Buletin Ilmiah Sarjana Teknik Elektro ISSN: 2685-9572

Prototype Design of Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area

Mufit Yogie Prayudha, Indah Sulistiyowati, Dwi Hadidjaja Rasjid Saputra

Department of Electrical Engineering, Universitas Muhammadiyah Sidoarjo, East Java, Indonesia

ARTICLE INFORMATION |

| ABSTRACT |

Article History: Submitted 13 January 2024 Revised 21 February 2024 Accepted 12 March 2024 |

|

PT SINAR INDOGREEN KENCANA is a company that produces AAC (Autoclave Aerated Concrete) lightweight bricks, the existence of a limestone grinding machine (Mill MTW) into lime powder and maturation of raw materials with the steam process of the autoclave machine, as well as the occurrence of rain that disrupts air circulation in the production area, causing a lot of dust and hot water vapor from the machining process to enter the production area, thus disrupting the performance of employees. This research aims to design a prototype blower for air quality control in the production area of PT SINAR INDOGREEN KENCANA. Where this system is designed to control and monitor dust and temperature levels, utilizing ESP8266 as a monitoring unit and Arduino UNO as a controller, with Blynk integration as a user interface. In operation, ESP8266 monitors dust levels and temperature through the I2C LCD, turning on the blower to suck dust and water vapor from the remaining hot production. Arduino UNO as a link between the GP2Y1010AU0F sensor for dust detection and the DHT22 sensor for temperature detection, sends data on dust levels and temperature to ESP8266. Through the BLYNK application, users can find out dust levels, temperature, and whether the blower is on or off. The application of this system obtained the result that the whole system provides an integrated and effective solution for controlling air quality in the production area of PT SINAR INDOGREEN KENCANA. |

Keywords: Automatic Blower; GP2Y1010AU0F Sensor; DHT22 Sensor; ESP8266; Arduino UNO |

Corresponding Author: Indah Sulistiyowati, Department of Electrical Engineering, Universitas Muhammadiyah Sidoarjo, East Java, Indonesia. Email: indah_sulistiyowati@umsida.ac.id |

This work is licensed under a Creative Commons Attribution-Share Alike 4.0

|

Document Citation: M. Y. Prayudha, I. Sulistiyowati, and D. H. R. Saputra, “Prototype Design Of Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 6, no. 1, pp. 63-71, 2024, DOI: 10.12928/biste.v6i1.10122. |

- INTRODUCTION

PT SINAR INDOGREEN KENCANA was established around 2012, this company has the brand name "Grand Elephant", a company that produces ACC (Autoclave Aerated Concrete) lightweight bricks, with products that are already innovative and also of high quality. "Grand Elephant" lightweight bricks are produced by international standards and quality, using the best machine technology and professional human resources. The "Grand Elephant" factory, located in Ponokawan Village, Krian District, Sidoarjo Regency, East Java, is one of the most advanced lightweight brick factories in Indonesia, with a production capacity of 350,000 m³/year (1100 m³/day).

The existence of a limestone grinding machine (Mill MTW) into lime powder and maturation of raw materials with the steam process of the autoclave machine, as well as the occurrence of rain that disrupts air circulation in the production area, causing a lot of dust and hot water vapor from the production process to enter the production area which greatly disrupts employee performance.

K3 is one of the programs created as an action or preventive effort to avoid accidents at work [1]. Factors that affect the performance of workers, such as dust and temperature. In the work environment, dust and temperature are two factors that cause changes in the workplace environment if the workplace environment is not suitable or not good, then employee performance will also be affected when carrying out their work or duties [2]. Air is a vital part of every life, as every breathing organism needs air [3]. Exposure to dust certainly makes humans feel uncomfortable and disturbed, and can even be bad for health [4]. Dust can cause health problems when in high amounts [5]. Apart from these effects, the risk of injury is high due to the high temperature and humidity in the workplace [6][7]. This leads to dehydration, sweat secretion process, metabolism in the body as well as blood flow will faster distribution [8].

For the air quality in the work environment to be healthy and clean so that employees can work smoothly and undisturbed, the Prototype Design Of the Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area was made by utilizing the sophistication of technology. In previous research, a study of dust monitoring systems using the GP2Y1010AU0F sensor has been carried out to determine the level of air quality in a room, it's just that the research does not provide a solution for how to make the dust in the room disappear and the temperature monitoring tool uses a DHT11 sensor which is less accurate than the DHT22 sensor [9]. There is no solution for the temperature and dust levels to decrease or stabilize [10]. This study uses the GP2Y1010AU0F sensor for dust level detection [11] and the DHT22 sensor for temperature detection which is assembled with the Arduino UNO and can be monitored through the LCD screen [12][13], this circuit also uses the BLYNK application communication via ESP 8266, so users can also monitor via smartphone. The results of this system are used to monitor dust and hot water vapor and turn on the blower so that the air quality in the production area remains clean and employee productivity and performance can be maintained properly.

- METHODS

This research updates and develops previous research by using a Research and Development (R&D) research approach [14][15]. namely the cycle of research and development stages by reviewing various research results in the field related to the product to be developed R&D [16][17]. Three stages are carried out, namely: making block diagrams, flow charts, and wiring diagrams that will be used [18]. Each process has a different purpose, but in the end, the three processes will be continuous with the ultimate goal, which is the creation of a prototype that can work effectively and have benefits.

- System Design

The design of this tool consists of three stages. The first stage in the system design process contains an explanation of the parts of the system and their relationships. In the second step, a flowchart should be created to show the workflow of the system and the interactions between its components. In the third step, a block diagram should be created to show the inputs, processing, and outputs of the system and their relationship to each other Overall, these three parts provide a complete picture of the functionality and architecture of the system.

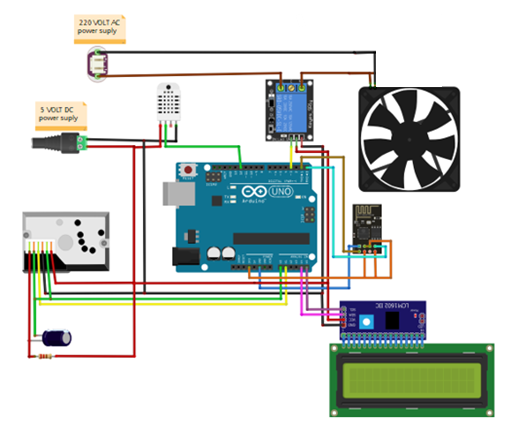

- Block Diagram System

The overall system block diagram is made to facilitate the design and fabrication of tools on existing devices. Below is a block diagram of the Prototype Design of the Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area. As shown in Figure 1.

Figure 1. Block diagram system

There are 3 parts of the blower system circuit at PT SINAR INDOGEEN KENCANA, namely: input, process, and output. In the input section, there are two sensors, namely the DHT-22 sensor which is used to measure temperature and humidity, Optical Dust Sensor GP2Y1010AU0F which is used to measure the value of dust levels. In the process section there is an Arduino UNO microcontroller to process input values from two input sensors and in the process section there is an ESP8266 type ESP-01 which is used to connect the Arduino UNO microcontroller with a wi-fi network on a smartphone. In the output section, there is a 16×2 LCD to display the condition of the tool and the reading value of the input sensor [19]. Blynk is used to monitor the work of the circuit via a smartphone, the relay is used to turn on the blower, and the relay will be active when the input value of the Optical Dust Sensor GP2Y1010AU0F is more than 50 mg/m3 and the DHT-22 sensor is more than 35ºC this is according to the limits set in the Arduino UNO microcontroller system.

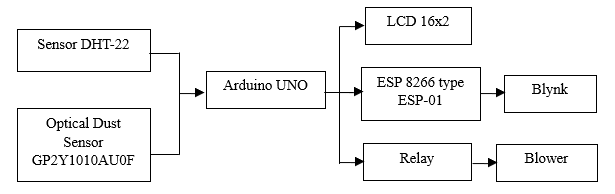

- Wiring Design

The wiring diagram in Figure 2 is the wiring harness used in this research. In the Figure 2, all components that function as inputs and outputs are connected to the microcontroller. A microcontroller connects the input and output components, the microcontrollers used are ESP8266 and Arduino UNO. For the tool used to work, all components used must be connected properly can be seen in Table 1.

Figure 2 shows some of the components used for the following purposes:

- GP2Y1010AU0F dust sensor as a component for measuring dust content values.

- DHT22 sensor as a component for measuring temperature and humidity values.

- LCD is used to display data from sensors and blower conditions

- ESP 8266 microcontroller as a link between the Arduino UNO microcontroller and the BLYNK application on a smartphone wirelessly used to monitor dust levels, temperature, humidity, and blowers.

- The Arduino UNO microcontroller is used as the brain of the circuit, its job is to process the data received by the sensor and then forward it to the component. sensor and then forward it to the output component. through ESP 8266, Arduino UNO will be connected to Wi-Fi so that it can connect to Blynk.

- Relay is used as a switch to turn the blower on and off.

- The blower is used as an output that will work if the dust content and temperature exceed the specified capacity.

Figure 2. Wiring Design

Table 1. Arduino UNO port usage

No | Arduino UNO port | Usage |

1 | GND | Ground ESP 8266 |

2 | 3.3V | Vin ESP 8266 |

3 | RX | RX ESP 8266 |

4 | TX | TX ESP 8266 |

5 | A0 | Vout Sensor GP2Y1010AU0F |

6 | A1 | LED Sensor GP2Y1010AU0F |

7 | D12 | Data Sensor DHT22 |

8 | D4 | IN Relay |

9 | A4 | SCL LCD 16×2 |

10 | A5 | SDA LCD 16×2 |

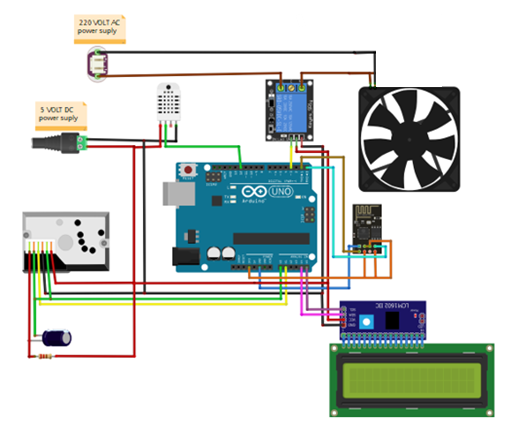

- System Flowchart

The flowchart is used to simplify the research process which can be seen in Figure 3. The program begins with initializing the program first, then the ESP 8266 microcontroller will connect the Arduino UNO microcontroller to the Blynk server on the smartphone with wi-fi, if wi-fi is connected then the Arduino UNO will take temperature data, and humidity from the DHT22 sensor and dust levels from the GP2Y1010AU0F sensor, from the data will be displayed to the Blynk server which is used as a monitoring system via a smartphone, the results of sensor readings and blower conditions can also be displayed on the 16×2 LCD screen.

Detection of temperature and humidity with a DHT22 sensor and detection of dust levels with a GP2Y1010AU0F sensor, if the temperature measurement results are above 35ºC and dust levels above 50 mg/m3 then the Arduino UNO microcontroller will activate the relay, if the relay is active, it will turn on the blower and the relay will not be active and the blower will turn off if the temperature is below 35ºC and dust levels below 50 mg/m3.

Figure 3. Flowchart program system

- RESULT AND DISCUSSION

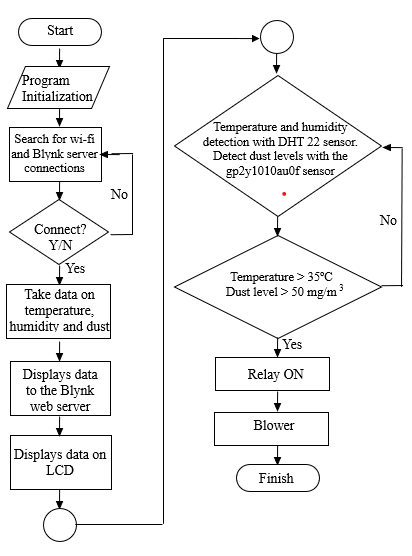

The research results of the realization of the Prototype Design Of the Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area can be seen in Figure 4. All components used will be explained by numbering as follows: 1. DHT22 sensor, 2. GP2Y1010AU0F sensor, 3. ESP 8266, 4. Arduino UNO, 5. LCD I2C, 6. Relay, 7. Blower. Steps to operate the prototype microcontroller, are as follows:

- The user can activate the Wi-Fi network that has been connected to the microcontroller before.

- As a power source, connect the microcontroller to the USB cable.

- The user can then access the Blynk app that has been connected to the microcontroller. In addition, the user can ensure that the LCD is well-lit and displays data such as temperature, humidity, dust levels, and blower conditions in the production area.

- After logging into the Blynk app, users can press the "monitoring system" button and make sure that Blynk is connected to the internet. Otherwise, Blynk cannot track the temperature, humidity, dust content, and blower condition. By taking direct measurements in the production area, the user can find out whether the prototype is running properly or not if all the circuits are on and connected.

- Direct measurement in the production area is carried out to determine the value of temperature, humidity, and dust levels in various weather and machine running conditions. By using Blynk, users can monitor temperature, humidity, dust levels, and blower conditions remotely via smartphone.

- The detailed explanation, this system has been set with a maximum measurement value limit of 35ºC for the temperature sensor and 50 mg/m3 for the dust sensor, if the measurement shows one or both sensors exceeding the value of the predetermined, then the blower will automatically turn on to clean and stabilize the air in the production area, the blower will automatically turn off if the temperature value and dust content value are the same or below 35ºC and 50 mg/m3. Blynk is used to make it easier for users to monitor air quality in the production area by simply monitoring through a smartphone.

Testing is carried out in the production area of PT SINAR INDOGREEN KENCANA to find out and get measurement results from the tools that have been made. In this test, several tests were carried out.

Figure 4. Result of tool realization

- Testing of Wi-Fi Connection to ESP 8266

Within 5 to 6 seconds, the Wi-Fi connection to the ESP 8266 was tested, and the results are shown in Table 2. According to the results, the ESP 8266.

Table 2. Testing Wi-Fi connection to ESP 8266

Testing to- | Wi-Fi ESP 8266 | Accuracy (%) |

Condition | Waiting Time (s) |

1st Test | Connected | 6 | Medium |

2nd Test | Connected | 6 | Medium |

3rd Test | Connected | 6 | Medium |

4th Test | Connected | 5 | Medium |

5th Test | Connected | 5 | Medium |

- Testing of Blynk Connection to Arduino UNO

Blynk to Arduino UNO connection testing was conducted within 5 to 7 seconds, and the results are shown in Table 3. The results show that Arduino UNO can create a stable wireless network.

Table 3. Testing Blynk connection Arduino UNO

Testing to- | Blynk Arduino UNO | Accuracy (%) |

Condition | Waiting Time (s) |

1st Test | Connected | 5 | Medium |

2nd Test | Connected | 7 | Medium |

3rd Test | Connected | 5 | Medium |

4th Test | Connected | 6 | Medium |

5th Test | Connected | 6 | Medium |

- Testing when the MTW Mill and Autoclave are Active in Non-Rainy Conditions

Tests, when the Mill MTW and Autoclave machines are active in non-rainy conditions, are carried out within 10 minutes in one location point, and the results are shown in Table 4. The largest measured dust level was 95 mg/m3 and a temperature of 42ºC, and the smallest dust level was 80 mg/m3 and a temperature of 39ºC.

Table 4. Testing when the Mill MTW and Autoclave Machines are Active in Non-Rainy Conditions

Testing time (every 10 minutes) | Temperature | Humidity | Dust level | Blower indicator |

1 | 39 ºC | 52 % | 80 mg/m3 | ON |

2 | 42 ºC | 44 % | 90 mg/m3 | ON |

3 | 40 ºC | 48 % | 84 mg/m3 | ON |

4 | 40 ºC | 52 % | 95 mg/m3 | ON |

5 | 41 ºC | 44 % | 90 mg/m3 | ON |

- Testing when the Mill MTW Machine and Autoclave are Active in Rainy Conditions

Tests, when the Mill MTW and Autoclave machines are active in rainy conditions, are carried out within 10 minutes in one location point, and the results are shown in Table 5. The largest measured dust level was 281 mg/m3 and a temperature of 38ºC, and the smallest dust level was 277 mg/m3 and a temperature of 35ºC.

Table 5. Testing when the MTW Mill and Autoclave are Active in Rainy Conditions

Testing time (every 10 minutes) | Temperature | Humidity | Dust level | Blower indicator |

1 | 37 ºC | 50 % | 281 mg/m3 | ON |

2 | 35 ºC | 50 % | 279 mg m3 | ON |

3 | 36 ºC | 49 % | 277 mg/m3 | ON |

4 | 38 ºC | 50 % | 280 mg/m3 | ON |

5 | 38 ºC | 49 % | 280 mg/m3 | ON |

- Testing when the Mill MTW Machine and Autoclave are Inactive in Non-Rainy Conditions

Tests, when the Mill MTW and Autoclave machines are inactive in non-rainy conditions, are carried out within 10 minutes in one location point, and the results are shown in Table 6. The dust content of the measurement results is 0 mg/m3, the largest temperature is 34ºC, and the smallest temperature is 32ºC.

Table 6. Testing when the Mill MTW Machine and Autoclave are Inactive in Non-Rainy Conditions

Testing time (every 10 minutes) | Temperature | Humidity | Dust level | Blower indicator |

1 | 32 ºC | 59 % | 0 mg/m3 | OFF |

2 | 33 ºC | 59 % | 0 mg/m3 | OFF |

3 | 32 ºC | 58 % | 0 mg/m3 | OFF |

4 | 33 ºC | 58 % | 0 mg/m3 | OFF |

5 | 34 ºC | 56 % | 0 mg/m3 | OFF |

- Testing when the Mill MTW Machine and Autoclave are Inactive in Rainy Conditions

Tests, when the Mill MTW and Autoclave machines are active in rainy conditions, are carried out within 10 minutes in one location point, and the results are shown in Table 7. The largest measured dust level was 17 mg/m3 and a temperature of 26ºC, and the smallest dust level was 6 mg/m3 and a temperature of 25ºC.

Table 7. Testing when the Mill MTW Machine and Autoclave are Inactive in Rainy Conditions

Testing time (every 10 minutes) | Temperature | Humidity | Dust level | Blower indicator |

1 | 25 ºC | 66 % | 8 mg/m3 | OFF |

2 | 25 ºC | 64 % | 8 mg/m3 | OFF |

3 | 26 ºC | 63 % | 6 mg/m3 | OFF |

4 | 26ºC | 68 % | 8 mg/m3 | OFF |

5 | 26ºC | 66 % | 8 mg/m3 | OFF |

- Blynk

In this research, the Blynk application is used as an interface, with the Blynk application the user can monitor the system work process easily. Before starting the application, the user must activate wifi so that the Arduino UNO microcontroller and ESP 8266 can be connected. Blynk can be used after the microcontroller and Blynk have been connected via wifi [20]. This system works automatically and has been programmed on the Arduino UNO microcontroller so that users only need to monitor temperature, humidity, dust levels, and blower conditions through the display screen on the user's Android. On the Blynk display, the blower indicator will be green if the blower is in Figure 5.

Figure 5. Menu in Blynk

- CONCLUSIONS

Based on the test results shows that the test has an optimal internet connection, and the device has been connected so that Blynk commands can be sent to Arduino UNO and ESP 8266. This tool works as expected. It is proven by sensors that have detected temperature, humidity, and dust levels with precision and can send data which will then be displayed on the LCD screen and smartphone through the BLYNK application. After several experiments with different conditions, this tool can still function normally as desired. The working principle of this tool is to control the temperature and dust levels in the production area which are processed by the performance of the sensor and then displayed on the monitoring device. The application of this system can facilitate the industry in the process of controlling air quality in the production area of PT SINAR INDOGREEN KENCANA so that the performance of employees who work is not disturbed and employee health can be maintained because it is protected from excessive temperature and dust levels.

REFERENCES

- J. Presnal, H. Houston and G. Maberry, "The Electrical Safety Program and the Value in Parterning with Health & Safety Professionals," 2020 IEEE IAS Electrical Safety Workshop (ESW), pp. 1-7, 2020, https://doi.org/10.1109/ESW42757.2020.9188320.

- R. Hojo, T. Sujino, C. Bördlein, Y. Koremura, and S. Shimizu, “Risk distribution method from worker behavior measurement using Behavior-Based Safety procedure,” in 2021 IEEE 3rd Global Conference on Life Sciences and Technologies (LifeTech), pp. 35–36, 2021, https://doi.org/10.1109/LifeTech52111.2021.9391969.

- G. Zhang, Y. Wang, B. Mu, and T. Wang, “Big Data and Safety Management Methods: The Reduction Model of Hot Work Number,” in 2019 IEEE 4th International Conference on Big Data Analytics (ICBDA), pp. 140–143, 2019, https://doi.org/10.1109/ICBDA.2019.8713251.

- G. Jin, W. Yan, C. Ma, and L. Guan, “Post-Processing Algorithm for Workplace Safety Risk Monitoring System Based on Deep-Learning Models,” in 2023 7th International Conference on System Reliability and Safety (ICSRS), pp. 362–370, 2023, https://doi.org/10.1109/ICSRS59833.2023.10381040.

- H. L. I. I. Floyd, “Through the Lens of Systems Safety: The Limitations of a Compliance-Based Safety Culture and Opportunities to Reduce Electrical Injuries,” in 2023 IEEE IAS Electrical Safety Workshop (ESW), pp. 34–36, 2023, https://doi.org/10.1109/ESW49992.2023.10188267.

- L. Fang, X. Shi, B. Mei, and Y. Liu, “Design and Development of Industrial Safety APPs,” in 2022 IEEE 2nd International Conference on Electronic Technology, Communication and Information (ICETCI), pp. 526–530, 2022, https://doi.org/10.1109/ICETCI55101.2022.9832162.

- J. Sun, L. Cheng, Y. Yu, and X. Wang, “Research on the Problems of Enterprise Safety Production Based on Alarm Data of Safety Information Platform in Chemical Industrial Park,” in 2021 International Conference on Education, Information Management and Service Science (EIMSS), pp. 179–183, 2021, https://doi.org/10.1109/EIMSS53851.2021.00047.

- O. A. Loktionov, N. V Vasileva, and O. E. Kondrateva, “Impact of the “well-being” system indicators on the safety culture level and health of power industry employees,” in 2023 5th International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE), pp. 1–5, 2023, https://doi.org/10.1109/R10-HTC.2017.8289064.

- R S. Chanthakit and C. Rattanapoka, "MQTT Based Air Quality Monitoring System using Node MCU and Node-RED," 2018 Seventh ICT International Student Project Conference (ICT-ISPC), pp. 1-5, 2018, https://doi.org/10.1109/ICT-ISPC.2018.8523891.

- R. Hojo, C. Bördlein, K. Hamajima, S. Umezaki, and S. Shimizu, “For a Quantitative Evaluation of Risk Assessment -Behavior-based Safety,” in 2020 IEEE 2nd Global Conference on Life Sciences and Technologies (LifeTech), pp. 378–380, 2020, https://doi.org/10.1109/LifeTech48969.2020.1570619864.

- N. L. Datta, A. Tabassum, J. Bhavani, K. Y. R. Kumar, R. V. H. Prasad, and A. R. Raja, “Design And Development of Dust Detection and Filtering System,” in 2023 9th International Conference on Advanced Computing and Communication Systems (ICACCS), pp. 739–743, 2023, https://doi.org/10.1109/ICACCS57279.2023.10112892.

- O. O. Akinwole, “Design, simulation and implementation of an Arduino microcontroller-based automatic water level controller with I2C LCD,” International Journal of Advances in Applied Sciences, vol. 9, no. 2, pp. 77–84, 2020, https://doi.org/10.11591/ijaas.v9.i2.pp77-84.

- I. Sulistiyowati, S. Soedibyo, M. Ashari, A. L. Setya Budi and D. R. Anggara Fitrah, "Fuel Cell Penetration Characteristics on Standalone Photovoltaic with Hybrid Energy Storage System," 2022 11th Electrical Power, Electronics, Communications, Controls and Informatics Seminar (EECCIS), pp. 40-44, 2022, https://doi.org/10.1109/EECCIS54468.2022.9902894.

- V. A. Safitri, L. Sari, and R. R. Gamayuni, “Research and Development, Environmental Investments, to Eco-Efficiency, and Firm Value,” The Indonesian Journal of Accounting Research, vol. 22, no. 03, pp. 377–396, 2019, https://doi.org/10.33312/ijar.446.

- P. Pegkas, C. Staikouras, and C. Tsamadias, “Does research and development expenditure impact innovation? Evidence from the European Union countries,” Journal of Policy Modeling, vol. 41, no. 5, pp. 1005-1025, 2019, https://doi.org/10.1016/j.jpolmod.2019.07.001.

- Lee, H. (2021). Changes in workplace practices during the COVID-19 pandemic: the roles of emotion, psychological safety and organisation support. Journal of Organizational Effectiveness: People and Performance, 8(1), 97-128, 2021, https://doi.org/10.1108/JOEPP-06-2020-0104.

- M. A. Juliyanto, I. Sulistiyowati, A. Ahfas, “ Design of Turbine Aerator with Remote Control and Internet of Things (IoT)-Based Water pH Monitoring,” Buletin Ilmiah Sarjana Teknik Elektro, vol. 5, no. 1, pp. 156-166, 2023, https://doi.org/10.12928/biste.v5i1.7863.

- Wu, D., Cui, D., Zhou, M., & Ying, Y. (2022). Information perception in modern poultry farming: A review. Computers and Electronics in Agriculture, 199, 107131, 2022, https://doi.org/10.1016/j.compag.2022.107131.

- I. Anshory, D. Hadidjaja, and I. Sulistiyowati, “Measurement, Modeling, and Optimization Speed Control of BLDC Motor Using Fuzzy-PSO Based Algorithm,” Journal of Electrical Technology UMY, vol. 5, no. 1, pp. 17–25, 2021, https://doi.org/10.18196/jet.v5i1.12113.

- S. C. S. Yanti and I. Sulistiyowati, “An Inventory Tool for Receiving Practicum Report Based on IoT by Using ESP32-CAM and UV Sterilizer: A Case Study at Muhammadiyah University of Sidoarjo,” Journal of Electrical Technology UMY, vol. 6, no. 1, pp. 49-56, 2022, https://doi.org/10.18196/jet.v6i1.14607.

AUTHOR BIOGRAPHY

| Mufit Yogie Prayudha was born in Sidoarjo district on April 11, 2000, his first education at SDN Wirobiting 2 Sidoarjo graduated in 2012, then continued his education at SMPN 1 Prambon, and in 2018 completed his Electrical Power Installation Engineering education at SMK KRIAN 1 Sidoarjo. In 2020 continued his education to obtain an undergraduate degree (S1) at Muhammadiyah Sidoarjo University in the Electrical Engineering Study Program. |

|

|

| Indah Sulistiyowati is a researcher who specializes in Renewable Energy Power Systems and Control Systems. Completed her master’s degree at Institut Teknologi Sepuluh Nopember majoring in Control System Electrical Engineering Subsidiary, and now is a lecturer at Universitas Muhammadiyah Sidoarjo. |

|

|

| Dwi Hadidjaja Rasjid Saputra he is an active lecturer in the Department of Electrical Engineering, Faculty of Science and Technology, Muhammadiyah University of Sidoarjo. He received a Bachelor's Degree from Muhammadiyah University of Surabaya, and a Master’s Degree from Brawijaya University. |

Prototype Design of Air Quality Control Blower at PT SINAR INDOGREEN KENCANA Production Area (Mufit Yogie Prayudha)