Magnetodeposited Nickel on Cu Substrate with the Angle Variation of Magnetic Field

DOI:

https://doi.org/10.12928/irip.v5i1.5816Keywords:

Cu/Ni sensor Electroplating Magnetic field Plating angle Sensor performanceAbstract

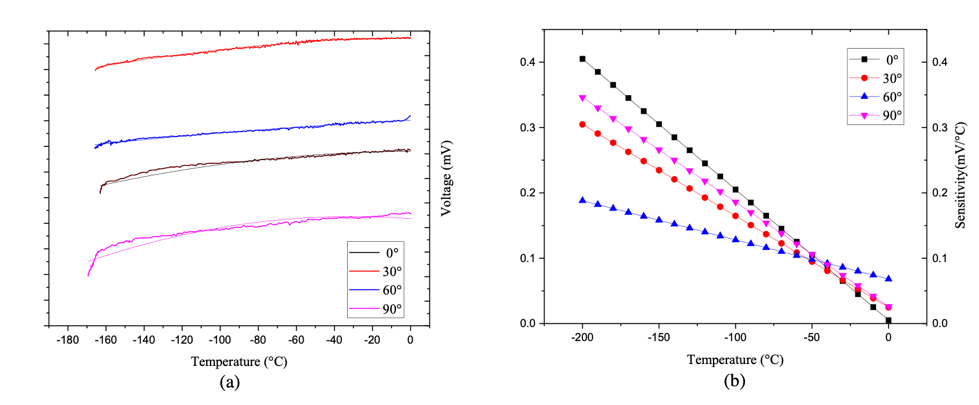

The performance of a thin layer of Cu/Ni as a cryogenic sensor is produced by electroplating at various angles with the aid of a 200G parallel magnetic field. Liquid nitrogen (LN2) is a low-temperature medium with temperatures varying from 0oC to -200oC. The characterization includes the sensor voltage range, sensor resistance, and sensor sensitivity. Thermocouple TCA-BTA -200oC to 1400oC is used as a temperature calibrator. The results showed that all sensors could measure the LN2 temperature in the range of 20oC to -200oC corresponds to the thermocouple's ability to measure up to -200oC. Each sensor has its advantages, but the sensor produced from coating each 3 minutes sample with an angle of 90o has the largest output voltage range up to 0.058 V, and the coating at an angle of 0o with the sensitivity level as a function of T is S(T) = 0.0051 - 0.002T, while the 3 minutes coating sensor with an angle of 60o has the smallest voltage range of 0.0439 V and sensitivity (1.88 ± 0.05) V/oC.

References

J. J. van Vonderen et al., “Pulse Oximetry Measures a Lower Heart Rate at Birth Compared with Electrocardiography,” J. Pediatr., vol. 166, no. 1, pp. 49–53, Jan. 2015, doi: 10.1016/j.jpeds.2014.09.015.

C.-T. Hsueh, C.-Y. Wen, and Y.-C. Ouyang, “A Secure Scheme Against Power Exhausting Attacks in Hierarchical Wireless Sensor Networks,” IEEE Sens. J., vol. 15, no. 6, pp. 3590–3602, Jun. 2015, doi: 10.1109/JSEN.2015.2395442.

M. Kulkarni, S. M. Sundaram, and V. Diwakar, “Development of Sensor and Optimal Placement for Smoke Detection in an Electric Vehicle Battery Pack,” in 2015 IEEE International Transportation Electrification Conference (ITEC), Aug. 2015, pp. 1–3, doi: 10.1109/ITEC-India.2015.7386868.

X. Zhang, D. Liu, X. Li, H. Dong, and Y. Xi, “The Effect of Modulation Ratio of Cu/Ni Multilayer Films on the Fretting Damage Behaviour of Ti-811 Titanium Alloy,” Materials (Basel)., vol. 10, no. 6, p. 585, May 2017, doi: 10.3390/ma10060585.

Q. Yang et al., “A Low Temperature Operating Gas Sensor with High Response to NO2 Based on Ordered Mesoporous Ni-Doped In2O3,” New J. Chem., vol. 40, no. 3, pp. 2376–2382, 2016, doi: 10.1039/C5NJ02325D.

H. Thomson, “The big freeze,” New Sci., vol. 231, no. 3080, pp. 26–31, Jul. 2016, doi: 10.1016/S0262-4079(16)31192-7.

A. D. Wolf, View Cryonics Technologies’ Validation Identification and Implementation. Germany: Advanced Neural Biosciences, Inc, 2014.

V. De Miguel-Soto et al., “Study of Optical Fiber Sensors for Cryogenic Temperature Measurements,” Sensors, vol. 17, no. 12, p. 2773, Nov. 2017, doi: 10.3390/s17122773.

C. J. Yeager and S. S. Courts, “A review of cryogenic thermometry and common temperature sensors,” IEEE Sens. J., vol. 1, no. 4, pp. 352–360, 2001, doi: 10.1109/7361.983476.

A. Ukil, H. Braendle, and P. Krippner, “Distributed Temperature Sensing: Review of Technology and Applications,” IEEE Sens. J., vol. 12, no. 5, pp. 885–892, May 2012, doi: 10.1109/JSEN.2011.2162060.

J. Fraden, Handbook of Modern Sensors. Cham: Springer International Publishing, 2016.

T. Chowdhury and H. Bulbul, “Design of a Temperature Sensitive Voltage Regulator for AC Load Using RTD,” Int. J. Eng. Sci. Technol., vol. 2, no. 12, pp. 7896–7903, 2010.

N. J. Blasdel, E. K. Wujcik, J. E. Carletta, K.-S. Lee, and C. N. Monty, “Fabric Nanocomposite Resistance Temperature Detector,” IEEE Sens. J., vol. 15, no. 1, pp. 300–306, Jan. 2015, doi: 10.1109/JSEN.2014.2341915.

Y.-M. Wang, D.-D. Zhao, Y.-Q. Zhao, C.-L. Xu, and H.-L. Li, “Effect of Electrodeposition Temperature on the Electrochemical Performance of a Ni(OH)2 Electrode,” RSC Adv., vol. 2, no. 3, pp. 1074–1082, 2012, doi: 10.1039/C1RA00613D.

R. L. Boylestad, Introductory Circuit Analysis, 13rd ed. United States: Pearson Education, 2016.

A. Maher, V. Velusamy, D. Riordan, and J. Walsh, “Modelling of Temperature Coefficient of Resistance of a Thin Film RTD Towards Exhaust Gas Measurement Applications,” Int. J. Smart Sens. Intell. Syst., vol. 7, no. 5, pp. 1–4, Jan. 2014, doi: 10.21307/ijssis-2019-026.

S. K. Sen, T. K. Pan, and P. Ghosal, “An Improved Lead Wire Compensation Technique for Conventional Four Wire Resistance Temperature Detectors (RTDs),” Measurement, vol. 44, no. 5, pp. 842–846, Jun. 2011, doi: 10.1016/j.measurement.2011.01.019.

M. Toifur, Y. Yuningsih, and A. Khusnani, “Microstructure, thickness and sheet resistivity of Cu/Ni thin film produced by electroplating technique on the variation of electrolyte temperature,” J. Phys. Conf. Ser., vol. 997, p. 012053, Mar. 2018, doi: 10.1088/1742-6596/997/1/012053.

J. Fraden, Handbook of Modern Sensors: Physics, Designs, and Applications, Fourth. New York: Springer, 2010.

Q. Li, L. Zhang, X. Tao, and X. Ding, “Review of Flexible Temperature Sensing Networks for Wearable Physiological Monitoring,” Adv. Healthc. Mater., vol. 6, no. 12, p. 1601371, Jun. 2017, doi: 10.1002/adhm.201601371.

E. K. Athanassiou, R. N. Grass, and W. J. Stark, “Large-scale production of carbon-coated copper nanoparticles for sensor applications,” Nanotechnology, vol. 17, no. 6, pp. 1668–1673, Mar. 2006, doi: 10.1088/0957-4484/17/6/022.

A. N. S. Bin Awangku Metosen, S. C. Pang, and S. F. Chin, “Nanostructured Multilayer Composite Films of Manganese Dioxide/Nickel/Copper Sulfide Deposited on Polyethylene Terephthalate Supporting Substrate,” J. Nanomater., vol. 2015, pp. 1–11, 2015, doi: 10.1155/2015/270635.

A. Garraud, P. Combette, and A. Giani, “Thermal stability of Pt/Cr and Pt/Cr2O3 thin-film layers on a SiNx/Si substrate for thermal sensor applications,” Thin Solid Films, vol. 540, pp. 256–260, Jul. 2013, doi: 10.1016/j.tsf.2013.06.012.

M. Lebioda, “Dynamic Properties of Cryogenic Temperature Sensors,” PRZEGL�D ELEKTROTECHNICZNY, vol. 1, no. 2, pp. 227–229, Feb. 2015, doi: 10.15199/48.2015.02.51.

M. Toifur, M. L. Khansa, Okimustava, A. Khusnani, and Ridwan, “The Effect of Deposition Time on the Voltage Range and Sensitivity of Cu/Ni as Low-Temperature Sensor Resulted from Electroplating Assisted by a Transverse Magnetic Field,” Key Eng. Mater., vol. 855, pp. 185–190, Jul. 2020, doi: 10.4028/www.scientific.net/KEM.855.185.

V. Ganesh, D. Vijayaraghavan, and V. Lakshminarayanan, “Fine grain growth of nickel electrodeposit: effect of applied magnetic field during deposition,” Appl. Surf. Sci., vol. 240, no. 1–4, pp. 286–295, Feb. 2005, doi: 10.1016/j.apsusc.2004.06.139.

L. T. Xia, G. Y. Wei, M. G. Li, H. F. Guo, Y. Fu, and H. Dettinger, “Preparation of Co–Pt–P thin films by magnetic electrodeposition,” Mater. Res. Innov., vol. 18, no. 5, pp. 386–391, Aug. 2014, doi: 10.1179/1433075X13Y.0000000154.

M. Ebadi, W. J. Basirun, and Y. Alias, “Influence of magnetic field on the electrodeposition of Ni-Co alloy,” J. Chem. Sci., vol. 122, no. 2, pp. 279–285, Mar. 2010, doi: 10.1007/s12039-010-0032-9.

Y. Yu et al., “Effect of Magnetic Fields on Pulse Plating of Cobalt Films,” Rare Met., vol. 31, no. 2, pp. 125–129, Apr. 2012, doi: 10.1007/s12598-012-0476-9.

L. M. A. Monzon and J. M. D. Coey, “Magnetic Fields In Electrochemistry: The Kelvin Force. A Mini-Review,” Electrochem. commun., vol. 42, pp. 42–45, May 2014, doi: 10.1016/j.elecom.2014.02.005.

R. A. Tacken and L. J. J. Janssen, “Applications of Magnetoelectrolysis,” J. Appl. Electrochem., vol. 25, no. 1, Jan. 1995, doi: 10.1007/BF00251257.

Y. D. Yu, Z. L. Song, H. L. Ge, and G. Y. Wei, “Influence of Magnetic Fields on Cobalt Electrodeposition,” Surf. Eng., vol. 30, no. 2, pp. 83–86, Feb. 2014, doi: 10.1179/1743294413Y.0000000229.

A. Krause, J. Koza, A. Ispas, M. Uhlemann, A. Gebert, and A. Bund, “Magnetic Field Induced Micro-Convective Phenomena Inside the Diffusion Layer During the Electrodeposition of Co, Ni and Cu,” Electrochim. Acta, vol. 52, no. 22, pp. 6338–6345, Jun. 2007, doi: 10.1016/j.electacta.2007.04.054.

A. Bund, S. Koehler, H. H. Kuehnlein, and W. Plieth, “Magnetic field effects in electrochemical reactions,” Electrochim. Acta, vol. 49, no. 1, pp. 147–152, Dec. 2003, doi: 10.1016/j.electacta.2003.04.009.

H. Matsushima, A. Ispas, A. Bund, W. Plieth, and Y. Fukunaka, “Magnetic field effects on microstructural variation of electrodeposited cobalt films,” J. Solid State Electrochem., vol. 11, no. 6, pp. 737–743, Jun. 2007, doi: 10.1007/s10008-006-0210-3.

E. Sugiarti, K. A. Zaini, Y. M. Wang, N. Hashimoto, S. Ohnuki, and S. Hayashi, “Effect of Pack Cementation Temperature on Oxidation Behavior of NiCoCrAl Coated Layer,” Adv. Mater. Res., vol. 1112, pp. 353–358, Jul. 2015, doi: 10.4028/www.scientific.net/AMR.1112.353.

A. Pandhi, “The Chilling Legality of Cryopreservation,” Int. J. Socio-Legal Anal. Rural Dev., vol. 2, no. 3, pp. 96–97, 2015.

F. Cimerman, B. Blagojevic, and I. Bajsic, “Identification of the Dynamic Properties of Temperature-Sensors in Natural and Petroleum Gas,” Sensors Actuators A Phys., vol. 96, no. 1, pp. 1–13, Jan. 2002, doi: 10.1016/S0924-4247(01)00759-2.

T. Chowdhury, “Study of Self-Heating Effects in GaN HEMTs,” Arizona State University, 2013.

B. Garnier and F. Lanzetta, “In Situ Realization/Characterization of Temperature and Heat Flux Sensors,” in Advanced Spring School “Thermal Measurements & Inverse techniques,” 2015, pp. 79–87.

Downloads

Published

Issue

Section

License

Copyright (c) 2022 Moh. Toifur, Effilia Allun Jaladri, Efi Kurniasari, Yuni Latifah, M. Taufiqurrahman

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish in IRiP agree to the following terms: Authors retain copyright and grant the IRiP right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material) the work for any purpose, even commercially with an acknowledgment of the work's authorship and initial publication in IRiP. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in IRiP. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).