Buletin Ilmiah Sarjana Teknik Elektro ISSN: 2685-9572

Dashboard for Industrial Load Control and Remote Power Factor Correction Based on Adafruit's MQTT

Irgi Surya, Jaja Kustija

Departement of Electrical Engineering Education, Universitas Pendidikan Indonesia, Bandung, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Submitted 02 January 2023 Revised 05 February 2023 Accepted 08 February 2023

|

|

One of the user interface problems in an internet of things (IoT) system is influenced by monitoring which is easy to access, flexible and efficient in its use, has been discussed a lot but the problem is still unresolved, one solution to this problem is by presenting the Adafruit mqtt, which by using the mqtt Adafruit user interface for monitoring on an internet of things system can facilitate control and remote control. In this case the use of Adafruit mqtt is used to monitor electrical loads and improve power factor. This research presents an internet of things system that is capable of monitoring electrical load and improving power factor that already uses the Adafruit mqtt as its user interface. The method used is through the Analysis, Design, Development, Implementation, Evaluation (ADDIE) approach. The results showed that this system is feasible to use because based on the experimental results this system is able to work well and provide convenience for users and can monitor in real time current, voltage, energy, frequency, power factor, real power, apparent power, and reactive power. only by using smartphones, laptops, tablets, or computers. It is hoped that in the future this research will be able to continue to be developed so that the use of electrical energy in industry can be much more effective and efficient. |

Keywords: MQTT; Adafruit; Monitoring; Electrical Loads; Internet of Things

|

Corresponding Author: Jaja Kustija, Departement of Electrical Engineering Education, Universitas Pendidikan Indonesia, Bandung, Indonesia. Email: jaja.kustija@upi.edu |

|

This work is licensed under a Creative Commons Attribution-Share Alike 4.0

|

|

Document Citation: I. Surya and J. Kustija, “Dashboard for Industrial Load Control and Remote Power Factor Correction Based on Adafruit's MQTT,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 5, no. 1, pp. 76-85, 2023, DOI: 10.12928/biste.v5i1.7494. |

- INTRODUCTION

This research presents an internet of things system that is capable of monitoring electrical load and improving power factor that already uses the Adafruit mqtt as its user interface[1], starting from the architecture globally then developed into a prototype and realized in the form of a system that can be used as a tool for controlling and monitoring the use of electric loads and repairing power factors in real time using NodeMCU ESP32 [2] and the Adafruit server where users can later control and monitor the use of electronic devices at home using only their smartphones [3]. Then this system is tested and its performance is measured both in terms of delay, server response, and the monitoring display of this system.

This research aims to design, manufacture, control, and evaluate a prototype that can make a system able to control electrical loads and can monitor in real time and can even be controlled remotely using the internet. [4] The method used is through the Analysis, Design, Development, Implementation, Evaluation (ADDIE) approach, namely by studying the literature [5] to analyze the research object, then design and develop the design results and implement the design results and then implement them on the research object, all suggestions for improvement are used as an evaluation for improving this system [6], The novelty of this research is to help users control and monitor electrical loads in real time and without the need to use applications or software that must be downloaded first [7], users only need to enter the Adafruit website, this is of course much easier and more flexible in use [8], unlike in previous studies that have been done, the user must download a software or application first and this system is also equipped with the use of sensors so that this system can work more efficiently [9].

The internet of things is a concept in which objects or objects are embedded with technologies such as sensors and software with the aim of communicating, controlling, connecting and exchanging data through other devices as long as they are still connected to the internet [8][10]. The Internet of Thing is a concept whereby an object has the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction [11]. The development of IoT can be seen starting from the level of convergence of wireless technology, microelectromechanical (MEMS), internet, and QR (Quick Responses) Code. IoT is also often identified with RFID (Radio Frequency Identification) as a method of communication [12][13]. In it’s development, the internet of things has modernized many electronic equipment that still has a conventional system, which has been converted into an embedded system [14] a program with a certain algorithm to be controlled, monitored, or monitored remotely [15].

NodeMCU is an open source IoT platform [16]. It consists of hardware in the form of the ESP32 on-chip system made by Esperessif System [17]. NodeMCU can be analogous to an Arduino board connected to ESP32 [18][19]. The ESP32 microcontroller is made by a company called Espressif Systems. One of the advantages possessed by the ESP32 is that it already has Wi-Fi and Bluetooth in it, so it will be very easy when we learn to create an IoT system that requires a wireless connection [13][20]. The ESP32 microcontroller has the advantage of being a low-cost, low-power system with a WiFi module that is integrated with the microcontroller chip and has Bluetooth with dual mode and power-saving features making it more flexible [21][22].

MQTT is a standards-based messaging protocol, or set of rules, used for machine-to-machine communication. Smart sensors, wearables, and other Internet of Things devices typically must send and receive data over networks with limited resources and bandwidth. Adafruit is a provider of MQTT server services for the Internet of Things [23], This service can be used to make NodeMCU ESP32 controllable remotely by using subscribe and publish facilities. Without the need to use other applications or software, users only need to access the available websites. The advantage of Adafruit is that users are not charged when creating an account and using it as a server to be connected to NodeMCU ESP32 [24].

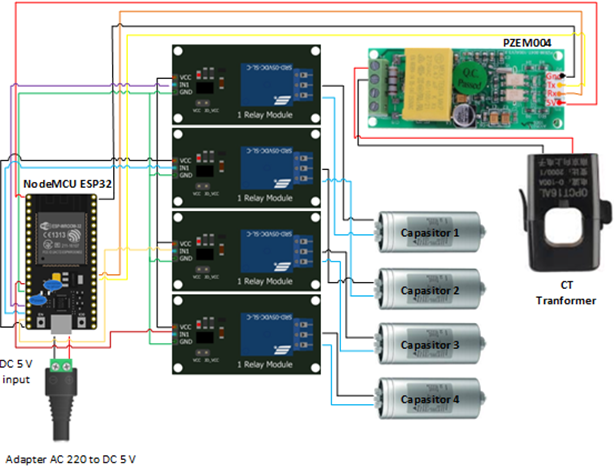

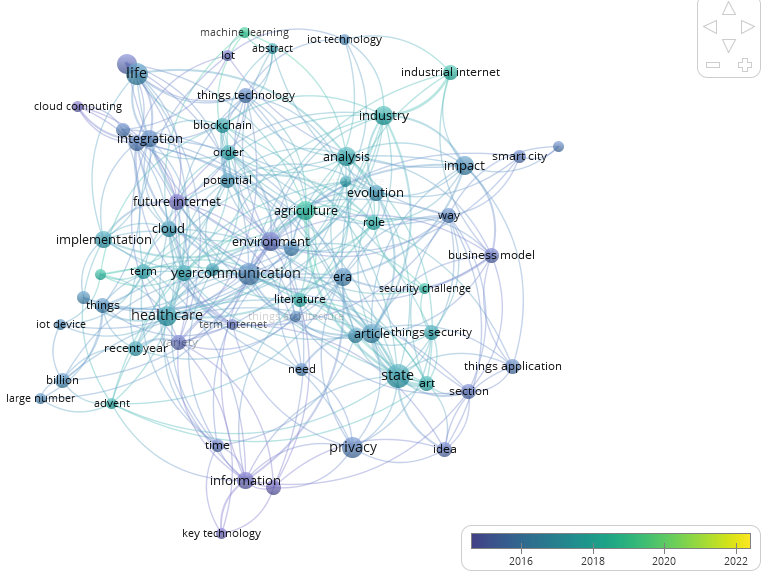

In this research to find out the position of the research to be carried out based on the results of previous research and to consider gaps and novelty or what is known as novelty. In this research, to map and visualize existing research using the help of Vosviewer software, the way this software works is by bibliometrically analyzing research data that already exists and has been published and then taken from indexing databases, for example taken from Google Scholar, Scopus, Web of Science, and others [25]. To find out research developments that are in accordance with this research topic, previously taking 400 journals in the last 10 years from 2012 to 2022 with the main topic “Internet of Things” [26] from the Google Scholar database, the visualization results show that research developments with the main topic “Internet of Things” in the last 10 years has led to 64 research topics which can be seen in Figure 1 and one of the highest focuses is research with industry main topics in 19 published journals which can be seen in Figure 2 [27].

Figure 1. Visualization results on vosviewer with the main topic Internet of Things

Figure 2. Visualization results on vosviewer with the main topic Industry

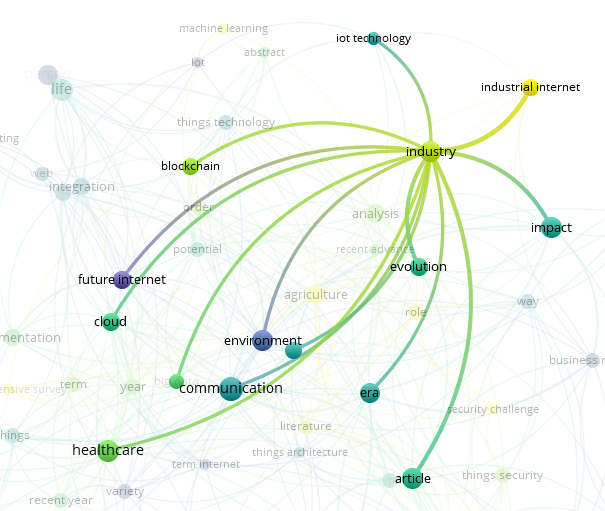

Based on the results of the analysis using the help of Vosviewer software, there are 5 topics that are most relevant to this research, but in general no one has yet used the user interface with mqtt Adafruit [28], the resulting visualization can be seen in Figure 3.

Figure 3. The results of visualization analysis on vosviewer

- METHODS

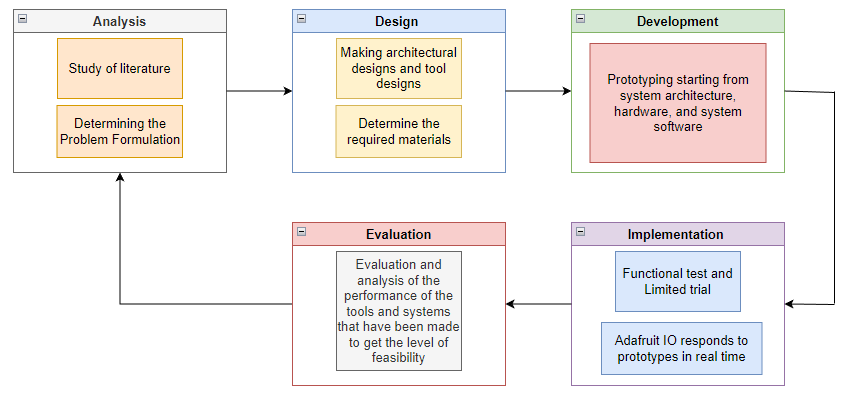

The research method used is the ADDIE approach (Analysis, Design, Development, Implementation, Evaluation) as shown in Figure 4. This method is a method that is widely used to produce a product or industrial tool. The product made in this case is a tool so that this research will fit the ADDIE approach [3][21].

Figure 4. The research method

Based on Figure 4 explained the research method:

- Stages of analysis

The analysis stage is the first step in this research, namely by conducting a literature study observing, comparing and reviewing the results of previous research that has previously been made and published in national and international journals, in this research the literature study stage is assisted by using software assistance vosviewer where the results of the analysis on vosviewer are used as a reference and recommendation to determine research gaps and research novelty, based on the results of the analysis on the vosviewer software it shows that in several similar studies there has not been a study using the Adafruit mqtt which is used as a user interface for its utilization in load monitoring electricity and power factor improvement. Next determine the formulation of the problem that will be a reference and follow-up action of this research.

- Stages of design

The design stage is a follow-up stage from the results of the literature study and the results of the problem formulation that have been predetermined, at this stage a system architecture is created that connects each core component of the tool to be made, there are three core parts to the system architecture, namely the first component of the user or user , both the cloud and mqtt components, and finally the three components on load. Then determine what materials will be used in this study, some of the core materials that have a major role in this system are the PZEM-004T module, NodeMCU ESP32, Relay, and Power factor correction capacitors.

- Stages of development

This development stage is a continuation of the process from the design stage, in which the results of the next design stage will be executed by making the tool, in the early stages of making this tool an experiment was carried out using only one relay intended for only one load but after successful use one relay is then added to four relays intended for four loads.

- Stages of implementation

This implementation stage is the next stage after the development stage was previously carried out, the tool that was previously made is entered at the implementation stage to be tested and implemented on the electrical load, this trial stage is important because it is to find out whether the tool can work and function as expected or not, then also tested the user interface whether it can be displayed on the Adafruit mqtt dashboard so whether the measurement results from the PZEM-004T module can display the measurement results of Voltage, Current, Real Power, Apparent Power, Reactive Power, and Power Factor or not, also tested on loads that are inductive and have a power factor of less than 0.85 will be corrected by attaching a capacitor to the load so that the power factor rises to close to one.

- Evaluation stage

The final stage is to evaluate, namely to carry out analysis and calculations with tool testing instrumentation, instrumentation testing is carried out by testing the tool with the same load but comparing the measurement results between the measurement results from this tool and the measurement results from standard factory tools that are commonly used, the results What has been obtained is then analyzed whether it is as expected, and provides recommendations and suggestions for further research.

2.1. System Architecture Design

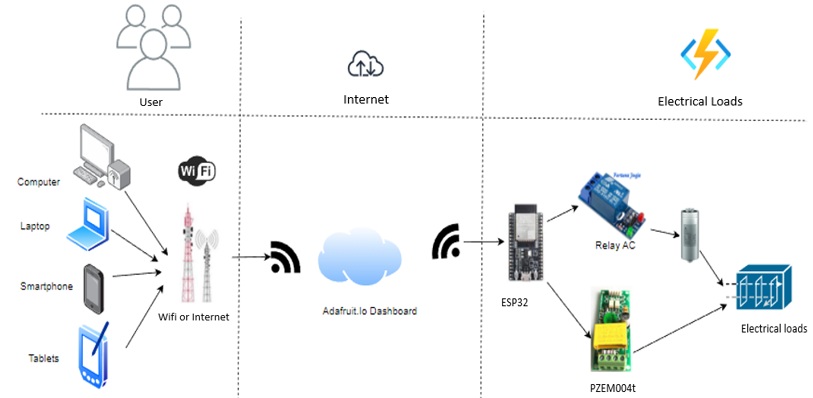

Based on Figure 5, it describes the system architecture components:

- Components on the user or users

Components on the user or user section can also be called the user interface section where in this component the user can monitor or improve the power factor by using his computer, laptop, smartphone or tablet as long as he can connect with good internet access then this can be done so that technicians do not need to go to the control and monitoring panel but can be done anywhere only with the help of devices owned by the user or users, so that this can make it easier and increase efficiency for technicians to monitor and improve power factor.

- Components on the internet system

Components on the internet system are one of the core components whose role in this case is to connect between the user component and the electrical load component, using the Adafruit mqtt later the user or user can monitor electrical loads such as Voltage, Current, Real Power, Apparent Power, Reactive Power , and Power Factor through the dashboard display, you can also make improvements to the power factor by turning on the relay connected to the power factor correction capacitor remotely with the pushbutton available on the dashboard.

- Components in the electrical load section

The components in the load section consist of the core materials of this tool, namely NodeMCU ESP32 which becomes a microcontroller and also acts as a liaison which later sends measurements from the PZEM-004T module to the Adafruit dashboard so that it can be displayed on the user interface. The PZEM-004T module is a multi sensor. functions that can be used to measure Voltage, Current, Real Power, Apparent Power, Reactive Power and Power Factor [29][30]. AC 220V relay is a material used to turn on and/or turn off power factor correction capacitors that have been connected to the relay.

Figure 5. Architecture System

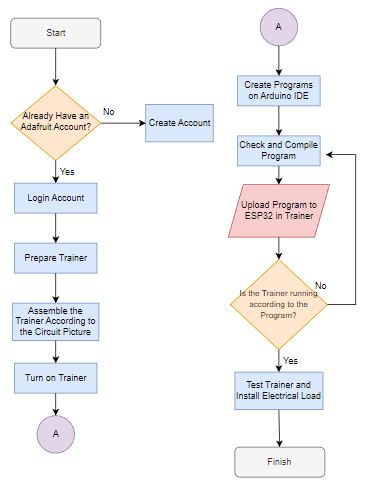

2.2. Flowchart of Tool Use

Based on Figure 6, the first step that must be done is to create an Adafruit account first, then the preparation that must be done is to turn on the device by pressing the ON button, after the device is turned on then do the creation and checking of the program that was created before, this tool uses a program in the Arduino IDE software which then if the program has been created, the final step is to upload the program to the ESP32 nodeMCU.

Figure 6. Flowchart of tool use

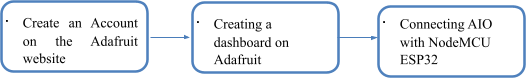

2.3. Settings Account Adafruit With Nodemcu Esp32

The AdaFruit company is a website-based Internet platform pf things which is engaged in the manufacture of open source hardware and also provides a server that can be connected to NodeMCU ESP32 to be able to control it remotely. By using Adafruit, users do not need to download applications or other supporting software. need to open an available website, the steps that must be taken to be able to set up NodeMCU ESP32 with the AdaFruit server can be seen in Figure 7.

Figure 7. Setting Adafruit

- RESULT AND DISCUSSION

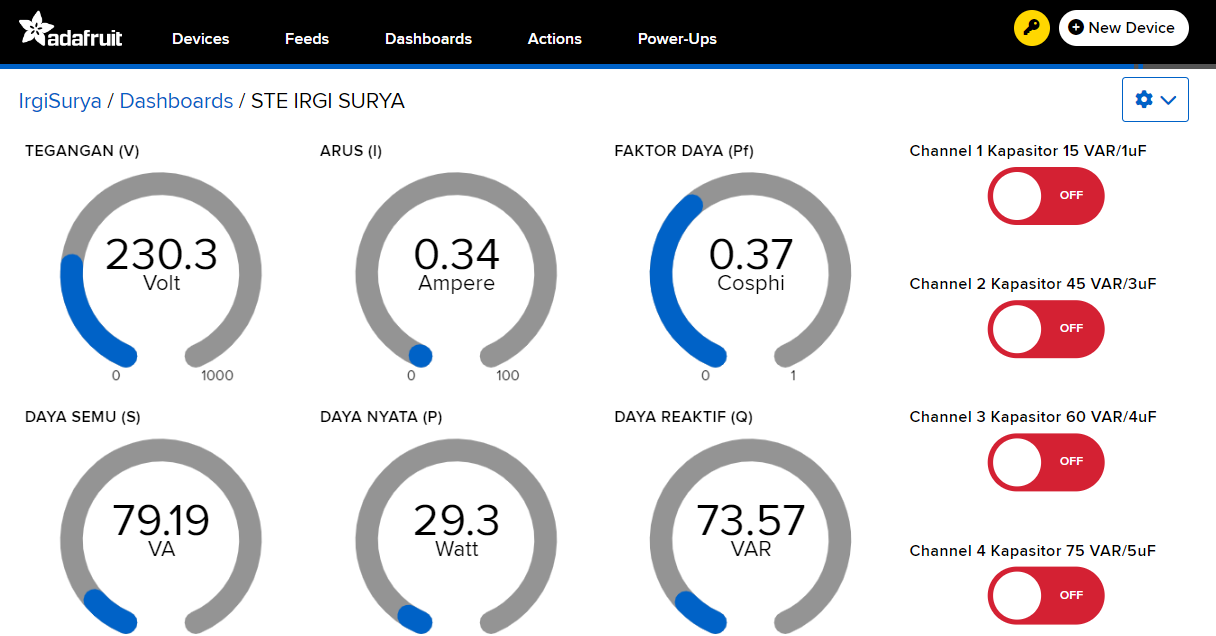

3.1. Make a Dashboard Display for the User Interface Using MQTT Adafruit

Adafruit is a provider of MQTT server services for Internet of Things, this service can be used to make NodeMCU ESP32 controllable remotely using subscribe and publish facilities. Without the need to use other applications or software, users only need to access the available website. The advantage of Adafruit is that users are not charged when creating an account and using it as a server that can connect with NodeMCU ESP32. In Figure 8 is the dashboard that has been made.

Figure 8. Display dashboard on Adafruit MQTT

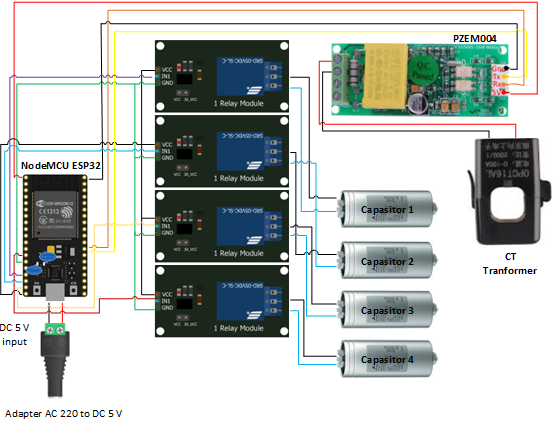

3.2. Make a Tool Wiring Drawing

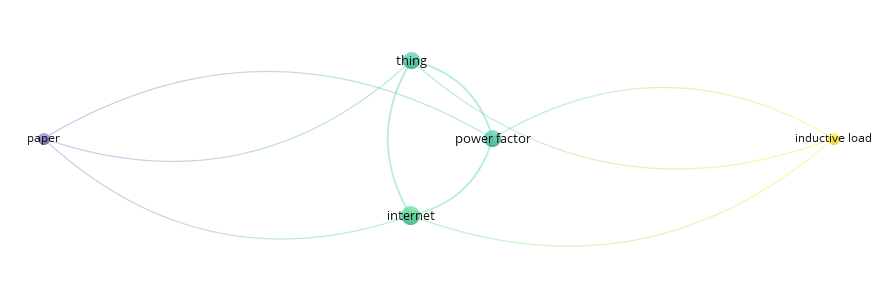

Based on Figure 9 for the wiring of the device, it can be seen in the study that 4 relays were used which were later connected in parallel with the power factor correction capacitor, the 4 relays were intended for 4 capacitors of different sizes, namely 15 VAR, 45 VAR, 60 VAR and for 75 VAR depends on the needs of the installed load.

Figure 9. Wiring drawing

3.3. Limited Testing

System testing is carried out by making a prototype using 4 lamps each connected to the Adafruit system and connected to the NodeMCU ESP32 as a microcontroller that can connect to the user's wifi and smartphone, this test measures the delay between the user, server and installed electronic equipment, as well measure the server response on the monitoring display displayed on the Adafruit server with a certain internet speed range. Can be seen in Table 1.

Table 1. Tests on the system measure wifi internet speed, user internet speed and delays that occur

Wifi Internet Speed (MBPS) | User Internet Speed (MBPS) | Delays (S) |

21-30 | 11-15 | 0.5 |

11-20 | 6-10 | 1 |

0-10 | 0-5 | 2 |

Based on Table 1, it can be seen that there is a significant influence between wifi internet speed, user internet speed, and the delay that occurs. In the range of 0-10 MBPS wifi internet speed and user internet speed are installed in the range of 0-5 MBPS then the delay that occurs is 1 second, in the range 11-20 wifi speed and user internet speed are installed in the range of 6-10 MBPS then the delay that occurs ie 0.8 seconds, and in the range 21-30 wifi internet speed and user internet speed are installed in the 11-15 MBPS range, the delay that occurs is 0.6 seconds, meaning that wifi internet speed and user internet speed are directly proportional to the delay in this system, the more the higher the wifi internet speed and the user's internet speed the smaller the delay that occurs in this system.

- CONCLUSIONS

Based on the results of the tools that have been made and limited instrumentation testing, it can be concluded that the results of limited instrumentation testing indicate that there is a delay of 0.5 to 2 seconds between the reading of the PZEM-004T module and the user interface display on the Adafruit dashboard, this occurs due to network factors the internet which is very influential on the speed of data transmission, based on the test results also show that this tool can work in real time as long as it can always be connected to an adequate and good internet network. The Adafruit mqtt display dashboard as a display user interface can work well and is easy to use, an attractive display to look at can also be used on digital devices that support good internet access such as smartphones, laptops, computers or tablets. Users do not need to be bothered with software or applications that must be downloaded first because they only need to access the Adafruit website to monitor them, so that it can make it easier for user.

ACKNOWLEDGEMENT

Thanks to all parties who have participated in this research process until the research paper is completed.

REFERENCES

[1] J. Kustija, K. S. Nur Adillawati, and D. Fauziah, “Smart home system to support Bandung smart city programme,” Pertanika J. Sci. Technol., vol. 25, no. S, pp. 77–88, 2017, http://www.pertanika.upm.edu.my/pjst/browse/special-issue?article=JST-S0318-2017.

[2] M. A. Rahman, Y. Li, T. Nabeed and M. T. Rahman, “Remote monitoring of heart rate and ECG signal using ESP32,” 2021 4th International Conference on Advanced Electronic Materials, Computers and Software Engineering (AEMCSE), pp. 604-610, 2021, https://doi.org/10.1109/AEMCSE51986.2021.00127.

[3] J. Kustija and N. Dwi Jayanto, “IoT Implementation for Development of Remote Laboratory (Case Study on Microscope Practice),” Reka Elkomika, vol. 3, no. 1, pp. 20–29, 2022, https://doi.org/10.26760/rekaelkomika.v3i1.20-29.

[4] J. Kustija and Purnawan, “Solutions To Overcome Inequality in Laboratory Facilities and Laboratory Sharing in Similar Institutions Remote Laboratory Based,” Journal of Engineering Science and Technology (JESTEC), vol. 17, no. 3, pp. 1792–1809, 2022, https://jestec.taylors.edu.my/Vol%2017%20Issue%203%20June%202022/17_3_13.pdf.

[5] J. Kustija and F. Andika, “Control - Monitoring System Of Oxygen Level, Ph, Temperature And Feeding in Pond Based on Iot,” REKA ELKOMIKA J. Pengabdi. Kpd. Masy., vol. 2, no. 1, pp. 1–10, 2021, https://doi.org/10.26760/rekaelkomika.v2i1.1-10.

[6] T. Vince et al., “IoT implementation in remote measuring laboratory VMLab analyses,” Journal of Universal Computer Science, vol. 26, no. 11, pp. 1402–1421, 2020, https://doi.org/10.3897/jucs.2020.074.

[7] N. D. Jayanto and J. Kustija, “Remote desktop system in IoT and HTML 5-based virtual laboratory for HMI (Human Machine Interface) practicum and hydraulic simulation,” IOP Conference Series: Materials Science and Engineering, vol. 830, no. 4, 2020, https://doi.org/10.1088/1757-899X/830/4/042052.

[8] P. W. Rusimamto, E. Endryansyah, L. Anifah, R. Harimurti and Y. Anistyasari, “Implementation of arduino pro mini and ESP32 cam for temperature monitoring on automatic thermogun IoT-based,” Indones. J. Electr. Eng. Comput. Sci., vol. 23, no. 3, pp. 1366–1375, 2021, https://doi.org/10.11591/ijeecs.v23.i3.pp1366-1375.

[9] J. Kustija, A. Ana and N. D. W. I. Jayanto, “Web-based and thinvnc remote laboratory implementation to support students skills in mechatronics course to face the industrial revolution 4.0,” Journal of Engineering Science and Technology (JESTEC), vol. 16, no. 2, pp. 1800–1813, 2021, https://jestec.taylors.edu.my/Vol%2016%20issue%202%20April%202021/16_2_63.pdf.

[10] A. Sumardiono, S. Rahmat, E. Alimudin and N. A. Ilahi, “Sistem Kontrol-Monitoring Suhu dan Kadar Oksigen pada Kolam Budidaya Ikan Lele,” JTERA (Jurnal Teknologi Rekayasa), vol. 5, no. 2, p. 231, 2020, https://doi.org/10.31544/jtera.v5.i2.2020.231-236.

[11] G. Ilieva, “IoT in Distance Learning during the COVID-19 Pandemic,” TEM Journal, vol. 9, no. 4, pp. 1669–1674, 2020, https://doi.org/10.18421/TEM94-45.

[12] I. Surya and J. Kustija, “Implementation of the Electricity Load Monitoring Trainer and Internet of Things-based Power Factor Improvement,” International Journal of Scientific and Research Publications, vol. 12, no. 11, pp. 206–215, 2022, https://doi.org/10.29322/IJSRP.12.11.2022.p13127.

[13] F. Jonathan and T. W. O. Putri, “Prototype of Home Power Monitoring Tool for Electrical Outlet Using ESP32,” 2021 International Conference on ICT for Smart Society (ICISS), pp. 1-5, 2021, https://doi.org/10.1109/ICISS53185.2021.9533189.

[14] Z. Chen, R. Khemmar, B. Decoux, A. Atahouet and J. -Y. Ertaud, “Real Time Object Detection, Tracking, and Distance and Motion Estimation based on Deep Learning: Application to Smart Mobility,” 2019 Eighth International Conference on Emerging Security Technologies (EST), pp. 1-6, 2019, https://doi.org/10.1109/EST.2019.8806222.

[15] S. Anand and V. Nath, “Study and design of smart embedded system for remote health monitoring using internet of things,” Lecture Notes in Electrical Engineering, vol. 511. pp. 409–414, 2019, https://doi.org/10.1007/978-981-13-0776-8_37.

[16] A. Škraba, A. Koložvari, D. Kofjač, R. Stojanović, E. Semenkin and V. Stanovov, “Prototype of Group Heart Rate Monitoring with ESP32,” 2019 8th Mediterranean Conference on Embedded Computing (MECO), pp. 1-4, 2019, https://doi.org/10.1109/MECO.2019.8760150.

[17] N. A. Afifie et al., “Evaluation Method of Mesh Protocol over ESP32 and ESP8266,” Baghdad Science Journal, vol. 18, no. 4, pp. 1397–1405, 2021, https://doi.org/10.21123/bsj.2021.18.4(Suppl.).1397.

[18] P. Megantoro, S. A. Aldhama, G. S. Prihandana, P. Vigneshwaran, “IoT-based weather station with air quality measurement using ESP32 for environmental aerial condition study,” Telkomnika (Telecommunication, Computing, Electronics and Control), vol. 19, no. 4, pp. 1316–1325, 2021, https://doi.org/10.12928/telkomnika.v19i4.18990.

[19] N. Nikolov and O. Nakov, “Research of Secure Communication of Esp32 IoT Embedded System to.NET Core Cloud Structure using MQTTS SSL/TLS,” 2019 IEEE XXVIII International Scientific Conference Electronics (ET), pp. 1-4, 2019, https://doi.org/10.1109/ET.2019.8878636.

[20] Y. H. Lin, “Novel smart home system architecture facilitated with distributed and embedded flexible edge analytics in demand-side management,” Int. Trans. Electr. Energy Syst., vol. 29, no. 6, 2019, https://doi.org/10.1002/2050-7038.12014.

[21] J. Kustija, I. Surya and D. Fahrizal, “Design of automated power factor monitoring and repair tool for industry in real time based on Internet of Things,” International Journal of Science and Technology Research Archive, vol. 3, no. 2, pp. 1–8, 2022, https://doi.org/10.53771/ijstra.2022.3.2.0106.

[22] R. B. Salikhov, V K. Abdrakhmanov and I. N. Safargalin, “Internet of things (IoT) security alarms on ESP32-CAM,” Journal of Physics: Conference Series, vol. 2096, no. 1, 2021, https://doi.org/10.1088/1742-6596/2096/1/012109.

[23] N. Fujii and N. Koike, “IoT Remote Group Experiments in the Cyber Laboratory: A FPGA-based Remote Laboratory in the Hybrid Cloud,” 2017 International Conference on Cyberworlds (CW), pp. 162-165, 2017, https://doi.org/10.1109/CW.2017.29.

[24] M. Babiuch and P. FoltÝnek, “Creating a Mobile Application with the ESP32 Azure IoT Development Board Using a Cloud Platform,” 2021 22nd International Carpathian Control Conference (ICCC), pp. 1-4, 2021, https://doi.org/10.1109/ICCC51557.2021.9454607.

[25] S. Nikolic, M. Ros, K. Jovanovic and Z. Stanisavljevic, “Remote, simulation or traditional engineering teaching laboratory: a systematic literature review of assessment implementations to measure student achievement or learning,” European Journal of Engineering Education, vol. 46, no. 6. pp. 1141–1162, 2021, https://doi.org/10.1080/03043797.2021.1990864.

[26] V. Pravalika, “Internet of things based home monitoring and device control using Esp32,” International Journal of Recent Technology and Engineering (IJRTE), vol. 8, no. 1S4, pp. 58–62, 2019, https://www.ijrte.org/wp-content/uploads/papers/v8i1s4/A10110681S419.pdf.

[27] A. Kumar and V. Nath, “Study and design of smart embedded system for smart city using internet of things,” Lecture Notes in Electrical Engineering, vol. 511. pp. 397–408, 2019, https://doi.org/10.1007/978-981-13-0776-8_36.

[28] A. Kumar, N. N. Raju, P. Muthukumar and P. V. Selvan, “Experimental studies on industrial scale metal hydride based hydrogen storage system with embedded cooling tubes,” International Journal of Hydrogen Energy, vol. 44, no. 26, pp. 13549–13560, 2019, https://doi.org/10.1016/j.ijhydene.2019.03.180.

[29] M. D. Tobi and V. N. V. Harling, “Prototype Design of Wireless Electric Energy Transmission System and Distance Electric Recording Record System Using PZEM004T and NRF24L01 Module,” Journal of Physics: Conference Series, vol. 1783, no. 1, 2021, https://doi.org/10.1088/1742-6596/1783/1/012074.

[30] K. Chooruang and K. Meekul, “Design of an IoT Energy Monitoring System,” 2018 16th International Conference on ICT and Knowledge Engineering (ICT&KE), pp. 1-4, 2018, https://doi.org/10.1109/ICTKE.2018.8612412.

AUTHOR BIOGRAPHY

| Irgi Surya a student who is pursuing a bachelor's degree in an electrical engineering education study program, research interests include the internet of things, artificial intelligence, Department of Electrical Engineering Education, Faculty of Technology and Vocational Education, Universitas Pendidikan Indonesia, Bandung, Indonesia. irgi.surya@upi.edu

|

|

|

| Jaja Kustija a lecturer at the Universitas Pendidikan Indonesia, research interests include the internet of things, artificial intelligence, remote laboratory, technology and vocational education, Department of Electrical Engineering Education, Faculty of Technology and Vocational Education, Universitas Pendidikan Indonesia, Bandung, Indonesia. jaja.kustija@upi.edu

|

|

|

Dashboard for Industrial Load Control and Remote Power Factor Correction Based on Adafruit's MQTT

(Irgi Surya)