Buletin Ilmiah Sarjana Teknik Elektro ISSN: 2685-9572

Battery Usage Monitoring System Internet of Things-Based Electric Cars (IoT) and Radio Telemetry

Ahmad Firdaus Hasibuan, Alfian Ma’arif

Department of Electrical Engineering, Universitas Ahmad Dahlan, Yogyakarta, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article history: Received 04 August 2024 Revised 04 September 2024 Published 08 September 2024 |

|

Making electric cars at Ahmad Dahlan University has started since 2019. The implementers in making this electric car are students from the Faculty of Teacher Training and Education, Automotive Technology Vocational Education Study Program and Faculty of Industrial Technology, Electrical Engineering Study Program which started by taking part in a Comparative Study at a Contest Indonesian Electric Car 2019. 2019 at Bandung State Polytechnic. The IoT and Radio Telemetry Based Electric Car Energy Usage Monitoring System created by researchers uses voltage sensor components and current sensors to detect voltage and current in electric cars, NodeMCU ESP32 as a microcontroller, voltage sensors to detect voltage, current sensors to detect current in car electricity and LCD as a reading output from the sensor. Also using IoT ThingSpeak as a display of sent sensor readings requires an internet connection to the microcontroller and radio telemetry as a display of sensor data on a serial monitor without requiring an internet connection. As a result, the tool created can monitor voltage and current accurately from a distance as long as it is connected to the internet and not connected to the internet. The best parameters obtained are the voltage and current sensors because the difference in reading error values from the sensor to the device does not reach 2, therefore they are the best parameters for this monitoring system. |

Keywords: Internet of Things; Telemetry; Voltage Divider; Current Sensor; ESP32 |

Corresponding Author: Alfian Ma’arif, Department of Electrical Engineering, Universitas Ahmad Dahlan, Yogyakarta, Indonesia. Email: alfian_maarif@ieee.org |

This work is licensed under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: A. F. Hasibuan and A. Ma’arif, “Battery Usage Monitoring System Internet of Things-Based Electric Cars (IoT) and Radio Telemetry,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 6, no. 3, pp. 214-222, 2024, DOI: 10.12928/biste.v6i3.11524. |

INTRODUCTION

The first electric car was introduced by Robert Anderson from Scotland in 1832-1839 but at that time the price of fuel oil (BBM) was relatively cheap so people around the world tended to develop combustion engines that used fuel. Currently, fuel prices are increasingly expensive and reserves are very limited and difficult to control for the future [1]-[4].

Apart from that, there are environmental issues that are of global concern which are stated in Education for Sustainable Development (EfSD). This has triggered the development of the use of electrical energy in transportation systems as a substitute for fossil fuels, because electrical energy is easily produced from various sources, including renewable energy sources. An electric car is a car that is driven by an electric motor, using electrical energy stored in a battery or other energy storage location. Electric cars were very popular in the late 19th and early 20th centuries, but their popularity faded due to advances in internal combustion engine technology and the cheaper price of gasoline vehicles [5]-[9].

The energy crisis in the 1970-1980s gave rise to little interest in electric cars, but it was only in the 2000s that new vehicle manufacturers paid serious attention to electric vehicles. This was caused by the soaring price of petroleum in the 2000s and many people in the 2000s. The world is already aware of the negative impact of greenhouse gas emissions. Electric cars are one of the means of transportation of the future because of their high efficiency and low pollution. High efficiency due to the absence of friction on the brush. Electric cars have several potential advantages compared to cars with internal combustion engines, the most important of which is that electric cars do not produce motor vehicle emissions, apart from that, this type of car also reduces greenhouse gas emissions because it does not require fossil fuels as fossil fuels. the main driver [10]-[15].

Currently, oil-fueled vehicles (cars) seem to have become a basic need for the wider community. The role of the car itself is very meaningful for all groups, from livelihoods to just material wealth. However, without realizing it, the increasing demand for car production is actually increasingly endangering human survival. The essence of this threat is the increasingly polluted air pollution on planet Earth. Therefore, a lot of research has been carried out on electric cars for modern development in developed countries. Making electric cars at Universitas Ahmad Dahlan has started since 2019. The implementers in making this electric car are students from the Faculty of Teacher Training and Education, Automotive Technology Vocational Education Study Program and Faculty of Industrial Technology, Electrical Engineering Study Program which started by taking part in a Comparative Study at a Contest Indonesian Electric Car 2019. 2019 at Bandung State Polytechnic. The support and role of the Academic Community of the Teacher Training and Education Faculty and the Faculty of Industrial Technology in making electric cars has increased the enthusiasm of students to produce an electric car called ADEV 01 Monalisa under the name Al-Qorni Team [16][17].

The electric cars that have been made are also being competed at national events such as FESC IIMS 2022 in Jakarta and Joint Electric Car Training between Universities by the Ministry of Public Works and Public Housing (PUPR) in the context of Road Day 2022 in Bandung and also the 2023 Indonesian Electric Car Contest in Bandung State Polytechnic to date. In the efforts to develop the Ahmad Dahlan University electric car team, they are still experiencing problems in the monitoring process of measuring the current and voltage emitted by the electric car. In monitoring systems, current and voltage measurements are usually still done manually and must be in direct contact with the object. This results in the process of controlling an electric car being long and less efficient. With a data monitoring and control system, the results of current and voltage measurements can be carried out in real time using a computer as a medium for monitoring readings of current, voltage and electrical energy [18]-[20].

METHOD

Software Design

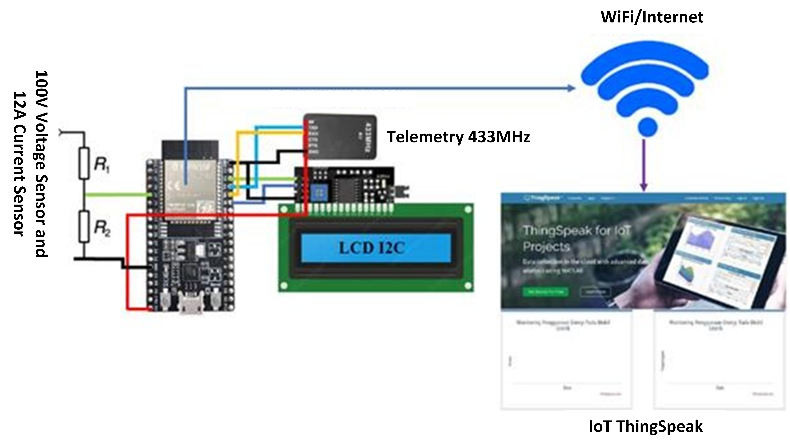

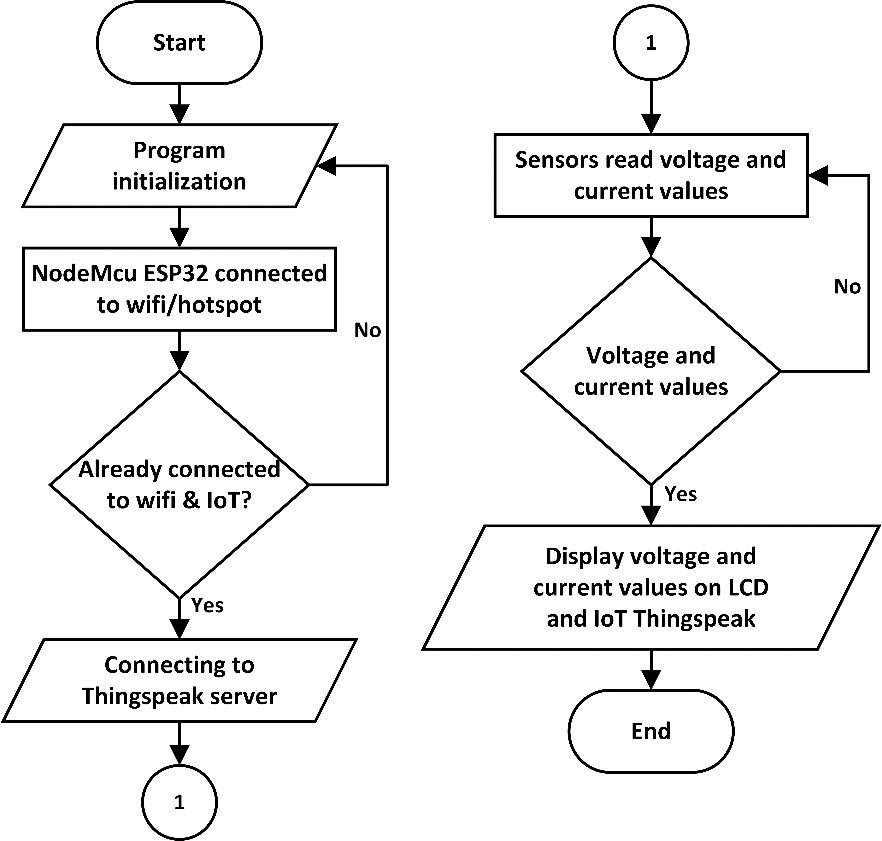

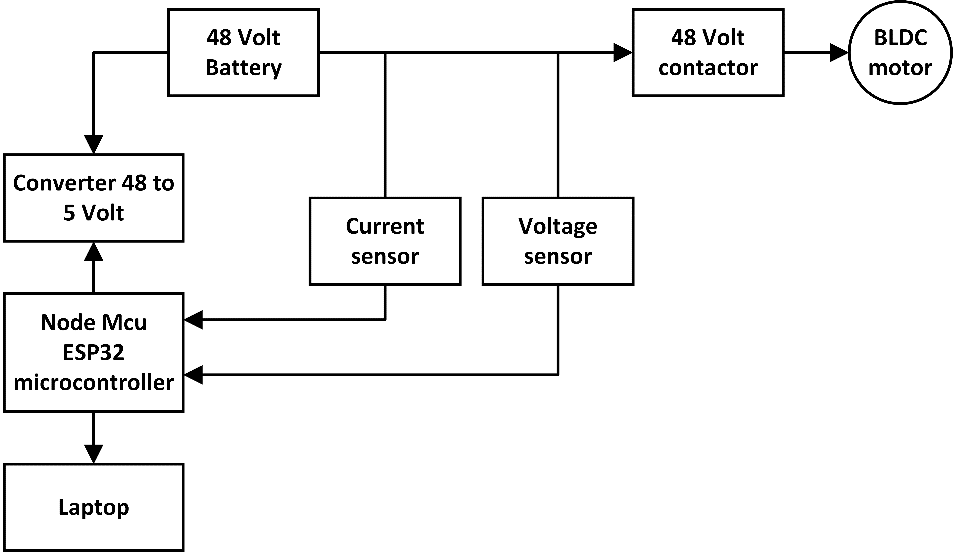

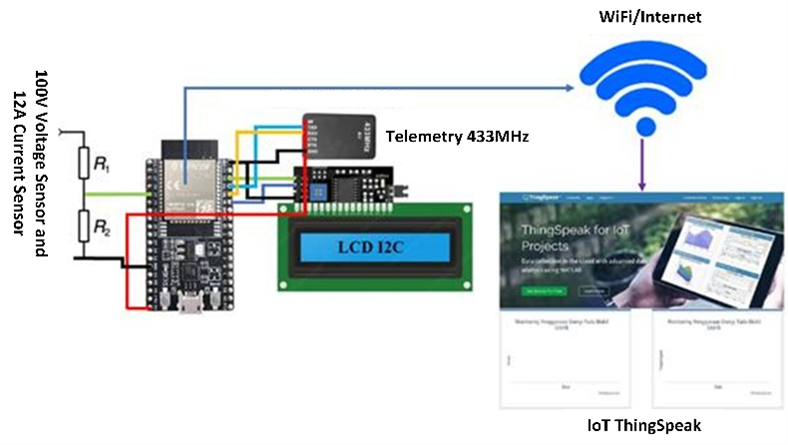

The flowchart starts from the voltage sensor which reads the voltage from the battery, then the current sensor which reads the current load from the bldc motor. After the sensor is read, the sensor will send data to the NodeMCU ESP32, then the NodeMCU ESP32 will send data to the output, namely IoT ThingSpeak which will display voltage and current data by requiring an internet connection also the NodeMCU ESP32 sends data to telemetry which will display the data to the serial monitor and I2C LCD. The flow diagram and tool block diagram can be seen in Figure 1 and Figure 2.

Figure 1. Flowchart

Figure 2. Block diagrams

Wiring Diagram

Wiring diagrams are made to understand the wiring paths in the system being created in order to minimize errors in connecting one component to another. Specifications and wiring diagram images can be seen in Table 1 and Figure 3.

Tabel 1. Wiring diagram specifications

No | NodeMCU ESP32 | Current Sensor | Voltage Sensor | Telemetry 433 MHz | LCD I2C |

1 | 18 | Out | Out | - | - |

2 | RX | - | - | RX | - |

3 | TX | - | - | TX | - |

4 | 21 | - | - | - | SDA |

5 | 22 | - | - | - | SCL |

6 | 5V | - | Positive | Positive | Positive |

7 | GND | Negative | Negative | Negative | Positive |

Figure 3. Wiring diagram

RESULTS AND DISCUSSION

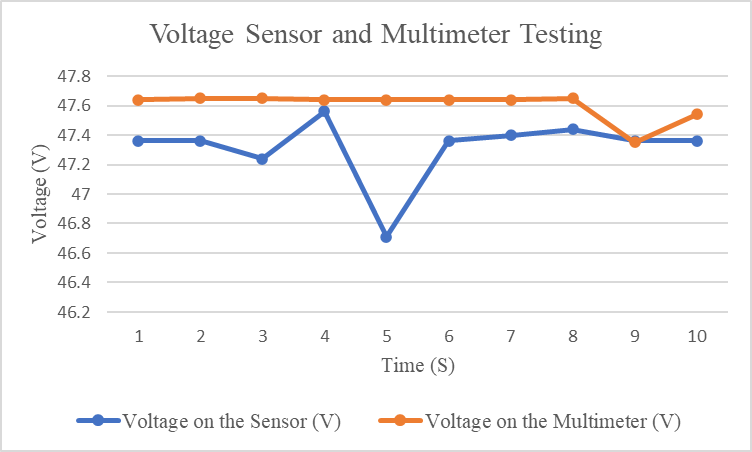

Voltage Sensor and Multimeter Testing

Voltage testing is carried out to observe the voltage on a car battery with a capacity of 46.60V. The part observed is the voltage of the car when it is on and running (10 seconds). The voltage sensor testing process is carried out by placing the voltage sensor on the battery and then connecting the sensor to the laptop to observe the voltage via the I2C LCD. In testing the voltage sensor, a voltage sensor is used which is made using a 100V capacity resistor connected in series. The test results are presented in Table 2 and also Figure 4.

Tabel 2. Voltage Sensor and Multimeter Testing

No | Voltage on the Sensor (V) | Voltage on the Multimeter (V) | Difference (V) |

1 | 47.36 | 47.64 | 0.28 |

2 | 47.36 | 47.65 | 0.29 |

3 | 47.24 | 47.65 | 0.41 |

4 | 47.56 | 47.64 | 0.08 |

5 | 46.71 | 47.64 | 0.93 |

6 | 47.36 | 47.64 | 0.28 |

7 | 47.40 | 47.64 | 0.24 |

8 | 47.44 | 47.65 | 0.21 |

9 | 47.36 | 47.35 | 0.01 |

10 | 47.36 | 47.54 | 0.18 |

Average | 47.315 | 47.604 | 0.289 |

Figure 4. Voltage sensor and multimeter testing graph

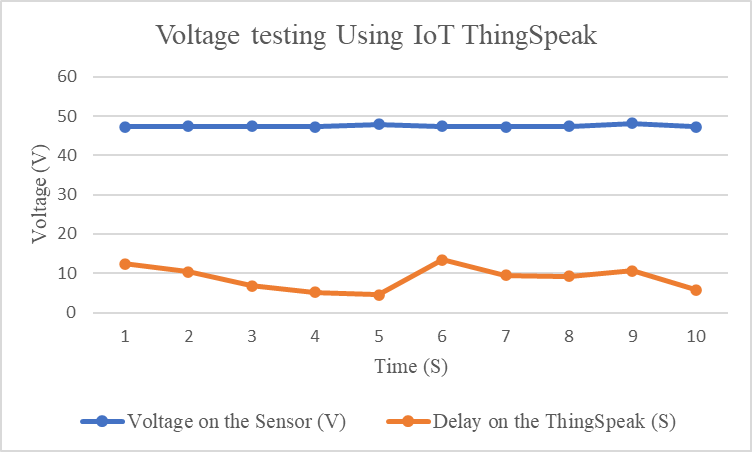

Voltage Testing Using IoT ThingSpeak

The ThingSpeak voltage test was carried out to observe the voltage on a car battery with a capacity of 46.60V. The part that is observed is the voltage of the car when it is turned on. The ThingSpeak testing process, where the voltage sensor is carried out by placing the voltage sensor on the battery, then connecting the sensor to the laptop, requires an internet connection. It also has a delay value of 15 seconds for each reception of data sent from the NodeMCU ESP32. In the ThingSpeak test, a voltage sensor is used which is made using a 100V resistor connected in series. The test results are presented in the form of Table 3 and also Figure 5.

Table 3. Voltage testing using IoT ThingSpeak

No | Voltage on the Sensor (V) | Voltage delay on the ThingSpeak (S) |

1 | 47.28 | 12.39 |

2 | 47.40 | 10.41 |

3 | 47.32 | 6.83 |

4 | 47.24 | 5.21 |

5 | 47.83 | 4.5 |

6 | 47.32 | 13.39 |

7 | 47.24 | 9.5 |

8 | 47.32 | 9.19 |

9 | 48.09 | 10.61 |

10 | 47.24 | 5.8 |

Average | 47.428 | 8.783 |

Figure 5. Voltage testing using IoT ThingSpeak graph

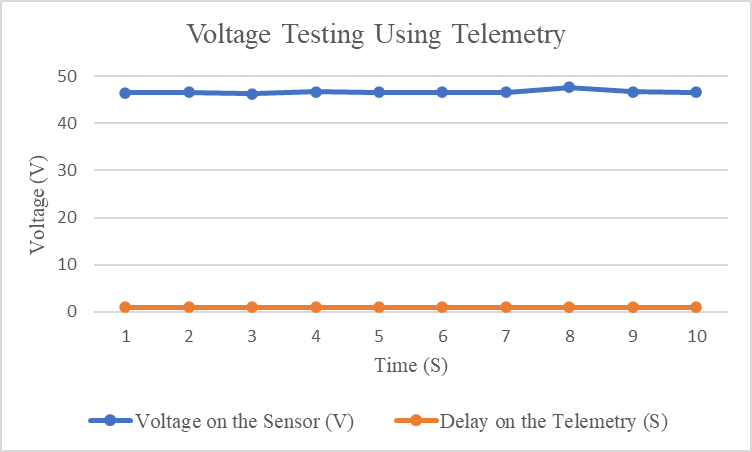

Voltage Testing Using Telemetry

Voltage testing using 433MHz Telemetry was carried out to observe the voltage on a car battery with a capacity of 46.48V. The part that is observed is the voltage of the car when it is turned on. The Telemetry testing process, where the voltage sensor is carried out by placing the voltage sensor on the battery, then the sensor is connected to the laptop without requiring an internet connection, also has a delay value of 1 second in real time for each reception. data sent from the ESP32 NodeMCU. In Telemetry testing, a voltage sensor is used which is made using a resistor with a capacity of 100V connected in series. The test results are presented in Table 4 and also Figure 6.

Table 4. Voltage testing using telemetry

No | Voltage on the Sensor (V) | Voltage delay on the Telemetry (S) |

1 | 46.48 | 1 |

2 | 46.60 | 1 |

3 | 46.23 | 1 |

4 | 46.64 | 1 |

5 | 46.56 | 1 |

6 | 46.60 | 1 |

7 | 46.56 | 1 |

8 | 47.58 | 1 |

9 | 46.64 | 1 |

10 | 46.56 | 1 |

Average | 46.645 | 1 |

Figure 6. Voltage testing using telemetry graph

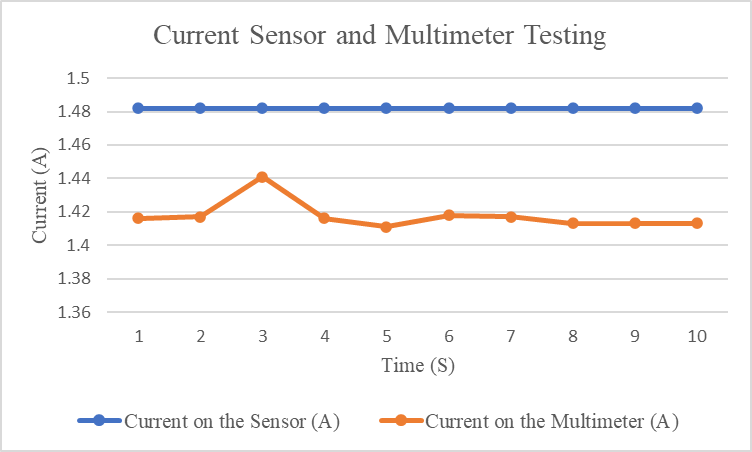

Current Sensor and Multimeter Testing

Current testing is carried out to observe the current in a car battery with a capacity of 1.482A. The part observed is the voltage of the car when it is on and running (10 seconds). The current sensor testing process is carried out by placing the current sensor on the battery and then connecting the sensor to the laptop to observe the current via the I2C LCD. In testing the current sensor, a current sensor is used which is made using a resistor with a capacity of 12A which is connected in series by dividing the total voltage of 48V by the resistance of 615.000Ω on the resistor to obtain the total current that can be generated. read is 12A. The test results are presented in Table 5 and also Figure 7.

Table 5. Current sensor and multimeter testing

No | Current on the Sensor (A) | Current on the Multimeter (A) | Difference (A) |

1 | 1.482 | 1.416 | 0.066 |

2 | 1.482 | 1.417 | 0.065 |

3 | 1.482 | 1.441 | 0.041 |

4 | 1.482 | 1.416 | 0.066 |

5 | 1.482 | 1.411 | 0.071 |

6 | 1.482 | 1.418 | 0.064 |

7 | 1.482 | 1.417 | 0.065 |

8 | 1.482 | 1.413 | 0.069 |

9 | 1.482 | 1.413 | 0.069 |

10 | 1.482 | 1.413 | 0.069 |

Average | 1.482 | 1.4175 | 0.064 |

Figure 7. Current sensor and multimeter testing raph

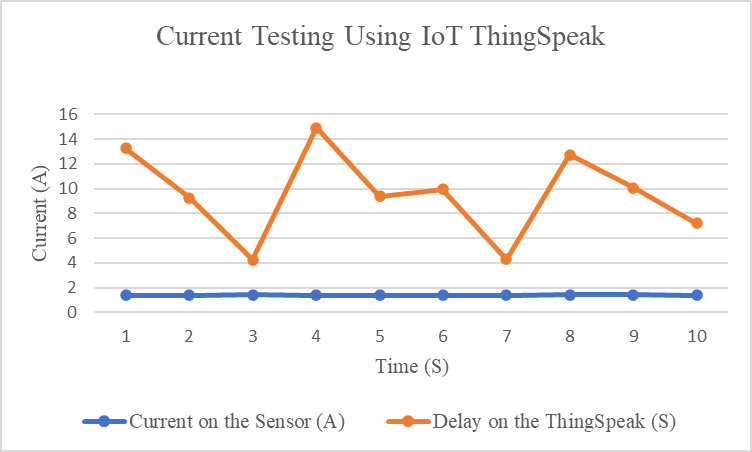

Current Testing Using IoT ThingSpeak

The ThingSpeak current test was carried out to observe the current in a car battery with a capacity of 1.408A. The part that is observed is the flow of cars while running. In testing the current sensor, a current sensor is used which is made using a resistor with a capacity of 12A which is connected in series by dividing the total voltage of 48V by the resistance of 615.000Ω on the resistor so that the total current that can be read is 12A. Then the current sensor is connected to the laptop and requires an internet connection. It also has a delay value of 15 seconds for each reception of data sent from the NodeMCU ESP32. The test results are presented in Table 6 and also in Figure 8.

Table 6. Current testing using IoT ThingSpeak

No | Current on the Sensor (A) | Delay on the ThingSpeak (S) |

1 | 1.408 | 13.27 |

2 | 1.393 | 9.24 |

3 | 1.413 | 4.27 |

4 | 1.400 | 14.89 |

5 | 1.408 | 9.36 |

6 | 1.396 | 9.96 |

7 | 1.408 | 4.28 |

8 | 1.426 | 12.74 |

9 | 1.412 | 10.07 |

10 | 1.395 | 7.2 |

Average | 1.4059 | 9.528 |

Figure 8. Current Testing Using IoT ThingSpeak Graph

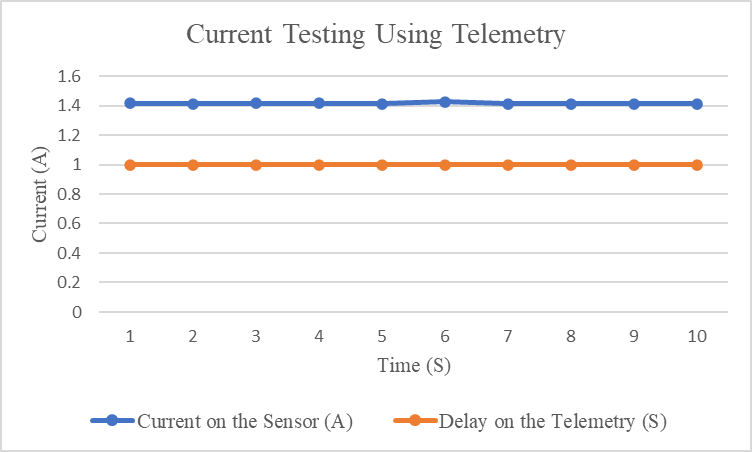

Current Testing Using Telemetry

Current testing using 433MHz Telemetry was carried out to observe the current in a car battery with a capacity of 1.482A. The part that is observed is the flow of cars while running. In testing the current sensor, a current sensor is used which is made using a resistor with a capacity of 12A which is connected in series by dividing the total voltage of 48V by the resistance of 615.000Ω on the resistor so that the total current that can be read is 12A. Then the current sensor is connected to the laptop without requiring an internet connection and also has a delay value of 1 second in real time every time it receives data sent from the NodeMCU ESP32. The test results are presented in Table 7 and also Figure 9.

Table 7. Current testing using telemetry

No | Current on the Sensor (A) | Delay on the Telemetry (S) |

1 | 1.416 | 1 |

2 | 1.413 | 1 |

3 | 1.415 | 1 |

4 | 1.417 | 1 |

5 | 1.413 | 1 |

6 | 1.427 | 1 |

7 | 1.413 | 1 |

8 | 1.412 | 1 |

9 | 1.413 | 1 |

10 | 1.413 | 1 |

Figure 9. Current testing using telemetry graph

CONCLUSION

Based on the research that has been carried out, several conclusions can be drawn, namely. Electric car battery usage monitoring system to display voltage and current where the sensors used in taking readings have a good level of accuracy because the sum of each error value on the sensor does not exceed 2. IoT ThingSpeak as a development device. The result is that the tool made can monitor voltage and current with a maximum delay of 15 seconds from a long distance as long as it is connected to an internet connection. Radio Telemetry as a receiver for sending data readings from voltage and current sensors which to ESP32 can be displayed on a serial monitor and LCD 12C in realtime has a delay of 1 second and a distance limit of 5 km without requiring an internet connection.

REFERENCES

- H. Liu, "Application research of computer monitoring system based on ubiquitous power Internet of things in substation," 2022 2nd International Conference on Networking, Communications and Information Technology (NetCIT), 2022, pp. 20-24, 2022, https://doi.org/10.1109/NetCIT57419.2022.00012.

- E. Lobato et al., “A monitoring system for electric vehicle charging stations: A prototype in the amazon,” Energies, vol. 16, no. 1, p. 152, 2022, https://doi.org/10.3390/en16010152.

- M. O. Hasanuddin, R. Augeetiansyah, G. A. Prakoso and B. R. Hermanto, "Design and Implementation of IMU, BLE Proximity and GPS-Based Theft Detection System," 2022 12th International Conference on System Engineering and Technology (ICSET), Bandung, Indonesia, 2022, pp. 1-5, 2022, https://doi.org/10.1109/ICSET57543.2022.10010979.

- A. I. Firmansyah, N. K. Supriatna, Y. Gunawan, G. T. Setiadanu and Slamet, "Performance Testing of Electric Motorcycle Conversion," 2022 7th International Conference on Electric Vehicular Technology (ICEVT), pp. 165-168, 2022, https://doi.org/10.1109/ICEVT55516.2022.9924921.

- M. S. R. Ganesh, K. S. D. Harshitha, K. P. Darshini, B. S. Lohitha, G. N. S. Aishwarya and K. Utpreksha, "Development of Restructured Electric Vehicle with Battery Charge Monitoring System using IoT," 2024 1st International Conference on Innovative Sustainable Technologies for Energy, Mechatronics, and Smart Systems (ISTEMS), pp. 1-6, 2024, https://doi.org/10.1109/ISTEMS60181.2024.10560154.

- N. Hou and Y. W. Li, "Overview and Comparison of Modulation and Control Strategies for a Nonresonant Single-Phase Dual-Active-Bridge DC–DC Converter," in IEEE Transactions on Power Electronics, vol. 35, no. 3, pp. 3148-3172, 2020, https://doi.org/10.1109/TPEL.2019.2927930.

- H. Tran-Dang, N. Krommenacker, P. Charpentier and D. -S. Kim, "Toward the Internet of Things for Physical Internet: Perspectives and Challenges," in IEEE Internet of Things Journal, vol. 7, no. 6, pp. 4711-4736, 2020, https://doi.org/10.1109/JIOT.2020.2971736.

- B. O. Varga, A. Sagoian, and F. Mariasiu, “Prediction of electric vehicle range: A comprehensive review of current issues and challenges,” Energies, vol. 12, no. 5, p. 946, 2019, https://doi.org/10.3390/en12050946.

- M. Wang, C. Yang, W. Wang, Z. Lu, L. Yang and R. Chen, "An Efficient Power Control Scheme for Heavy-Duty Hybrid Electric Vehicle With Online Optimized Variable Universe Fuzzy System," in IEEE Transactions on Fuzzy Systems, vol. 32, no. 5, pp. 2725-2737, 2024, https://doi.org/10.1109/TFUZZ.2024.3359414.

- K. M, A. A, K. Balachander, M. S. Ramkumar, G. Emayavaramban and S. Divvapriva, "IoT Based Design and Implementation of Hybrid Electric Vehicle Using Control of DC Motor," 2021 5th International Conference on Trends in Electronics and Informatics (ICOEI), pp. 382-387, 2021, https://doi.org/10.1109/ICOEI51242.2021.9452868.

- V. Rahatal, P. More, M. Salunke, S. Makeshwar and R. D. Joshi, "IoT Based Communication System for Autonomous Electric Vehicles," 2021 7th International Conference on Signal Processing and Communication (ICSC), pp. 66-72, 2021, https://doi.org/10.1109/ICSC53193.2021.9673164.

- C. L. Nge, I. U. Ranaweera, O. M. Midtgård, and L. Norum, “A real-time energy management system for smart grid integrated photovoltaic generation with battery storage,” Renewable energy, vol. 130, pp. 774-78, 2019, https://doi.org/10.1016/j.renene.2018.06.073.

- R. G. Congalton and K. Green. Assessing the accuracy of remotely sensed data: principles and practices. CRC press. 2019. https://doi.org/10.1201/9780429052729.

- P. Hoddie and L. Prader. IoT Development for ESP32 and ESP8266 with JavaScript: A Practical Guide to XS and the Moddable SDK. Berkeley, CA, USA: Apress. 2020. https://doi.org/10.1007/978-1-4842-5070-9.

- S. Singh and J. Malik, “Review of efficiency enhancement techniques and linearization techniques for power amplifier,” International Journal of Circuit Theory and Applications, vol. 49, no. 3, pp. 762-777, 2021, https://doi.org/10.1002/cta.2956.

- D. Mohanraj et al., "A Review of BLDC Motor: State of Art, Advanced Control Techniques, and Applications," in IEEE Access, vol. 10, pp. 54833-54869, 2022, https://doi.org/10.1109/ACCESS.2022.3175011.

- B. J. S. Bayu, G. A. P. Gurum, A. R. Agus, and A. Surtono, “Design and Build Voltage and Current Monitoring Parameters Device of Rechargeable Batteries in Real-Time Using the INA219 GY-219 Sensor,” Journal of Energy, Material, and Instrumentation Technology, 4(2), 58-71, 2023, https://doi.org/10.23960/jemit.v4i2.137.

- V. Vaideeswaran, S. Bhuvanesh and M. Devasena, "Battery Management Systems for Electric Vehicles using Lithium Ion Batteries," 2019 Innovations in Power and Advanced Computing Technologies (i-PACT), pp. 1-9, 2019, https://doi.org/10.1109/i-PACT44901.2019.8959965.

- F. Zhang, L. Wang, S. Coskun, H. Pang, Y. Cui, and J. Xi, “Energy management strategies for hybrid electric vehicles: Review, classification, comparison, and outlook,” Energies, vol. 13, no. 13, p. 3352, 2020, https://doi.org/10.3390/en13133352.

- S. Sadowski and P. Spachos, “Wireless technologies for smart agricultural monitoring using internet of things devices with energy harvesting capabilities,” Computers and Electronics in Agriculture, vol. 172, p. 105338, 2020, https://doi.org/10.1016/j.compag.2020.105338.

Battery Usage Monitoring System Internet of Things-Based Electric Cars (IoT) and Radio Telemetry (Ahmad Firdaus Hasibuan)