Buletin Ilmiah Sarjana Teknik Elektro ISSN: 2685-9572

Automatic Satay Grill Using 5 Volt Stepper Motor for Home Business

Dimas Dwi Prayoga, Izza Anshory, Arief Wicaksono, Syamsudduha Syahrorini

Department of Electrical Engineering, Universitas Muhammadiyah Sidoarjo, East Java, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Received 20 May 2024 Revision 12 June 2024 Publication 26 June 2024 |

|

Increased consumer demand for satay dishes as one of the traditional culinary demands innovation in the manufacturing process to improve efficiency and consistency. This research aims to design and implement a dc stepper motor-based automatic satay grill system as a solution for small businesses. This system uses a DC stepper motor as the main component, using an Arduino UNO microcontroller programmed to regulate the temperature and automatic rotation of the satay. The measurement uses a built-in LM35 temperature sensor to monitor the temperature during grilling to ensure optimal doneness. In addition, the system is equipped with an interface using an LCD screen connected to the Arduino UNO microcontroller to monitor the temperature and condition of the satay grill, allowing the user to easily set the grilling parameters according to preference. During testing of the prototype, results showed that this automatic satay grill system is capable of producing satay with uniform doneness and meeting quality standards. In addition, time and labor efficiency improved, making a positive contribution to the productivity of small and medium enterprises. Overall, this development provides an innovative and effective solution in improving the satay production process, positively impacting traditional culinary businesses. |

Keywords: Automatic Grill; Sensor LM35; Motor Stepper 5 Volt; Arduino UNO |

Corresponding Author: Izza Anshory, Department of Electrical Engineering, Universitas Muhammadiyah Sidoarjo, East Java, Indonesia. Email: izzaanshory@umsida.ac |

This work is licensed under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: D. D. Prayoga, I. Anshory, A. Wicaksono, and S. Syahrorini “Automatic Satay Grill Using 5 Volt Stepper Motor for Home Business,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 6, no. 2, pp. 155-163, 2024, DOI: 10.12928/biste.v6i2.10519. |

- INTRODUCTION

The method and method of roasting greatly affect the level of maturity of a food. Small entrepreneurs still use simple and less environmentally friendly technology. The tools used are traditional grills for burning fish, chicken, mutton or satay (using manual fans). Where the combustion process is carried out using coconut shell charcoal which is given an iron support [1]. Processing is done by flipping until it feels cooked enough. Some researchers have conducted research on meat grills designed by utilizing nickel wire as a converter of electrical energy into heat energy [2].

Technology makes everything that is done easier. Humans always try to create something that can facilitate their activities, this is what drives the development of technology which has produced many tools as tools to facilitate human activities and even replace the role of humans in a particular function [3]. The selection of technology must also be based on its economic and efficiency aspects so that the type of energy technology chosen is the most optimal in terms of economic and environmental aspects [4].

Satay is processed meat made from various types of meat, such as beef, chicken, lamb, and fish, cut into cubes. Various satays go through a process of marinating the meat with spices, then skewered with a fork, then grilled over hot coals, seasoned again like grilled satay, so that the taste of the satay is more pronounced [5]. Satay is a popular food in Indonesia, this food is very unique and one of the must-try foods [6]. Indonesia is a country with a diversity of different cultures, a recipe for every region, a culinary destination for every tourist. [7].

Satay comes from the word "satai", which means small pieces of meat skewered and grilled, seasoned with peanuts or soy sauce: -- chicken; -- goat. The variety of satay dishes in Indonesia is very diverse both in terms of flavor, and in the way it is served [8][9].

In order to simplify the process of grilling satay at home businesses, an automatic satay grill using a 5 Volt stepper motor at home businesses is the result of utilizing technological sophistication. In previous research, an assessment of the grill monitoring system using the LM35 sensor was carried out [9][10] to determine the combustion temperature, it's just that this study did not compare the measurement with the temperature using a temperature measuring device [11], so that the temperature measurement using only the LM35 sensor is quite doubtful [12][13]. This research compares the temperature measurement between the LM35 sensor and the Krisbow brand thermogun tool in order to get definite temperature measurement results. This tool uses a microcontroller [14][15] Arduino UNO [16]. to control the 5 volt stepper motor used to rotate the satay, there are two modes of rotating the satay, namely the satay rotates continuously and the satay rotates every 90º angle [17] tool conditions and temperature conditions can be monitored through the LCD screen by making this tool in order to facilitate home businesses in carrying out their production processes.

- METHODS

A Research and Development (R&D) research approach was used in this study to update and develop previous research [18]. The R&D approach includes a cycle of research and development stages by considering various research findings in the field related to the product to be developed [19]. Creating block diagrams, flow charts, and wiring diagrams that will be used are three steps that must be done [20]. Each process has a different goal, but in the end the three processes will collaborate to achieve the final goal, which is the creation of a tool that is effective and profitable for home-based businesses.

- System Design

The design of this tool consists of three stages. First, an explanation of the parts of the system and their relationships. In the second stage, a flowchart should be created to show the workflow of the system and its relationship. In the third stage, block diagrams should be created to show the inputs, processing, and outputs of the system and their relationship to each other. Taken together, these three stages provide a complete picture of the system as a whole.

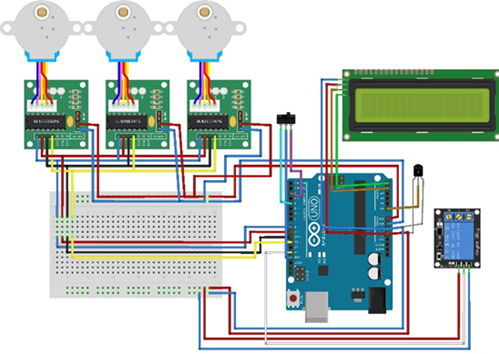

- Block Diagram System

The overall system block diagram is made to facilitate the design and fabrication of tools on existing devices. Below is a block diagram of an automatic satay grill using a 5 Volt stepper motor in a home business. As shown in Figure 1. There are 3 parts of the satay grill system circuit, namely: input, process, and output. In the input section there is a sensor, namely the LM35 sensor which is used to measure temperature and the ON-OFF-ON Switch which is used to turn on the stepper motor with two control modes, for the first mode to move the stepper motor continuously and the second mode to move the stepper motor every 90º will stop and rotate. In the process section there is an Arduino UNO microcontroller to process the input value from the input sensor and in the process, section also processes the input value on the ON-OFF-ON switch. In the output section there is a 16x2 LCD to display the condition of the tool and the reading value of the input sensor.

Figure 1. Block Diagram System

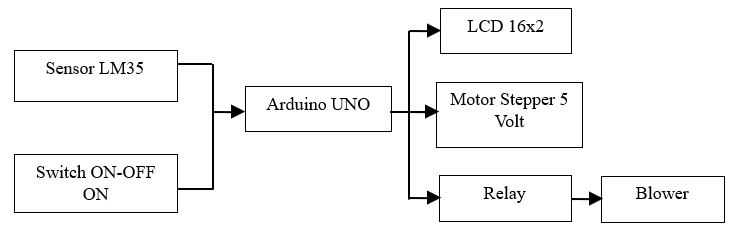

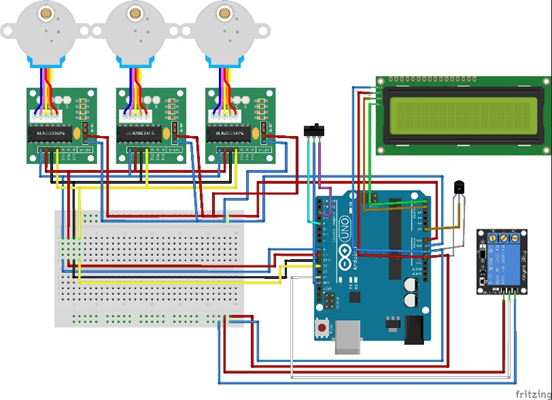

- Wiring Design

The wiring diagram in Figure 2 is the wiring circuit used in this study, In the Figure 2, all components that function as inputs and outputs are connected to the microcontroller. A microcontroller connects the input and output components, the microcontroller used is Arduino UNO can be seen in Table 1. In order for the tool used to work, all components used must be connected properly.

Figure 2 shows some of the components used for the following purposes:

- LM35 sensor as the temperature value measurement component.

- ON-OFF-ON switch is used to turn the stepper motor on and off.

- LCD display is used as a tool interface from the user

- 5 Volt Stepper motor is used as a medium to rotate the satay.

- Arduino UNO microcontroller is used as the brain of the circuit, its task is to process input data from

Swtich and sensor sensors then forward it to the components.

- Relay is used as a switch to turn the blower on and off.

- The blower is used as an output that will work if the dust and temperature levels exceed the specified capacity.

Figure 2. Wiring Design

Table 1. Arduino UNO Port Usage

No | Arduino UNO Port | Usage |

1 | 4 | Switch ON 1 |

2 | 2 | Switch ON 2 |

3 | GND | IN Switch |

4 | 5V | Vcc sensor LM35 |

5 | A0 | Data sensor LM35 |

6 | GND | GND sensor LM35 |

7 | 8 | IN 1 motor stepper |

8 | 9 | IN 2 motor stepper |

9 | 10 | IN 3 motor stepper |

10 | 11 | IN 4 motor stepper |

11 | 3 | IN Relay |

12 | A4 | SCL LCD 16x2 |

13 | A5 | SDA LCD 16x2 |

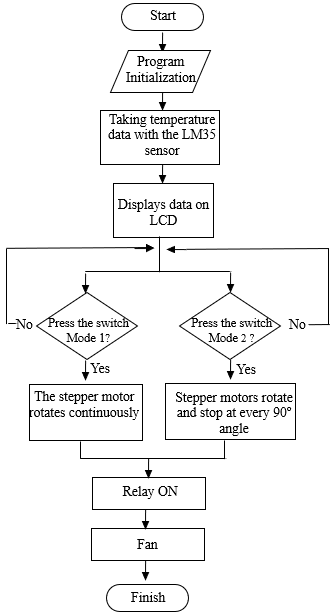

- System Flowchart

The flowchart in Figure 3 is used to facilitate the research process. The program begins by initializing the program first, then the LM35 sensor will take temperature data which will be processed by the Arduino UNO microcontroller, temperature data and tool conditions will be displayed via a 16x2 LCD screen which can be used to monitor the tool. If mode switch 1 is activated, the stepper motor will rotate continuously and if mode switch 1 is turned off, the stepper motor will turn off. If mode switch 2 is activated, the stepper motor will rotate and stop at each 90º angle with a time lag of 2 seconds each, and if mode switch 2 is turned off, the stepper motor will turn off. If the stepper motor is turned on either from mode switch 1 or from mode switch 2, the Arduino UNO microcontroller directly processes the data to turn on the relay, and from the relay it will activate the fan which will be used to heat the coals in the automatic satay grill circuit.

Figure 3. Flowchart program system

- RESULTS AND DISCUSSIONS

The research results of the realization of an automatic satay grill using a 5 Volt stepper motor in a home business can be seen in Figure 4. All components used will be explained by numbering as follows: 1. LM25 sensor, 2. 5-volt Stepper Motor, 3. Arduino UNO, 4. LCD I2C, 5. Relay, 6. Fan.

The steps to operate the prototype microcontroller are as follows:

- The user can prepare the tools and materials used in the testing process.

- As a power source, connect the microcontroller to a 9 volt adapter.

- The user inserts a skewer in the hole found on each stepper motor. In addition, users can ensure that the LCD is well lit and displays data such as temperature, and the condition of the stepper motor on or off.

- After the skewers have been placed in the right position, the user can press the switch, there are two switch modes for two kinds of skewer drive, if the user presses the mode 1 switch, the stepper motor will move to rotate the skewers continuously and the LCD shows the mode 1 switch ON. Also the fan will turn on if the stepper motor starts moving.

- If the user presses the mode 2 switch, the stepper motor will move and stop rotating the skewers at each 90º angle with a stop time and move every two seconds and the LCD shows mode 2 switch ON. Also the fan will turn on if the stepper motor starts moving.

- If the stepper motor starts moving, this will automatically activate the relay then from the active relay it will be used to turn on the fan to keep the embers in the satay roasting process alive.

|

|

Figure 4. Result of tool realization

- Testing the Condition and Performance of the Satay Grill

Testing the condition and performance of the tool is done in order to know that the assembled tool is really perfect and feasible before using the specified materials. the results obtained from the test obtained the assembled tool runs normally as expected and is ready for testing with the specified materials can be seen in Table 2.

Table 2. Testing the condition and performance of the satay grill

Testing time (every 1 minute) | Power Input Arduino UNO | Switch Mode 1 | Switch Mode 2 | DC motor Stepper | LM35 sensor condition | LCD condition | visual conditions |

1 | 9 Volt | ON | - | Working | Normal | Normal | Good |

2 | 9 Volt | ON | - | Working | Normal | Normal | Good |

3 | 9 Volt | ON | - | Working | Normal | Normal | Good |

4 | 9 Volt | ON | - | Working | Normal | Normal | Good |

5 | 9 Volt | ON | - | Working | Normal | Normal | Good |

6 | 9 Volt | - | ON | Working | Normal | Normal | Good |

7 | 9 Volt | - | ON | Working | Normal | Normal | Good |

8 | 9 Volt | - | ON | Working | Normal | Normal | Good |

9 | 9 Volt | - | ON | Working | Normal | Normal | Good |

10 | 9 Volt | - | ON | Working | Normal | Normal | Good |

- Testing Sensor LM35 With Thermogun Krisbow

This test is carried out to ensure the accuracy of the LM35 temperature sensor measurement by comparing the temperature measurement using a krisbow thermogun which can be seen in Figure 5. Measurements are taken every 1 minute, and the results are shown in Table 3. According to the results of the study, the measurement of the LM35 sensor with the Krisbow thermogun tool has no significant difference in the measurement results, it can be concluded that the LM35 sensor is in good condition and can be used.

Figure 5. The training network structure

Table 3. Testing Sensor LM35 With Thermogun Krisbow

Testing time (every 1 minute) | Sensor LM35 | Thermogun Krisbow | Difference | Error |

1 | 120 ºC | 121 ºC | 1 | 0.008 % |

2 | 119 ºC | 119 ºC | 0 | 0 % |

3 | 120 ºC | 120 ºC | 0 | 0 % |

4 | 122 ºC | 121 ºC | 1 | 0.008 % |

5 | 120 ºC | 120 ºC | 0 | 0 % |

6 | 120 ºC | 120 ºC | 0 | 0 % |

7 | 121 ºC | 120 ºC | 1 | 0.008 % |

8 | 120 ºC | 119 ºC | 1 | 0.008 % |

9 | 122 ºC | 122 ºC | 0 | 0 % |

10 | 121 ºC | 121 ºC | 0 | 0 % |

Table 3 is the result of testing the temperature comparison that has been measured using the Krisbow thermogun and the LM35 sensor. The percentage of measurement error is obtained from dividing the difference value of the reading by the value of the thermometer then multiplied by 100%.

Based on the formula above, the calculation results obtained are as follows:

- Testing Fan Distance on the Effect of the Temperature of the Grill Embers

Testing the distance of the fan to the effect of the temperature of the coals of the grill uses the LM35 sensor in its measurement and the results are shown in Table 4. The results showed that the closer the fan distance to the coals, the higher the temperature on the grill coals. The results of the appropriate temperature test and will be used on a satay grill tool around 150 ºC, then in the satay grill test the distance set between the fan and the coals is 5 cm.

Table 4. Testing fan distance on the effect of the temperature of the grill embers

Testing time (every 1 minute) | Fan | Distance | Temperature |

1 | ON | 1 cm | 170 ºC |

2 | ON | 5 cm | 151 ºC |

3 | ON | 10 cm | 136 ºC |

4 | ON | 15 cm | 117 ºC |

5 | ON | 20 cm | 100 ºC |

6 | ON | 25 cm | 88 ºC |

7 | ON | 30 cm | 70 ºC |

- Testing Stepper Motor Mode 1 Rotating Skewers Continuously

Testing stepper motor mode 1 rotates the satay continuously to find which comparison is better between mode 1 or mode 2 in grilling chicken satay. In the test results of the automatic satay grill, the condition of the chicken satay is in perfect condition can be seen in Table 5.

Table 5. Testing stepper motor mode 1 rotating skewers continuously

Testing time (every 1 minute) | Fan | Temperature | Satay Condition |

1. | ON | 149 ºC | Mature |

2. | ON | 151 ºC | Mature |

3. | ON | 150 ºC | Mature |

4. | ON | 150 ºC | Mature |

5. | ON | 151 ºC | Mature |

6. | ON | 149 ºC | Mature |

7. | ON | 152 ºC | Mature |

8. | ON | 151 ºC | Mature |

9. | ON | 150 ºC | Mature |

10. | ON | 151 ºC | Mature |

- Testing Stepper Motor Testing Will Move and Stop Rotating the Satay at Each 90º Angle

Stepper motor testing will move and stop rotating the satay at each 90º angle is done to find a better comparison between mode 1 or mode 2 in grilling chicken satay. In the test results of the condition of the chicken satay in spite of being cooked but more testing the results were burnt can be seen in Table 6.

Table 6. Testing Stepper motor testing will move and stop rotating the satay at each 90º angle

Testing time (every 1 minute) | Fan | Temperature | satay condition |

1 | ON | 150 ºC | Mature |

2 | ON | 150 ºC | Burnt |

3 | ON | 152 ºC | Mature |

4 | ON | 149 ºC | Burnt |

5 | ON | 150ºC | Burnt |

6 | ON | 150ºC | Burnt |

7 | ON | 152ºC | Burnt |

8 | ON | 151ºC | Burnt |

9 | ON | 150ºC | Burnt |

10 | ON | 151ºC | Burnt |

- CONCLUSIONS

Based on the test results, it shows that the LM35 sensor has a good level of accuracy. This tool works as expected. Proven by the sensor that can detect the temperature precisely, the circuit can work perfectly, and can send data which will then be displayed on the LCD. After several experiments, this tool can function as desired. The results of testing the automatic satay grill tool between mode switch 1 and mode switch 2, found that mode switch 1 is better at grilling satay than mode switch 2, therefore mode switch 1 is more recommended for grilling satay. Overall, this development provides an innovative and effective solution in improving the satay production process, so that the invention of this tool can have a positive impact on home culinary businesses.

REFERENCES

- L. Garcia, M. Lupaca, D. Cardenas, and K. Munoz, “Implementation of an automatic control system on a roaster of peruvian andes grains,” In IOP Conference Series: Materials Science and Engineering, vol. 707, no. 1, p. 012007, 2019, https://doi.org/10.1088/1757-899X/707/1/012007.

- A. Onopiuk, K. Kołodziejczak, M. Marcinkowska-Lesiak, I. Wojtasik-Kalinowska, A. Szpicer, A. Stelmasiak, and A. Poltorak, “Influence of plant extract addition to marinades on polycyclic aromatic hydrocarbon formation in grilled pork meat,” Molecules, vol. 27, no. 1, p. 175, 2021, https://doi.org/10.3390/molecules27010175.

- K. Berezina, O. Ciftci, and C. Cobanoglu, “Robots, artificial intelligence, and service automation in restaurants,” In Robots, artificial intelligence, and service automation in travel, tourism and hospitality, pp. 185-219, 2019, https://doi.org/10.1108/978-1-78756-687-320191010.

- K. M. Hasib, M. A. Rahman, M. Tahsin, A. Karim, S. Azam and F. DeBoer, "LFR Waiter: Arduino Based Android Application Controlled Waiter Robot," TENCON 2022 - 2022 IEEE Region 10 Conference (TENCON), pp. 1-6, 2022, https://doi.org/10.1109/TENCON55691.2022.9977936.

- F. Estévez, A. Arnaud, B. Bellini and M. Miguez, "Smart Platform for Active Electrical Materials - A Dimmer for LED Lighting," 2021 IEEE URUCON, Montevideo, Uruguay, 2021, pp. 147-150, 2021, https://doi.org/10.1109/URUCON53396.2021.9647376.

- A. Nurhikmat, A. Susanto, A. Kusumaningrum, A. F. Amri, R. Z. Amdani, and S. Prayogi, “General assessment on the sensory properties of traditional cuisine from java island after canning process,” In IOP Conference Series: Earth and Environmental Science, vol. 759, no. 1, p. 012003, 2021, https://doi.org/10.1088/1755-1315/759/1/012003.

- S. Wijaya, “Indonesian food culture mapping: a starter contribution to promote Indonesian culinary tourism,” Journal of Ethnic Foods, vol. 6, no. 1, pp. 1-10, 2019, https://doi.org/10.1186/s42779-019-0009-3.

- B. Zhang, K. Li, H. Cheng, J. Hu, X. Qi, and X. Guo, “Effect of thermal treatments on volatile profiles and fatty acid composition in sweet corn (Zea mays L.),” Food Chemistry: X, 18, p. 100743, 2023, https://doi.org/10.1016/j.fochx.2023.100743.

- A. Mardatillah, “The enterprise culture heritage of Minangkabau cuisine, West Sumatra of Indonesia as a source of sustainable competitive advantage,” Journal of Ethnic Foods, vol. 7, no. 1, p. 34, 2020, https://doi.org/10.1186/s42779-020-00059-z.

- B. Purwantana, R. P. Alamsyah, and H. D. Prawira, “Design of Portable Coffee Roaster for Home Industry,” In IOP Conference Series: Earth and Environmental Science, vol. 327, no. 1, p. 012019, 2019, https://doi.org/10.1088/1755-1315/327/1/012019.

- W. A. Jabbar et al., "Design and Fabrication of Smart Home With Internet of Things Enabled Automation System," in IEEE Access, vol. 7, pp. 144059-144074, 2019, https://doi.org/10.1109/ACCESS.2019.2942846.

- F. Salehi, “Recent applications and potential of infrared dryer systems for drying various agricultural products: A review,” International Journal of Fruit Science, vol. 20, no. 3, pp. 586-602, 2020, https://doi.org/10.1080/15538362.2019.1616243.

- S. Rochman and R. Mukodah, “AUTOMATIC FISH GRILLER BASED ON TEMPERATURE CONTROLLER,” BEST: Journal of Applied Electrical, Science, & Technology, vol. 2, no. 2, pp. 33-36, 2020, https://doi.org/10.36456/best.vol2.no2.3475.

- I. Anshory et al., “Optimization DC-DC boost converter of BLDC motor drive by solar panel using PID and firefly algorithm,” Results in Engineering, vol. 21, p. 101727, 2024, https://doi.org/10.1016/j.rineng.2023.101727.

- S. Wongkhead, S. Tunyasrirut, W. Permpoonsinsup and D. Puangdownreong, "State Space Model for BLDC Motor Based on Digital Sigal Processors TMS320F28335 for Speed Control by Using Proportional Integral Controller," 2019 7th International Electrical Engineering Congress (iEECON), pp. 1-4, 2019, https://doi.org/10.1109/iEECON45304.2019.8938880.

- I. Maity et al., "Exploring Arduino based Electronic Circuit Design: A Study of Innovative Applications and Prototypes," 2023 7th International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 2023, pp. 1-5, 2023, https://doi.org/10.1109/IEMENTech60402.2023.10423427.

- M. I. Al-Amayreh and A. Alahmer, “On improving the efficiency of hybrid solar lighting and thermal system using dual-axis solar tracking system,” Energy Reports, vol. 8, pp. 841-847, 2022, https://doi.org/10.1016/j.egyr.2021.11.080.

- O. Suhartati, “Flipped Classroom Learning Based on Android Smart Apps Creator (SAC) in Elementary Schools,” In Journal of Physics: Conference Series, vol. 1823, no. 1, p. 012070, 2021, https://doi.org/10.1088/1742-6596/1823/1/012070.

- S. Papadakis, M. Kalogiannakis, and N. Zaranis, “Teaching mathematics with mobile devices and the Realistic Mathematical Education (RME) approach in kindergarten,” Advances in Mobile Learning Educational Research, vol. 1, no. 1, pp. 5-18, 2021, https://doi.org/10.25082/AMLER.2021.01.002.

- X. R. Bina and J. E. Bina, “Vibrio cholerae RND efflux systems: mediators of stress responses, colonization and pathogenesis,” Frontiers in Cellular and Infection Microbiology, vol. 13, p. 1203487, 2023, https://doi.org/10.3389/fcimb.2023.1203487.

AUTHOR BIOGRAPHY

| Dimas Dwi Prayoga born in Sidoarjo district on April 02, 2002, his first education was at SDN Katerungan krian sidoarjo graduated in 2014, then continued his education at SMPN 1 prambon, and in 2017, then completed his Electrical Power Installation Engineering education at Smk Persatuan Tulangan 2 Sidoarjo in 2020. After that in 2020 continued his education to obtain a bachelor's degree (S1) at Muhammadiyah Sidoarjo University in the Electrical Engineering Study Program. |

|

|

| Izza Anshory is a researcher who specializes in power electronics, mechatronics, electric vehicle technology and telecommunication networks. He completed his undergraduate education at Unibraw Malang with Electrical Engineering graduated in 1999. Then S2 at the Sepuluh Nopember Institute of Technology with the field of Electrical Engineering and graduated in 2007. Then continued with his doctoral degree at the Sepuluh Nopember Institute of Technology with a field of Electrical Engineering graduated in 2021. Now he is a lecturer as well as the head of the Electrical Engineering department at Muhammadiyah Sidoarjo University. |

|

|

| Arief Wisaksono he is an active lecturer at the Department of Electrical Engineering, Faculty of Science and Technology, Universitas Muhammadiyah Sidoarjo. He obtained his Bachelor's degree from Universitas Muhammadiyah Surabaya in 1992 and his Master's degree from Dr. Soetomo University in 2010. |

|

|

| Syamsudduha Syahrorini she is one of the lecturers at the Muhammadiyah University of Sidoarjo who specializes in the electrical engineering department. He took degrees at the University of Muhammadiyah Malang in 1995, Institut Teknologi Sepuluh Nopemver 2008, and Universitas Brawijaya 2019. |

Automatic Satay Grill Using 5 Volt Stepper Motor for Home Business (Dimas Dwi Prayoga)