ISSN: 2685-9572 Buletin Ilmiah Sarjana Teknik Elektro

Vol. 7, No. 3, September 2025, pp. 468-480

Temperature-Controlled Process for Recycled Waste Tire Polymer-Polymer Composites: An Innovative and Sustainable Solution for Marine Fender Applications

Ali Habel Zaibel 1, Safaa A. S. Almtori 2, Raheem Al-Sabur 3, Abdel-Nasser Sharkawy 4,5

1 Department of Mechanical Engineering, University of Basrah, Basrah 61001, Iraq

2 Department of Materials Engineering, University of Basrah, Basrah 61001, Iraq

3 Department of Mechanical Engineering, University of Basrah, Basrah 61001, Iraq

4 Mechanical Engineering Department, Faculty of Engineering, South Valley University, Qena 83523, Egypt

5 Mechanical Engineering Department, College of Engineering, Fahad Bin Sultan University, Tabuk 47721, Saudi Arabia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Received 30 June 2025 Revised 10 July 2025 Accepted 05 September 2025 |

|

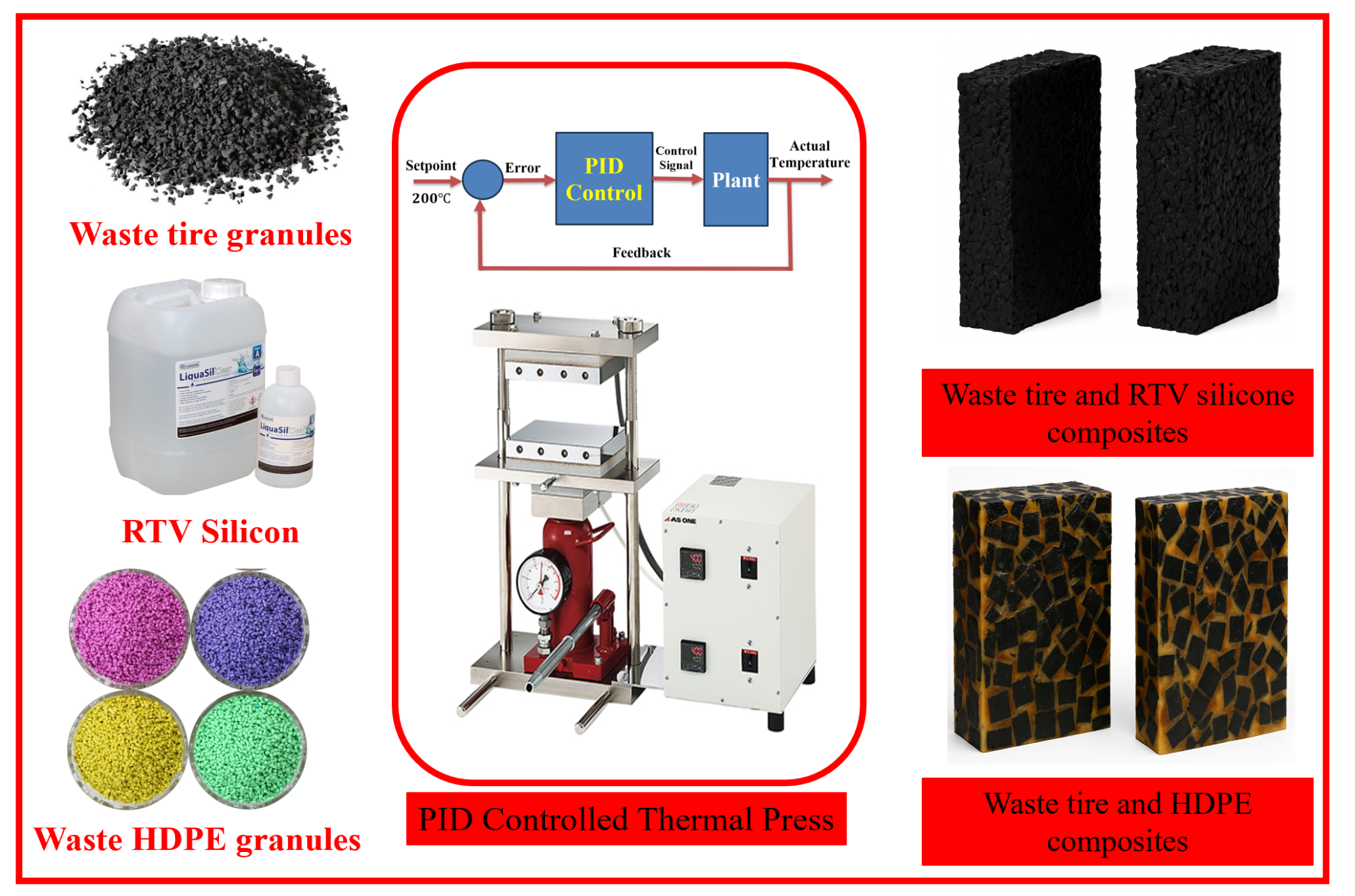

Marine fender prototypes play a critical role in protecting the ship and the berthing infrastructure from damage during docking. Recycling waste polymers, such as waste tires, into composite materials for marine fenders, can contribute to environmental sustainability and resource conservation. In marine Fender applications, compression testing often plays a crucial role; we should also test factors such as elasticity, stiffness, and hardness. In this study, pressure and hardness were selected, and Young's modulus was calculated for two types of composite materials: one manufactured from waste tires and high-density polyethylene (HDPE) and the other from waste tires and room-temperature vulcanized (RTV) silicone both in varying proportions. These types of materials were produced using a press machine equipped with a PID controller, which enables the adjustment of the temperature to a desired value, thereby achieving the best results. Prototypes containing 85% waste tire with 15% HDPE and 50% waste tire with 50% RTV silicone showed superior energy absorption and durability for marine fender applications. Despite achieving satisfactory hardness and hardness values, the waste tire and RTV silicone composite did not exceed those of the waste tire and HDPE composites, which had Young's modulus and Shore hardness values of 1.74 MPa and 56.6, respectively. The compression test showed that the waste tire and RTV silicone composites achieved higher values, surpassing 1990 kN. The findings provide a crucial foundation for utilizing waste composite materials in marine fender production. |

Keywords: Fenders; Recycling; Sustainability; HDPE; RTV; Waste Tire; PID Control |

Corresponding Author: Abdel-Nasser Sharkawy, Mechanical Engineering Department, Faculty of Engineering, South Valley University, Qena 83523, Egypt. Email: abdelnassersharkawy@eng.svu.edu.eg |

This work is open access under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: A. H. Zaibel, S. A. S. Almtori, R. Al-Sabur, and A. -N. Sharkawy, “Temperature-Controlled Process for Recycled Waste Tire Polymer-Polymer Composites: An Innovative and Sustainable Solution for Marine Fender Applications,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 7, no. 3, pp. 468-480, 2025, DOI: 10.12928/biste.v7i3.13813. |

INTRODUCTION

Ships and ports are considered the lifeline and main link between manufacturers and consumers. Ship berthing requirements are regarded as the most critical factor in port quality. There is no doubt that marine fenders represent the fundamental element of protection when docking ships [1]. Researchers find that fenders absorb shocks between ships, small boats, and docks or vessels [2]. Historically, people crafted fenders from rope in diverse patterns and shapes, often repurposing damaged lines that were no longer safe for mooring boats or carrying loads. Then, in boats, it developed to the point where it became an air-filled ball or a device in various shapes and materials used to absorb the kinetic energy of a ship. Later, developers divided marine fenders into two main sections: ship-to-berth (STB) fenders and ship-to-ship (STS) fenders [3]. It also varied according to usage: cylindrical fenders, corner fenders, arch fenders, cone fenders, square fenders, D fenders, keyhole fenders, cone fenders, pneumatic fenders, hydro-pneumatic fenders, foam elastomer fenders, tugboat fenders, solid rubber fenders, and floating rubber fenders.

Traditional marine fenders faced various difficulties, most notably the harsh marine environments, the recent high rates of corrosion, and the limitations of the fender’s lifespan [4]. These challenges, combined with the significant damage to marine fenders, make them one of the weak elements of sustainable development. The quality of the product and the possibility of recycling it is considered two decisive factors in the global trend towards sustainability, which contributes to achieving the requirements of the Paris Climate Agreement. This pressure has generated an increasing need to develop new materials for marine fenders that can withstand these challenges and provide better performance [5]. The last decade has seen a growing application of composite materials, particularly in areas such as robotics [6], medical applications [7], military applications [8], and marine applications [9], including the marine fender industry [10]. New composite materials have not been the only growing applications; other topics have incorporated recycled composite materials. The recycling of polymeric materials has advanced significantly, leading to its utilization in unconventional applications like bricks and the creation of waste polymer-polymer matrix composites [11]-[13].

Rubber is considered the main ingredient in producing many types of marine fenders. However, rubber is a complex material to recycle, as it is not biodegradable and has an energy-intensive consumption [14]. The global annual generation of waste tires is approximately 4 billion tons [15]. In truck tires, the percentages of natural and synthetic rubber are 27% and 14%, respectively, while these ratios differ in passenger tires [16]. Tires also incorporate varying amounts of carbon black, steel, accelerators, fillers, fabric, and antiozonants. Tire waste mounds frequently serve as breeding sites for insects and vermin, such as mosquitoes, which spread infectious and unidentified diseases. Landfilling used tires takes up a significant portion of priceless land [17]. The scribed tires can be recycled/reused as a new rubber product in civil or industrial applications, where they can be used as gaskets, wheel chocks, playgrounds, doormats, sports surfacing, etc [18].

The use of tires and waste polymers to create different composite materials—including those for marine fenders—has gained popularity in recent years. These recycled materials are a viable substitute for traditional fender materials because they provide several benefits over conventional materials, including increased durability, lower cost, and less environmental effect [19]. Room temperature vulcanized (RTV) silicone rubbers are widely used in numerous applications due to their innocuity, insulative, resistance to elements, and wear resistance [20]. These properties make RTV silicone an attractive material for marine fender pr©ototypes. High-density polyethylene (HDPE) is another promising material for this application, as it is lightweight and possesses good tensile strength, while its counterpart, low-density polyethylene (LDPE), exhibits good chemical resistance [21].

The production of marine fenders typically involves selecting suitable materials, designing the fender's shape and size, and employing an appropriate manufacturing process. The development of marine fender production has evolved significantly over the past decades, despite its long-standing use in the marine industry. Design criteria were first compiled by TT Lee in the 1960s [22]. He stated that an effective fender design requires optimising key performance parameters, such as energy absorption, peak reaction forces, and contact pressure distribution. Later, H. Agerschou et al. [23] introduced more progressive design ideas encompassing various design aspects, risks, and economic considerations and found that the straight and vertical hull sides are essential in fender design. JW Gaythwaite [24] conducted a study on marine facilities and methods of berthing, mooring, and repairing vessels for ships. Moreover, Gaythwaite reported that berthing loads are important in marine fender design. R Iversen et al. [25] also investigated berthing velocities for designing fender systems and accurate monitoring of berthing velocity helps minimize the impact load on marine fenders, improving their operational efficiency. Numerous other studies have focused on designing marine fenders using raw and non-recycled materials. In fender piling applications, the filling material serves to bond the outer layers with the internal inserts, enhancing the structure’s ability to absorb impact forces [26][27]. Several barriers still limit the widespread use of composite pilings as load-bearing elements in fender applications [26][27].

In today's eco-conscious world, numerous 100% recycled marine products are utilized [28], such as recycled plastic lumber, plastic floats and buoys, plastic furniture, and fishing nets and ropes. Using recycled rubber fenders aligns with this sustainable trend, further emphasizing the value of recycling and repurpose materials in the marine industry. Research is scarce regarding developing marine fenders made from recycled materials or plastic waste. However, several brands claim that their marine fender products are either entirely or partially manufactured using recycled materials or plastic waste, such as Lankhorst KLP®-PE (www.lankhorst-recycling.com) [29] AIMPLAS (https://www.aimplas.net) [30], and ECOCHOICE (https://ecochoice.co.uk/recycled-plastic-fenders), which is highlighting the growing interest in sustainable solutions within the industry.

While many studies have explored the use of recycled polymers in construction and transportation, there has been little research specifically assessing their viability and mechanical performance in marine fender systems. Most existing studies do not thoroughly analyze either how recycled composites behave under impact and compression or overlook how these materials meet the unique demands of marine environments. The present study addresses the research gap by investigating plastic waste recycling in producing polymer-polymer composites for marine fenders. The novelty of our work lies in developing and characterizing two types of recycled specimens, consisting of waste tires combined with either RTV silicon or high-density polyethylene (HDPE). By conducting a series of mechanical tests, including Hardness, elastic modulus, and compression tests, we aim to evaluate the performance of these composite materials and assess their suitability as marine fenders. Our findings can potentially contribute to developing more sustainable and cost-effective solutions for marine fender applications, ultimately reducing the environmental impact of fender manufacturing and waste disposal.

EXPERIMENTAL WORK

This section consists of three subsections. The first subsection presents the press machine, which is used for the manufacturing of composite materials. Additionally, there was a brief discussion about the PID temperature control that the press machine is equipped with. The second subsection shows the preparation of the waste tire and RTV silicone composites. The third subsection shows the preparation of waste tires and HDPE composites.

Press Machine Equipped by PID Temperature Control

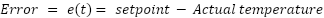

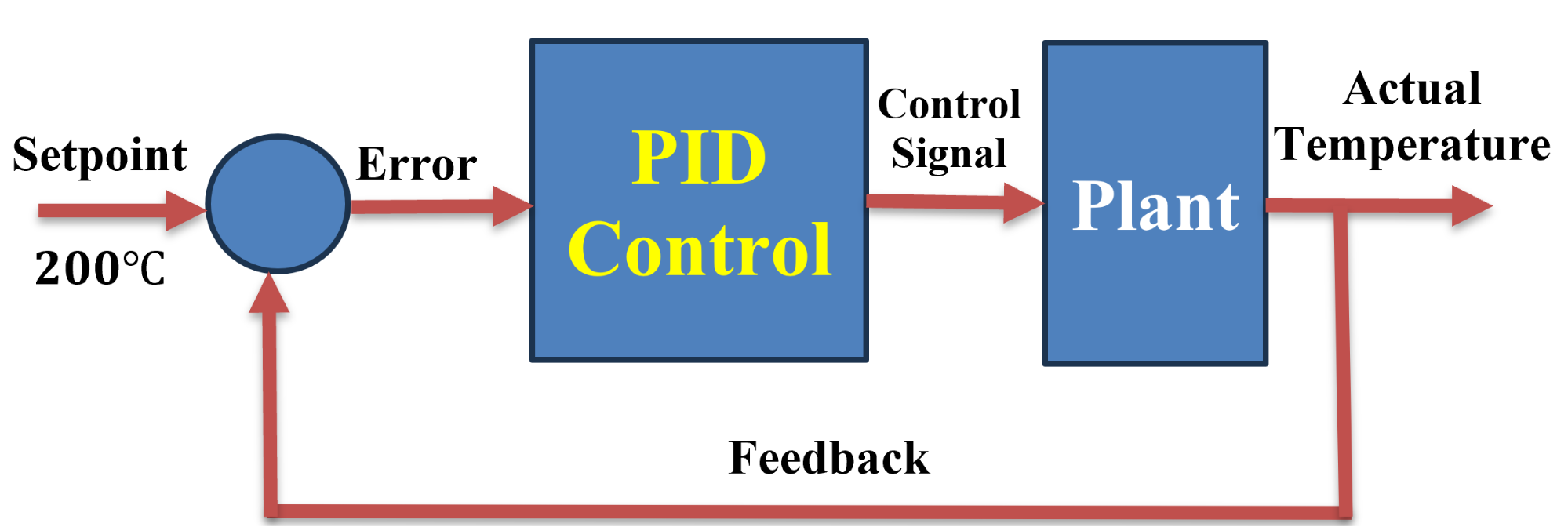

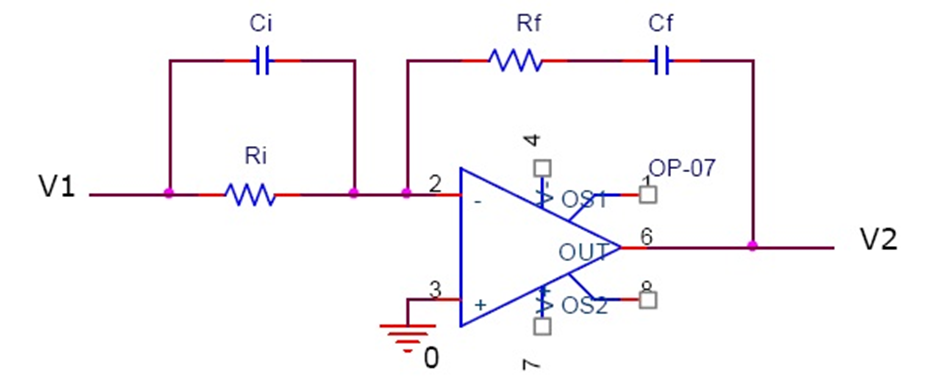

This section covers the experimental methods for creating two polymer-polymer composite specimens from recycled scrap tires. The function of PID temperature control is to adjust the actual temperature and maintain it at the set point for the desired temperature. PID temperature control is essential in thermal press machines for ensuring high performance and consistency in heat-driven processes. PID controllers maintain exact temperature setpoints (±5°C or better) [31][32], eliminating harmful fluctuations that could compromise material properties in recycled polymer composites, such as waste tires and HDPE. Figure 1 illustrates that the control signal generated by this type of controller is directly related to the error signal, which is the difference between the setpoint and the actual temperature. The related equations are presented as follows [33][34]. Where,  is the proportional gain of the PID controller,

is the proportional gain of the PID controller,  is the integral gain of the PID controller, and

is the integral gain of the PID controller, and  is the derivative gain of the PID controller.

is the derivative gain of the PID controller.

|

| (1) |

|

| (2) |

Therefore, using PID control can enhance the system's performance by adjusting the actual temperature and maintaining it at the desired set point. The press machine is integrated with PID control, and its gains are tuned automatically. We do our best to find the method used for tuning the PID control gains on this press machine, but the information about this issue in the machine's catalogue is missing. However, the method used for gain tuning is the Ziegler-Nichols method, which is the most famous one. Table 1 indicates the function of the PID controller Gains used in this study. The electronic circuit of PID control can be presented by an operational amplifier (op amp), as in Figure 2.

Figure 1. PID control for the adjustment of the temperature

Table 1. The main functions of the PID controller gain

Gain | Function |

Proportional Gain  | Increasing the value of this gain can minimize the period of the transient response stage, which is unsteady. In other words, reaching a steady-state condition will be faster. In addition, the error will be reduced but not eliminated. |

Integral Gain  | Increasing the value of this gain can also minimize the period of transient response stage. In addition, the error will be eliminated and be very close to zero. |

Derivative Gain  | This gain can improve the performance of the system in terms of stability and damping. In another meaning, the overshoots and oscillations can be reduced. |

Figure 2. The electronic circuit of the PID controller using operational amplifier [35]

By analyzing this electrical circuit, the PID controller gains are obtained as follows:

If the values of the capacitors and resistors are chosen well and correctly, a high-performance controller will be achieved.

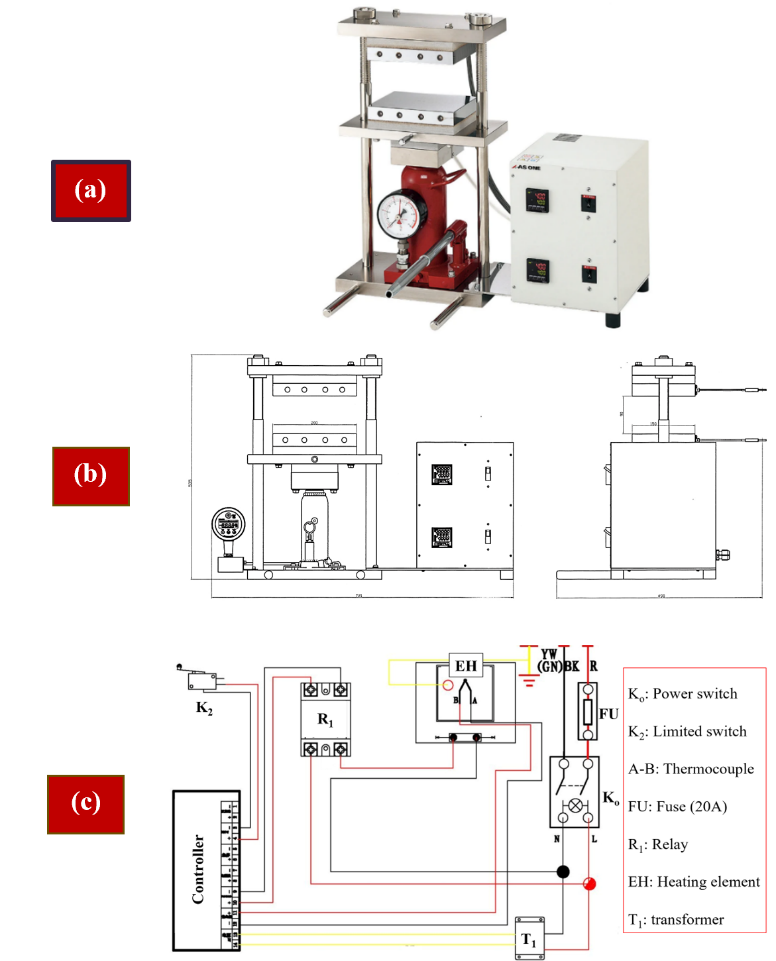

The composites are made from waste tires and room-temperature vulcanizing (RTV) silicone. The specimens were fabricated using a press machine, as shown in Figure 3. Figure 3 illustrates the press machine, including the heating source (Figure 3(a)), a schematic drawing of the press machine (Figure 3(b)), and the electrical wire connections within the press machine (Figure 3(c)). The press machine is equipped with a PID temperature control adjustment. Through experiments, rubber has been identified as a critical component because it requires a high temperature to reach the softening state necessary for tire production. Experiments have shown that the temperature can be achieved within the range of 180-200 degrees. Temperatures above this limit will lead to rubber deterioration [36]. Since the approximate oxidation onset temperatures of pure HDPE and rubber are ~200–250°C and 150–200°C, respectively, the temperature is set at 180–220°C for the waste rubber and HDPE mixture to overcome the oxidation process [37][38]. Therefore, the applied PID system was designed to control this temperature range for the thermal press.

Once the molding and curing were complete, the composites went through standard post-processing. The HDPE-based samples were left to air-cool at room temperature - this gradual cooling helped prevent thermal stress and kept the material's structure intact. With the RTV silicone composites, nothing extra was required beyond the standard 24-hour curing time at room temperature. To ensure the homogeneity of the mixture, the waste tire granules and polymer (HDPE or RTV silicone) were manually pre-mixed for 5–10 minutes to achieve even distribution before being placed in the mold. During the preparation of the composite materials, all safety measures were implemented, including laboratory ventilation necessary to remove vapors resulting from the melting of polymer materials. In addition, protective clothing and heat-resistant gloves were worn.

Figure 3. a) The press machine with the heating source, b) Schematic drawing of the press machine, and c) the electrical wire connections in the press machine

Waste Tire and RTV Silicone Composites Preparation

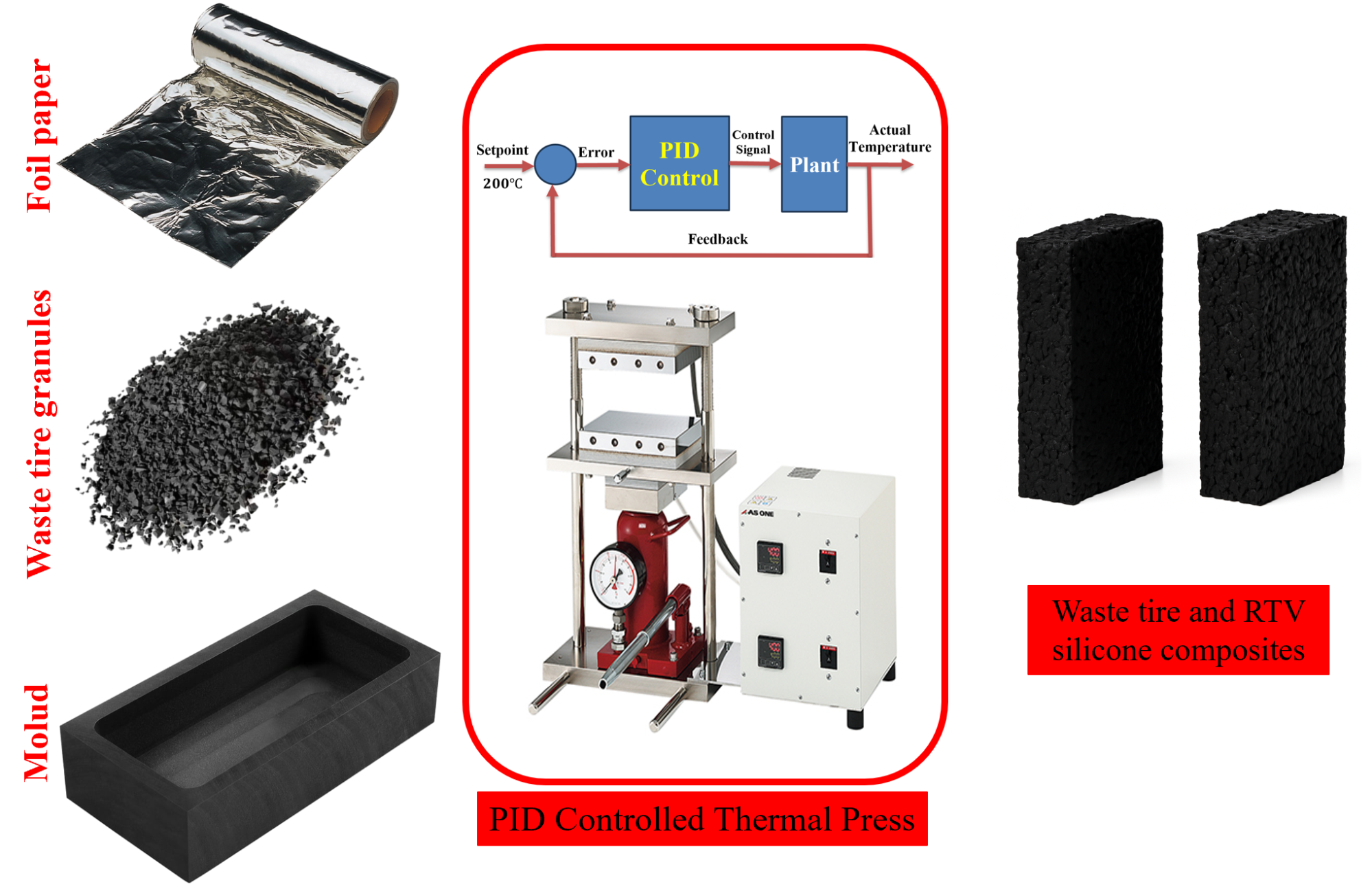

Previous studies have described the preparation of waste tire and RTV silicone composite samples as the ideal method for such applications. Proper mould preparation is essential for manufacturing composite materials, whether raw or recycled. An aluminum mould weighing approximately 1.5 kg was prepared to prepare the samples, which had fixed dimensions of 1.5 x 3 x 6 cm. The mold was covered with aluminum foil to facilitate the handling of the samples, making them ready. Use a sensitive digital weighing scale to measure the required proportions of each waste tire and raw material made from RTV silicone adhesive. Then, the samples will be installed through layers of waste tire and RTV silicone adhesive in preparation for heating and pressing them in the compression machine. The sample weighed 235 g. Finally, the mould with the prepared specimen was placed in a high-temperature heat press machine (H400-15, ASONE Company, Japan) and subjected to pressure. The machine offers hot pressing up to 400°C with PID temperature control, enabling precise temperature adjustment in the range of 180-200°C. The temperature range of 180–200°C was selected for RTV silicone due to its optimal thermal stability and curing behavior. Within this range, the material maintains structural integrity while ensuring strong adhesion to waste rubber particles, preventing early degradation [20]. The hot plate dimensions of the thermal press are 200 x 150 mm, and the operation stroke is 0-90 mm, with a maximum pressing capacity of 15 tons. Several auxiliary instruments, including a digital balance, and vernier caliper, were used. Aluminum foil paper can prevent oxygen and light rays from spoiling the recycled product [39].

A waste tire shredder was used to prepare waste tire samples measuring 50 mm x 50 mm, and then a stainless-steel grinder was used to obtain smaller granules. These pieces were then processed using a stainless-steel grinder, which reduced them to granules with an average particle size ranging between 2–5 mm. The resulting samples were mixed with an RTV silicone adhesive, which can withstand temperatures higher than 200°C. For composites containing RTV silicone, a curing time of 24 hours at room temperature was applied. Fossil paper was used to separate the samples from the mould. Figure 4 illustrates the procedures for the waste tire and RTV silicone composite. The resulting samples were subjected to a high-temperature heat press machine to produce the required specimens. The prepared specimens were made using the following ratio indicated in Table 3.

Figure 4. Waste tire and RTV silicone composites procedures

Table 3. Composition of the waste tire and RTV silicone specimens.

Samples | Composition ratio (wt%) |

1 | 10% waste tire + 90% RTV silicone |

2 | 20% waste tire + 80% RTV silicone |

3 | 30% waste tire + 70% RTV silicone |

4 | 40% waste tire + 60% RTV silicone |

5 | 50% waste tire + 50% RTV silicone |

6 | 75% waste tire + 25% RTV silicone |

7 | 85% waste tire + 15% RTV silicone |

Waste Tire and HDPE Composites Preparation

The method for preparing waste tire and HDPE composites is not significantly different from that described for waste tires and RTV silicone composites. The same heat press with a PID unit was used to prevent rubber deterioration and HDPE oxidation. The same mould and foil paper were also used, and the sample dimensions were identical to those of the waste tires and RTV silicone composites. The raw materials, waste tire and HDPE, were weighed, and the waste tire material was brushed into the mould in layers, with HDPE adhesive applied between the layers. The mould was then placed in the high-temperature heat press machine and subjected to a temperature of 180-200°C for one hour. The sample results are shown in Figure 5. The prepared specimens were made using the following ratio indicated in Table 4.

Figure 5. Marine Fender prototypes of waste tire and HDPE composites

Table 4. Composition of the waste tire and HDPE specimens.

Samples | Composition ratio (wt%) |

1 | 20% waste tire + 80% HDPE |

2 | 40% waste tire + 60% HDPE |

3 | 50% waste tire + 50% HDPE |

4 | 75% waste tire + 25% HDPE |

5 | 85% waste tire + 15% HDPE |

6 | 90% waste tire + 10% HDPE |

RESULTS AND DISCUSSION

This section presents the results from the compression and hardness tests for the two composite materials. Furthermore, we present the tested specimens' modulus of elasticity. Pressure and hardness were selected as the primary testing methods due to their direct relevance to the operational performance of marine fenders, where impact resistance and surface durability are critical.

Compression Test

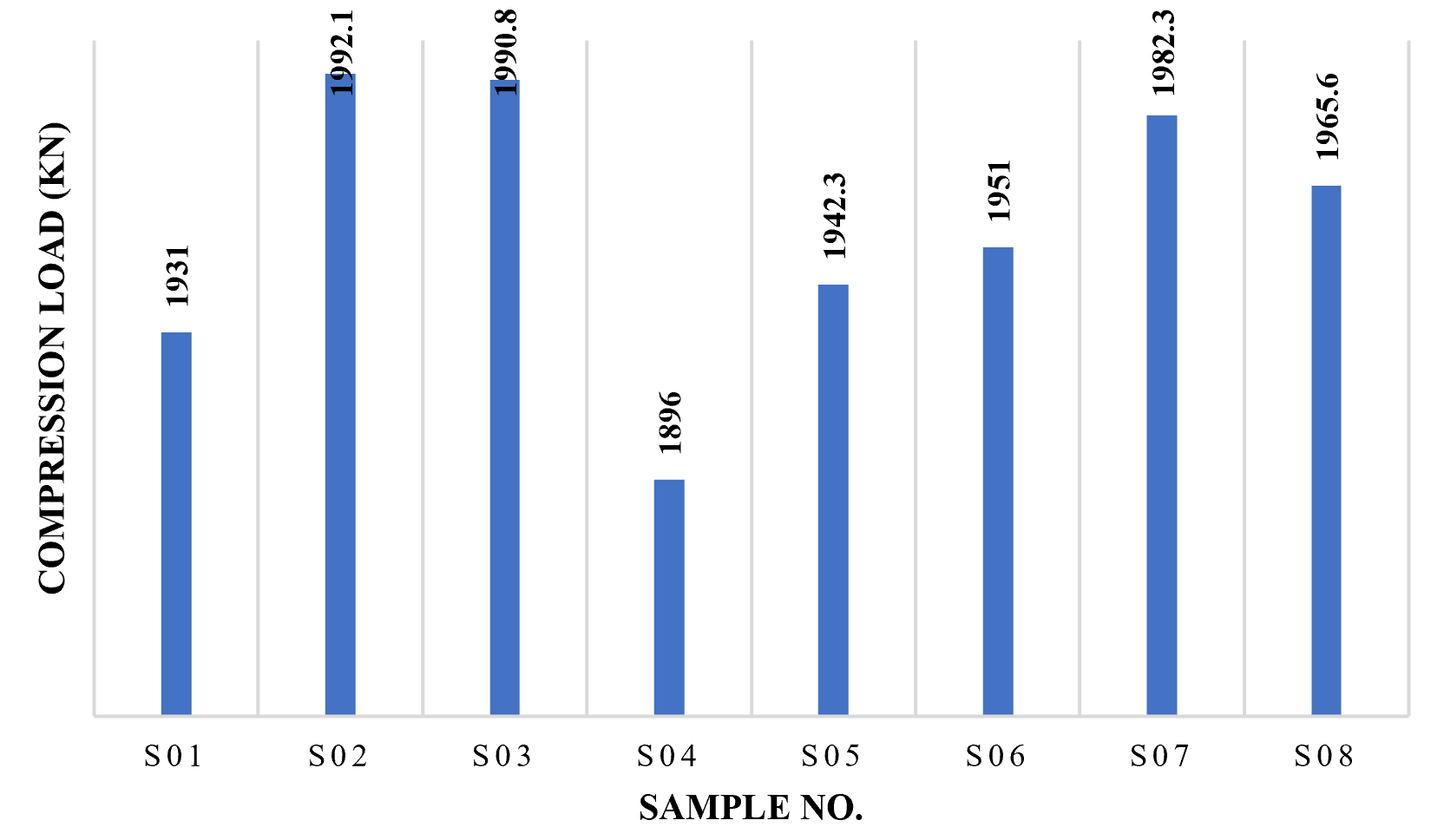

The compression tests revealed how effectively the material could absorb impacts, essential for marine fenders facing constant berthing loads. A compression testing machine (Digitec MATEST) was used to investigate the load capacity of the waste tire and polymer composite specimens. The test findings provided important information about the composites' compressive strength and potential use as marine fenders. Table 5 shows the compression load values for selected specimens from both groups. As indicated in Figure 6, the compression test results show several trends. The waste tire and RTV silicone composites deliver a generally more elevated compression load capability than the waste tire and HDPE composites, indicating that the waste tire and RTV silicone composite give better resistance to deformation. The compression load capacity increases by increasing waste tire content by up to 75% for the waste tire and RTV silicone composites. The current results provide the best balance between stiffness and compressive load resistance. Moreover, the waste tire and HDPE composite exhibit a more consistent trend, with the compression load capacity increasing slightly as waste tire content increases.

Table 5. Compression load of the specimens

Sample No | Specimen Components (wt%) |

S1 | 50% waste tire + 50% RTV silicone |

S2 | 65% waste tire + 35% RTV silicone |

S3 | 75% waste tire + 25% RTV silicone |

S4 | 90% waste tire + 10% RTV silicone |

S5 | 50% waste tire + 50% HDPE |

S6 | 75% waste tire + 25% HDPE |

S7 | 85% waste tire + 15% HDPE |

S8 | 90% waste tire + 10% HDPE |

Figure 6. Compression load variation according to the specimens

Hardness Test

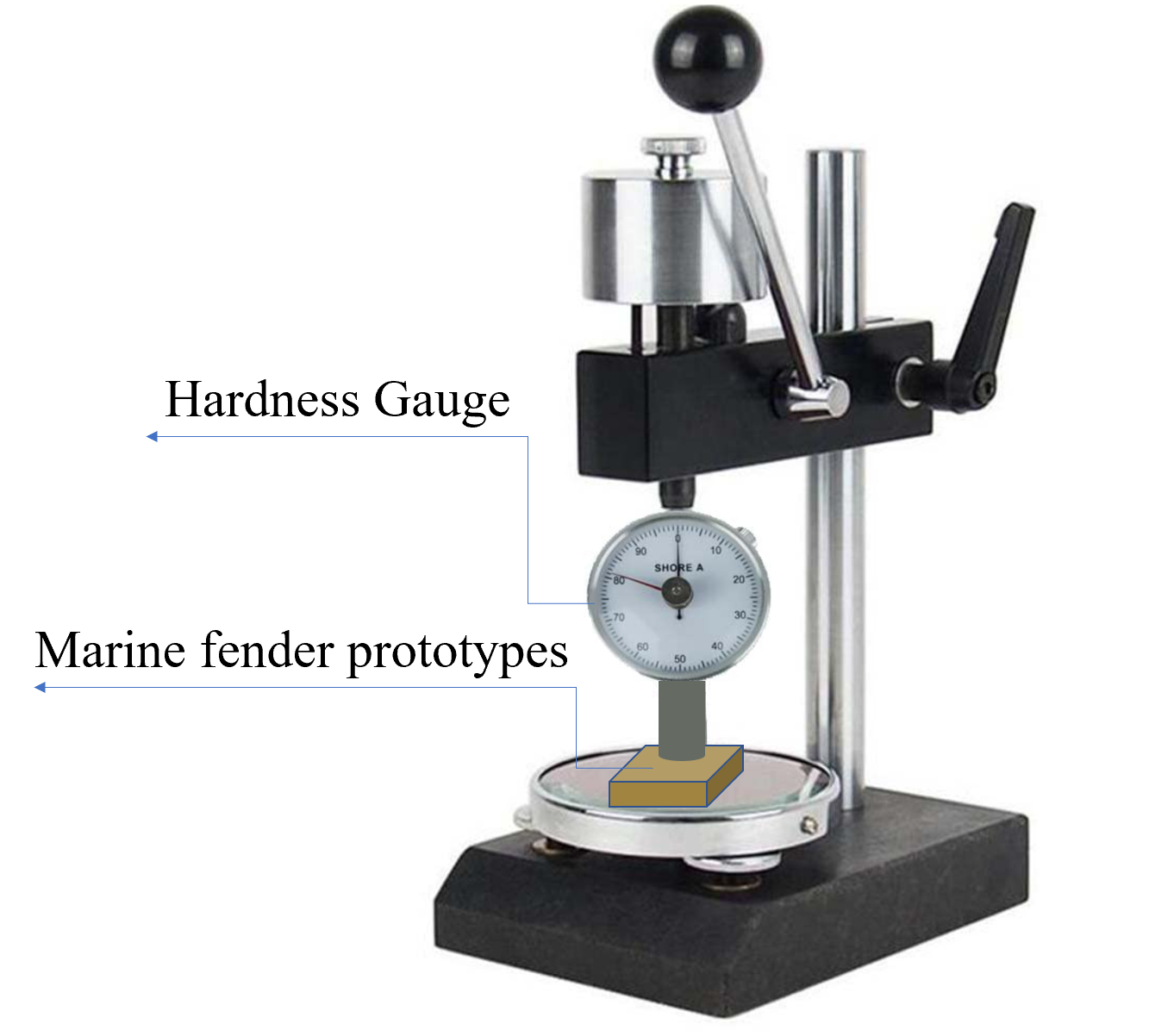

Hardness testing assessed surface resistance to deformation, indicating how well the fenders would withstand years of abrasion from vessel hulls. Plastics and polymer materials differ because their hardness is not measured by traditional methods such as the Burnell, Rockwell, and Vickers hardness scales but rather by more specialized methods. The hardness of the most flexible rubber materials is often measured on a scale called Shore A, which ranges from 0 to 100. When hard rubbers are semi-rigid, they are measured by the Shore D Hardness Scale. It helps engineers and designers select the most appropriate material for specific applications, such as seals, gaskets, tires, and protective coatings. The two groups of composite specimens were then subjected to various mechanical tests, including Shore A and Shore D hardness tests, elastic modulus calculations, and compression tests, to assess their suitability as marine fenders. Both Shore A and Shore D hardness tests are critical tools for understanding the mechanical behavior and durability of recycled rubber/HDPE composites [40][41]. These tests can provide insights into blend behavior and help ensure material reliability. This study used Durometer Hardness Tester LAC-YJ to measure specimens' Hardness, as shown in Figure 7. Table 6 presents the results of the Shore hardness tests for both groups of specimens, where each ratio had four measurements (R1-R4). The average value of these measurements is reported as the R average.

It can be observed that the Shore hardness values of the waste tire and HDPE composite specimens (samples 1-4) were generally higher compared to the waste tire and RTV silicone composite specimens (samples 5-7), indicating that the waste tire and HDPE composites may have higher resistance to indentation and better mechanical performance as marine fenders. It can also be seen that the hardness values of the waste tire and HDPE composites tend to increase with an increase in the waste tire content, except for the 90% waste tire + 10% HDPE composition. The hardness values for the waste tire and RTV silicone composites show a less consistent trend. The perfect balance between the components of RTV silicone and waste tire gave high hardness results, which was clearly demonstrated by using an equal ratio (50%:50%).

Figure 7. Shore Hardness apparatus with fender prototype setup

Table 6. Hardness of selected specimens and average values

Samples (wt%) | Shore Type | R1 | R2 | R3 | R4 | R mean |

50% waste tire + 50% HDPE | D | 76 | 79 | 72 | 70 | 74.25 |

75% waste tire + 25% HDPE | D | 85 | 77 | 76 | 82 | 80.00 |

85% waste tire + 15% HDPE | D | 83 | 84 | 80 | 85 | 83.00 |

90% waste tire + 10% HDPE | D | 76 | 81 | 78 | 83 | 79.50 |

40% waste tire + 60% RTV silicon | A | 76 | 79 | 73 | 75 | 75.75 |

50% waste tire + 50% RTV silicon | A | 92 | 75 | 100 | 75 | 85.50 |

85% waste tire + 15% RTV silicon | A | 70 | 75 | 73 | 80 | 74.50 |

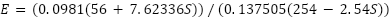

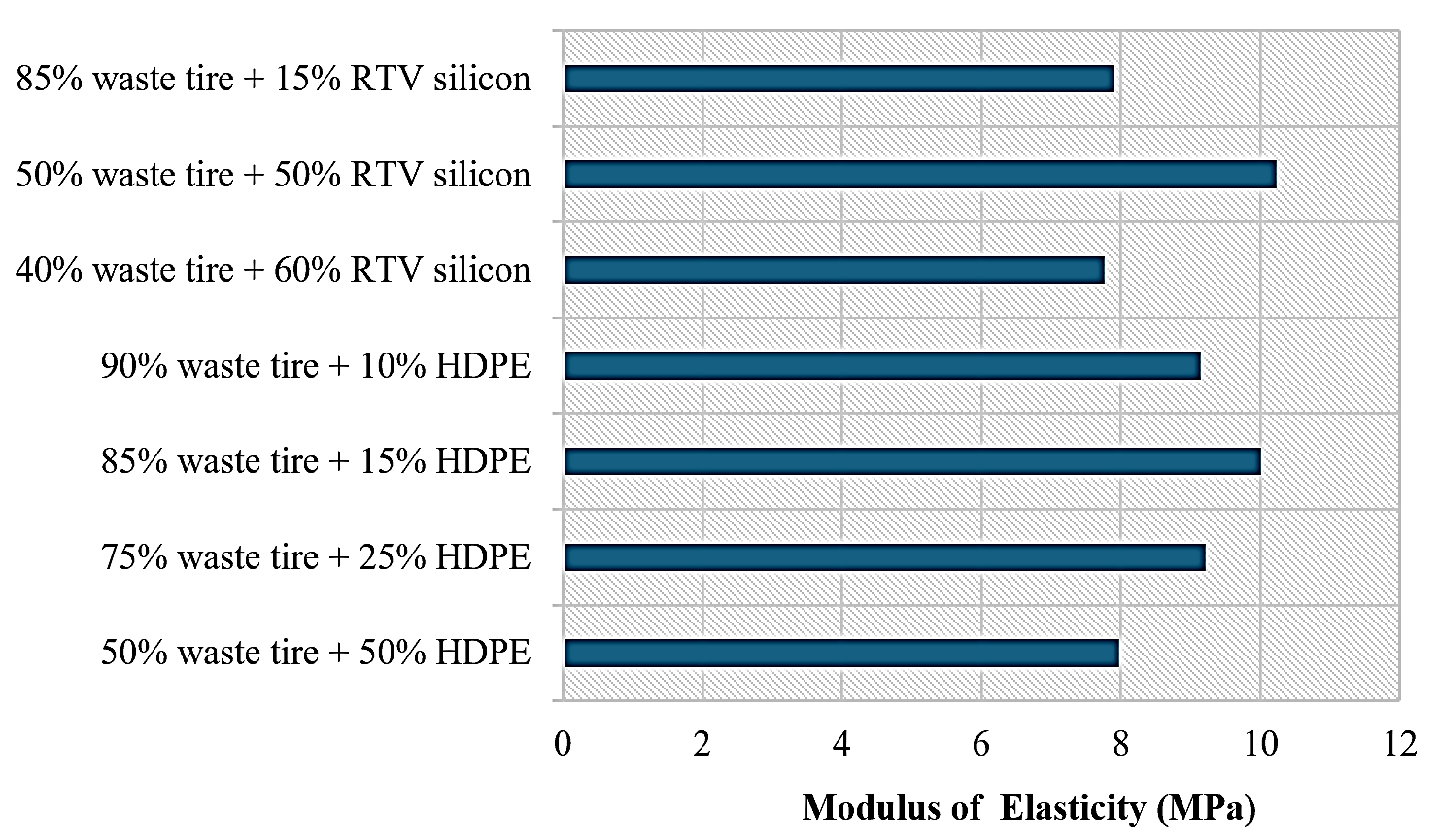

Modulus of Elasticity Calculation

The modulus of elasticity (Young's modulus) is critical for the fenders because it influences their stiffness and effectively absorbs energy while minimizing the risk of permanent deformation or material failure. The modulus of elasticity (E) of the marine fender prototypes in this work is determined using an empirical equation based on Shore hardness (S) [42][43]. This method provides a practical approach when direct tensile testing is not feasible. The correlation relates Shore hardness to Young’s modulus through established equations, offering an approximate but useful measure of stiffness for comparative analysis. Using the above equation, Figure 8 shows the calculated modulus of elasticity for the different specimens. The findings show that the specimens with more waste tire content had an increased elastic modulus, which implies that a substantial portion of the composite material's rigidity is derived from the scrap tire component. Prototypes with higher waste tire content (e.g., 85% waste tire + 15% HDPE and 50% waste tire + 50% RTV silicon) may offer superior energy absorption and durability in marine fender applications compared to those with lower waste tire contents.

|

| (3) |

Figure 8. Modulus of Elasticity of the tested specimens

CONCLUSION AND FUTURE WORK

Recycling waste polymers—like used tires and HDPE—is crucial for protecting the environment. It also helps support a circular economy by transforming waste into useful products with longer lifespans. In the current study, two groups of composite materials were prepared from waste tires and high-density polyethylene (HDPE) once, and waste tires and room-temperature vulcanized (RTV) silicone were used again as marine fenders. The following conclusions can be drawn:

- Prototypes containing 85% waste tire with 15% HDPE and 50% waste tire with 50% RTV silicone showed superior energy absorption and durability for marine fender applications

- The waste tire and HDPE composites exhibit higher Shore hardness (up to 56.6) and Young's modulus values (up to 1.74 MPa) compared to the waste tire and RTV silicone composites (Shore hardness up to 51.8 and Young's modulus up to 1.44 MPa).

- The compression test results indicate that the waste tire and RTV silicone composites generally exhibit a higher compression load capacity.

- The Shore hardness and compression test results indicate an optimal waste tire content, where a 75% waste tire content in the RTV silicone composites gives the highest compression load capacity.

- The marine Fender models manufactured in this study were based on the use of recycled materials, which contribute to the goals of sustainability locally and internationally. The nature of the use of marine fenders, which put them in direct contact with sea or river water, contributes to their adaptation to the atmosphere, whether it is extremely hot or extremely cold.

The recycling of such materials (tires, HDPE, RTV silicone) will be part of sustainability goals (e.g., carbon footprint reduction, waste diversion) in the coming years. In addition, the nature of the manufacture of these materials, which uses high pressure with high temperatures, starting from room temperature up to 200 °C, also contributes to making them more flexible to deal with a wide range of temperatures in use. In-depth knowledge of the effect of temperature changes on use could be a proposed focus of future studies. Finaly, although the study successfully prepared marine fender prototypes that passed pressure and hardness tests, further testing is needed to produce models of marine fenders with realistic dimensions and expose them to actual marine conditions. Moreover, researching the long-term wear resistance and calculating the economic model for the recycled marine fender would provide suitable ideas for future studies.

DECLARATION

Supplementary Materials

Not applicable

Author Contribution

All authors contributed equally to the main contributor to this paper. All authors read and approved the final paper.

Funding

This research received no external funding.

Acknowledgement

Not applicable

Conflicts of Interest

The authors declare no conflict of interest.

REFERENCES

- S. Shiraishi, K. Nagai, and H. Akiyama, “Durability test and statistical evaluation of rubber fenders for vessel berthing,” Journal of Japan Society of Civil Engineers, vol. 9, no. 1, pp. 71–85, 2021, https://doi.org/10.2208/journalofjsce.9.1_71.

- W. Galor, “The Analysis Of Effective Energy Of Ship’s Berthing To The Quay,” Journal of KONES. Powertrain and Transport, vol. 19, no. 4, 2015, https://doi.org/10.5604/12314005.1138340.

- C. A. Thoresen, Port Designer’s Handbook. 2018. https://doi.org/10.1680/pdhbfe.63075.

- G. Wang et al., “Condition Assessment of Aging Ships and Offshore Structures,” 17th International Ship and Offshore Structures Congress (ISSC2009), pp. 309-366, 2009, https://www.croris.hr/crosbi/publikacija/prilog-knjiga/41459.

- S. Mita, K. Yamashita, and C. Nonomura, “Influence of the bow collision condition on the characteristic of the new material fender with bridge piers,” Nippon Kikai Gakkai Ronbunshu, A Hen/Transactions of the Japan Society of Mechanical Engineers, Part A, vol. 70, no. 1, 2004, https://doi.org/10.1299/kikaia.70.120.

- R. Al-Sabur, Y. M. Ameen, H. I. Khalaf, A. Mishra, and A.-N. Sharkawy, “Modeling the Structural Dynamics of Carbon Fiber Composites for Robotic Systems Under Sinusoidal Load,” International Journal of Robotics and Control Systems, vol. 5, no. 1, pp. 570–584, 2025, https://doi.org/10.31763/ijrcs.v5i1.1693.

- M. Bhong et al., “Review of composite materials and applications,” Mater Today Proc, 2023, https://doi.org/10.1016/j.matpr.2023.10.026.

- G. Marsh, “Composites fight for share of military applications,” Reinforced Plastics, vol. 49, no. 5, 2005, https://doi.org/10.1016/S0034-3617(05)70641-X.

- R. A. Shenoi, J. M. Dulieu-Barton, S. Quinn, J. I. R. Blake, and S. W. Boyd, “Composite Materials for Marine Applications: Key Challenges for the Future,” in Composite Materials, pp. 69-89, 2011, https://doi.org/10.1007/978-0-85729-166-0_3.

- M. S. Atiq, A. K. J. Shajib, and K. N. Hoque, “Analysis of Marine Fender Systems Minimizing the Impact of Collision Damage,” SSRN Electronic Journal, 2023, https://doi.org/10.2139/ssrn.4445128.

- D. C. Ali, A. K. Jassim, and R. Al-Sabur, “Recycling of Polyethylene and Polypropylene Waste to Produce Plastic Bricks,” Journal of Sustainable Development of Energy, Water and Environment Systems, vol. 11, no. 4, 2023, https://doi.org/10.13044/j.sdewes.d11.0462.

- S. A. S. Almtori, R. J. Jassim, D. C. Ali, E. H. Kadhim, and R. Al-Sabur, “Sustainable Manufacturing Process Applied to Produce Waste Polymer-Polymer Matrix Composites,” Environmental Research, Engineering and Management, vol. 79, no. 1, pp. 122–132, 2023, https://doi.org/10.5755/j01.erem.79.1.32907.

- A. S. Safaa, N. H. J. Al Hassan, D. C. Ali, M. A. Mohammed, and R. Al-Sabur, “Assessing the compressive performance of PVC coating on steel wire mesh reinforced concrete,” Cogent Eng, vol. 10, no. 1, 2023, https://doi.org/10.1080/23311916.2023.2231700.

- L. Valentini and M. A. L. Manchado, “Classification of rubbers and components for harsh environmental systems,” in High-Performance Elastomeric Materials Reinforced by Nano-Carbons: Multifunctional Properties and Industrial Applications, pp. 1-14, 2019, https://doi.org/10.1016/B978-0-12-816198-2.00001-3.

- C. Sathiskumar and S. Karthikeyan, “Recycling of waste tires and its energy storage application of by-products –a review,” Sustainable Materials and Technologies, vol. 22, p. e00125, 2019, https://doi.org/10.1016/j.susmat.2019.e00125.

- Z. Čepić, V. Mihajlović, S. Đurić, M. Milotić, M. Stošić, B. Stepanov, and M. Ilić Mićunović, “Experimental analysis of temperature influence on waste tire pyrolysis,” Energies, vol. 14, no. 17, p. 5403, 2021, https://doi.org/10.3390/en14175403.

- A. Alsaleh and M. L. Sattler, “Waste Tire Pyrolysis: Influential Parameters and Product Properties,” Current Sustainable/Renewable Energy Reports, vol. 1, no. 4, pp. 129-135, 2014, https://doi.org/10.1007/s40518-014-0019-0.

- N. Oikonomou and S. Mavridou, “The use of waste tyre rubber in civil engineering works,” in Sustainability of Construction Materials, pp. 213-238 ,2009, https://doi.org/10.1533/9781845695842.213.

- J. Nikiema and Z. Asiedu, “A review of the cost and effectiveness of solutions to address plastic pollution,” Environmental Science and Pollution Research, vol. 29, no. 17, pp. 24547-24573, 2022, https://doi.org/10.1007/s11356-021-18038-5.

- J. J. Wang, L. J. Feng, A. L. Lei, A. J. Yan, and X. J. Wang, “Thermal stability and mechanical properties of room temperature vulcanized silicone rubbers,” J Appl Polym Sci, vol. 125, no. 1, 2012, https://doi.org/10.1002/app.35669.

- H. N. Dhakal and S. O. Ismail, “Introduction to composite materials,” Sustainable Composites for Lightweight Applications, pp. 1–16, 2021, https://doi.org/10.1016/B978-0-12-818316-8.00001-3.

- T. T. Lee, “Design criteria recommended for marine fender systems,” In Coastal Engineering 1968, pp. 1159-1184, 1968, https://doi.org/10.9753/icce.v11.73.

- H. Agerschou et al., Planning and design of ports and marine terminals. Chichester: Wiley. 1983. https://doi.org/10.1016/0191-2607(84)90023-2.

- J. Gaythwaite, Design of Marine Facilities for the Berthing, Mooring, and Repair of Vessels. 2004. https://doi.org/10.1061/9780784407264.

- R. Iversen, M. L. Argo, S. C. Cortes, and J. J. Pyun, “Analysis of Measured Marine Oil Terminal Berthing Velocities,” in Ports 2019: Port Planning and Development - Papers from Sessions of the 15th Triennial International Conference, pp. 162-172, 2019, https://doi.org/10.1061/9780784482629.016.

- F. Rubino, A. Nisticò, F. Tucci, and P. Carlone, “Marine application of fiber reinforced composites: A review,” Journal of Marine Science and Engineering, vol. 8, no. 1, p. 26, 2020, https://doi.org/10.3390/jmse8010026.

- K. Zyka and A. Mohajerani, “Composite piles: A review,” Construction and building materials, vol. 107, pp. 394-410 2016, https://doi.org/10.1016/j.conbuildmat.2016.01.013.

- M. Haward, “Ocean plastics charter,” In Essential Concepts of Global Environmental Governance, pp. 171-172, 2020, https://doi.org/10.4324/9780367816681-70.

- J. Qian, L. Sun, and L. Song, “Material selection for hawsers for a side-by-side offloading system,” Journal of Marine Science and Application, vol. 13, no. 4, 2014, https://doi.org/10.1007/s11804-014-1272-8.

- “AIMPLAS focuses on more efficient composites recycling,” Reinforced Plastics, vol. 65, no. 1, 2021, https://doi.org/10.1016/j.repl.2020.12.041.

- H. Liang, Z. K. Sang, Y. Z. Wu, Y. H. Zhang, and R. Zhao, “High precision temperature control performance of a PID neural network-controlled heater under complex outdoor conditions,” Appl Therm Eng, vol. 195, 2021, https://doi.org/10.1016/j.applthermaleng.2021.117234.

- M. Fiducioso, S. Curi, B. Schumacher, M. Gwerder, and A. Krause, “Safe contextual Bayesian optimization for sustainable room temperature PID control tuning,” arXiv preprint arXiv:1906.12086, 2019, https://doi.org/10.24963/ijcai.2019/811.

- M. B. N. Shah et al., “PID-based temperature control device for electric kettle,” International Journal of Electrical and Computer Engineering, vol. 9, no. 3, 2019, https://doi.org/10.11591/ijece.v9i3.pp1683-1693.

- A. H. Akbar, A. Ma’arif, C. Rekik, A. J. Abougarair, and A. M. Mekonnen, “Implementing PID Control on Arduino Uno for Air Temperature Optimization,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 6, no. 1, pp. 1–13, 2024, https://doi.org/10.12928/biste.v6i1.9725.

- S. B. Joseph, E. G. Dada, A. Abidemi, D. O. Oyewola, and B. M. Khammas, “Metaheuristic algorithms for PID controller parameters tuning: Review, approaches and open problems,” Heliyon, vol. 8, no. 5, 2022, https://doi.org/10.1016/j.heliyon.2022.e09399.

- S. Zeng, W. Li, Y. Peng, Y. Zhang, and G. Zhang, “Mechanism of Accelerated Deterioration of High-Temperature Vulcanized Silicone Rubber under Multi-Factor Aging Tests Considering Temperature Cycling,” Polymers (Basel), vol. 15, no. 15, 2023, https://doi.org/10.3390/polym15153210.

- A. A. Cuadri and J. E. Martín-Alfonso, “The effect of thermal and thermo-oxidative degradation conditions on rheological, chemical and thermal properties of HDPE,” Polym Degrad Stab, vol. 141, 2017, https://doi.org/10.1016/j.polymdegradstab.2017.05.005.

- T. Mengistu and R. J. Pazur, “The thermal oxidation of hydrogenated acrylonitrile-co-butadiene rubber from ambient to 150 °C,” Polym Degrad Stab, vol. 188, 2021, https://doi.org/10.1016/j.polymdegradstab.2021.109574.

- D. Obradovic and L. N. Mishra, “Mechanical Properties Of Recycled Paper And Cardboard,” The Journal of Engineering and Exact Sciences, vol. 6, no. 3, pp. 0429–0434, 2020, https://doi.org/10.18540/jcecvl6iss3pp0429-0434.

- H. Zhao, D. Allanson, and X. J. Ren, “Use of Shore Hardness Tests for In-Process Properties Estimation/Monitoring of Silicone Rubbers,” Journal of Materials Science and Chemical Engineering, vol. 03, no. 07, 2015, https://doi.org/10.4236/msce.2015.37019.

- R. Mohan, B. N. Das, and R. Sundaresan, “Effect of hardness and surface roughness on slip resistance of rubber,” J Test Eval, vol. 43, no. 6, 2015, https://doi.org/10.1520/JTE20140249.

- A. N. Gent, “On the Relation between Indentation Hardness and Young’s Modulus,” Rubber Chemistry and Technology, vol. 31, no. 4, 1958, https://doi.org/10.5254/1.3542351.

- D. Bakošová and A. Bakošová, “Testing of Rubber Composites Reinforced with Carbon Nanotubes,” Polymers (Basel), vol. 14, no. 15, p. 3039, 2022, https://doi.org/10.3390/polym14153039.

AUTHOR BIOGRAPHY

| Dr. Ali Habel Zaibel is a lecturer in the Department of Mechanical Engineering at the University of Basrah, Iraq. He received his Ph.D. in 2000 from the University of Basrah, focusing on the analysis of creep, recovery, and relaxation behaviors of plastics under combined loading systems. He also earned his M.Sc. in 1995 from the same university, specializing in fracture mechanics analysis using the Boundary Element Method. His B.Sc. degree was obtained from the University of Kuwait. Dr. Zaibel's research interests include material behavior under complex loading, fracture mechanics, and tribological systems, and he has published work on topics such as the dynamically loaded analysis of adjustable hydrodynamic pad bearings. |

|

|

| Prof. Dr. Safaa A. S. Almtori is a professor at the College of Materials Engineering, University of Basrah, Iraq. He earned his M.Sc. from the University of Baghdad in 1993 and his Ph.D. from the University of Basrah in 2000, specializing in the evaluation of epoxy and composite materials. His research focuses on polymer composites, recycling of waste materials, and sustainable manufacturing processes. He has published several papers on topics such as thermoelectric properties, polymer-based composites, and the reuse of industrial and household waste in engineering applications. |

|

|

| Raheem Al-Sabur received his Ph.D. in Mechanical Engineering with a specialization in friction stir welding. He is a member of both the American Welding Society (AWS) and the German Welding Society (DVS). Since 2002, he has been serving as a faculty member in the Department of Mechanical Engineering at the University of Basrah, Iraq. With nearly two decades of academic and teaching experience, Dr. Al-Sabur has developed expertise across a range of mechanical engineering domains, particularly in welding technologies. His research and instructional interests include fusion and solid-state welding processes, welding defects and inspection, as well as both destructive and non-destructive testing methods. He also possesses practical experience in computational tools and optimization techniques, including the use of Minitab, neural networks, and image-based analysis for engineering applications. Dr. Al-Sabur serves as a reviewer for more than 50 international journals and has been invited as a keynote speaker at over 20 national and international conferences. |

|

|

| Abdel-Nasser Sharkawy is an associate Professor at Mechatronics Engineering, Mechanical Engineering Department, Faculty of Engineering, South Valley University (SVU), Qena, Egypt. Sharkawy was graduated with a first-class honors B.Sc. degree in May 2013 and received his M.Sc. degree in April 2016 from Mechatronics Engineering, Mechanical Engineering Department, SVU, Egypt. In March 2020, Sharkawy received his Ph.D. degree from Robotics Group, Department of Mechanical Engineering and Aeronautics, University of Patras, Patras, Greece. His PhD was about “Intelligent Control and Impedance Adjustment for Efficient Human-Robot Cooperation”. Sharkawy has an excellent experience for teaching the under-graduate and postgraduate courses in the field of Mechatronics and Robotics Engineering. Sharkawy has published more than 75 papers in international scientific journals, book chapters and international scientific conferences. He serves as reviewer for about 50 journals and 10 conferences. His research areas of interest include robotics, human-robot interaction, mechatronic systems, neural networks, machine learning, and control and automation. |

Ali Habel Zaibel (Temperature-Controlled Process for Recycled Waste Tire Polymer-Polymer Composites: An Innovative and Sustainable Solution for Marine Fender Applications)