Comparison of continuous review system method and min-max method in soybean inventory control

DOI:

https://doi.org/10.12928/bamme.v4i2.11670Keywords:

continuous review system, inventory control, min-max method, soybean raw material, tofu productionAbstract

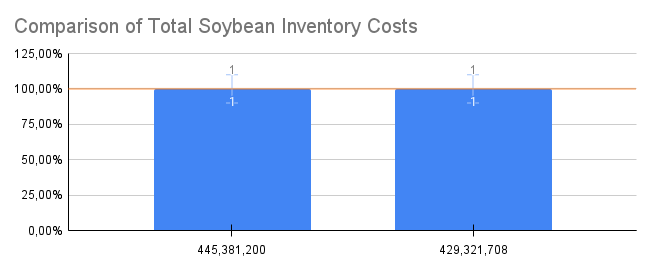

This study aims to compare the effectiveness of two inventory control methods, namely continuous review system and min-max in controlling soybean raw material inventory in tofu production. The continuous review system method is an inventory control system where raw material inventory is checked continuously while the min-max method is a method that maintains raw materials between the minimum and maximum limits. The data used are data on soybean raw material inventory and needs at the Ali Musa tofu factory in Serdang Bedagai Regency, Indonesia. Based on the results of the analysis of total inventory costs using the continuous review system method, it is IDR 418,978,693 in 2021 and IDR 430,271,763 in 2022. While the total inventory cost using the min-max method is IDR 366,272,031 in 2021 and IDR 367,964,100 in 2022. While the company uses IDR 429,321,708 in 2021 and IDR 445,381,200 in 2022. From the calculations above, the min-max method is more effective in reducing total inventory costs with infrequent ordering frequencies. Since orders are not made regularly, this strategy reduces the number of soybean orders and reduces the cost of ordering. When the reorder limit is reached, the company will place the order. The choice of inventory control method must be adjusted to the needs and operational characteristics of the company. The continuous review system method is better for companies with high and fluctuating raw material needs, while min-max can be used for companies with more stable raw material needs. The findings and the method used in this study could be beneficial for the factory to organize its inventory efficiently.

References

Agustin, R. (2020). Analisis pengendalian persediaan bahan baku sapu ijuk dengan metode continuous review system (Q) dan periodic review system (P) dalam menunjang kelancaran proses produksi pada UD. Brengos Bondowoso. Bachelor Thesis. Universitas Jember.

Amri, S. (2020). Analisis pengendalian persediaan tandan buah segar dengan menggunakan metode economic order quantity (EOQ) di PT. Perkebunan Nusantara II PKS Kwala Sawit Kabupaten Langkat-Sumatera Utara. Bachelor Thesis. Universitas Medan Area.

Astuti, K., Ramdhani, D. M., & Khasanah, I. N. (2023). Analisis produktivitas jagung dan kedelai di Indonesia. Hasil Survei Ubinan, p. 32. Badan Pusat Statistik.

Beno, J., Silen, A. P., & Yanti, M. (2022). Dampak pandemi Covid-19 pada kegiatan ekspor impor: Studi pada PT. Pelabuhan Indonesia II (Persero) Cabang Teluk Bayur. Jurnal Saintek Maritim, 22(2), 117–126.

Br Sirait, N. O. R., & Nasution, P. K. (2023). Penerapan metode continuous review pada pusat oleh-oleh keripik rumah adat Minang. Edumatsains : Jurnal Pendidikan, Matematika dan Sains, 7(2), 281–291. https://doi.org/10.33541/edumatsains.v7i2.4282

Fadhilah, A. T., & Saifudin, J. A. (2023). Pengendalian persediaan bahan baku menggunakan metode min-max stock. Rekayasa: Journal of Science and Technology, 16(2), 212–218.

Fatma, E., & Pulungan, D. S. (2018). Analisis pengendalian persediaan menggunakan metode probabilistik dengan kebijakan backorder dan lost sales. Jurnal Teknik Industri, 19(1), 40-51.

Hany, R., & Khairani, N. (2023). Perencanaan kebijakan persediaan vaksin booster dengan metode continuous review untuk mengurangi overstock di Rumah Sakit Tentara Kota Pematangsiantar. Jurnal Riset Rumpun Matematika dan Ilmu Pengetahuan Alam (JURRIMIPA), 2(2).

Herdhiansyah, D., Reza, R., Sakir, S., & Asriani, A. (2022). Kajian proses pengolahan tahu: Studi kasus industri tahu di Kecamatan Kabangka Kabupaten Muna. Agritech : Jurnal Fakultas Pertanian Universitas Muhammadiyah Purwokerto, 24(2), 232–237.

Kadafi, A. M., & Delvina, A. (2021). Analisis pengendalian persediaan bahan baku dengan safety stock optimum. Forum Ekonomi, 23(3), 553–560.

Kecamatan Dolok Masihul. (2023). Kampung Tahu: Desa Wisata Kuliner di Dolok Manampang. https://www.masterplandesa.com/wisata/kampung-tahu-desa-wisata-kuliner-di-dolok-manampang/

Masdani, S. (2022). Perencanaan persediaan bahan baku dengan analisis always better control (ABC), metode min max, model Q (continuous review) dan model P (period review) pada PT. Eastwind Mandiri. Bachelor Thesis. Universitas Islam Sultan Agung.

Nadya, Y., Yusnawati, & Handayani, N. (2020). Analisis Produksi bersih di UKM pengolahan tahu di Gampong Alue Nyamok Kec. Birem Bayeun Kab. Aceh Timur. Jurnal Teknologi, 12(2), 133–140.

Octaviani, J. D., & Fitriani, R. (2022). Analisis pengendalian persediaan bahan baku menggunakan metode min-max stock pada PT. XYZ. Jurnal Teknik Industri, 8(2), 231–235.

Pramuditya, R. (2023). Penerapan metode min-max untuk menentukan perencanaan barang dagang di Sakinah Mart Surabaya. Bachelor Thesis. Universitas Dinamika.

Purnomo, H., & Riani, L. P. (2018). Optimasi Pengendalian Persediaan. Universitas Nusantara PGRI Kediri.

Rachmawati, N. L., & Lentari, M. (2022). Penerapan metode min-max untuk minimasi stockout dan overstock persediaan bahan baku. Jurnal Intech Teknik Industri Universitas Serang Raya, 8(2), 143–148.

Rizal, A., Lolowang, T. F., & Sondakh, M. L. (2020). Analisis persediaan bahan baku pada industri tahu UD. Mandiri di Kelurahan Walian Kecamatan Tomohon Selatan Kota Tomohon. Agrirud, 1(4), 404–409.

Rizkina, A., Lubis, R. S., & Widyasari, R. (2022). Analisis pengendalian persediaan menggunakan metode min-max dan economic order quantity (EOQ). Humantech: Jurnal Ilmiah Multi Disiplin Indonesia, 1(11), 1700–1711.

Rozaq, M. R. A., & Mahbubah, N. A. (2022). Efisiensi persediaan kantong semen berbasis metode min-max, EOQ, dan two-bin di packing plant PT. Aka. Sigma Teknika, 5(2), 259–266.

Sanni El Randi, T. R., & Meirini, D. (2021). Analisis manajemen persediaan menggunakan metode economic order quantity dan reorder point dalam pengendalian persediaan gas LPG 3 kg pada SPBE PT. BCP Cirebon. Fair Value: Jurnal Ilmiah Akuntansi dan Keuangan, 4(4), 1263–1279.

Sari, N., Cipta, H., & Lubis, R. S. (2023). Analisis pengendalian persediaan kelapa sawit sebagai bahan baku minyak dengan metode continous review system. Phytagoras: Jurnal Program Studi Pendidikan Matematika, 12(1), 27–35.

Setiawan, I., Rasul, R., & Rusman, M. (2023). Analisis pengendalian persediaan produk menggunakan metode continuous review system (Metode Q) dan periodic review system (Metode P) untuk meminimalkan biaya persediaan. Jurnal Rekayasa Sistem dan Industri, 10(01), 47–53.

Sirait, E. E., Nelvia, N., & Fauzana, H. (2020). Pertumbuhan dan hasil tanaman kedelai (Glycine max L.) terhadap pemberian vermikompos dan biochar di tanah ultisol. Jurnal Solum, 17(2), 29–41.

Yanto, E., Halid, A., & Saleh, Y. (2022). Analisis pendapatan usaha produksi industri olahan tahu di Desa Harapan Kecamatan Wonosari Kabupaten Boalemo (Studi kasus industri rumah tangga “Bapak Nono Purnomo”). Agrinesia: Jurnal Ilmiah Agribisnis, 6(3), 179–186.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Ellysa Syafitri, Riri Syafitri Lubis

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).