoki, and T. Takemoto, “Effects of Silver Coating Covered with Copper Filler on Electrical Resistivity of Electrically Conductive Adhesives,” Mater. Trans., vol. 51, no. 10, pp. 1785–1789, 2010, https://doi.org/10.2320/matertrans.MJ201020.

E. Napieralska-Juszczaka, K. Komeza, F. Morganti, J. K. Sykulski, G. Vega, and Y. Zeroukhi, “Measurement of Contact Resistance for Copper and Aluminium Conductors,” Int. J. Appl. Electromagn. Mech., vol. 53, no. 4, pp. 617–629, Apr. 2017, https://doi.org/10.3233/JAE-160025.

F. Cemin, D. Lundin, D. Cammilleri, T. Maroutian, P. Lecoeur, and T. Minea, “Low Electrical Resistivity in Thin and Ultrathin Copper Layers Grown by High Power Impulse Magnetron Sputtering,” J. Vac. Sci. Technol. A Vacuum, Surfaces, Film., vol. 34, no. 5, p. 051506, Sep. 2016, https://doi.org/10.1116/1.4959555.

J. Mackey, F. Dynys, and A. Sehirlioglu, “Uncertainty Analysis for Common Seebeck and Electrical Resistivity Measurement Systems,” Rev. Sci. Instrum., vol. 85, no. 8, p. 085119, Aug. 2014, https://doi.org/10.1063/1.4893652.

K. Ilse, T. Tänzer, C. Hagendorf, and M. Turek, “Geometrical Correction Factors for Finite-Size Probe Tips in Microscopic Four-Point-Probe Resistivity Measurements,” J. Appl. Phys., vol. 116, no. 22, p. 224509, Dec. 2014, https://doi.org/10.1063/1.4903964.

F. Algahtani, K. B. Thulasiram, N. M. Nasir, and A. S. Holland, “Four Point Probe Geometry Modified Correction Factor for Determining Resistivity,” Micro/Nano Mater. Devices, Syst., vol. 8923, p. 89235D, 2013, https://doi.org/10.1117/12.2034057.

T. Bécherrawy, Electromagnetism: Maxwell Equations, Wave Propagation and Emission. John Wiley & Sons, 2013.

J. Vanderlinde, Classical Electromagnetic Theory. United States of America: Kluwer Academic Publishers, 2004.

J. Franklin, Classical Electromagnetism, 2nd ed. New York: Dover Publications, Inc., 2017.

M. Toifur, “Memahami Resistivitas berbagai Jenis Probe Arus-Tegangan,” in Prosiding Pertemuan Ilmiah XXVIII HFI Jateng & DIY, 2014, pp. 1–7.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Moh. Toifur, Moh. Irma Sukarelawan, Okimustava

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish in IRiP agree to the following terms: Authors retain copyright and grant the IRiP right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material) the work for any purpose, even commercially with an acknowledgment of the work's authorship and initial publication in IRiP. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in IRiP. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).