ISSN: 2685-9572 Buletin Ilmiah Sarjana Teknik Elektro

Vol. 7, No. 3, September 2025, pp. 382-396

A Comprehensive Review of Optimization Techniques in Industrial Applications: Trends, Classifications, and Future Directions

Hayati Mukti Asih 1, Effendi Mohamad 2, Irianto 3, Alfian Ma’arif 4

1 Department of Industrial Engineering, Universitas Ahmad Dahlan, Indonesia

2 Faculty of Industrial and Manufacturing Technology and Engineering,

Universiti Teknikal Malaysia Melaka (UTeM), Malaysia

3 Mathematics, Rabdan Academy, United Arab Emirates

4 Department of Electrical Engineering, Universitas Ahmad Dahlan, Yogyakarta, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Received 15 April 2025 Revised 10 June 2025 Accepted 06 August 2025 |

|

In recent years, optimization techniques have played a central role in enhancing operational efficiency and decision-making across diverse industrial sectors, including manufacturing, logistics, and transportation, energy, healthcare, and agriculture. These sectors face complex, large-scale, and often nonlinear challenges that demand both precision and adaptability. The research contribution of this review is to provide a structured classification of optimization methods—namely exact algorithms, heuristics, metaheuristics, and AI-integrated hybrid models—and to critically evaluate their practical applications, limitations, and emerging trends across industries. This study adopts a review approach to identify and compare those techniques in solving various optimization problems. Through a detailed analysis of over 30 recent publications for last four years, the review highlights how these techniques are being applied in real-world industrial environments, including cold chain logistics, smart energy systems, precision agriculture, and healthcare scheduling. The results indicate a growing reliance on hybrid and AI-enhanced models due to their superior scalability, adaptability, and potential alignment with Industry 4.0 and Sustainable Development Goals (SDGs). However, challenges remain in areas such as computational efficiency, model interpretability, and real-time data integration. In conclusion, this study provides valuable insights for both researchers and practitioners seeking to apply optimization techniques more effectively in industrial systems, while also identifying critical research gaps for future exploration by addressing the growing complexity and sustainability demands of modern industry. |

Keywords: Optimization Techniques; Industrial Applications; Metaheuristics; Hybrid AI-integration; Exact Algorithm |

Corresponding Author: Hayati Mukti Asih, Department of Industrial Engineering, Universitas Ahmad Dahlan, Indonesia. Email: hayati.asih@ie.uad.ac.id |

This work is open access under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: H. M. Asih, E. Mohamad, I. Irianto, and A. Ma’arif, “A Comprehensive Review of Optimization Techniques in Industrial Applications: Trends, Classifications, and Future Directions,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 7, no. 3, pp. 382-396, 2025, DOI: 10.12928/biste.v7i3.13261. |

INTRODUCTION

In recent decades, optimization techniques have become indispensable tools across various industrial domains, serving as core enablers for enhancing efficiency, reducing operational costs, and supporting data-driven decision-making [1]-[3]. The complexity of modern industrial systems—ranging from dynamic production lines and large-scale logistics networks to energy distribution and healthcare service management—has necessitated the adoption of advanced optimization methods capable of addressing multi-objective, nonlinear, and large-scale problems.

To meet these multifaceted challenges, a wide spectrum of optimization methodologies has been developed. Classical techniques, such as linear programming and integer programming, have long formed the foundation of structured decision-making. These methods offer robust mathematical frameworks for optimizing well-defined problems [4][5]. However, the growing complexity and dimensionality of real-world applications have necessitated the adoption of more flexible and exploratory approaches [6]. Metaheuristic algorithms—including Genetic Algorithms (GA), Particle Swarm Optimization (PSO), Ant Colony Optimization (ACO), and Simulated Annealing (SA)—have emerged as powerful alternatives, offering heuristic solutions to problems that are nonlinear, multi-objective, and computationally intractable by exact methods [7]-[11].

Moreover, the rapid convergence of optimization with artificial intelligence (AI) and machine learning (ML) has expanded the boundaries of what these techniques can achieve [12][13]. This integration enables optimization models to learn from data, adapt to uncertain environments, and operate effectively under real-time constraints—capabilities that are increasingly essential in the era of digital transformation [14][15]. Technologies such as Industry 4.0, the Internet of Things (IoT), and sustainability imperatives are further reshaping the landscape of optimization applications, introducing both new opportunities and complex challenges for researchers and practitioners alike [16][17]. These advancements demand more adaptive, data-driven, and real-time optimization approaches to manage dynamic systems, heterogeneous data streams, and conflicting performance objectives such as efficiency, resilience, and environmental impact.

In contrast, the current body of literature tends to remain fragmented. Most existing reviews are limited in scope, often concentrating on specific algorithmic categories or confined to particular industrial domains. As a result, there is a noticeable gap in comprehensive, cross-sectoral analyses that not only trace the evolution of optimization strategies but also compare their real-world effectiveness and limitations. Furthermore, few studies have systematically examined how emerging technological and sustainability trends are influencing the development and deployment of optimization solutions.

This review seeks to bridge these gaps by presenting an integrative overview of optimization techniques applied across diverse industries. We classify these methods according to their algorithmic foundations, explore their sectoral applications, and critically analyze emerging patterns, limitations, and future directions. In doing so, this work aims to serve as a valuable reference for both academic researchers and industry professionals striving to align optimization strategies with the evolving demands of contemporary industrial systems.

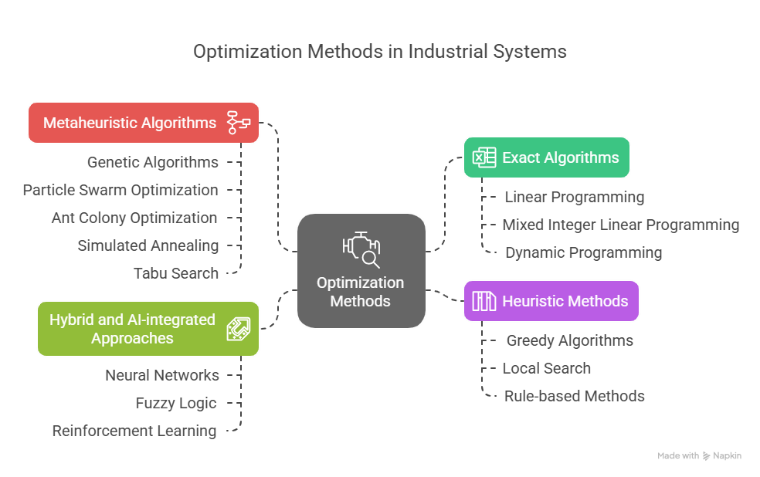

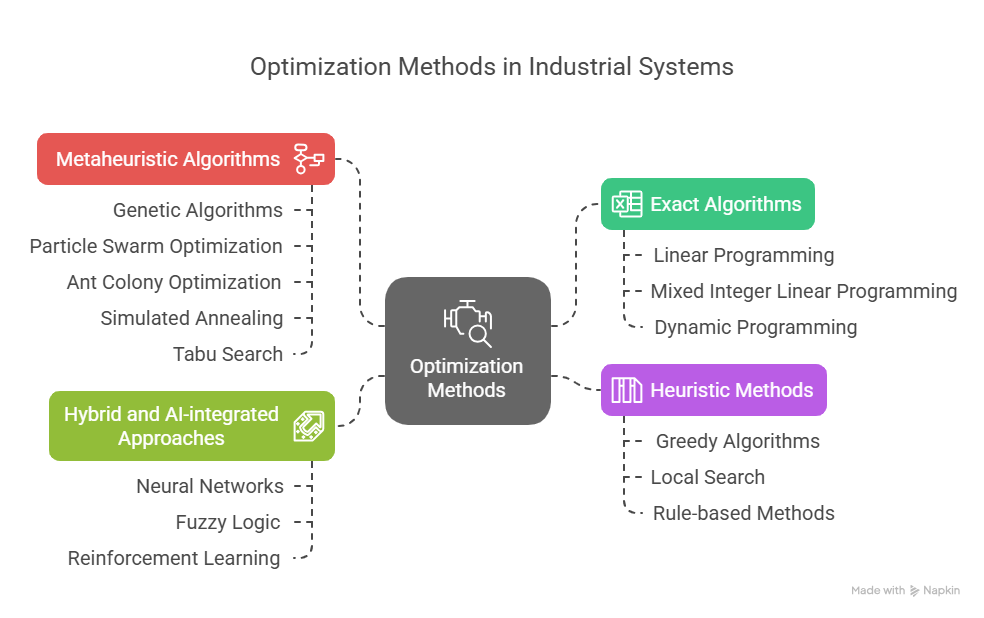

CLASSIFICATION OF OPTIMIZATION TECHNIQUE

Optimization problems encountered in industrial systems vary widely in structure, scale, and complexity. Accordingly, a diverse array of solution techniques has been developed and applied to address these challenges [18][19]. Based on a comprehensive review of the literature, optimization methods can be broadly classified into four major categories (refer to Figure 1): exact algorithms, heuristic methods, metaheuristic algorithms, and hybrid or AI-integrated approaches [19]. Each class in this figure offers unique strengths and is suited to different problem contexts, reflecting the trade-offs between accuracy, computational efficiency, and scalability.

- Exact Algorithms

Exact optimization techniques provide mathematically rigorous solutions and are often preferred when optimality is critical and problem structures are well-defined [20][21]. Among the most prominent are Linear Programming (LP) [22][23], Mixed Integer Linear Programming (MILP) [24], and Dynamic Programming (DP) [25].

LP is a mathematical technique used for optimizing a linear objective function subject to linear equality and inequality constraints. It is computationally efficient and suitable for large-scale continuous-variable problems. Its main strength lies in the ability to provide exact solutions quickly, especially when model assumptions are linear and well-defined [26]. However, LP is limited in handling problems involving discrete decisions or non-linear dynamics, which restricts its applicability in more complex, real-world systems [27].

MILP extends LP by incorporating integer variables, allowing for the modeling of more complex decisions such as on/off states and discrete choices. This makes MILP particularly effective for problems like scheduling [28], facility layout [29], and energy system optimization [30]. MILP’s advantage lies in its flexibility and precision. However, it is computationally intensive, especially for large-scale problems, due to its NP-hard nature. Recent advancements in distributed MILP methods have aimed to address this by reducing computational times through relaxed assumptions and decomposition techniques [31] Despite these improvements, MILP remains resource-intensive, often necessitating the use of high-performance solvers and simplification heuristics for practical applications [32].

DP is a recursive optimization approach that solves problems by breaking them down into simpler subproblems. It is especially effective for multi-stage decision problems where the system evolves over time. One key advantage of DP is its ability to handle both discrete and continuous variables, accommodating complex, time-dependent decision environments. In hybrid approaches, DP has been successfully applied alongside MILP to decompose large-scale optimization problems, thereby enhancing scalability and computational feasibility [29]. However, DP suffers from the “curse of dimensionality,” meaning its computational demand increases exponentially with the number of state variables, limiting its standalone application in high-dimensional industrial problems.

These methods guarantee the identification of the global optimum, making them ideal for small to medium-sized problems with linear or deterministic constraints [33]. However, their applicability tends to diminish with increasing problem complexity or dimensionality, as the required computational resources grow exponentially [34]. In summary, while LP offers simplicity and speed, MILP provides modeling flexibility at the cost of computational load, and DP excels in time-dependent decision-making but struggles with scalability. Hybrid and decomposition-based approaches are increasingly adopted to leverage the strengths of these methods while mitigating their individual limitations.

- Heuristic Methods

Heuristic techniques are problem-specific strategies designed to produce satisfactory solutions in a relatively short time [35]. Unlike exact algorithms, heuristic methods do not guarantee finding the optimal solution. However, they are particularly valuable in fast-paced industrial environments where rapid decision-making is critical [36]. These approaches are specifically designed to produce satisfactory, near-optimal solutions within a reasonable amount of time, making them highly suitable for real-world applications where time and computational resources are limited. Common examples include greedy algorithms [37], local search [38], and rule-based methods [39].

Greedy algorithms make a series of locally optimal choices with the hope of finding a global optimum. They are highly efficient and easy to implement, offering rapid solutions with minimal computational overhead. However, their main limitation is the tendency to converge prematurely to suboptimal solutions due to a lack of global search capabilities [40]k. To mitigate this, hybrid approaches often integrate greedy initialization with more robust optimization methods.

Local search algorithms, on the other hand, iteratively improve a candidate solution by exploring its neighborhood, making them particularly suitable for complex scheduling and layout problems. These methods excel in fine-tuning solutions and are often embedded within metaheuristics like Iterated Local Search (ILS) and Iterated Greedy (IG) algorithms to enhance solution quality. Their strengths lie in exploiting local optima efficiently, though they can still suffer from stagnation without diversification mechanisms [41][42].

Rule-based heuristics, often used in priority scheduling and dispatching, are characterized by their transparency and adaptability. These methods rely on predefined rules derived from expert knowledge or empirical patterns to guide decisions. While their simplicity and speed are advantageous, their effectiveness is highly dependent on the relevance and accuracy of the encoded rules, which may not generalize well to dynamic or unfamiliar environments [43]. To overcome this, recent studies have embedded rule-based reasoning into adaptive metaheuristics, enhancing both scalability and responsiveness in uncertain conditions.

These heuristic methods are commonly applied in real-time scheduling, dispatching, and other operational tasks, where obtaining a sufficiently good solution is often more valuable than achieving the optimal solution after a delay [44]. In summary, while greedy algorithms and rule-based methods offer speed and simplicity, and local search methods improve solution refinement, their individual limitations are increasingly being addressed through hybrid combinations tailored for industrial optimization tasks.

- Metaheuristic Algorithms

Metaheuristics represent a more flexible and generalized class of optimization methods capable of addressing large-scale, nonlinear, and multi-objective problems [45][46]. These algorithms are inspired by natural processes and intelligent behavior, enabling them to explore vast solution spaces effectively [47]. Popular metaheuristic techniques include GA, PSO, ACO, SA, and TS [48].

GA are inspired by the principles of natural evolution and operate through processes such as selection, crossover, and mutation [49]. They are known for their global search capability and adaptability across diverse domains. However, GAs can suffer from slow convergence and premature stagnation if not properly tuned [50]. On the other hand, PSO is based on the social behavior of birds flocking or fish schooling [51]. It excels in fast convergence and ease of implementation, making it suitable for continuous optimization problems, although it may struggle with premature convergence and local optima in complex landscapes [52].

ACO mimics the foraging behavior of ants and has demonstrated effectiveness in discrete and combinatorial problems like routing and scheduling. While ACO is robust and scalable, it often requires extensive computation and can be prone to stagnation without diversification strategies [53]. SA is inspired by the annealing process in metallurgy and is appreciated for its ability to escape local optima by accepting worse solutions with a certain probability. Its primary drawbacks include sensitivity to cooling schedule parameters and slower convergence compared to other algorithms [54]. TS utilizes memory structures to avoid cycles and guide the search process. It is particularly effective in combinatorial optimization, offering strong exploitation capabilities. However, it may get trapped in local optima if diversification mechanisms are weak or memory structures are not adequately managed [55].

Their ability to escape local optima and search globally makes them particularly suitable for complex applications such as supply chain optimization, production planning, and energy scheduling [51],[56]-[62]. Each algorithm has its unique strengths and limitations. There is no single method that universally superior. The choice of algorithm must align with the problem characteristics, and hybrid approaches often outperform standalone techniques in real-world applications.

- Hybrid and AI-integrated Approaches

The increasing complexity of contemporary industrial challenges—characterized by high levels of uncertainty, dynamic conditions, and real-time data—has driven a significant rise in the adoption of hybrid optimization methods [63][64]. These approaches combine the strengths of multiple techniques to better address the multifaceted nature of modern problems. Notably, the integration of metaheuristic algorithms with artificial intelligence (AI) techniques, such as neural networks (NN), fuzzy logic, and reinforcement learning, has expanded the frontier of optimization capabilities [65]-[67].

NN are computational models inspired by the structure and functioning of the human brain, capable of learning complex nonlinear relationships from data. Their strength lies in their adaptability, parallel processing, and high accuracy in pattern recognition tasks, making them valuable in domains such as fault detection and forecasting. However, traditional neural networks often suffer from interpretability issues and are data-hungry, limiting their generalization in cases with limited or noisy data [68][69].

Fuzzy logic provides a framework for reasoning under uncertainty by using linguistic variables and approximate reasoning, which is especially useful in environments where systems are difficult to model precisely. Its primary advantage is interpretability and its ability to encode expert knowledge into rule-based systems. However, fuzzy systems often struggle with scalability and require careful tuning of membership functions and rules [70]. Hybrid fuzzy neural networks have emerged to address the limitations of both paradigms by combining the generalization capacity of NNs with the interpretability of fuzzy systems [71].

Reinforcement learning is a learning paradigm where agents learn optimal actions through interactions with their environment by maximizing cumulative rewards. RL excels in sequential decision-making and real-time control tasks such as robotics, energy management, and adaptive control systems. Its key advantage is the ability to learn optimal policies without explicit models, but it faces challenges such as high computational cost, convergence instability, and the need for large training data or interaction time [72][73].

These hybrid models are designed to improve convergence speed, enhance solution quality, and increase adaptability in rapidly changing environments [74]. The combination of these techniques—such as reinforcement learning-based tuning of fuzzy controllers or integration with neural networks—has resulted in robust, adaptive, and explainable models capable of performing well in uncertain, dynamic, and data-scarce environments [75][76]. In smart manufacturing settings, for example, AI-enabled systems can learn from historical and real-time data, while embedded optimization algorithms continuously adjust operational strategies to support tasks such as predictive maintenance, sustainability, resource allocation, and energy efficiency [77][78].

In summary, the spectrum of optimization methods—from exact algorithms to AI-integrated hybrid approaches—reflects a continuum of trade-offs between solution accuracy, computational efficiency, adaptability, and scalability. Exact methods such as LP, MILP, and DP offer precision and mathematical rigor but are often constrained by problem size and complexity. Heuristic methods provide speed and simplicity for problem-specific applications, while metaheuristics extend optimization capabilities to complex, nonlinear, and multi-objective problems by leveraging global search strategies. Hybrid and AI-integrated approaches represent the frontier of industrial optimization, combining the strengths of multiple paradigms to tackle uncertainty, dynamic environments, and real-time decision-making. Selecting the appropriate method requires a careful match between problem characteristics and algorithmic capabilities, with hybridization increasingly serving as a strategic bridge to balance accuracy, efficiency, and robustness in modern industrial systems.

Figure 1. Optimization Methods

INDUSTRIAL APPLICATIONS OF OPTIMIZATION

Optimization techniques have become foundational across a wide range of industrial sectors, each presenting distinct challenges, performance goals, and operational constraints. From enhancing process efficiency to enabling strategic and data-driven decision-making, optimization continues to transform how organizations respond to complexity, uncertainty, and the demand for greater sustainability. The diverse applications of optimization span sectors such as manufacturing, logistics, energy, healthcare, and agriculture—each leveraging different methodologies tailored to their unique problem landscapes.

In the manufacturing industry, optimization is extensively employed to streamline production scheduling, manage inventory levels, and optimize facility layouts. Given the combinatorial nature of problems such as machine loading and resource allocation, some metaheuristic approaches are frequently used. These methods allow for efficient exploration of large solution spaces and are particularly valuable in environments that demand rapid, flexible, and adaptive decision-making to maintain competitive advantage.

Logistics and transportation systems, which form the backbone of global supply chains, are another critical domain where optimization has a profound impact. Vehicle Routing Problems (VRP), fleet management, and delivery scheduling are key areas where metaheuristics have proven highly used. These techniques enable dynamic route planning and real-time dispatching, helping to minimize transportation costs and improve service reliability—capabilities that are increasingly vital in today’s fast-paced, customer-centric markets.

In the realm of energy systems, where reliability and sustainability are paramount, optimization supports a range of activities including load forecasting, renewable energy allocation, and smart grid management. The nonlinear, stochastic nature of energy environments has driven the adoption of hybrid models that integrate metaheuristics with AI. These combinations enhance the adaptability of decision models, enabling them to operate efficiently under uncertainty and optimize the use of renewable resources in real time.

Within the healthcare sector, optimization serves not only to improve operational efficiency but also to address sensitive human-centered outcomes. It is used in applications such as surgery scheduling, emergency response allocation, and patient flow optimization. Given the ethical and service-quality requirements of healthcare, both exact and heuristic approaches are applied to ensure robust, reliable decision-making. Optimization in this field must balance precision with responsiveness, making it one of the most demanding yet impactful areas of application.

In agriculture, optimization plays an increasingly strategic role in addressing both productivity and sustainability goals. It is widely used for irrigation planning, crop scheduling, and supply chain coordination. As agricultural systems become more complex due to climate variability and resource constraints, hybrid optimization methods have gained prominence. These techniques help decision-makers navigate trade-offs between environmental concerns and economic performance, offering actionable insights for sustainable agricultural development. Among these sectors, the agricultural logistics domain has seen particularly notable progress in recent years, driven by the growing need for intelligent and sustainable food supply chains. Literature published between 2022 and 2025 illustrates the optimization techniques in some industrial applications, as summarized in Table 1.

Dong et al. [79] underscore the importance of joint inventory and transportation planning using Ant Colony Optimization (ACO). Their approach is especially relevant for handling perishable goods, where both storage and delivery times are critical. While ACO is effective in pathfinding, its application to large-scale logistics networks can be limited by scalability and convergence speed issues. Li [80] contributes to the dialogue on green logistics, applying Particle Swarm Optimization (PSO) to enhance sustainability outcomes. PSO demonstrates strong potential in optimizing logistics network layouts, though it may suffer from premature convergence in complex search spaces—a limitation that warrants further methodological refinement.

A more advanced hybrid framework is presented by Yu and Cheng [81], who integrate AHP-TOPSIS with Large Neighborhood Search and Simulated Annealing for cold chain route planning. This approach effectively balances structured multi-criteria decision-making with solution space exploration, though challenges remain in terms of scalability and subjectivity in criteria weighting. In a related contribution, Grytsiuk and Mysiv [82] apply Dynamic Programming (DP) in conjunction with routing algorithms to logistics scheduling problems. DP offers a methodical approach to handling sequential decisions, but its applicability in high-dimensional contexts is constrained by the well-known "curse of dimensionality”. The most cutting-edge development comes from Liu et al. [83], who utilize Deep Reinforcement Learning (DRL) integrated with Swarm Intelligence for site and route optimization in cold chain logistics. This AI-driven method enables adaptive, real-time learning and decision-making. However, its practical deployment may be hindered by high data and computational requirements, especially in resource-limited agricultural settings.

These studies collectively highlight a broadening methodological landscape and a shift toward intelligent, adaptive optimization techniques in industrial settings. While no single approach can be deemed universally superior, the choice of technique must be informed by the specific characteristics of the problem, the available data, and the operational objectives at hand. The ongoing integration of AI, the focus on sustainability, and the push for scalable, real-time solutions signal a dynamic future for optimization research and its real-world applications.

Table 1. Optimization Techniques in Some Industrial Applications

Year | Author | Industrial Sector | Optimization Method | Research Objective | Proposed Optimization Method |

2022 | [79] | Agriculture | Inventory and transportation coordination | To jointly optimize inventory and route planning in Agri-logistics | Ant Colony Optimization (ACO) |

2023 | [80] | Agriculture | Logistics network layout optimization | To improve green logistics performance using PSO | Particle Swarm Optimization (PSO) |

2023 | [81] | Agriculture | Cold chain distribution route planning | To evaluate vehicle options and optimize distribution paths for cost, quality, and environmental goals | AHP-TOPSIS, Large Neighborhood Search with SA |

2024 | [82] | Agriculture | Route optimization and logistics scheduling | Route optimization and logistics scheduling | Routing algorithms, Dynamic Programming |

2024 | [83] | Agriculture | Site and route selection in cold chain logistics | To optimize logistics efficiency while reducing emissions | Deep Reinforcement Learning with Swarm Intelligence |

2025 | [84] | Agriculture | Throughput rate prediction | To optimize throughput rate via predictive modeling | AI-integrated (CRISP-DM + Machine Learning + OR) |

2025 | [11] | Agriculture | Distribution of perishable goods under stochastic demand | To optimize availability and net profit in agri-food logistics | Metaheuristic (Modified Simulated Annealing) |

2024 | [85] | Energy system | Energy and logistics resource balancing | To jointly optimize logistics and energy operations in ports | Hybrid system modeling and collaborative optimization |

2024 | [86] | Energy system | EV charging station placement | To minimize power loss and improve voltage profile | Improved Bald Eagle Search (IBES) algorithm |

2022 | [87] | Healthcare | Cold chain delivery path optimization | To improve reliability and security in hospital logistics | Bee-Ant Optimization Algorithm (BAOA) |

2023 | [88] | Healthcare | Cold chain routing with time windows | To ensure timely delivery and minimize risks in medical logistics | VRPTW (Vehicle Routing with Time Windows), Minimax model |

2023 | [89] | Logistics and transportation | Travelling Salesman Problem (TSP) | To optimize initial solutions for TSP | Heuristic (Augmented Tour Construction) |

2024 | [90] | Logistics and transportation | System availability and routing | To evaluate and compare metaheuristics for CPS logistics performance | Grey Wolf Optimizer, Cat Swarm Optimization, Cuckoo Search |

2024 | [91] | Logistics and transportation | Freight rate forecasting | To optimize ocean freight pricing predictions | Machine Learning (ML) |

2024 | [92] | Logistics and transportation | EV routing optimization | To minimize operational cost including charging and penalties | Exact (Mixed Integer Linear Programming) |

2025 | [93] | Logistics and transportation | Carbon impact in logistics | To optimize logistics operations and reduce emissions using AI | AI-integrated optimization |

2025 | [94] | Logistics and transportation | Localization inefficiencies in IoT networks | To optimize localization accuracy and energy use | Hybrid (Metaheuristic + Machine Learning) |

2022 | [95] | Manufacturing industry | Time-series-based process optimization | To use RNNs to predict and optimize outcomes in production environments | Recursive Neural Networks (RNN) |

2023 | [96] | Manufacturing Industry | Order allocation and supplier selection | To optimize supplier selection and order planning | Hybrid (GA + TOPSIS) |

2023 | [97] | Manufacturing Industry | Unconstrained continuous optimization | To optimize continuous functions | Metaheuristic (Cholesterol Algorithm) |

2024 | [98] | Manufacturing industry | Sustainable production planning | To integrate human-centric AI and multi-objective optimization for sustainability | Genetic Algorithm, PSO, Reinforcement Learning |

2024 | [99] | Manufacturing Industry | Flexible job shop scheduling | To minimize makespan, energy, and CPU usage | Metaheuristic (Elitist Spotted Hyena Optimization) |

2024 | [100] | Manufacturing Industry | Welding parameter optimization | To optimize weld strength and predict bending properties | AI-integrated (Neural Networks - CFNM & FNNM) |

2024 | [101] | Manufacturing Industry | Fault diagnosis in bearings | To optimize diagnosis accuracy | AI-integrated (Clustering with K-Means) |

2024 | [102] | Manufacturing Industry | Assembly line balancing with HRC | To optimize assembly line design with setup time | Metaheuristic (Genetic Algorithm) |

2024 | [103] | Manufacturing Industry | Sales prediction | To optimize sales forecasting | AI-integrated (Neural Network) |

2024 | [104] | Manufacturing Industry | Dynamic product pricing | To optimize pricing strategy based on perception and service | Hybrid (Interval Type-2 Fuzzy Logic System) |

2025 | [105] | Manufacturing Industry | Downtime prediction and reduction | To optimize production efficiency through ML-driven maintenance | Machine learning (AI-integrated) |

2025 | [106] | Manufacturing Industry | Defect prediction and process quality | To optimize surface quality using Six Sigma & ML | Hybrid method (DOE + ML + Six Sigma) |

2025 | [107] | Manufacturing Industry | Inspection resource allocation | To optimize inspection cost without reducing quality | Exact (Linear Programming) |

2025 | [108] | Manufacturing Industry | Weighted Set Covering Problem (WSCP) | To optimize WSCP solution testing with new data sets | Exact (Integer Programming - Gurobi/CPLEX) |

EMERGING TRENDS AND RESEARCH GAPS

Recent advances in optimization techniques for industrial applications—particularly within the frameworks of Industry 4.0 and Industry 5.0—are increasingly aligned with the objectives of the United Nations Sustainable Development Goals (SDGs), particularly SDG 9 (Industry, Innovation and Infrastructure), SDG 12 (Responsible Consumption and Production), and SDG 13 (Climate Action). A critical review of recent literature reveals key trends and exposes persistent research gaps, both in methodologies and across specific industrial domains. Data-driven and AI-integrated optimization methods are increasingly used, especially in supply chains and manufacturing. Operations research (OR) modeling and reinforcement learning have been emphasized for their potential to enhance dynamic decision-making, yet scalability and practical deployment remain significant barriers [109][110]. In industrial manufacturing, exact algorithms and heuristic approaches are applied to tasks such as predictive maintenance and scheduling. However, gaps remain in hybridizing these techniques to improve adaptability and responsiveness to real-time constraints [111]. Across domains such as logistics, energy, healthcare, and agriculture, the adoption of optimization techniques continues to expand but faces domain-specific hurdles that mirror those observed in manufacturing.

In logistics and transportation, metaheuristic algorithms such as GA and PSO are widely employed for routing, fleet management, and last-mile delivery. Yet, integration with AI to handle uncertain or time-varying parameters is still underexplored, leading to inefficiencies in dynamic urban settings [94],[109]. In the energy systems sector, especially smart energy, optimization efforts have largely focused on asset performance management using data mining and hybrid AI-based forecasting models. However, there is a lack of robust frameworks that can effectively integrate historical process knowledge with real-time control, limiting scalability and reliability [110],[112].

In the healthcare sector, optimization is gaining traction in areas such as medical logistics, patient scheduling, and resource allocation. Despite the adoption of heuristic and metaheuristic approaches, challenges persist in ensuring explainability, reliability, and integration with electronic health records in real-time systems [113][114]. The agricultural sector faces distinct optimization challenges in areas like precision farming, resource scheduling, and supply chain coordination. Although hybrid AI models have been explored, limited progress has been made in applying scalable optimization frameworks that can adapt to regional constraints, climatic variability, and fragmented data sources [115].

Industry 5.0 introduces additional complexity by prioritizing human-centric, resilient, and sustainable optimization models. Technologies like federated learning, collaborative robotics, and autonomous systems have potential to revolutionize optimization strategies but currently suffer from fragmented research and insufficient implementation guidelines [113]. Moreover, cybersecurity considerations remain an overlooked yet critical element in optimization design, particularly as industries become more digitally interconnected [116]. In conclusion, while there is robust development in optimization methods such as exact, heuristic, metaheuristic, and AI-integrated techniques across industrial domains, persistent gaps in adaptability, integration, standardization, and domain-specific applicability present vital opportunities for future research.

CONCLUSION

This comprehensive review has illustrated the evolving landscape of optimization techniques as applied across various industrial domains. By categorizing methods into exact, heuristic, metaheuristic, and hybrid/AI-integrated approaches, the study provides a foundational understanding of how different strategies align with the structural and operational needs of manufacturing, logistics, energy systems, healthcare, and agriculture. It is evident that no single method is universally optimal; instead, the suitability of a technique depends on problem complexity, data availability, and specific industrial constraints. Recent studies demonstrate a strong trend toward hybrid and AI-driven approaches, which enhance the adaptability, convergence speed, and robustness of traditional models. These methods are increasingly deployed in smart environments that require real-time responses and sustainable decision-making, aligning well with the objectives of Industry 4.0, Industry 5.0, and the SDGs. Despite this progress, notable research gaps remain in areas such as scalability, integration with real-time systems, explain ability, and cybersecurity. Moreover, the potential of emerging technologies—like federated learning, collaborative robotics, and intelligent edge computing—remains underexplored in optimization contexts. In conclusion, while substantial advancements have been made, the continued refinement of optimization techniques, particularly in the context of hybrid and intelligent systems, will be essential to addressing the growing complexity and sustainability demands of modern industry. Future research should focus on bridging methodological gaps, enhancing cross-disciplinary integration, and developing resilient, transparent, and ethically responsible optimization frameworks. Collaboration between operations research, computer science, industrial engineering, data science, and domain-specific fields—such as healthcare, energy, and agriculture—is crucial. Operations research and industrial engineering offer structured decision models, computer science contributes algorithmic scalability and AI integration, data science ensures robust data handling and analytics, while domain experts provide contextual insights essential for developing solutions that are both practical and impactful.

DECLARATION

Author Contribution

All authors contributed equally to the main contributor to this paper. All authors read and approved the final paper.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

REFERENCES

- A. Bousdekis, K. Lepenioti, D. Apostolou, and G. Mentzas, “A Review of Data-Driven Decision-Making Methods for Industry 4.0 Maintenance Applications,” Electronics (Basel), vol. 10, no. 828, pp. 1–20, 2021, https://doi.org/10.3390/electronics.

- C. Zhang and Z. Wang, “Data-driven distributionally robust optimization under combined ambiguity for cracking production scheduling,” Comput Chem Eng, vol. 181, p. 108538, Feb. 2024, https://doi.org/10.1016/j.compchemeng.2023.108538.

- F. S. Rohman et al., “Application of multi-objective neural network algorithm in industrial polymerization reactors for reducing energy cost and maximising productivity,” Digital Chemical Engineering, vol. 13, 2024, https://doi.org/10.1016/j.dche.2024.100181.

- D. Darvishi, S. Liu, and J. Yi-Lin Forrest, “Grey linear programming: a survey on solving approaches and applications,” Grey Systems: Theory and Application, vol. 11, no. 1, pp. 110–135, 2020, https://doi.org/10.1108/GS-04-2020-0043.

- A. C. Leuveano, P. H. Kasih, M. I. Ridho, A. R. K. Lisan, A. A. Muhamed, and M. Z. Rafique, “Sustainable waste solutions: Optimizing location-allocation of 3R waste management sites in Gondokusuman, Yogyakarta, Indonesia through multi-maximal covering location approach,” International Journal of Industrial Optimization, pp. 1–15, 2024, https://doi.org/10.12928/ijio.v5i1.9251.

- K. Rajwar and K. Deep, “Structural bias in metaheuristic algorithms: Insights, open problems, and future prospects,” Swarm Evol Comput, vol. 92, p. 101812, 2025, https://doi.org/10.1016/j.swevo.2024.101812.

- H. Wang, B. Chen, H. Sun, A. Li, and C. Zhou, “AnFiS-MoH: Systematic exploration of hybrid ANFIS frameworks via metaheuristic optimization hybridization with evolutionary and swarm-based algorithms,” Appl Soft Comput, vol. 167, p. 112334, 2024, https://doi.org/10.1016/j.asoc.2024.112334.

- F. Cao, M. Han, H. Shi, M. Li, and Z. Liu, “Comparative study on metaheuristic algorithms for optimising wave energy converters,” Ocean Engineering, vol. 247, p. 110461, 2022, https://doi.org/10.1016/j.oceaneng.2021.110461.

- P. Burggräf, F. Steinberg, T. Weißer, and O. Radisic-Aberger, “Deciding on when to change – a benchmark of metaheuristic algorithms for timing engineering changes,” Int J Prod Res, vol. 62, no. 9, pp. 3230–3250, 2024, https://doi.org/10.1080/00207543.2023.2226778.

- T. Cura, “A rapidly converging artificial bee colony algorithm for portfolio optimization,” Knowl Based Syst, vol. 233, p. 107505, 2021, https://doi.org/10.1016/j.knosys.2021.107505.

- T. B. Dagne, “Agri-food distribution optimization using modified simulated annealing algorithm considering stochastic market demand,” IJIO, vol. 6, no. 1, pp. 1–16, 2025, https://doi.org/10.12928/ijio.v6i1.9406.

- F. A. Alenizi, S. Abbasi, A. Hussein Mohammed, and A. Masoud Rahmani, “The artificial intelligence technologies in Industry 4.0: A taxonomy, approaches, and future directions,” Comput Ind Eng, vol. 185, p. 109662, 2023, https://doi.org/10.1016/j.cie.2023.109662.

- C. He et al., “A Review on Artificial Intelligence Enabled Design, Synthesis, and Process Optimization of Chemical Products for Industry 4.0,” Processes, vol. 11, no. 2, p. 330, 2023, https://doi.org/10.3390/pr11020330.

- A. Matin, M. R. Islam, X. Wang, H. Huo, and G. Xu, “AIoT for sustainable manufacturing: Overview, challenges, and opportunities,” Internet of Things, vol. 24, p. 100901, 2023, https://doi.org/10.1016/j.iot.2023.100901.

- F. Walas Mateo and A. Redchuk, “IIoT/IoT and Artificial Intelligence/Machine Learning as a Process Optimization Driver under Industry 4.0 Model,” Journal of Computer Science & Technology, vol. 21 2021, https://doi.org/10.24215/16666038.21.e15.

- M. I. Khan et al., “Integrating industry 4.0 for enhanced sustainability: Pathways and prospects,” Sustainable Production and Consumption, vol. 54, pp. 149-189, 2025, https://doi.org/10.1016/j.spc.2024.12.012.

- M. Javaid, A. Haleem, R. P. Singh, R. Suman, and E. S. Gonzalez, “Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability,” Sustainable Operations and Computers, vol. 3, pp. 203–217, 2022, https://doi.org/10.1016/j.susoc.2022.01.008.

- M. S. Uzer, “New Hybrid Approaches Based on Swarm-Based Metaheuristic Algorithms and Applications to Optimization Problems,” Applied Sciences, vol. 15, no. 3, p. 1355, 2025, https://doi.org/10.3390/app15031355.

- S. W. Rulita, Gunawan, and M. D. A. Fakhri, “Optimization of Nesting Systems in Shipbuilding: A Review,” Journal of Marine Science and Application, vol. 24, no. 1, pp. 152–175, 2025, https://doi.org/10.1007/s11804-025-00644-1.

- P. G. Saghand and H. Charkhgard, “Exact solution approaches for integer linear generalized maximum multiplicative programs through the lens of multi-objective optimization,” Comput Oper Res, vol. 137, p. 105549, 2022, https://doi.org/10.1016/j.cor.2021.105549.

- C. C. Rodríguez, A. A. Romero Quete, G. O. Suvire, and S. R. Rivera, “Optimization of multi-period investment planning in street lighting systems by mixed-integer linear programming,” International Journal for Simulation and Multidisciplinary Design Optimization, vol. 14, p. 14, 2023, https://doi.org/10.1051/smdo/2023017.

- M. Rabe, Y. Bilan, K. Widera, and L. Vasa, “Application of the Linear Programming Method in the Construction of a Mathematical Model of Optimization Distributed Energy,” Energies (Basel), vol. 15, no. 5, 2022, https://doi.org/10.3390/en15051872.

- A. Alotaibi and F. Nadeem, “A Review of Applications of Linear Programming to Optimize Agricultural Solutions,” International Journal of Information Engineering and Electronic Business, vol. 13, no. 2, pp. 11–21, 2021, https://doi.org/10.5815/ijieeb.2021.02.02.

- I. Pappas et al., “Multiobjective Optimization of Mixed-Integer Linear Programming Problems: A Multiparametric Optimization Approach,” Ind Eng Chem Res, vol. 60, no. 23, pp. 8493–8503, 2021, https://doi.org/10.1021/acs.iecr.1c01175.

- S. Raja, B. Arguello, and B. J. Pierre, “Dynamic Programming Method to Optimally Select Power Distribution System Reliability Upgrades,” IEEE Open Access Journal of Power and Energy, vol. 8, pp. 118–127, 2021, https://doi.org/10.1109/OAJPE.2021.3062330.

- A. Grimaldi, F. D. Minuto, J. Brouwer, and A. Lanzini, “Profitability of energy arbitrage net profit for grid-scale battery energy storage considering dynamic efficiency and degradation using a linear, mixed-integer linear, and mixed-integer non-linear optimization approach,” J Energy Storage, vol. 95, 2024, https://doi.org/10.1016/j.est.2024.112380.

- P. Balaguer-Herrero, J. C. Alfonso-Gil, C. I. Martinez-Marquez, G. Martinez-Navarro, S. Orts-Grau, and S. Segui-Chilet, “Two-Scale Model Predictive Control for Resource Optimization Problems With Switched Decisions,” IEEE Access, vol. 10, pp. 57824–57834, 2022, https://doi.org/10.1109/ACCESS.2022.3178846.

- F. Superchi, N. Giovannini, A. Moustakis, G. Pechlivanoglou, and A. Bianchini, “Optimization of the power output scheduling of a renewables-based hybrid power station using MILP approach: The case of Tilos island,” Renew Energy, vol. 220, 2024, https://doi.org/10.1016/j.renene.2023.119685.

- Y. Xiao, Y. Zhang, S. Kulturel-Konak, A. Konak, Y. Xu, and S. Zhou, “The aperiodic facility layout problem with time-varying demands and an optimal master-slave solution approach,” Int J Prod Res, vol. 59, no. 17, pp. 5216–5235, 2021, https://doi.org/10.1080/00207543.2020.1775909.

- P. Marocco, D. Ferrero, E. Martelli, M. Santarelli, and A. Lanzini, “An MILP approach for the optimal design of renewable battery-hydrogen energy systems for off-grid insular communities,” Energy Convers Manag, vol. 245, 2021, https://doi.org/10.1016/j.enconman.2021.114564.

- Z. Liu and O. Stursberg, “Efficient solution of distributed Milp in control of networked systems,” in IFAC-PapersOnLine, pp. 6723–6729, 2020, https://doi.org/10.1016/j.ifacol.2020.12.102.

- R. Rikkas and R. Lahdelma, “Energy supply and storage optimization for mixed-type buildings,” Energy, vol. 231, 2021, https://doi.org/10.1016/j.energy.2021.120839.

- A. V. Panteleev and A. A. Kolessa, “Optimal Open-Loop Control of Discrete Deterministic Systems by Application of the Perch School Metaheuristic Optimization Algorithm,” Algorithms, vol. 15, no. 5, 2022, https://doi.org/10.3390/a15050157.

- Y. Lee and K. Lee, “New integer optimization models and an approximate dynamic programming algorithm for the lot-sizing and scheduling problem with sequence-dependent setups,” Eur J Oper Res, vol. 302, no. 1, pp. 230–243, 2022, https://doi.org/10.1016/j.ejor.2021.12.032.

- P.-S. Chen and Z.-Y. Zeng, “Developing two heuristic algorithms with metaheuristic algorithms to improve solutions of optimization problems with soft and hard constraints: An application to nurse rostering problems,” Appl Soft Comput, vol. 93, p. 106336, 2020, https://doi.org/10.1016/j.asoc.2020.106336.

- G. A. Rolim, M. S. Nagano, and B. de A. Prata, “Effective Heuristics and an Iterated Greedy Algorithm to Schedule Identical Parallel Machines Subject to Common Restrictive Due Windows,” Arab J Sci Eng, vol. 47, no. 3, pp. 3899–3913, 2022, https://doi.org/10.1007/s13369-021-06244-9.

- T. Zhang, Q. Zeng, and X. Zhao, “Optimal local dimming based on an improved greedy algorithm,” Applied Intelligence, vol. 50, no. 12, pp. 4162–4175, 2020, https://doi.org/10.1007/s10489-020-01769-2.

- J. A. P. Golak, C. Defryn, and A. Grigoriev, “Optimizing fuel consumption on inland waterway networks: Local search heuristic for lock scheduling,” Omega (United Kingdom), vol. 109, 2022, https://doi.org/10.1016/j.omega.2021.102580.

- M. S. M. Pakpahan, L. E. Nugroho, and Widyawan, “Comparative analysis of rule-based heuristic algorithms for microservice chain placement in fog computing,” Results in Engineering, vol. 25, 2025, https://doi.org/10.1016/j.rineng.2025.104299.

- T. Zhang, Q. Zeng, and X. Zhao, “Optimal local dimming based on an improved greedy algorithm,” Applied Intelligence, vol. 50, no. 12, pp. 4162–4175, 2020, https://doi.org/10.1007/s10489-020-01769-2.

- S. Aqil and K. Allali, “Local search metaheuristic for solving hybrid flow shop problem in slabs and beams manufacturing,” Expert Syst Appl, vol. 162, p. 113716, 2020, https://doi.org/10.1016/j.eswa.2020.113716.

- X.-L. Jing, Q.-K. Pan, and L. Gao, “Local search-based metaheuristics for the robust distributed permutation flowshop problem,” Appl Soft Comput, vol. 105, p. 107247, 2021, https://doi.org/10.1016/j.asoc.2021.107247.

- M. M. Ferdaus, F. Zaman, and R. K. Chakrabortty, “Performance Improvement of a Parsimonious Learning Machine Using Metaheuristic Approaches,” IEEE Trans Cybern, vol. 52, no. 8, pp. 7277–7290, 2022, https://doi.org/10.1109/TCYB.2021.3051242.

- S. Aqil, “Effective Population-Based Meta-heuristics with NEH and GRASP Heuristics Minimizing Total Weighted flow Time in No-Wait Flow Shop Scheduling Problem Under Sequence-Dependent Setup Time Constraint,” Arab J Sci Eng, vol. 49, no. 9, pp. 12235–12258, 2024, https://doi.org/10.1007/s13369-023-08642-7.

- B. Toaza and D. Esztergár-Kiss, “A review of metaheuristic algorithms for solving TSP-based scheduling optimization problems,” Appl Soft Comput, vol. 148, 2023, https://doi.org/10.1016/j.asoc.2023.110908.

- S. U. Seçkiner and Ş. Yilkici Yüzügüldü, “A new health-based metaheuristic algorithm: cholesterol algorithm,” International Journal of Industrial Optimization, vol. 4, no. 2, pp. 115–130, 2023, https://doi.org/10.12928/ijio.v4i2.7651.

- S. Kim, A. C. Hooker, Y. Shi, G. H. J. Kim, and W. K. Wong, “Metaheuristics for pharmacometrics,” CPT Pharmacometrics Syst Pharmacol, vol. 10, no. 11, pp. 1297–1309, 2021, https://doi.org/10.1002/psp4.12714.

- A. Hamdan, S. San Nah, G. Say Leng, C. Kang Leng, and T. Wei King, “Recent Evolutionary Algorithm Variants for Combinatorial Optimization Problem,” Applications of Modelling and Simulation, vol. 7, pp. 214–238, 2023, https://arqiipubl.com/ojs/index.php/AMS_Journal/article/view/515.

- H. M. Asih, K. E. Chong, and M. Faishal, “Capacity planning and product allocations under testing time uncertainty in electronic industry,” Journal of Advanced Manufacturing Technology, vol. 12, no. 1, pp. 103–115, 2018, https://jamt.utem.edu.my/jamt/article/view/2106.

- Z. N. Ansari and S. D. Daxini, “A State-of-the-Art Review on Meta-heuristics Application in Remanufacturing,” Archives of Computational Methods in Engineering, vol. 29, no. 1, pp. 427–470, 2022, https://doi.org/10.1007/s11831-021-09580-z.

- A. Rahman and H. M. Asih, “Optimizing shipping routes to minimize cost using particle swarm optimization,” International Journal of Industrial Optimization, vol. 1, no. 1, p. 53, 2020, https://doi.org/10.12928/ijio.v1i1.1605.

- S. Alam, X. Zhao, I. K. Niazi, M. S. Ayub, and M. A. Khan, “A comparative analysis of global optimization algorithms for surface electromyographic signal onset detection,” Decision Analytics Journal, vol. 8, 2023, https://doi.org/10.1016/j.dajour.2023.100294.

- P. Burggräf, F. Steinberg, T. Weißer, and O. Radisic-Aberger, “Deciding on when to change – a benchmark of metaheuristic algorithms for timing engineering changes,” Int J Prod Res, vol. 62, no. 9, pp. 3230–3250, 2024, https://doi.org/10.1080/00207543.2023.2226778.

- T. Cura, “A rapidly converging artificial bee colony algorithm for portfolio optimization,” Knowl Based Syst, vol. 233, p. 107505, 2021, https://doi.org/10.1016/j.knosys.2021.107505.

- M. Abid, S. El Kafhali, A. Amzil, and M. Hanini, “Optimization of UAV Flight Paths in Multi-UAV Networks for Efficient Data Collection,” Arab J Sci Eng, vol. 50, no. 10, pp. 7207-7232, 2024, https://doi.org/10.1007/s13369-024-09369-9.

- D. Maharana, R. Kommadath, and P. Kotecha, “An innovative approach to the supply-chain network optimization of biorefineries using metaheuristic techniques,” Engineering Optimization, vol. 55, no. 8, pp. 1278–1295, 2023, https://doi.org/10.1080/0305215X.2022.2080204.

- X. Jin, “Application of Metaheuristic algorithm in intelligent logistics scheduling and environmental sustainability,” Intelligent Decision Technologies, vol. 18, no. 3, pp. 1727–1740, 2024, https://doi.org/10.3233/IDT-240280.

- K. E. Chong, H. M. Asih, “An Integrated Robust Optimization Model of Capacity Planning under Demand Uncertainty in Electronic Industry,” International Journal of Mechanical & Mechatronics Engineering, vol. 15, no. 03, pp. 88–96, 2015, https://www.researchgate.net/publication/280063875_An_Integrated_Robust_Optimization_Model_of_Capacity_Planning_under_Demand_Uncertainty_in_Electronic_Industry.

- [59] H. M. Asih, R. A. C. Leuveano, A. Rahman, and M. Faishal, “Traveling Salesman Problem With Prioritization for Perishable Products in Yogyakarta, Indonesia,” Journal of Advanced Manufacturing Technology, vol. 16, no. 3, pp. 15–27, 2022, https://jamt.utem.edu.my/jamt/article/view/6405.

- H. M. Asih, R. A. C. Leuveano, and D. A. Dharmawan, “Optimizing lot sizing model for perishable bread products using genetic algorithm,” Jurnal Sistem dan Manajemen Industri, vol. 7, no. 2, pp. 139–154, 2023, https://doi.org/10.30656/jsmi.v7i2.7172.

- R. A. C. Leuveano, H. M. Asih, M. I. Ridho, and D. A. Darmawan, “Balancing Inventory Management : Genetic Algorithm Optimization for A Novel Dynamic Lot Sizing Model in Perishable Product Manufacturing,” Journal of Robotics and Control (JRC), vol. 4, no. 6, pp. 878–895, 2023, https://doi.org/10.18196/jrc.v4i6.20667.

- H. M. Asih, R. Achmad, C. Leuveano, D. A. Dharmawan, A. Ardiansyah, and A. Dahlan, “Genetic algorithm to optimize green vehicle routing and allocation planning for perishable products,” International Journal of Advances in Intelligent Informatics, vol. 11, no. 2, pp. 175–191, 2025, https://doi.org/10.26555/ijain.v11i2.1784.

- A. Seyyedabbasi, R. Aliyev, F. Kiani, M. U. Gulle, H. Basyildiz, and M. A. Shah, “Hybrid algorithms based on combining reinforcement learning and metaheuristic methods to solve global optimization problems,” Knowl Based Syst, vol. 223, p. 107044, 2021, https://doi.org/10.1016/j.knosys.2021.107044.

- F. Keivanian and R. Chiong, “A novel hybrid fuzzy–metaheuristic approach for multimodal single and multi-objective optimization problems,” Expert Syst Appl, vol. 195, p. 116199, 2022, https://doi.org/10.1016/j.eswa.2021.116199.

- H. Wang, B. Chen, H. Sun, A. Li, and C. Zhou, “AnFiS-MoH: Systematic exploration of hybrid ANFIS frameworks via metaheuristic optimization hybridization with evolutionary and swarm-based algorithms,” Appl Soft Comput, vol. 167, p. 112334, 2024, https://doi.org/10.1016/j.asoc.2024.112334.

- P. Mehrabi, S. Honarbari, S. Rafiei, S. Jahandari, and M. Alizadeh Bidgoli, “Seismic response prediction of FRC rectangular columns using intelligent fuzzy-based hybrid metaheuristic techniques,” J Ambient Intell Humaniz Comput, vol. 12, no. 11, pp. 10105–10123, 2021, https://doi.org/10.1007/s12652-020-02776-4.

- A. Mazouzi, N. Hadroug, W. Alayed, A. Hafaifa, A. Iratni, and A. Kouzou, “Comprehensive optimization of fuzzy logic-based energy management system for fuel-cell hybrid electric vehicle using genetic algorithm,” Int J Hydrogen Energy, vol. 81, pp. 889–905, 2024, https://doi.org/10.1016/j.ijhydene.2024.07.237.

- K. Zhou, S.-K. Oh, J. Qiu, W. Pedrycz, and K. Seo, “Reinforced Two-Stream Fuzzy Neural Networks Architecture Realized With the Aid of One-Dimensional/Two-Dimensional Data Features,” IEEE Transactions on Fuzzy Systems, vol. 31, no. 3, pp. 707–721, 2023, https://doi.org/10.1109/TFUZZ.2022.3186181.

- H. Han, H. Liu, and J. Qiao, “Data-Knowledge-Driven Self-Organizing Fuzzy Neural Network,” IEEE Trans Neural Netw Learn Syst, vol. 35, no. 2, pp. 2081–2093, 2024, https://doi.org/10.1109/TNNLS.2022.3186671.

- J. Tavoosi, A. Mohammadzadeh, and K. Jermsittiparsert, “A review on type-2 fuzzy neural networks for system identification,” Soft comput, vol. 25, no. 10, pp. 7197–7212, 2021, https://doi.org/10.1007/s00500-021-05686-5.

- A. M. E. Ramirez-Mendoza, W. Yu, and X. Li, “A Novel Fuzzy System With Adaptive Neurons for Earthquake Modeling,” IEEE Access, vol. 8, pp. 101369–101376, 2020, https://doi.org/10.1109/ACCESS.2020.2998446.

- D. Lee, S. J. Lee, and S. C. Yim, “Reinforcement learning-based adaptive PID controller for DPS,” Ocean Engineering, vol. 216, p. 108053, 2020, https://doi.org/10.1016/j.oceaneng.2020.108053.

- N. T.-T. Vu, H. D. Nguyen, and A. T. Nguyen, “Reinforcement Learning-Based Adaptive Optimal Fuzzy MPPT Control for Variable Speed Wind Turbine,” IEEE Access, vol. 10, pp. 95771–95780, 2022, https://doi.org/10.1109/ACCESS.2022.3205124.

- J. Barraza, L. Rodríguez, O. Castillo, P. Melin, and F. Valdez, “An Enhanced Fuzzy Hybrid of Fireworks and Grey Wolf Metaheuristic Algorithms,” Axioms, vol. 13, no. 7, p. 424, 2024, https://doi.org/10.3390/axioms13070424.

- L. Ou, Y.-C. Chang, Y.-K. Wang, and C.-T. Lin, “Fuzzy Centered Explainable Network for Reinforcement Learning,” IEEE Transactions on Fuzzy Systems, vol. 32, no. 1, pp. 203–213, 2024, https://doi.org/10.1109/TFUZZ.2023.3295055.

- N. Guo, C. Li, T. Gao, G. Liu, Y. Li, and D. Wang, “A Fusion Method of Local Path Planning for Mobile Robots Based on LSTM Neural Network and Reinforcement Learning,” Math Probl Eng, vol. 2021, pp. 1–21, 2021, https://doi.org/10.1155/2021/5524232.

- H. M. Asih, A. Sutrisno, C. E. A. Wuisang, and M. Faishal, “Sustainability decision-making in poultry slaughterhouses: A comparative analysis of AHP and fuzzy AHP,” MethodsX, vol. 14, no. November, 2025, https://doi.org/10.1016/j.mex.2025.103193.

- A. Bajwa, F. Jahan, I. Ahmed, and N. A. Siddiqui, “A Systematic Literature Review on AI-Enabled Smart Building Management Systems for Energy Efficiency and Sustainability,” American Journal of Scholarly Research and Innovation, vol. 03, no. 02, pp. 01–27, 2025, https://doi.org/10.63125/4sjfn272.

- B. Dong, M. Duan, and Y. Li, “Exploration of Joint Optimization and Visualization of Inventory Transportation in Agricultural Logistics Based on Ant Colony Algorithm,” Comput Intell Neurosci, vol. 2022, 2022, https://doi.org/10.1155/2022/2041592.

- H. Li, “Model and Simulation of Green Logistics for Agricultural Products Based on Particle Swarm Optimization,” in 2023 IEEE 5th Eurasia Conference on IOT, Communication and Engineering (ECICE), pp. 631–634, 2023, https://doi.org/10.1109/ECICE59523.2023.10383148.

- J. Yu and L. Cheng, “Vehicle Path Optimization of Agricultural Products Cold Chain Logistics Based on Green Evaluation,” INMATEH - Agricultural Engineering, vol. 70, no. 2, pp. 441–454, 2023, https://doi.org/10.35633/inmateh-70-43.

- M. Grytsiuk and V. Mysiv, “Optimization of Logistics and Sales of Products in Agricultural Enterprises Under the Conditions of Cooperation,” Market Infrastructure, no. 76, 2024, https://doi.org/10.32782/infrastruct76-1.

- H. Liu, J. Zhang, Z. Zhou, Y. Dai, and L. Qin, “A Deep Reinforcement Learning-Based Algorithm for Multi-Objective Agricultural Site Selection and Logistics Optimization Problem,” Applied Sciences (Switzerland), vol. 14, no. 18, 2024, https://doi.org/10.3390/app14188479.

- R. I. Lestari, L. Andrawina, and I. Mufidah, “Optimization of throughput rate prediction in animal feed industry using crisp-dm and operational research approaches,” IJIO, vol. 6, no. 1, pp. 87–102, 2025, https://doi.org/10.12928/ijio.v6i1.11357.

- A. Mo, Y. Zhang, Y. Xiong, F. Ma, and L. Sun, “Energy–Logistics Cooperative Optimization for a Port-Integrated Energy System,” Mathematics, vol. 12, no. 12, 2024, https://doi.org/10.3390/math12121917.

- F. Ahmad, A. Iqbal, I. Ashraf, M. Marzband, and I. Khan, “The Optimal Placement of Electric Vehicle Fast Charging Stations in the Electrical Distribution System with Randomly Placed Solar Power Distributed Generations,” Distributed Generation and Alternative Energy Journal, vol. 37, no. 4, pp. 1277–1304, 2022, https://doi.org/10.13052/dgaej2156-3306.37416.

- G. Vijaiprabhu, P. Pandia Rajammal, S. Rema Devi, and P. Karthika, “Secured Optimal Path to Identify the Networking Model using Cold Chain Logistics in Hospital Environment,” in IOP Conference Series: Earth and Environmental Science, vol. 1057, no. 1, p. 012005, 2022, https://doi.org/10.1088/1755-1315/1057/1/012005.

- K. Ransikarbum, C. Chaiyaphan, M. Sainakham, and A. Apichottanakul, “Model and Analysis of Delivery Route in the Healthcare Cold Chain Network using Minimax Vehicle Routing Problem with Time Window (VRPTW),” in 2023 5th International Conference on Management Science and Industrial Engineering, pp. 333–341, 2023, https://doi.org/10.1145/3603955.3603977.

- Z. Ursani and A. A. Ursani, “Augmented tour construction heuristics for the travelling salesman problem,” International Journal of Industrial Optimization, vol. 4, no. 2, pp. 131–144, 2023, https://doi.org/10.12928/ijio.v4i2.7875.

- M. Saini, V. S. Maan, A. Kumar, and D. K. Saini, “Metaheuristic algorithms and their applications in performance optimization of cyber-physical systems having applications in logistics,” International Journal of System Assurance Engineering and Management, vol. 15, no. 6, pp. 2202–2217, 2024, https://doi.org/10.1007/s13198-023-02236-0.

- J. Almaazmi, M. Alzaabi, and D. K. Naidu, “Development of Novel Predicting System to Forecast Ocean Spot and Forward Prices Using Machine Learning,” in ADIPEC, p. D031S101R005, 2024. https://doi.org/10.2118/222874-MS.

- Y. Astri, A. Kinanti, T. Bakhtiar, and F. Hanum, “A Heterogeneous Fleet Electric Vehicle Routing Model with Soft Time Windows,” International Journal of Industrial Optimization, vol. 5, no. 2, pp. 93–105, 2024, https://doi.org/10.12928/ijio.v5i2.9014.

- H. M. Al-Jawahry, J. Sravanthi, J. Seetaram, S. S. J, K. S, and M. Ramya, “AI Integration in FI and VSC Technologies,” in 2025 International Conference on Intelligent Control, Computing and Communications (IC3), pp. 1121–1127, 2025, https://doi.org/10.1109/IC363308.2025.10957349.

- F. Abbes, M. Sami, and T. Val, “Localization for transportation and urban planning in smart cities: interest, challenges, and solutions,” vol. 6, no. 1, pp. 28–46, 2025, https://doi.org/10.12928/ijio.v6i1.11027.

- I. S. Lazukhin, M. I. Petrovskii, and I. V. Mashechkin, “Investigation and Development of Recursive Neural Networks for the Analysis of Industrial Processes,” Computational Mathematics and Modeling, vol. 33, no. 1, pp. 53–71, 2022, https://doi.org/10.1007/s10598-022-09556-z.

- N. Harale, S. Thomassey, and X. Zeng, “Dynamic small-series fashion order allocation and supplier selection: a ga-topsis-based model,” International Journal of Industrial Optimization, vol. 4, no. 2, pp. 82–102, 2023, https://doi.org/10.12928/ijio.v4i2.7640.

- S. U. Seçkiner and Ş. Yilkici Yüzügüldü, “A new health-based metaheuristic algorithm: cholesterol algorithm,” International Journal of Industrial Optimization, vol. 4, no. 2, pp. 115–130, 2023, https://doi.org/10.12928/ijio.v4i2.7651.

- S. C. Chen, H. M. Chen, H. K. Chen, and C. L. Li, “Multi-Objective Optimization in Industry 5.0: Human-Centric AI Integration for Sustainable and Intelligent Manufacturing,” Processes, vol. 12, no. 12, 2024, https://doi.org/10.3390/pr12122723.

- A. N. Senthilvel, T. Hemamalini, and G. Geetha, “Multi-objective elitist spotted hyena resource optimized flexible job shop scheduling,” International Journal of Industrial Optimization, pp. 81–92, 2024, https://doi.org/10.12928/ijio.v5i1.8743.

- D. K. Chaturvedi and A. Suri, “Modeling and simulation of friction stir welding process: A neural approach,” International Journal of Industrial Optimization, pp. 60–80, 2024, https://doi.org/10.12928/ijio.v5i1.9010.

- Y. Xia, X. Guo, E. Su, and L. Kong, “Research on bearing fault diagnosis technology based on machine learning,” International Journal of Industrial Optimization, pp. 45–59, 2024, https://doi.org/10.12928/ijio.v5i1.8106.

- A. Ma’ruf and D. Budhiarti, “Development of genetic algorithm for human-robot collaboration assembly line design,” International Journal of Industrial Optimization, vol. 5, no. 2, pp. 118–133, 2024, https://doi.org/10.12928/ijio.v5i2.10027.

- M. M. Yuniar and R. Ambarwati, “Prediction analysis of retail store sales level using neural network algorithm method based on customer segments,” International Journal of Industrial Optimization, pp. 177–188, 2025, https://doi.org/10.12928/ijio.v5i2.9889.

- M. R. A. Purnomo and I. S. Saputro, “Product pricing based on customer perception quality and service convenience using interval type-2 fuzzy logic system,” International Journal of Industrial Optimization, pp. 161–176, 2025, https://doi.org/10.12928/ijio.v5i2.10825.

- S. Phongmoo, C. Suedumrong, C. Kuensaen, R. Sinthavalai, and K. Leksakul, “Predictive maintenance in semiconductor manufacturing: Comparative analysis of machine learning models for downtime reduction,” Comput Ind Eng, vol. 205, p. 111211, 2025, https://doi.org/10.1016/j.cie.2025.111211.

- H. Mansour, H. Abohashima, H. Elkhouly, and N. Harraz, “Smart quality control: integrating six sigma, machine learning and real-time defect prediction in manufacturing,” International Journal of Lean Six Sigma, 2025, https://doi.org/10.1108/IJLSS-07-2024-0150.

- S. Ahmad and M. Kamruzzaman, “Inspection cost minimization by optimizing the number of inspectors in apparel manufacturing,” IJIO, vol. 6, no. 1, pp. 71–86, 2025, https://doi.org/10.12928/ijio.v6i1.9279.

- F. J. Vasko, Y. Lu, M. S. Song, and D. Rando, “Filling the gap in weighted set covering problem test instances: implications for both researchers and practitioners,” International Journal of Industrial Optimization, vol. 6, no. 1, pp. 17–27, 2025, https://doi.org/10.12928/ijio.v6i1.10836.

- Z. Xu, A. Elomri, R. Baldacci, L. Kerbache, and Z. Wu, “Frontiers and trends of supply chain optimization in the age of industry 4.0: an operations research perspective,” Ann Oper Res, vol. 338, no. 2–3, pp. 1359–1401, 2024, https://doi.org/10.1007/s10479-024-05879-9.

- H. Liu and G. Zhang, “Enhancing Efficiency and Energy Optimization: Data-Driven Solutions in Process Industrial Manufacturing,” EAI Endorsed Transactions on Energy Web, vol. 11, pp. 1–11, 2024, https://doi.org/10.4108/ew.6098.

- A. Manta-Costa, S. O. Araújo, R. S. Peres, and J. Barata, “Machine Learning Applications in Manufacturing—Challenges, Trends, and Future Directions,” IEEE Open Journal of the Industrial Electronics Society, vol. 5, pp. 1085–1103, 2024, https://doi.org/10.1109/OJIES.2024.3431240.

- N. T. Viet and A. G. Kravets, “The New Method for Analyzing Technology Trends of Smart Energy Asset Performance Management,” Energies (Basel), vol. 15, no. 18, 2022, https://doi.org/10.3390/en15186613.

- A. Zia and M. Haleem, “Bridging Research Gaps in Industry 5.0: Synergizing Federated Learning, Collaborative Robotics, and Autonomous Systems for Enhanced Operational Efficiency and Sustainability,” IEEE Access, vol. 13, pp. 40456–40479, 2025, https://doi.org/10.1109/ACCESS.2025.3541822.

- D. Tripathi and S. Wairya, “A Cost Efficient QCA Code Converters for Nano Communication Applications,” International Journal of Computing and Digital Systems, vol. 12, no. 1, pp. 345–352, 2022, https://doi.org/10.12785/ijcds/120128.

- R. Kwasi Bannor and K. Kofi Arthur, “A systematic review and bibliometric analysis on agribusiness gaps in emerging markets,” Research in Globalization, vol. 8, p. 100214, 2024, https://doi.org/10.1016/j.resglo.2024.100214.

- R. Kour, R. Karim, P. Dersin, and N. Venkatesh, “Cybersecurity for Industry 5.0: trends and gaps,” Frontiers in Computer Science, vol. 6, p. 1434436, 2024, https://doi.org/10.3389/fcomp.2024.1434436.

AUTHOR BIOGRAPHY

| Assoc. Prof. Hayati Mukti Asih, S.T., M.Sc., Ph.D. is a lecturer and researcher in the field of Industrial Engineering, currently working at Universitas Ahmad Dahlan, Yogyakarta, Indonesia. She earned her Doctoral degrees in Manufacturing Engineering from Universiti Teknikal Malaysia Melaka (UTeM), supported by prestigious awards such as the Zamalah Scholarship and the Malaysia International Scholarship. With expertise spanning operations management, production planning, simulation, artificial intelligence, and sustainable manufacturing, her research focuses on the application of metaheuristic optimization methods such as genetic algorithms and particle swarm optimization in solving complex industrial problems, including logistics, inventory control, and manufacturing system. Actively engaged in community service, she has contributed to projects on eco-friendly detergent innovation, waste-to-product conversion, green technology, and supply chain enhancement for local enterprises. In addition to her academic and research achievements, she has served as Editor-in-Chief for the SPEKTA journal, International Journal of Industrial Optimization (IJIO) journal, and co-authored a book on green management practices. |

|

|

| Prof. Ts. Dr. Effendi Mohamad is a professor at the Faculty of Industrial and Manufacturing Technology and Engineering, Universiti Teknikal Malaysia Melaka (UTeM). He has been with the university since 2005, actively contributing to teaching, research, and academic development. Prior to joining academia, he gained valuable industry experience at NEC Semiconductors Sdn Bhd, Perodua Sales Sdn Bhd, and ST Microelectronics Sdn Bhd, serving in various engineering capacities, including as an industrial engineer and process engineer. At UTeM, he has held numerous key administrative and leadership positions, including Head of the Department of Manufacturing Management; Director of the Community Development and I-COE Centre; Director of the Centre for Collaboration with Industry and Community; Dean of the Faculty of Mechanical and Manufacturing Engineering; Director of the Centre for Collaboration Management of RICE UTeM–Melaka; and member of the UTeM Executive Council. He currently serves on the UTeM Senate, contributing to the university’s academic affairs, governance, and strategic direction. |

|

|

| Irianto, Ph.D. received his PhD degree in Applied and Computational Statistics from Universiti Putra Malaysia in April 2021. Since graduation from his master degree in 2009, he started to teach at several universities in Indonesia. From 2012 to 2021, he was a lecturer at the Faculty of Engineering Technology, Universiti Teknikal Malaysia Melaka. In 2021, he was an assistant professor at American International University, Kuwait. He has been an assistant professor at Rabdan Academy, UAE, since 2022. His research interests are applied mathematics and multivariate statistical process control. |

|

|

| Ir. Alfian Ma’arif, S.T., M.Eng. obtained a bachelor's degree in engineering (S.T.) from the electrical engineering department of the Islamic University of Indonesia in 2014 and a master's degree in engineering (M.Eng.) from the electrical engineering department of Gadjah Mada University in 2017. Currently, he is a lecturer in the Electrical Engineering program at Ahmad Dahlan University since 2018. His research topics include the field of control systems. He is a member of the IEEE, ASCEE, and IAENG organizations. In addition to teaching, he is also the advisor for the UAD robotics team and the UAD electric vehicle team. He is also an editor for the international journals IJRCS, JRC, and JITEKI, a peer reviewer for international and national journals, and an editor for the national journal BISTE. In addition to mastering the fields of instrumentation and electronics, the author is also proficient in programming languages such as Matlab and LaTeX. |

Hayati Mukti Asih (A Comprehensive Review of Optimization Techniques in Industrial Applications: Trends, Classifications, and Future Directions)