Buletin Ilmiah Sarjana Teknik Elektro ISSN: 2685-9572

Monitoring Temperature and Humidity of Boiler Chicken Cages Based on Internet of Things (IoT)

Dhimas Dwiki Sanjaya, Abdul Fadlil

Department of Electrical Engineering, Universitas Ahmad Dahlan, Yogyakarta, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Submitted 22 September 2021 Revised 20 October 2021 Accepted 10 May 2023 |

|

Animal husbandry is a business sector that is growing rapidly. Poultry is very popular with the community, especially broiler chickens. However, breeders find it difficult to maintain the condition of broiler chickens because these poultry are heat stress birds that are easily stressed if the coop conditions are too hot or cold. Because of this, this research was conducted to design a system that can control the temperature and humidity values of the chicken coop automatically. The system designed in this study uses a DHT11 sensor which is useful for detecting the temperature and humidity values of the chicken coop. The microcontroller used is NodeMCU. The temperature and humidity values are sent via IoT (Internet of Things) to the ThingSpeak media platform. The fan will turn on if the temperature value is more than 31° C. The mist maker will light up if the humidity value is less than 55%, and the incandescent lamp will light up if the temperature value is less than 29° C. The system testing performed resulted in a temperature error value of 1,05% and humidity error value of 2,39%. The system's ability to turn on fans, mist makers, and incandescent lamps when the temperature value does not match the conditions can also run well. |

Keywords: Temperature; Humidity; DHT11; IoT (Internet of Things); Thingspeak

|

Corresponding Author: Abdul Fadlil, Department of Electrical Engineering, Universitas Ahmad Dahlan, Bantul, Yogyakarta, Indonesia. Email: fadlil@ee.uad.ac.id |

This work is licensed under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: D. D. Sanjaya and A. Fadlil, “Monitoring Temperature and Humidity of Boiler Chicken Cages Based on Internet of Things (IoT),” Buletin Ilmiah Sarjana Teknik Elektro, vol. 5, no. 2, pp. 180-189, 2023, DOI:10.12928/biste.v5i2.4897. |

- INTRODUCTION

Currently animal husbandry is one of the fields that is developing very rapidly and has a high enough demand in the community, especially poultry such as broiler chickens. The field of broiler chicken farming has one thing that must be considered, namely the environmental conditions of the chicken coop. Many people are still concerned about how to care for chickens, even though this breeding activity is quite simple, because the temperature and humidity values of the chicken coop environment must be at a certain value so that the chickens will feel comfortable in the coop [1][2][3]. The temperature and humidity of the chicken coop environment can affect the growth of the chickens. In principle, the maximum growth and efficiency of food use in chickens will not be achieved if the temperature and environmental conditions are not suitable [4][5][6].

Poultry is an animal that does not have sweat glands which causes poultry to be classified as warm-blooded animals. Biological conditions like this result in poultry in hot conditions having difficulty dissipating body heat into the environment. The problem faced in the poultry industry in the tropics is that high environmental temperatures will create heat stress on broiler chickens [7][8]. Heat stress is a condition of increasing extreme temperatures experienced by livestock originating from outside and from inside the chicken coop environment. The temperature of broiler chickens can be maintained by adjusting the temperature and humidity in the broiler environment [9][10].

As a way to overcome these problems, we need a system that can control the temperature and humidity values of the Internet of Things (IoT) based chicken coop environment. Monitoring is a process of monitoring, observing, controlling and managing all activities of inanimate objects and organisms that you want to know [11][12][13][14]. Internet of Things (IoT) is a global network connection infrastructure, which can connect physical and virtual objects through communication technology [15]. The IoT section contains networks and internet that have been developed. IoT is useful for creating an identity for objects so that these objects can recognize other objects and facilitate interaction between many people and these objects wherever and whenever [16][17][18].

In previous studies, an IoT testing method was carried out on systems built using NodeMCU and using Blynk software to control the temperature and humidity of chicken coops [19]. In addition, there is research using the ATMega 8535 microcontroller and the LM35 temperature sensor [20]. Because the IoT system has been successful in previous research, this research will recommend IoT to control the temperature and humidity values of the chicken coop environment using the DHT11 sensor and then it will be sent to the Thingspeak platform in real-time.

- METHOD

- System Design

There are two stages in the system design that will be made, namely software design (software) and hardware design (hardware). In the software design section contains algorithm diagrams about the operation of the system. The hardware design section contains block diagrams of hardware systems and wiring diagrams of system circuits.

- Software Design

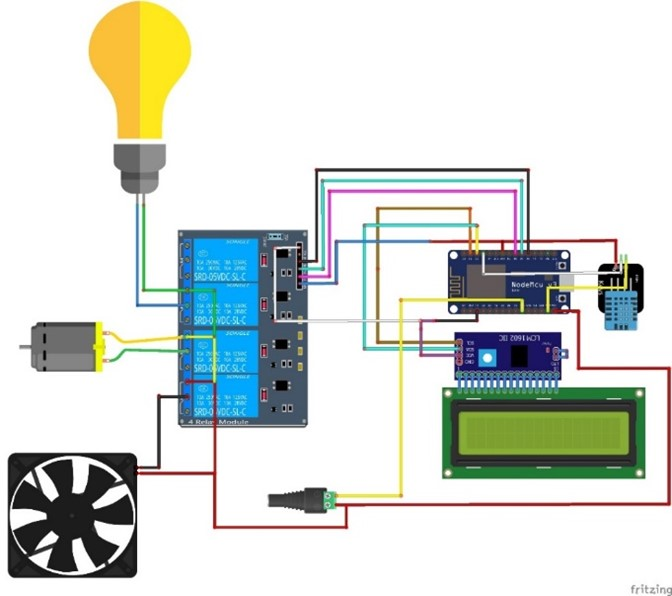

In designing this system, using the Arduino IDE software as a tool to program NodeMCU in C++. Before programming the system using the Arduino IDE software, a flowchart of the system to be designed is made. The flowchart shown in Figure 1 is a work system design of a device monitoring the temperature and humidity values of a controlled chicken coop using IoT. Starting from providing input voltage to the NodeMCU microcontroller which will later be connected to the internet network.

After connecting to the internet network, the DHT11 sensor will automatically detect the temperature and humidity values of the chicken coop environment. Apart from that, there is a program that uses NTP (Network Time Protocol) to detect the time and date of that day, both of which will then be processed by NodeMCU. The data that has been processed by NodeMCU will be sent to the Thingspeak media platform. There is also a relay that will be used to turn on the fan if the detected temperature value exceeds the existing limit. Then turn on the incandescent lamp if the detected temperature value is less than a predetermined limit. As well as turning on the mist maker if the detected humidity value of the chicken coop is less than a predetermined limit.

Figure 1. Flowchart of reading and sending data on the system

- Hardware Design

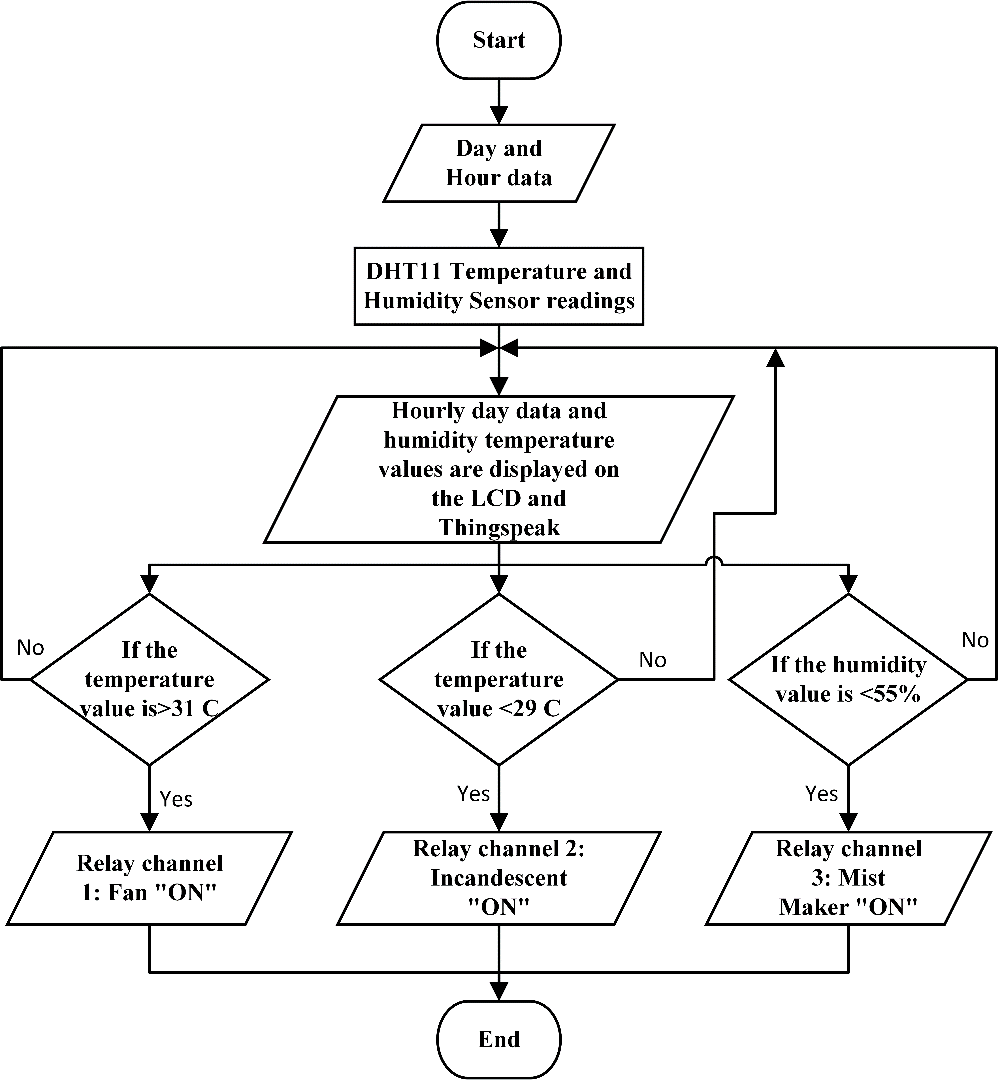

The hardware design of the designed system is the NodeMCU microcontroller which functions as the controller of the read data values which are then processed and sent to Thingspeak. The system design block diagram can be seen in Figure 2.

Figure 2. System design system block diagram

The system design used in this study uses a microcontroller in the form of NodeMCU. NodeMcu is an open source Internet of Things (IoT) platform. NodeMCU includes hardware and firmware for the ESP8226-12 system on a system chip (SoC) of an expressive system that uses the LUA instruction set programming language [21][22][23][24]. Data on temperature and humidity values originating from the DHT11 sensor will be read by NodeMCU and later this data will determine whether or not the existing relay is on [25][26][27]. All temperature and humidity data from the DHT11 sensor will also be sent to the media platform in the form of Thingspeak using the IoT method [28][29][30].

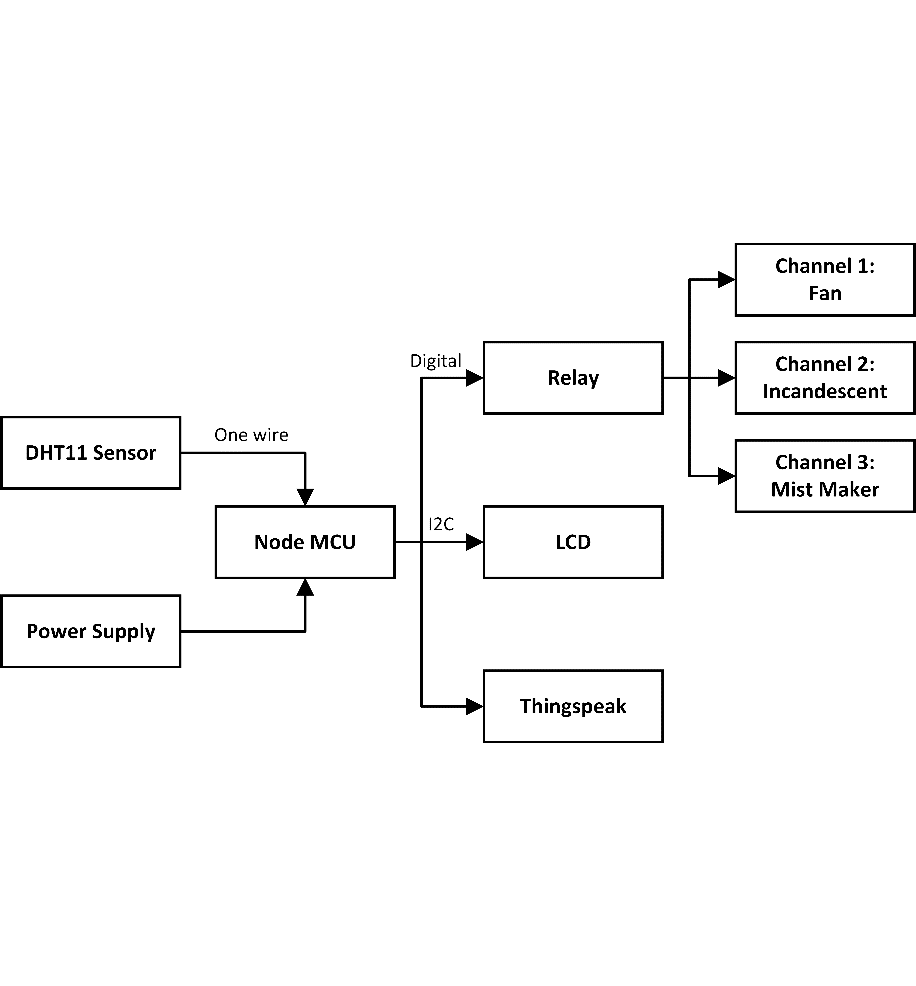

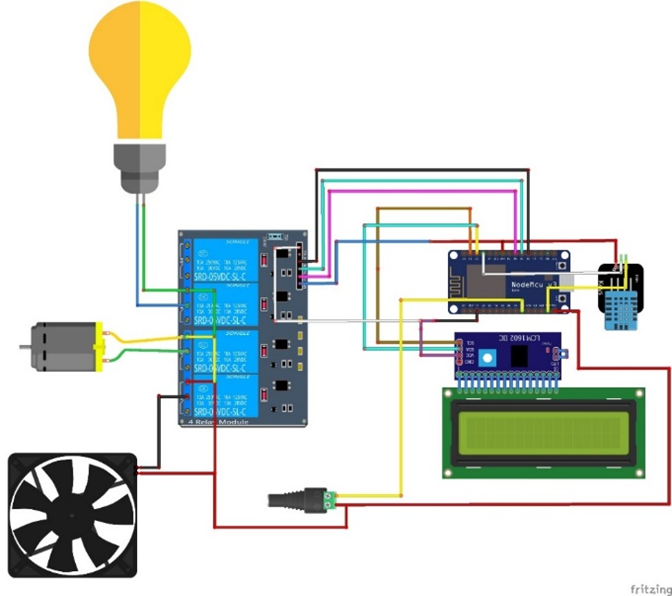

Hardware assembly is part of the process of connecting all existing devices or components, so that they can read the DHT11 sensor values which will later trigger performance from the output. The circuit of the entire hardware can be seen in Figure 3.

Figure 3. Hardware design diagram

NodeMCU has data in the form of input and output used in the designed system. These inputs and outputs can be seen in Table 1.

Table 1. Input Output

NodeMCU Pin | Sensors/Actuators |

D1, D2 | LCD |

D3 | DHT11 Sensor |

D6, D7, D8 | 4 Channel Relay |

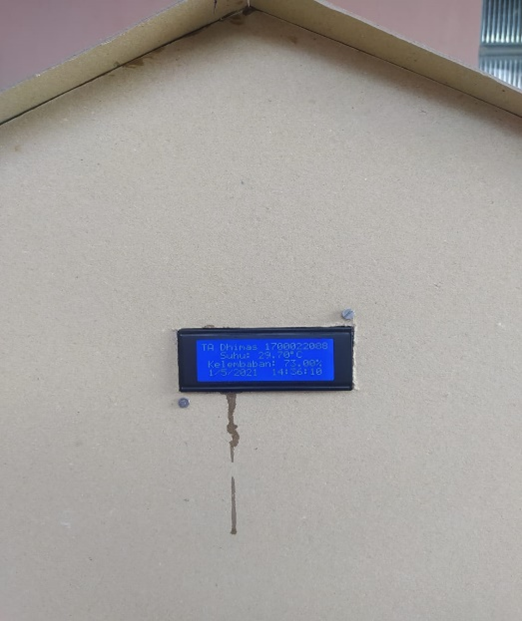

- Research Flowchart

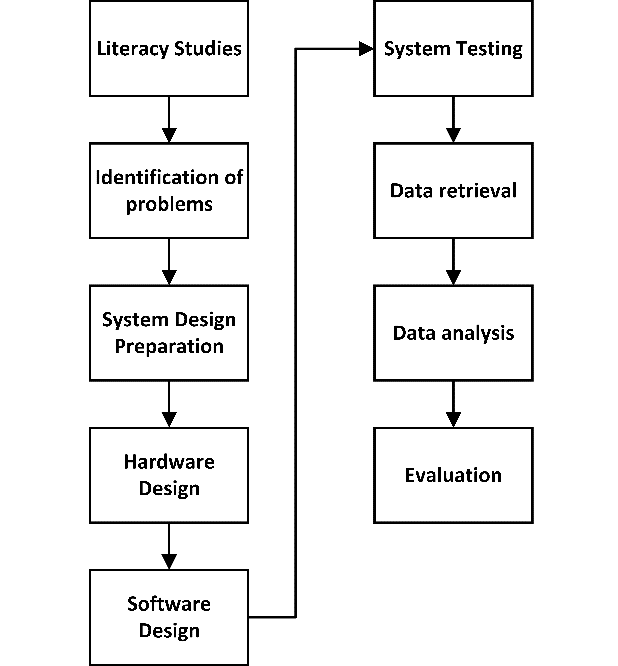

There are several stages of research conducted to create a system that has been designed. After conducting literacy studies and identifying problems, then carry out the preparatory process for designing the system. At this stage, all the things needed in the research are prepared. If so, enter the hardware and software design stage. After the designed system has been made, the tool testing process is carried out. If the tool is successful, then enter the process of data collection and analysis. After all stages have been completed, an evaluation process of the research carried out is carried out. The research flowchart can be seen in Figure 4.

Figure 4. Research flowchart

- RESULTS AND DISCUSSION

- DHT11 Sensor Testing

Testing the DHT11 sensor produces temperature and humidity values compared to tested factory-made devices. The DHT11 sensor is connected to NodeMCU, which is then measured for a certain period of time. This sensor test also aims to determine the level of error that exists on the sensor.

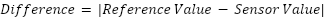

Temperature and humidity data collection was carried out in conditions that were quite hot, namely at 13.00-16.00. There are two variables tested from the DHT11 sensor, namely the temperature value and humidity value. Testing the temperature value from the DHT11 sensor can be seen in Table 2 and testing the humidity value from the DHT11 sensor can be seen in Table 3. The error from this test can be determined using the formulas in Equation (1) and Equation (2).

|

| (1) |

|

| (2) |

Table 2. Testing of DHT11 sensor temperature values

No | Temperature DHT11 (° C) | Termometer (° C) | Error (%) |

1 | 33.5 | 33.2 | 0.9 |

2 | 33.8 | 33.4 | 1.1 |

3 | 33.9 | 33.6 | 0.8 |

4 | 33.8 | 33.5 | 0.8 |

5 | 34.2 | 33.7 | 1.4 |

6 | 34.2 | 33.8 | 1.1 |

7 | 34.4 | 33.9 | 1.4 |

8 | 34.5 | 34.1 | 1.1 |

9 | 34.6 | 34.2 | 1.1 |

10 | 34.7 | 34.4 | 0.8 |

Average error | 1.05 |

The results of sensor testing and calibration of the DHT11 sensor are that the sensor can work normally in measuring temperature and humidity. The temperature produced by DHT11 is between 0-500C and humidity is a minimum value of 20% RH to a maximum of 90% RH. Error reading from the DHT11 sensor for temperature is 20° C, while for humidity from the DHT11 sensor it is 5% RH. The error reading of the temperature and humidity values is in accordance with the datasheet from the DHT11 sensor [11].

Table 3. Testing the DHT11 humidity sensor values

No | Humidity DHT11 (%) | Higrometer (%) | Error (%) |

1 | 56 | 55 | 1.8 |

2 | 54 | 53 | 1.9 |

3 | 55 | 53 | 3.7 |

4 | 53 | 52 | 1.9 |

5 | 52 | 50 | 0.4 |

6 | 54 | 52 | 3.8 |

7 | 52 | 51 | 1.9 |

8 | 51 | 50 | 0.2 |

9 | 50 | 48 | 4.1 |

10 | 49 | 47 | 4.2 |

Average error | 2.39 |

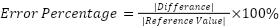

- Set of Tools

The entire series of tools in hardware form can be seen in Figure 5 and Figure 6. There is an LCD display on the front of the system. Then there is a fan behind which works if the temperature does not match what has been set. The DHT11 sensor and mist maker and glow lamp are located inside the system.

Figure 5. View of the Toolkit from the front

Figure 6. View of the Toolkit from the back

- System Testing

Comfortable temperature and humidity for boiler chickens can be seen in Table 4.

Table 4. Temperature and humidity for chickens

Temperature and Humidity Levels for Chickens |

Age (days) | Temperature (o C) | Humidity (%) |

1-7 | 29-31 | 55-65 |

8-14 | 27-29 | 55-65 |

15-21 | 25-27 | 55-65 |

22-28 | 23-25 | 55-65 |

>28 | 22-23 | 55-65 |

Broiler chickens that have not been able to regulate their own body temperature are 0-5 days old. Chickens that are only one week old can regulate their own body temperature optimally [3]. So, temperature automation is needed to keep the coop in the chicken's comfort zone. In this study, the system that has been designed will be tested in the period 14.00-21.00 to determine whether the performance of the system is working properly or not. The chickens used in data collection were 7-21 days old. The data being tested are the temperature and humidity values of the chicken coop, which then from these values can turn on the relay according to the command or not. The results of system testing data can be seen in Table 5.

Table 5. System testing results

No | Time | Temperature Value (° C) | Humidity Value (%) | Fan Condition | Mist Maker Condition | Incandescent Lamp Conditions |

1 | 14.00-14.30 | 34.7 | 55 | ON | ON | OFF |

2 | 14.30-15.00 | 34.1 | 55 | ON | ON | OFF |

3 | 15.00-15.30 | 33.8 | 56 | ON | OFF | OFF |

4 | 15.30-16.00 | 34.1 | 55 | ON | ON | OFF |

5 | 16.00-16.30 | 33.4 | 56 | ON | OFF | OFF |

6 | 16.30-17.00 | 32.3 | 57 | ON | OFF | OFF |

7 | 17.00-17.30 | 31.2 | 58 | ON | OFF | OFF |

8 | 17.30-18.00 | 30.1 | 57 | ON | OFF | OFF |

9 | 18.00-18.30 | 29.8 | 58 | ON | OFF | OFF |

10 | 18.30-19.00 | 29.6 | 58 | ON | OFF | OFF |

11 | 19.00-19.30 | 29.5 | 57 | ON | OFF | OFF |

12 | 19.30-20.00 | 28.9 | 60 | OFF | OFF | ON |

13 | 20.00-20.30 | 28.8 | 64 | OFF | OFF | ON |

14 | 20.30-21.00 | 28.7 | 65 | OFF | OFF | ON |

The data in Table 5 are the temperature and humidity values in the chicken coop which were measured at 14.00-21.00 WIB. In the range of 14.00-14.30 the temperature in the chicken coop is 34.7° C with a humidity value of 55% so that the fan and mist maker in the chicken coop will turn on. In the range of 14.30-15.00 the temperature of the chicken coop is 34.1° C with a humidity value of 55% so that the fan and mist maker in the chicken coop will turn on. In the range of 15.00-15.30 the temperature in the chicken coop is 33.8° C with a humidity value of 56% so that only the fan in the chicken coop will turn on. In the range of 15.30-16.00 the temperature of the chicken coop is 34.1° C with a humidity value of 55% so that the fan and mist maker in the chicken coop will turn on. In the range of 16.00-16.30 the temperature in the chicken coop is 33.4° C with a humidity value of 56% so that only the fan in the chicken coop will turn on. In the range of 16.30-17.00 the temperature in the chicken coop is 32.3° C with a humidity value of 57% so that only the fan in the chicken coop will turn on.

Furthermore, in the range of 17.00-17.30 the temperature in the chicken coop is 31.2° C with a humidity value of 58% so that only the fan in the chicken coop will turn on. In the range of 17.30-18.00 the temperature in the chicken coop is 30.1° C with a humidity value of 57% so that only the fan in the chicken coop will turn on. In the range of 18.00-18.30 the temperature in the chicken coop is 29.8° C with a humidity value of 58% so that only the fan in the chicken coop will turn on. In the range of 18.30-19.00 the temperature in the chicken coop is 29.2 ͦC with a humidity value of 58% so that only the fan in the chicken coop will turn on. In the range 19.00-19.30 the temperature in the chicken coop is 29.5° C with a humidity value of 57% so that only the fan in the chicken coop will turn on.

Then in the range of 19.30-20.00 the temperature in the chicken coop is 28.4° C with a humidity value of 60% so that only the incandescent light in the chicken coop will light up. In the range of 20.00-20.30 the temperature in the chicken coop is 28.6° C with a humidity value of 64% so that only the incandescent lamp in the chicken coop will light up. In the range of 20.30-21.00 the temperature in the chicken coop is 28.7° C with a humidity value of 65% so that only the incandescent lamp in the chicken coop will light up.

Excessive temperature and humidity in the chicken coop can be reduced with the help of DC fans and mist makers. When the temperature of the chicken coop is too cold, the temperature will be raised with the help of a 25 Watt incandescent lamp.

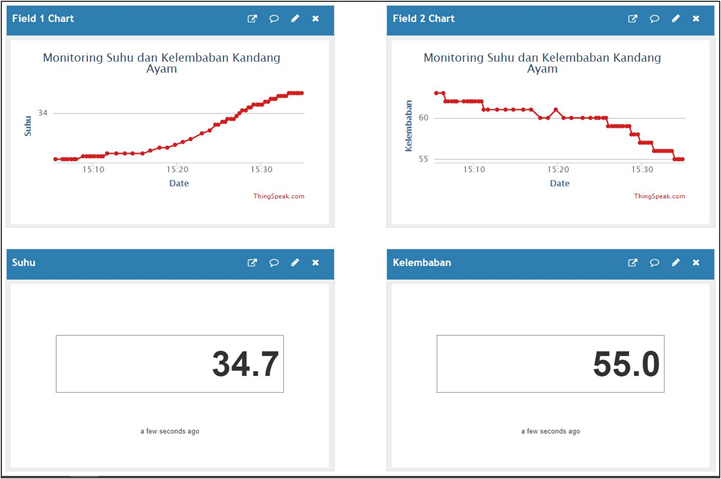

3.4. IoT Testing

The IoT used in this research is Thingspeak. This IoT test aims to see the performance of the ability to receive data by Thingspeak. The data sent is the temperature and humidity values measured using the DHT11 sensor. The data display appears in the form of graphs and numbers on Thingspeak, so it's easy to understand. The complete temperature and humidity data can also be downloaded in real-time. The graphical display of data on the Thingspeak media can be seen in Figure 7.

Figure 7. Display of temperature and humidity data on Thingspeak

- CONCLUSION

After conducting this research, the problem of controlling the temperature and humidity values of the chicken coop so that it is maintained and makes the chickens comfortable can be overcome with the system that has been created. The DHT11 sensor can detect the temperature and humidity values in the chicken coop. There is an error value that is on the sensor. This error is in accordance with the existing datasheet on the DHT11 sensor. Relays can also work properly when turning on fans, mist makers, and incandescent lamps according to existing temperature and humidity conditions. The resulting data can be viewed on the Thingspeak media platform in graphical form. All sensors and hardware components can work with the help of a Wi-Fi-connected NodeMCU microcontroller.

REFERENCES

[1] M. M. Erdaw and W. T. Beyene, "Trends, prospects and the socio-economic contribution of poultry production in sub-Saharan Africa: a review," World's Poultry Science Journal, vol. 78, no. 3, pp. 835-852, 2022, https://doi.org/10.1080/00439339.2022.2092437.

[2] A. Cartoni Mancinelli, A. Dal Bosco, S. Mattioli, D. Ranucci and C. Castellini, "Mobile poultry processing unit as a resource for small poultry farms: planning and economic efficiency, animal welfare, meat quality and sanitary implications," Animals, vol. 8, no. 12, p. 229, 2018, https://doi.org/10.3390/ani8120229.

[3] M. H. Haque et al., "Sustainable antibiotic-free broiler meat production: Current trends, challenges, and possibilities in a developing country perspective." Biology, vol. 9, no. 11, p. 411, 2020, https://doi.org/10.3390/biology9110411.

[4] F. J. Adha, R. Ramli, M. H. Alkawaz, M. G. M. Johar and A. I. Hajamydeen, "Assessment of Conceptual Framework for Monitoring Poultry Farm's Temperature and Humidity," 2021 IEEE 11th International Conference on System Engineering and Technology (ICSET), Shah Alam, Malaysia, 2021, pp. 40-45, https://doi.org/10.1109/ICSET53708.2021.9612437.

[5] Y. A. Liani et al., "The Broiler Chicken Coop Temperature Monitoring Use Fuzzy Logic and LoRAWAN," 2021 3rd International Conference on Electronics Representation and Algorithm (ICERA), Yogyakarta, Indonesia, 2021, pp. 161-166, https://doi.org/10.1109/ICERA53111.2021.9538771.

[6] R. D. M. Nicolas, W. S. Zhou, S. C. Kitamura and M. J. C. Samonte, "An IoT Monitoring Assistant for Chicken Layer Farms," 2019 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Korea (South), 2019, pp. 71-75, https://doi.org/10.1109/ICTC46691.2019.8939845.

[7] A. Nawab et al., "Heat stress in poultry production: Mitigation strategies to overcome the future challenges facing the global poultry industry," Journal of thermal biology, 78, 131-139, 2018, https://doi.org/10.1016/j.jtherbio.2018.08.010.

[8] M. Saeed et al., "Heat stress management in poultry farms: A comprehensive overview," Journal of thermal biology, vol. 84, pp. 414-425, 2019, https://doi.org/10.1016/j.jtherbio.2019.07.025.

[9] N. Z. Malika, R. Ramli, M. H. Alkawaz, M. G. Md Johar and A. I. Hajamydeen, "IoT based Poultry Farm Temperature and Humidity Monitoring Systems: A Case Study," 2021 IEEE 9th Conference on Systems, Process and Control (ICSPC 2021), Malacca, Malaysia, 2021, pp. 64-69, https://doi.org/10.1109/ICSPC53359.2021.9689101.

[10] A. Costantino, E. Fabrizio, A. Ghiggini and M. Bariani, "Climate control in broiler houses: A thermal model for the calculation of the energy use and indoor environmental conditions," Energy and Buildings, vol. 169, pp. 110-126, 2018, https://doi.org/10.1016/j.enbuild.2018.03.056.

[11] S. Ivanova, A. Prosekov and A. Kaledin, "A Survey on Monitoring of Wild Animals during Fires Using Drones," Fire, vol. 5, no. 3, p. 60, 2022, https://doi.org/10.3390/fire5030060.

[12] A. Ghasempour, "Internet of things in smart grid: Architecture, applications, services, key technologies, and challenges," Inventions, vol. 4, no. 1, p. 22, 2019, https://doi.org/10.3390/inventions4010022.

[13] A. Rokade and M. Singh, "Analysis of Precise Green House Management System using Machine Learning based Internet of Things (IoT) for Smart Farming," 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 2021, pp. 21-28, https://doi.org/10.1109/ICOSEC51865.2021.9591962.

[14] Y. Qun, Y. Zhang, X. Wang, Z. Zhou, P. Xian and F. Zhang, "Research on Master-Slave Distributed Large-Scale Poultry Farming Measurement and Control System," 2019 International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Atlanta, GA, USA, 2019, pp. 552-557, https://doi.org/10.1109/iThings/GreenCom/CPSCom/SmartData.2019.00110.

[15] M. Ayaz, M. Ammad-Uddin, Z. Sharif, A. Mansour and E. -H. M. Aggoune, "Internet-of-Things (IoT)-Based Smart Agriculture: Toward Making the Fields Talk," in IEEE Access, vol. 7, pp. 129551-129583, 2019, https://doi.org/10.1109/ACCESS.2019.2932609.

[16] S. Munirathinam, "Industry 4.0: Industrial internet of things (IIOT)," In Advances in computers, vol. 117, no. 1, pp. 129-164, 2020, https://doi.org/10.1016/bs.adcom.2019.10.010.

[17] A. Rahmatulloh, D. Wahyudin, N. Widiyasono and I. Darmawan, "IoT-Based Temperature Monitoring System For Smart Cage," 2022 International Conference on Advanced Creative Networks and Intelligent Systems (ICACNIS), Bandung, Indonesia, 2022, pp. 1-6, https://doi.org/10.1109/ICACNIS57039.2022.10055769.

[18] A. Ikpehai et al., "Low-Power Wide Area Network Technologies for Internet-of-Things: A Comparative Review," in IEEE Internet of Things Journal, vol. 6, no. 2, pp. 2225-2240, April 2019, https://doi.org/10.1109/JIOT.2018.2883728.

[19] M. S. Farooq, S. Riaz, A. Abid, K. Abid and M. A. Naeem, "A Survey on the Role of IoT in Agriculture for the Implementation of Smart Farming," in IEEE Access, vol. 7, pp. 156237-156271, 2019, https://doi.org/10.1109/ACCESS.2019.2949703.

[20] M. A. A. Razali, M. Kassim, N. A. Sulaiman and S. Saaidin, "A ThingSpeak IoT on Real Time Room Condition Monitoring System," 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 2020, pp. 206-211, https://doi.org/10.1109/I2CACIS49202.2020.9140127.

[21] W. A. Jabbar et al., "Design and Fabrication of Smart Home With Internet of Things Enabled Automation System," in IEEE Access, vol. 7, pp. 144059-144074, 2019, https://doi.org/10.1109/ACCESS.2019.2942846.

[22] A. A. Hapsari, A. I. Hajamydeen, D. J. Vresdian, M. Manfaluthy, L. Prameswono and E. Yusuf, "Real Time Indoor Air Quality Monitoring System Based on IoT using MQTT and Wireless Sensor Network," 2019 IEEE 6th International Conference on Engineering Technologies and Applied Sciences (ICETAS), Kuala Lumpur, Malaysia, 2019, pp. 1-7, https://doi.org/10.1109/ICETAS48360.2019.9117518.

[23] P. Serikul, N. Nakpong and N. Nakjuatong, "Smart Farm Monitoring via the Blynk IoT Platform: Case Study: Humidity Monitoring and Data Recording," 2018 16th International Conference on ICT and Knowledge Engineering (ICT&KE), Bangkok, Thailand, 2018, pp. 1-6, https://doi.org/10.1109/ICTKE.2018.8612441.

[24] A. Najmurrokhman, Kusnandar, A. Daelami, E. Nurlina, U. Komarudin and H. Ridhatama, "Development of Temperature and Humidity Control System in Internet-of-Things based Oyster Mushroom Cultivation," 2020 3rd International Seminar on Research of Information Technology and Intelligent Systems (ISRITI), Yogyakarta, Indonesia, 2020, pp. 551-555, https://doi.org/10.1109/ISRITI51436.2020.9315426.

[25] G. Verma, P. Mittal and S. Farheen, "Real Time Weather Prediction System Using IOT and Machine Learning," 2020 6th International Conference on Signal Processing and Communication (ICSC), Noida, India, 2020, pp. 322-324, https://doi.org/10.1109/ICSC48311.2020.9182766.

[26] A. Sarah, T. Ghozali, G. Giano, M. Mulyadi, S. Octaviani and A. Hikmaturokhman, "Learning IoT: Basic Experiments of Home Automation using ESP8266, Arduino and XBee," 2020 IEEE International Conference on Smart Internet of Things (SmartIoT), Beijing, China, 2020, pp. 290-294, https://doi.org/10.1109/SmartIoT49966.2020.00051.

[27] C. A. Jamhari, W. K. Wibowo, A. R. Annisa and T. M. Roffi, "Design and Implementation of IoT System for Aeroponic Chamber Temperature Monitoring," 2020 Third International Conference on Vocational Education and Electrical Engineering (ICVEE), Surabaya, Indonesia, 2020, pp. 1-4, https://doi.org/10.1109/ICVEE50212.2020.9243213.

[28] S. H. Sasono, S. Kusumastuti, E. Supriyanto and I. D. Putri, "Sensor Data Analysis On Monitoring And Control System Of Temperature And Humidity Based On Android In Soybean Seed Storage Room Using Nodemcu," JAICT, vol. 3, no. 1, p. 8, 2019, https://doi.org/10.32497/jaict.v3i1.1290.

[29] A. Setiawan, S. J. Sahat, L. B. Subekti, Y. Bandung and K. Mutijarsa, "Design and Implementation of IoT Sensor System for Home Power Manager and Environment Condition Monitor," 2018 International Symposium on Electronics and Smart Devices (ISESD), Bandung, Indonesia, 2018, pp. 1-6, https://doi.org/10.1109/ISESD.2018.8605464.

[30] A. Ani and P. Gopalakirishnan, "Automated Hydroponic Drip Irrigation Using Big Data," 2020 Second International Conference on Inventive Research in Computing Applications (ICIRCA), Coimbatore, India, 2020, pp. 370-375, https://doi.org/10.1109/ICIRCA48905.2020.9182908.

AUTHOR BIOGRAPHY

| Dhimas Dwiki Sanjaya is a student of the Department of Electrical Engineering, Faculty of Industrial Technology, Universitas Ahmad Dahlan, Yogyakarta, Indonesia.

|

|

|

| Abdul Fadlil completed his undergraduate education in the Department of Physics at Universitas Gadjah Mada, completed his master's education in the Department of Electrical Engineering at Universitas Gadjah Mada, completed his doctoral education in the Department of Electrical Engineering at the Universitas Teknologi Malaysia. Currently is a permanent lecturer in the Department of Electrical Engineering at Universitas Ahmad Dahlan. His research areas are pattern recognition and intelligent systems.

|

|

|

Monitoring Temperature and Humidity of Boiler Chicken Cages Based on Internet of Things (IoT)

(Dhimas Dwiki Sanjaya)